Method for eccentrically orienting a laser cutting beam in relation to a nozzle axis and for cutting at an angle, corresponding laser machining head and laser machining tool

A laser processing machine and laser cutting technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., to achieve the effect of improving melt discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

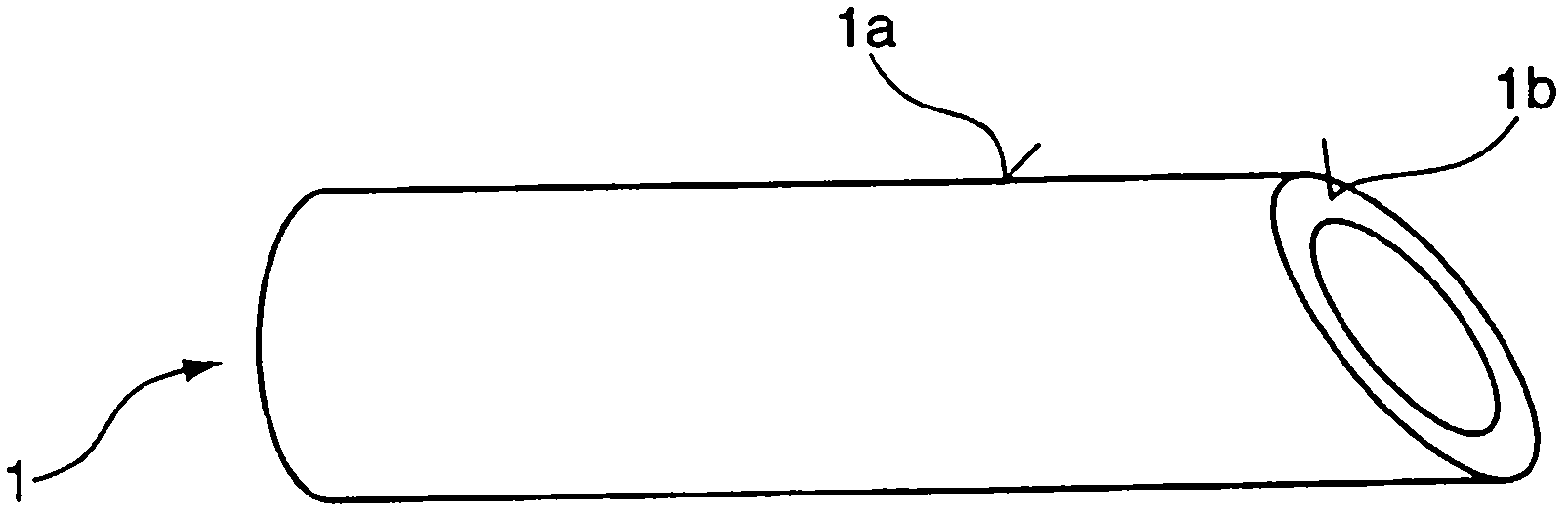

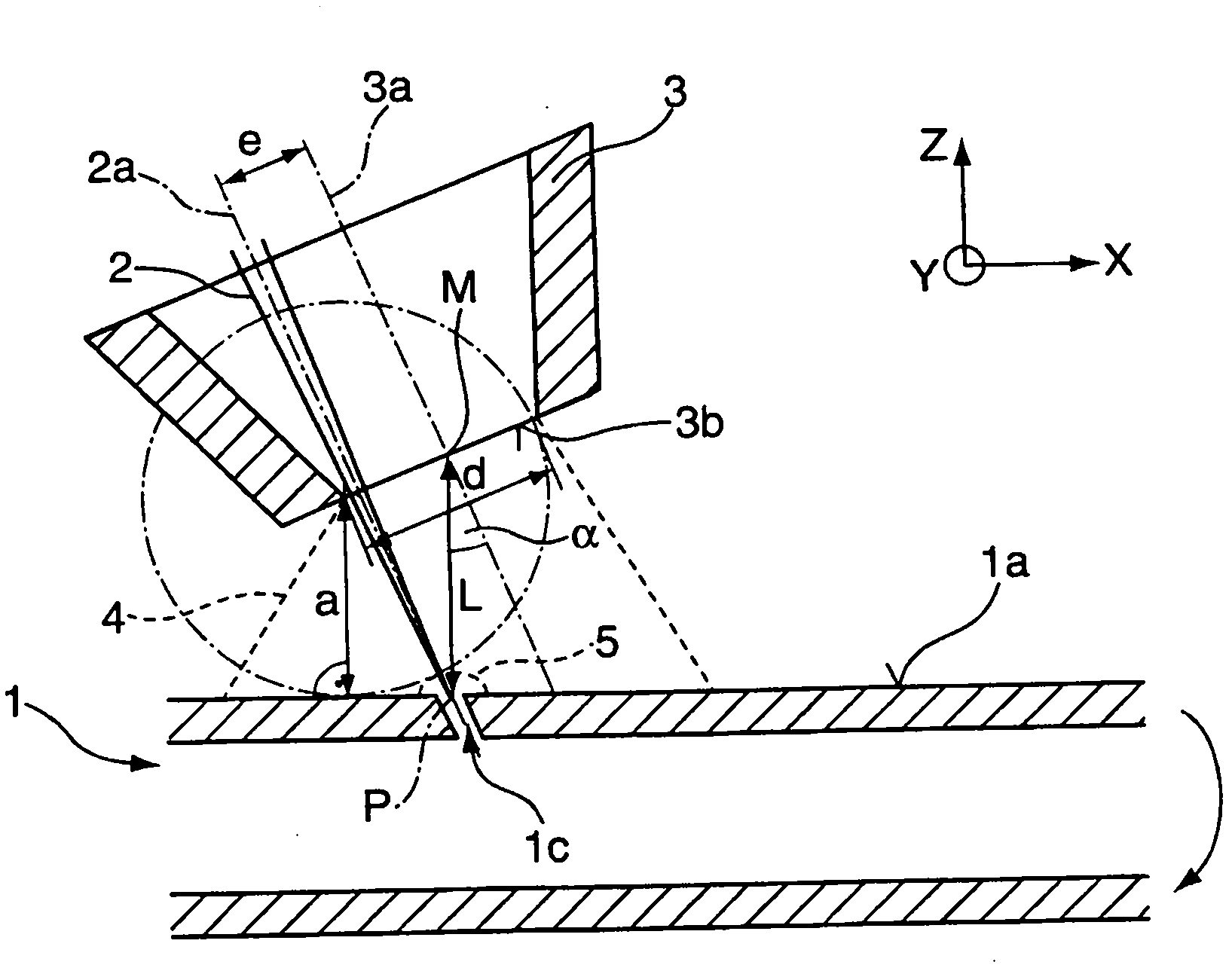

[0033] Figure 1a Shown is a tubular workpiece 1 on which a 45° incision is made with a flat cutting surface 1b that can be formed at 90° with an additional (not shown) tubular workpiece with a flat cutting surface Corner cases are welded along the thin weld seam connecting these cut faces. In order to produce a flat cutting surface 1b, it is necessary to perform a bevel cutting process on the tubular workpiece 1, in which the bevel cutting angle α (see Figure 1b ) varies in the range between −45° and 45°, because a distorted cut surface is produced on the workpiece 1 during conventional cutting with a constant bevel angle α.

