Continuous carbon fiber reinforced polyphenylene sulfide composite material

A polyphenylene sulfide and composite material technology, which is applied in the field of continuous carbon fiber reinforced polyphenylene sulfide composite materials, can solve the problem that the surface of carbon fiber is inert, the activity of common modifiers is low, and the strength of carbon fiber polyphenylene sulfide reinforced material is continuously improved. Unsatisfactory and other issues to achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

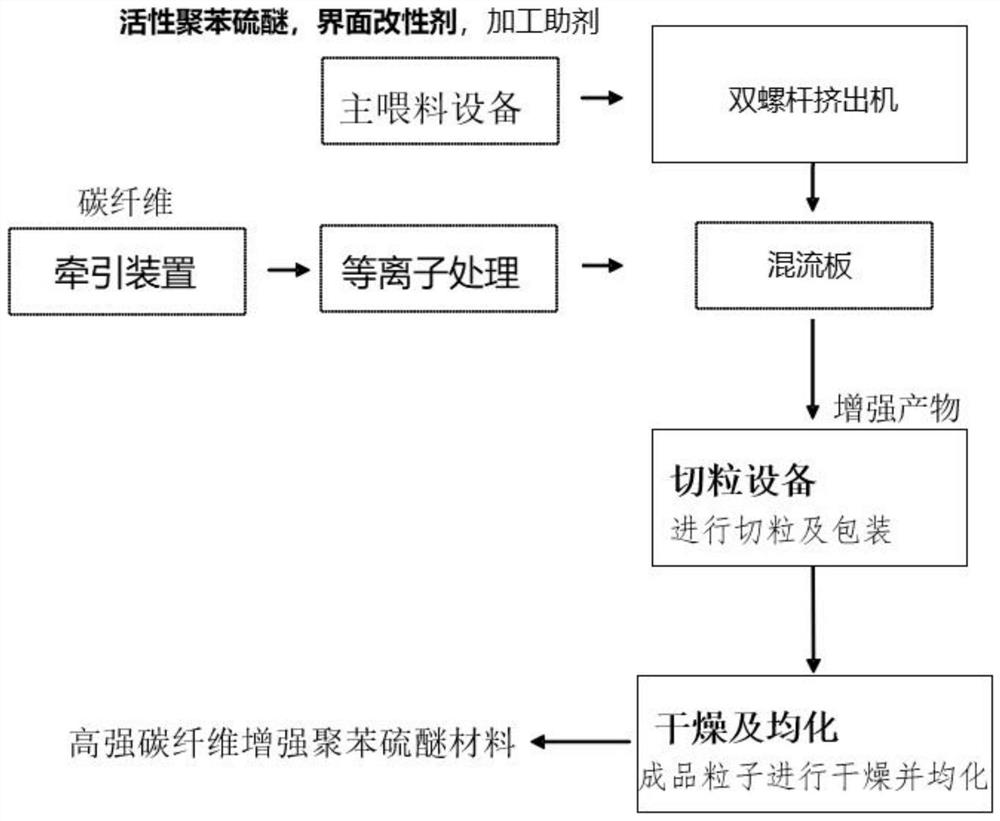

[0050] Interface modifier direct addition method

[0051] The continuous carbon fiber is plasma-treated and pulled to the mixing plate;

[0052] The polyphenylene sulfide / interface modifier / processing aid are mixed evenly, enter the extruder through the feeding equipment to melt and mix, and introduce the mixed flow plate;

[0053] The melt is mixed with carbon fiber through a mixed flow plate, dragged and granulated, and a continuous carbon fiber reinforced polyphenylene sulfide composite material is obtained.

[0054] Among them, the extrusion temperature has 7 sections from the feeding section to the head temperature, which are 285, 290, 300, 320, 320, 320, and 320°C, and the temperature of the mixed flow plate is 330°C.

Embodiment 2

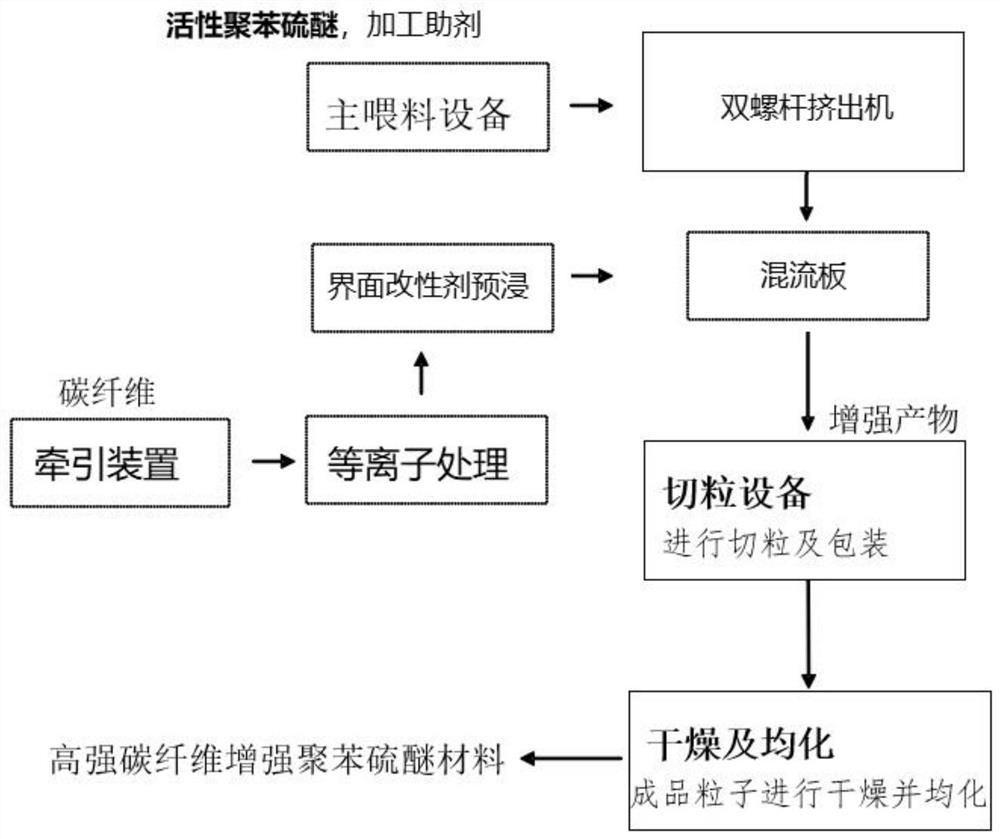

[0056] Interfacial Modifier Carbon Fiber Prepreg Method

[0057] The continuous carbon fiber is treated by plasma, pulled to the pre-impregnation tank of the interface modifier, and introduced into the mixed flow plate after reaction;

[0058] The polyphenylene sulfide / processing aid is mixed evenly, enters the extruder through the feeding equipment to melt and mix, and is introduced into the mixing plate;

[0059] The melt is mixed with carbon fiber through a mixed flow plate, dragged and granulated, and a continuous carbon fiber reinforced polyphenylene sulfide composite material is obtained.

[0060] Among them, the extrusion temperature has 7 sections from the feeding section to the head temperature, which are 285, 290, 300, 320, 320, 320, and 320°C, and the temperature of the mixed flow plate is 330°C.

[0061] Wherein, the pre-dipping temperature of the interface modifier is 90-110°C, and the pre-dipping time is 0.5-10s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com