Cutting machine

A technology of cutting machines and cutting knives, applied in the field of cutting machines, can solve problems such as hindering cutting knives, reducing cutting efficiency, dulling, etc., and achieve the effect of reducing replacement operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

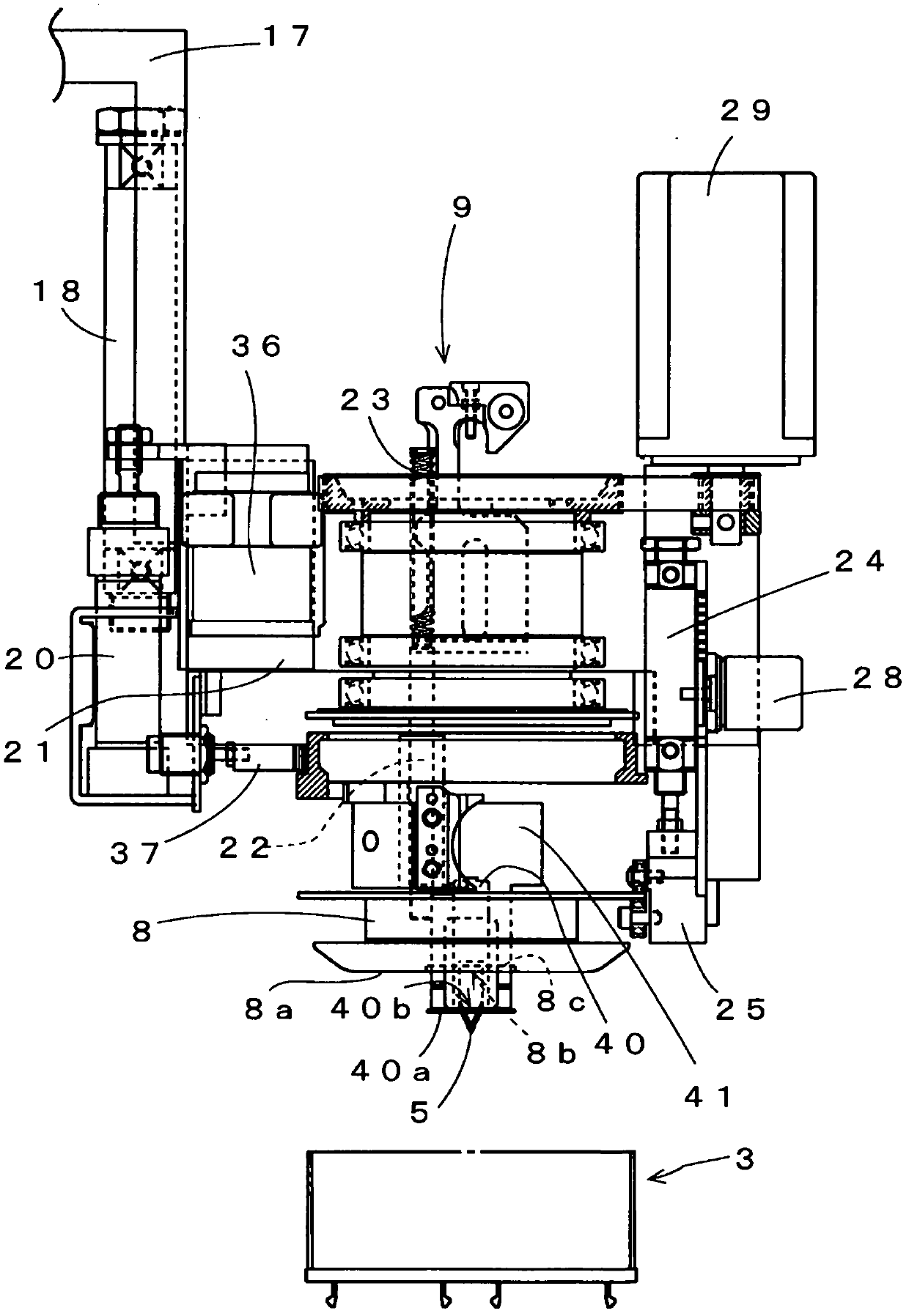

[0050]Below, use Figure 1 to Figure 7 An example of the present invention will be described. In the description of each figure, reference numerals that do not exist in the figure but exist in the previously described drawings may be used for description, or the same parts as those shown in the previously described drawings are given the same Reference numerals are used to omit repeated explanations.

