A high-capacity secure 26650 lithium ion battery and its making method

A technology of lithium-ion batteries and manufacturing methods, which is applied in the directions of battery electrodes, secondary batteries, battery pack components, etc., and can solve problems such as limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

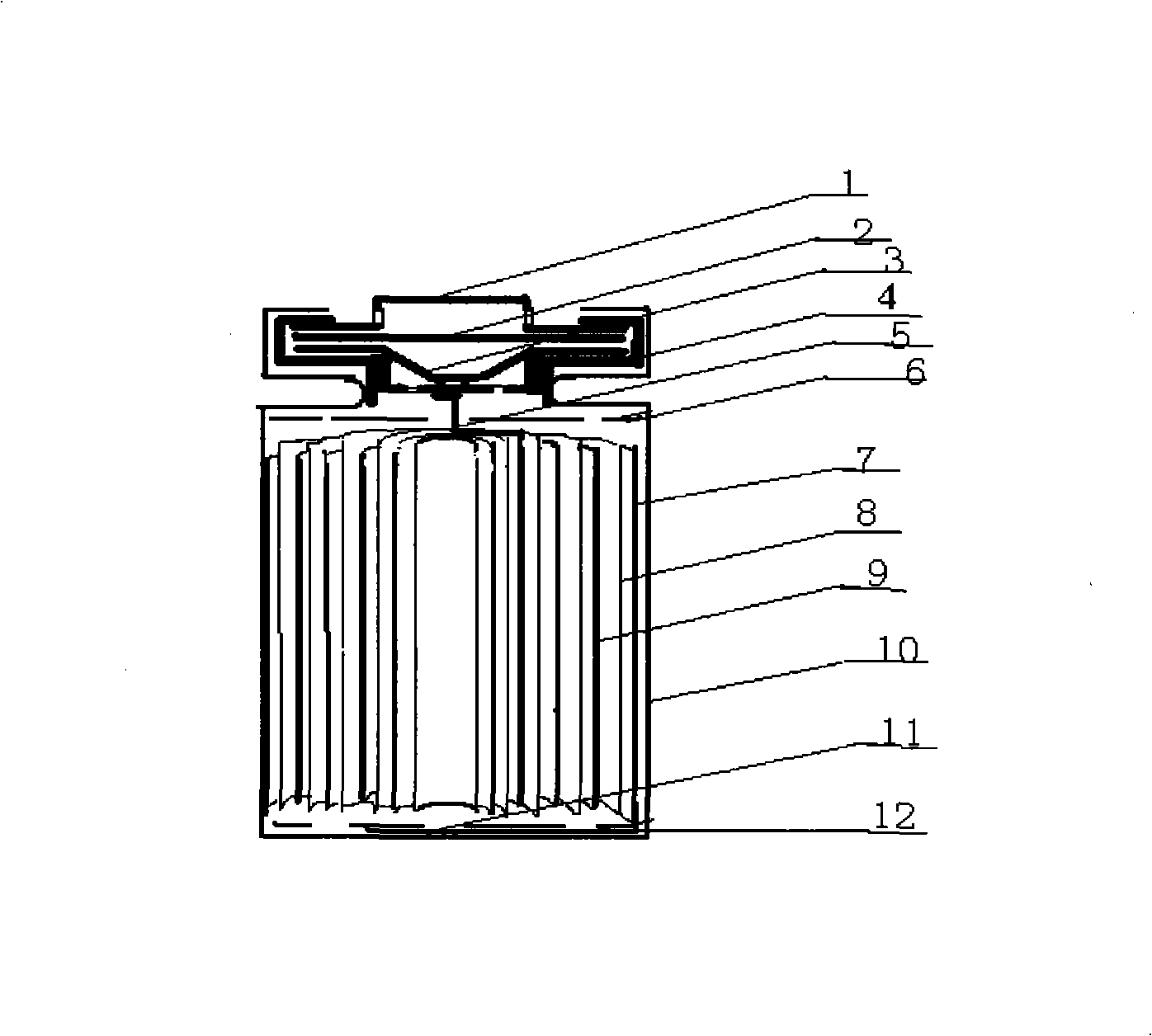

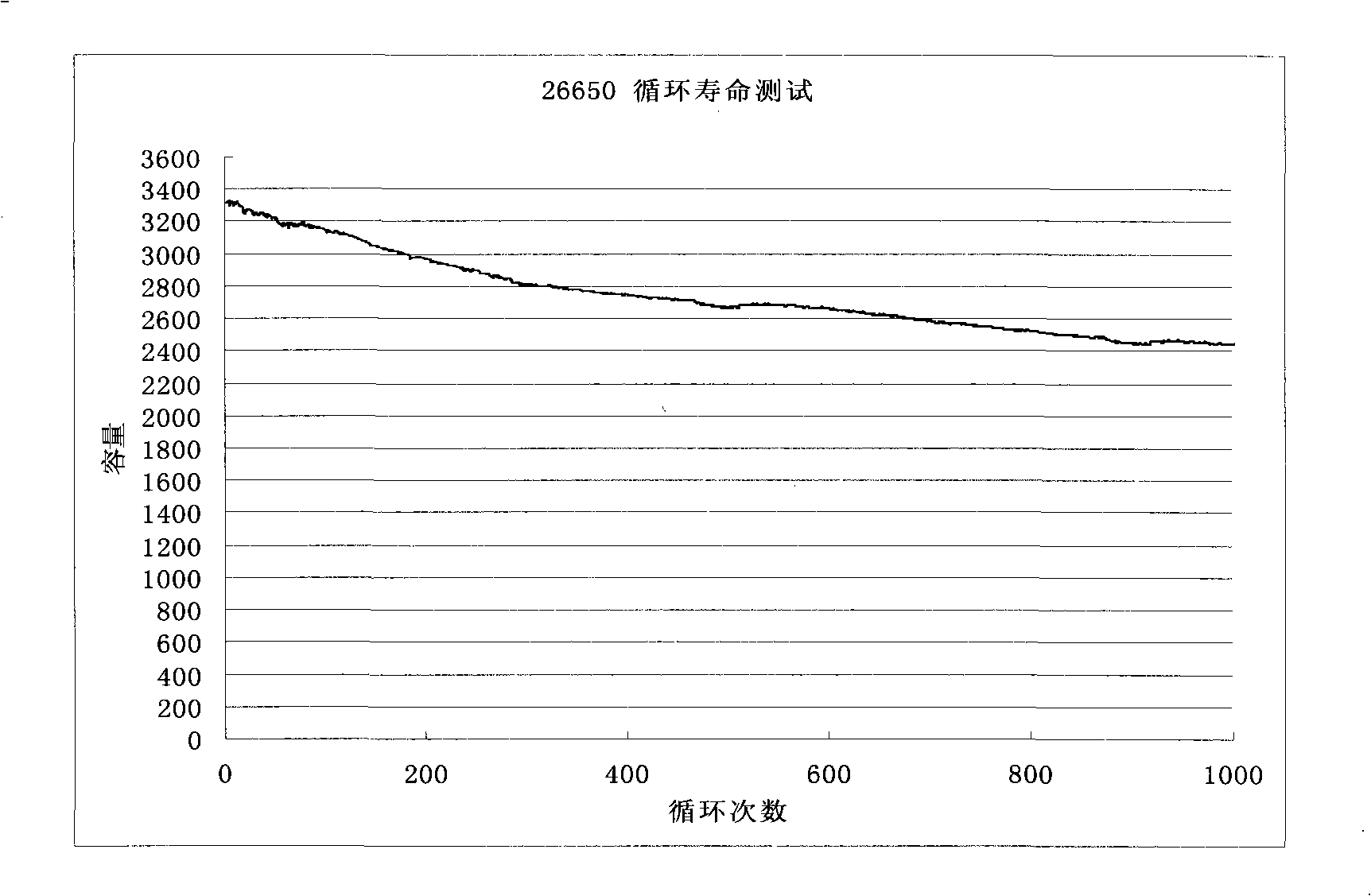

[0048] The present invention provides a high-capacity safe 26650 lithium-ion battery and the detailed steps of its manufacturing method are as follows:

[0049] 1. Make positive electrode solution (slurry)

