Device and method for efficiently preparing gradually varied laser carbonization furnace

A technology for preparing a device and a carbonization furnace is applied in the field of carbon fiber manufacturing to achieve the effects of high carbonization efficiency, space saving, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

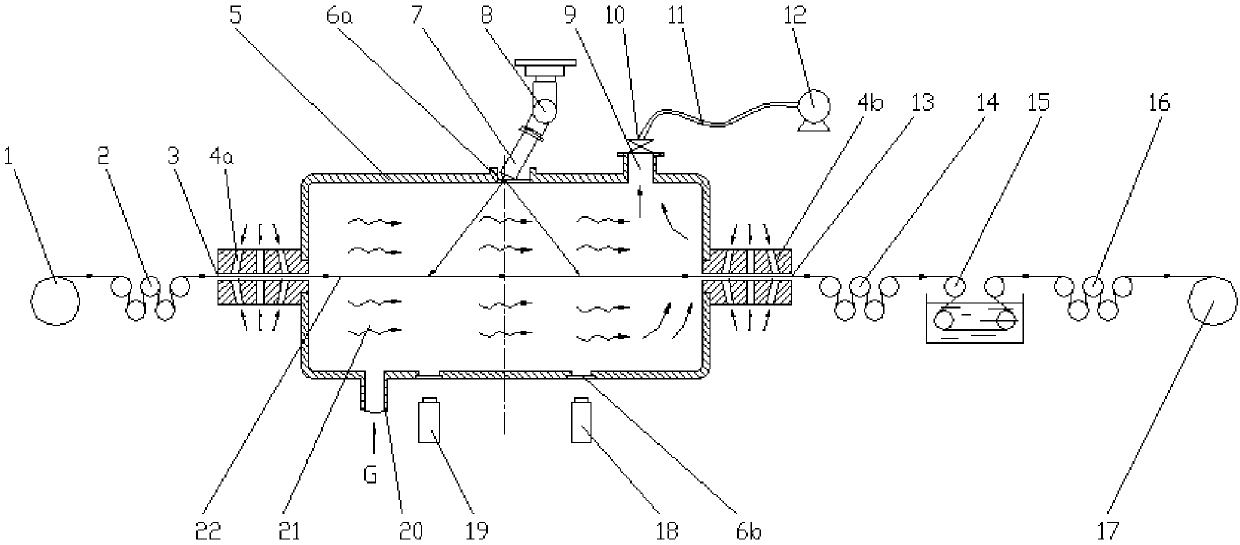

[0025] An efficient preparation method of a gradient laser carbonization furnace according to the present invention is as follows: firstly, the carbon fiber filaments to be processed are drawn, that is, the carbon fiber filaments pass through the front drafting device 2, the gradient laser carbonization furnace, the rear drafting device 14, and the sizing device 15. The drying device 16 and the wire receiving device 17 are mainly to make the carbon fiber thread pass through the furnace body 5. Before the carbon fiber is heat-treated, it is necessary to ensure that the heat treatment environment is filled with an inert gas, and nitrogen gas 21 is passed through the air-tight hole of the gas-tight device. To prevent gas exchange between the outside air and the gas in the furnace, vacuumize the furnace body of the carbonization furnace, and then inject nitrogen gas from the air inlet. The device releases the wire, and the drafting device with adjustable draft ratio moves toward th...

