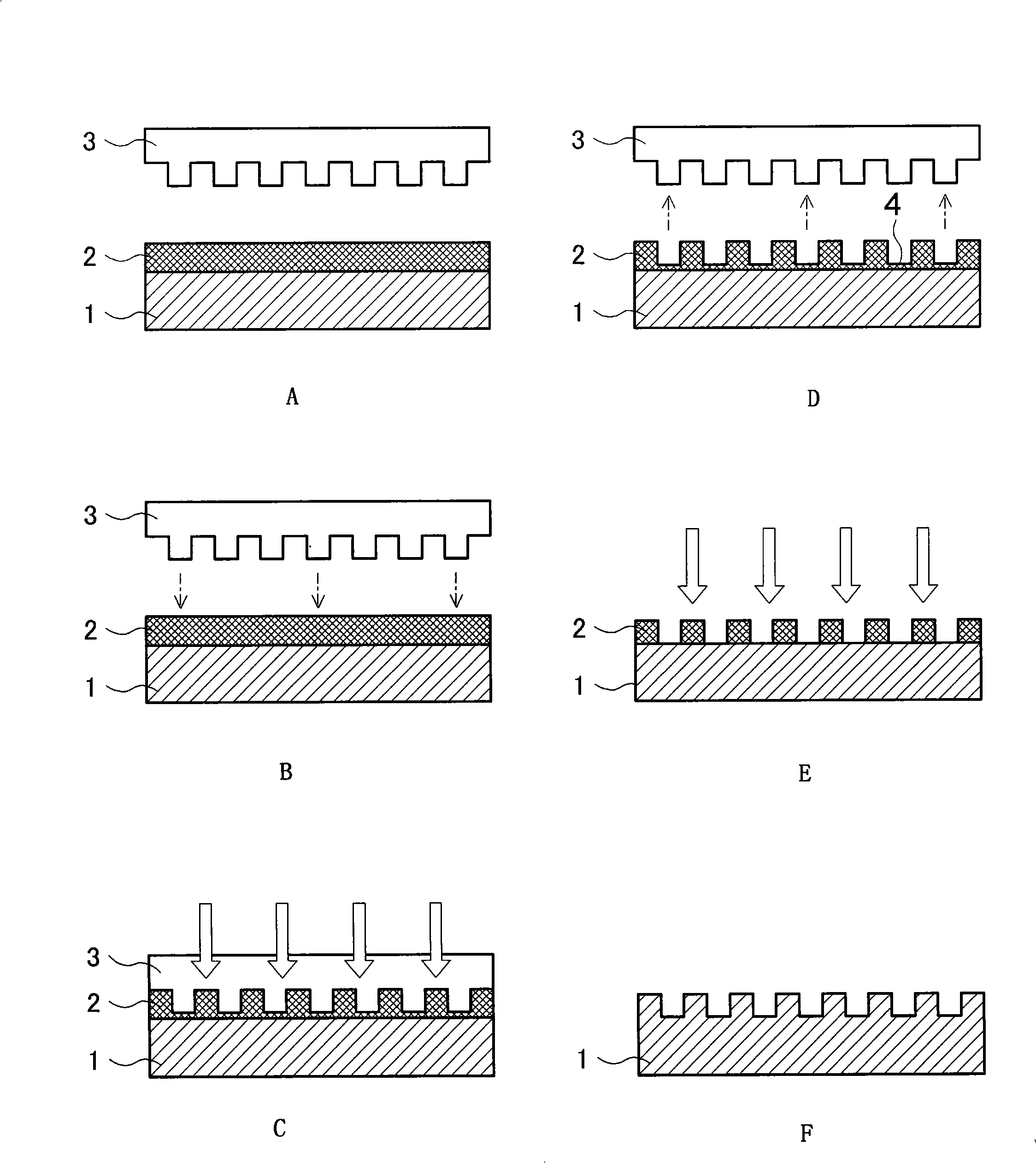

Film forming composition for nanoimprinting and method for pattern formation

A technology of nano-imprinting and composition, applied in the directions of nanotechnology, nanotechnology, nanotechnology for information processing, etc., can solve problems such as yield decline, transfer pattern peeling, photoresist heating, etc., and achieve the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0176] 1 mol of tetraethoxysilane, 0.5 mol of monoacryloxypropyltrimethoxysilane and 0.5 mol of monovinyltrimethoxysilane were dissolved in 170 g of isopropanol. Next, 190 g of pure water and 0.02 g of concentrated nitric acid were added, followed by stirring at room temperature for 6 hours. The resulting composition was then diluted with isopropanol so that the SiO 2 The converted solid content value was 7%. Next, 1 g of photopolymerization initiator IRGACURE 369 (manufactured by Ciba Specialty Chemicals: 2-benzyl-2-dimethylamino-1-(4-morpholinophenyl) butan-1-one) was added to 100 g of the obtained liquid, to prepare coating solutions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com