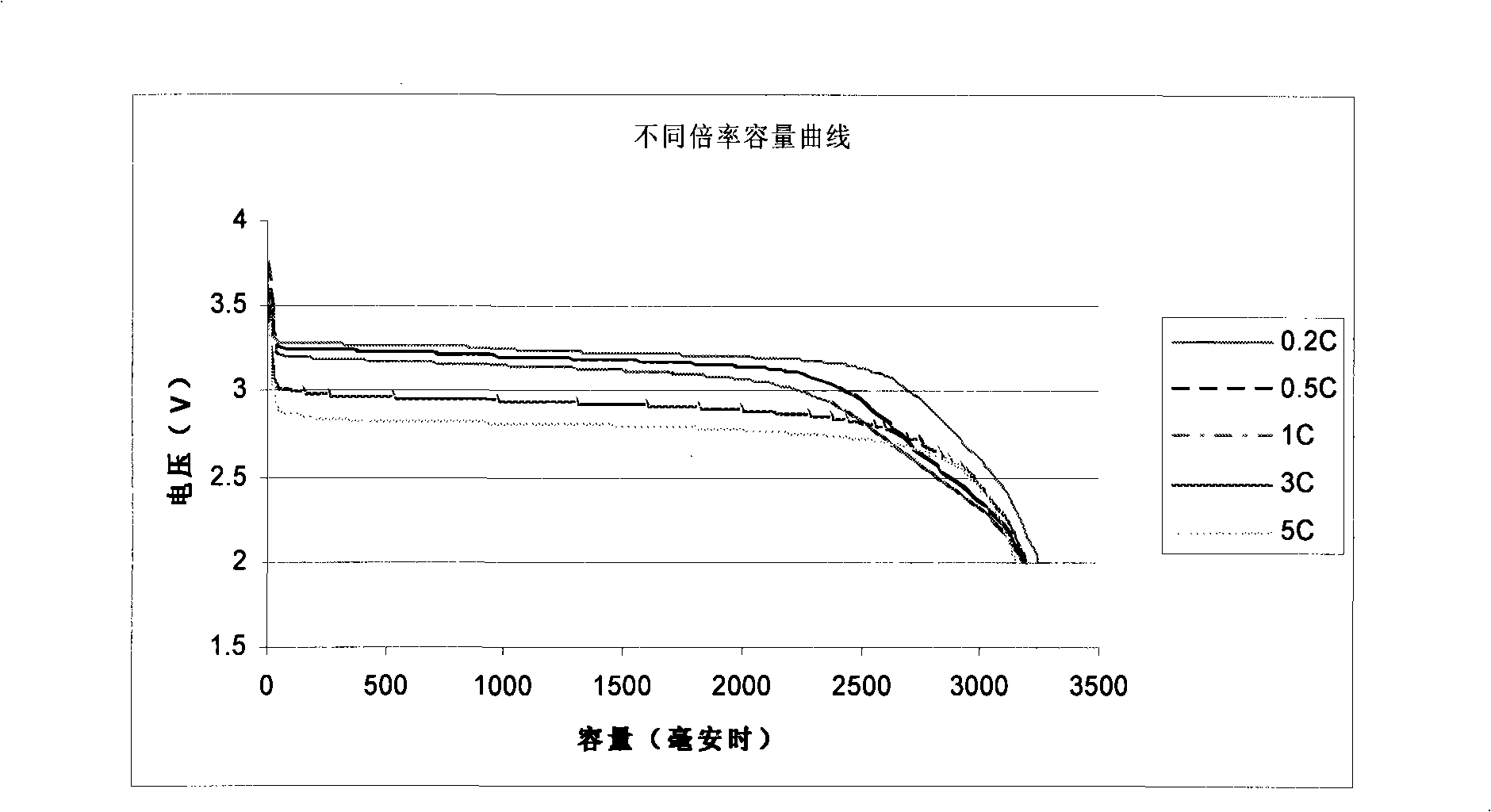

[0050] First, mix PVDF and NMP to form an 8% solution, use a high-speed disperser to mix, use a revolution speed of 35 rpm, and rotate at a speed of 1500 rpm for 1 hour, add conductive carbon materials to increase the rotation speed Stir at 2000 rpm for 1 hour; add lithium iron phosphate powder, and stir at a speed above 2000 rpm for 3 hours, then add solvent NMP to adjust the viscosity of the solution; the ratio of the final solution is as follows: lithium iron phosphate: conductive carbon: PVDF: NMP = 100: 1: 3: 70, adjusted according to the characteristics of the equipment used, the positive electrode solution is configured, the viscosity is tested with a rotational viscometer, the viscosity is 13000mPaS, the particle size is measured with a particle size analyzer, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com