Embodiment 2

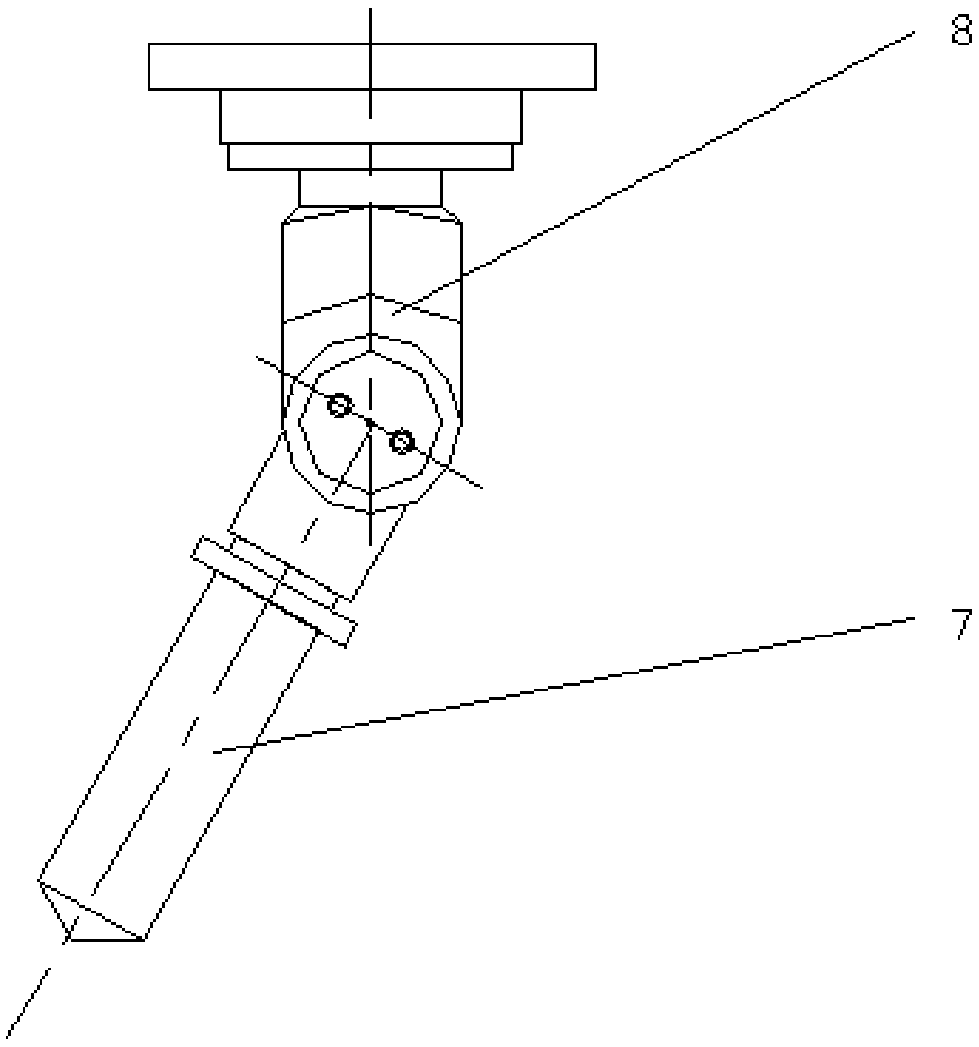

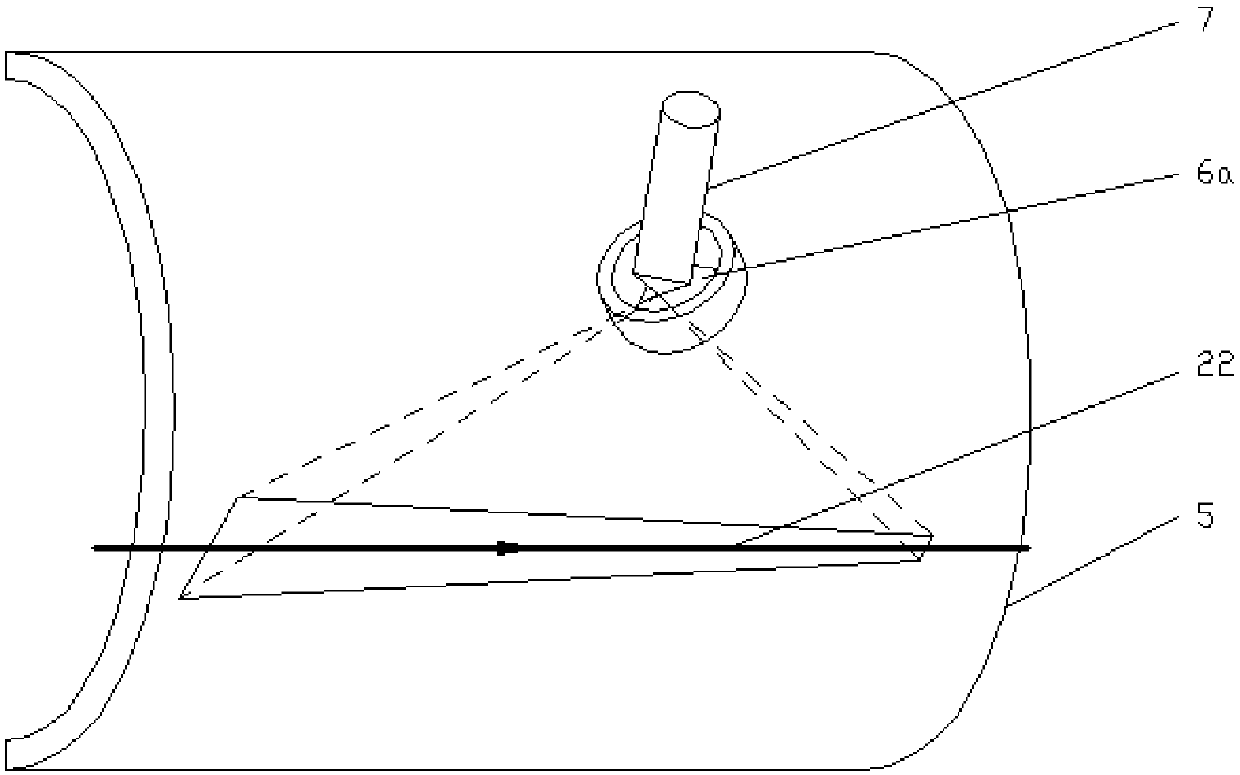

[0026] Embodiment 2: A kind of high-efficiency preparation device and method of a gradual changeable laser carbonization furnace of the present invention, in the process of preparing graphite fibers, a laser variable angle clamping device 8 is set to adjust the inclination angle of the laser 7 to 20°-40°, and irradiate The carbon fiber 22 produces a trapezoidal spot with a length of 100-800mm and a bottom edge of 5-40mm. The power of the laser generator is adjusted to 100-1000w. The infrared detector 18 in the high temperature area near the silk outlet detects that the temperature of the carbon fiber 22 is 2500-3300 ℃, the temperature of the carbon fiber 22 near the wire inlet detected by the infrared detector 19 in the low temperature area at the wire inlet is 300-800°C, and a gradual temperature of 300-3300°C is generated on the fiber to realize the integration of carbonization and graphitization of the fiber efficient heat treatment process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com