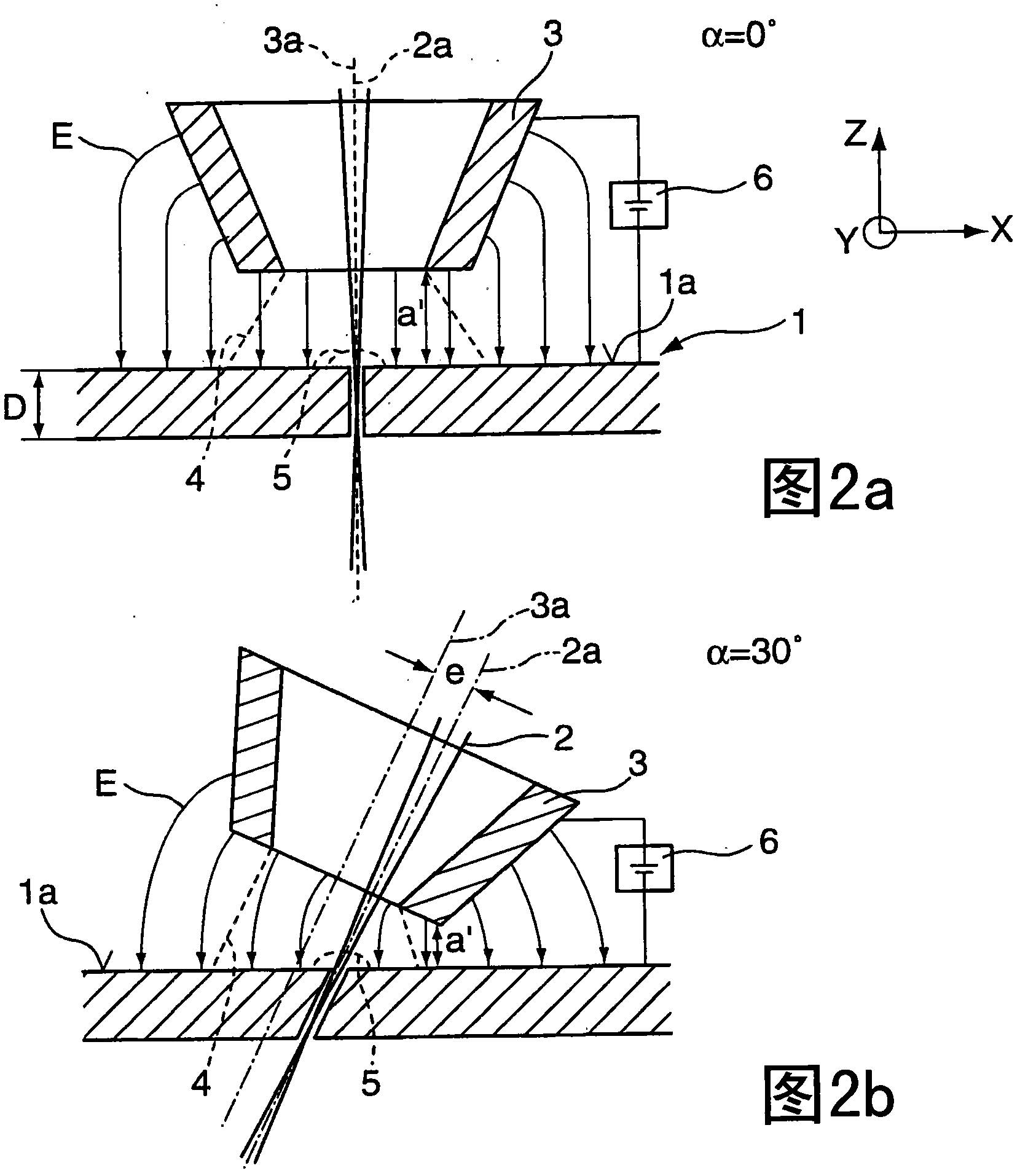

[0034] Figure 1b A transient diagram showing such a laser beam bevel cutting process on a tubular workpiece 1 at a bevel cutting angle α of approximately 20°, at which the laser cutting beam 2 with its beam axis 2a is relative to the workpiece surface 1a Orientation of the face normal on . The nozzle axis 3 a of the cutting gas nozzle 3 is oriented...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com