Blended fabric of COOLMAX fiber, bamboo fiber and electroconductive fiber

A technology of conductive fibers and blended fabrics, applied in the direction of fabrics, textiles, textiles and papermaking, etc., can solve the problems of singleness of fibers and achieve the effect of meeting the functional requirements of fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

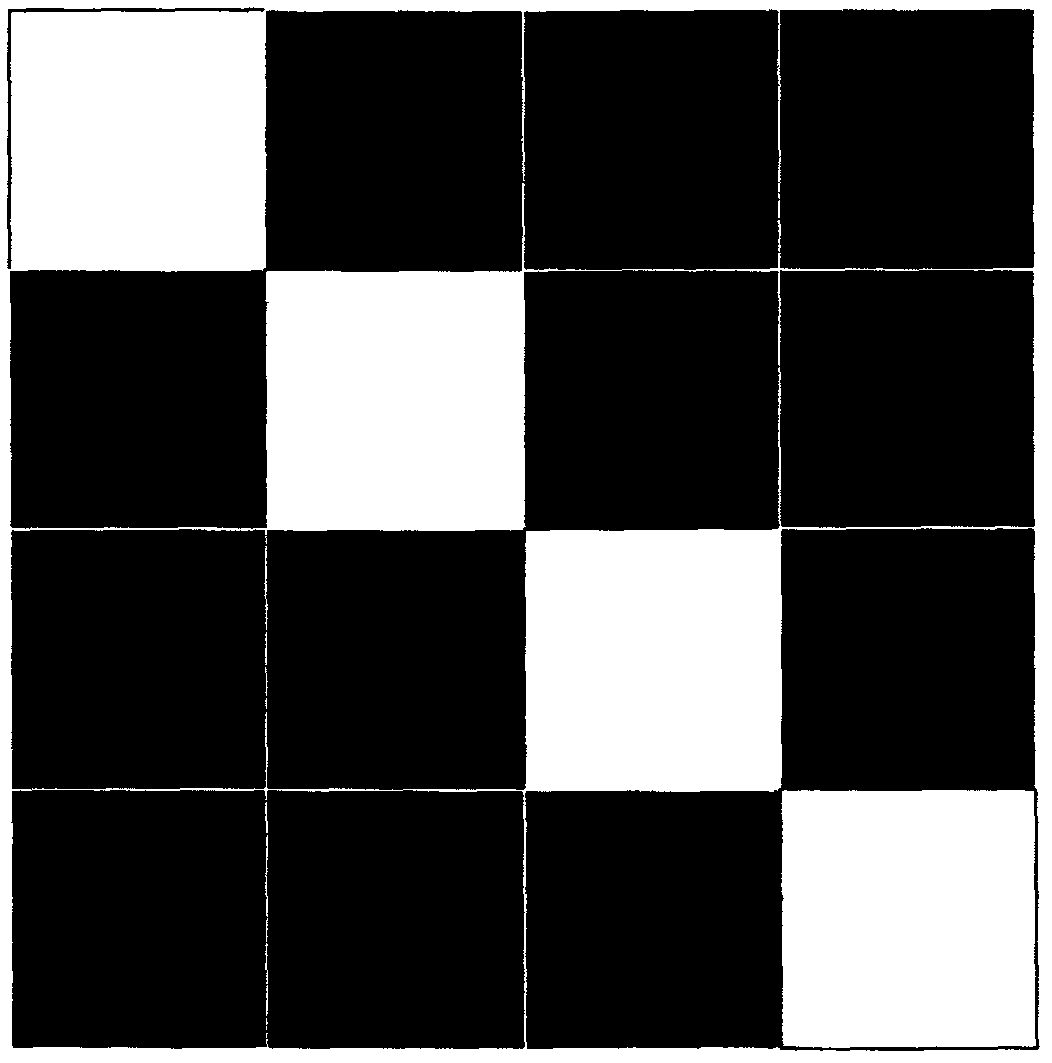

[0012] figure 1 As shown, the vertical grid represents the longitude, and the horizontal grid represents the latitude.

[0013] COOLMAX fiber, bamboo fiber and conductive fiber blended fabric, the warp and weft adopt three-up and one-down twill weave, and the warp and weft are all made of COOLMAX fiber, bamboo fiber and conductive fiber blended yarn.

[0014] In a preferred embodiment, the warp is selected from 40S / 2COOLMAX fiber, bamboo fiber and conductive fiber blended yarn; the weft is selected from 20S / 2COOLMAX fiber, bamboo fiber and conductive fiber blended yarn,

[0015] In a preferred embodiment, the warp weight of the fabric is 225.6g / m, the weft weight of the fabric is 190.5g / m, the warp density is 490 threads / 10cm, and the weft density is 195 threads / 10cm.

[0016] After the warp is inspected, winder → warping → sizing → threading, threading → weaving → inspection, repair, repair → gray cloth storage;

[0017] After the weft is inspected, winder→weaving→inspectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com