[0051] 【Example】

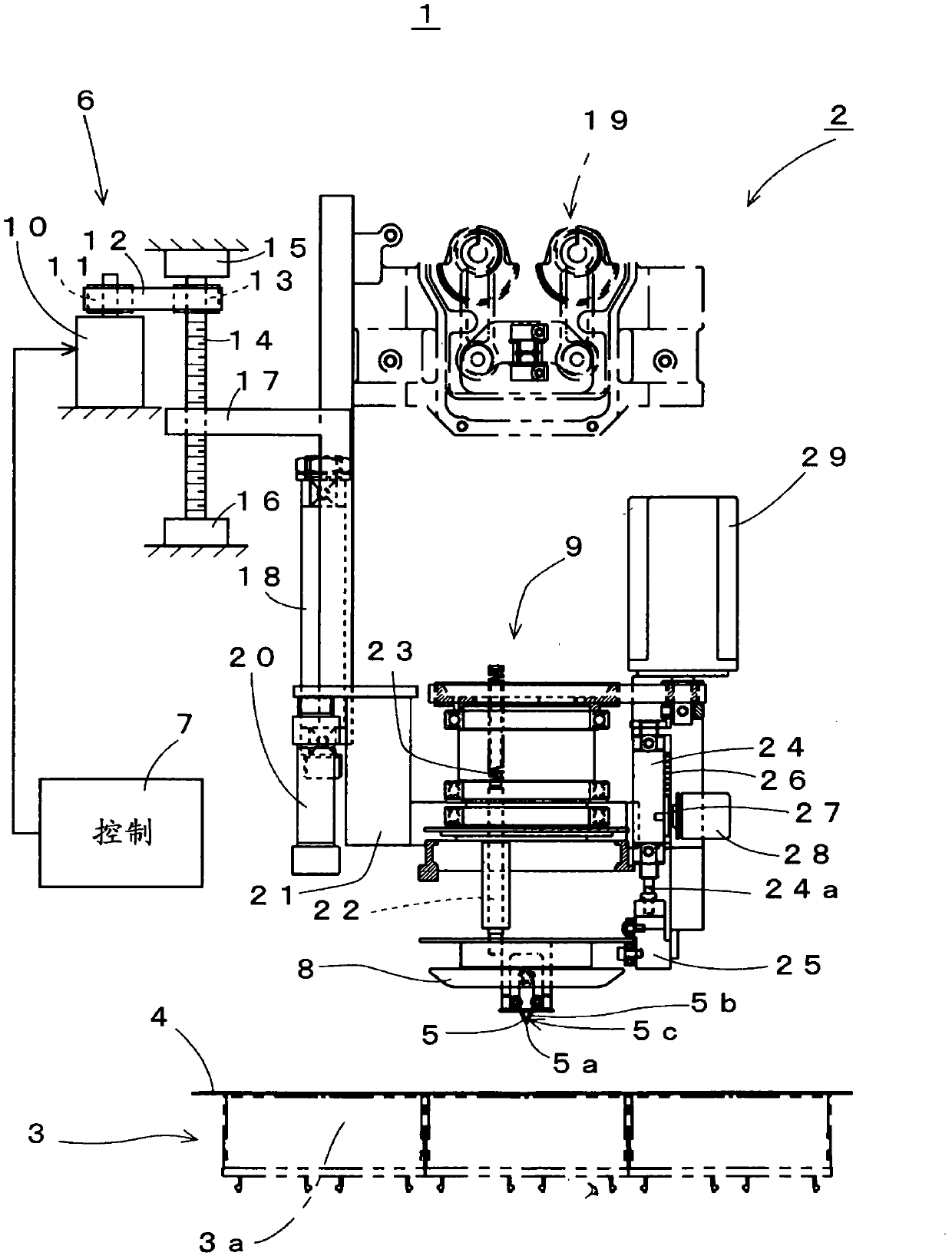

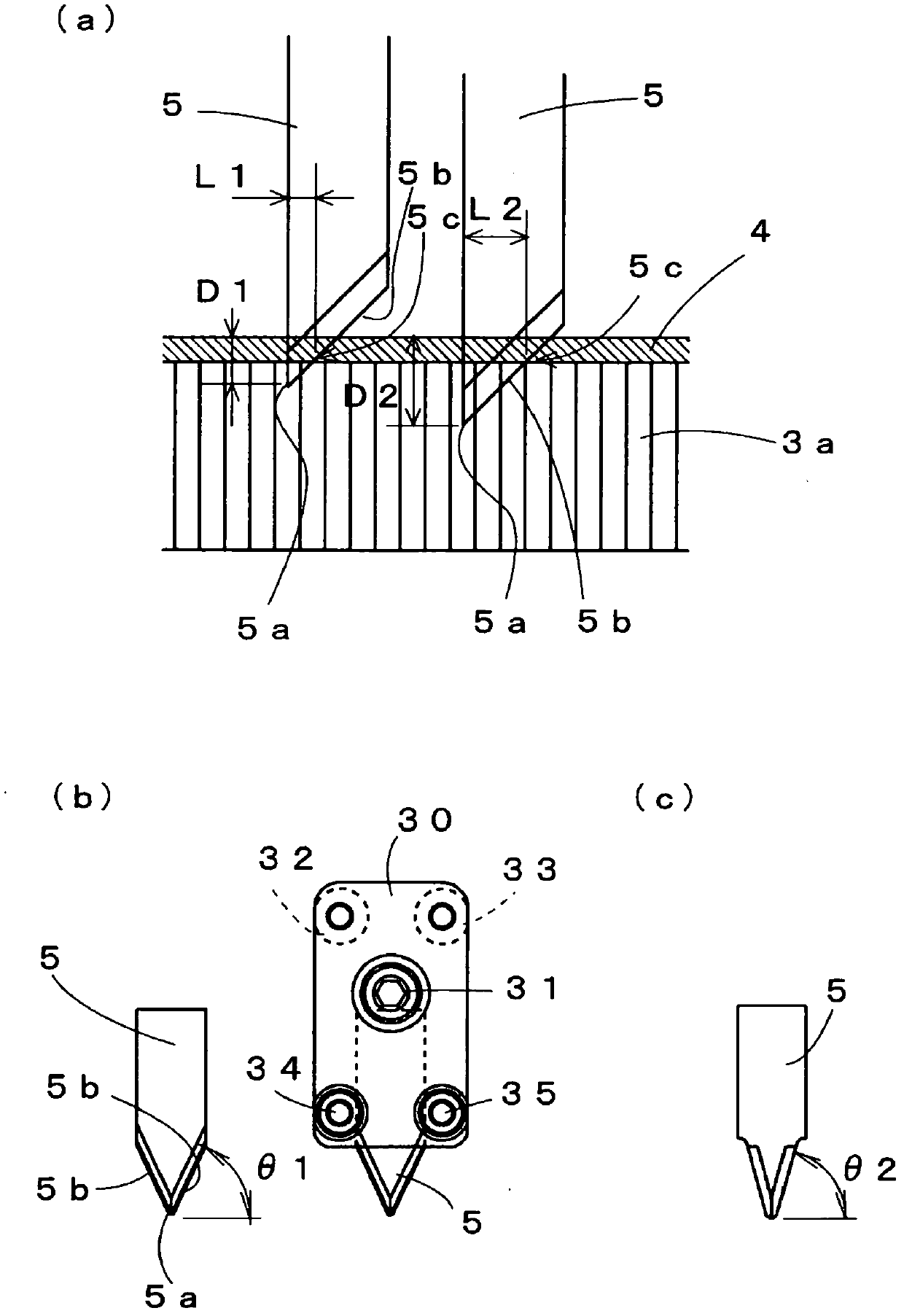

[0052] figure 1 The schematic structure of the main part of the cutting machine 1 which is one embodiment of this invention, especially the cutting head 2 is shown. The basic structures of the cutting machine 1 and the cutting head 2 are the same as those described in Patent Document 2. That is, the cutting head 2 cuts while moving along the XY plane on the surface of the sheet 4 placed on the horizontal table 3 . The table 3 is lined with bristle brushes 3a and formed of bristles standing upright from below, and includes an air-permeable surface capable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com