Tobacco stalk processing method

A processing method and technology for tobacco stems, which are applied in the field of tobacco stem treatment on a silk-making line, can solve problems such as affecting the ability to purify tobacco stems, long processing time, and inability to rapidly expand tobacco stems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

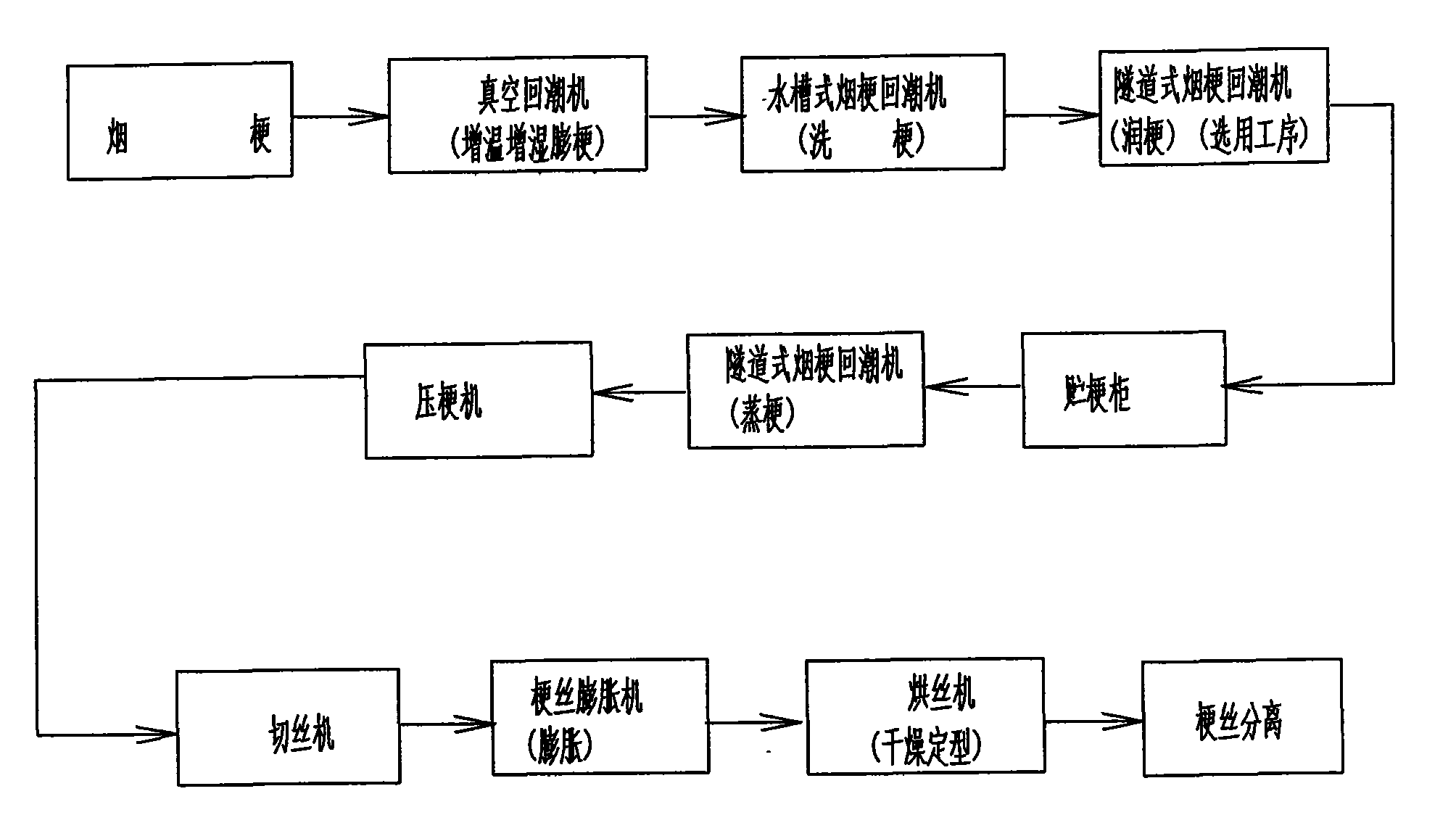

[0020] The tobacco stem treatment method of the present invention is to increase the tobacco stem vacuum rehydration treatment process at the front end of the traditional tobacco stem treatment process, use the principle of negative pressure to separate out the gas in the tobacco stem cells, and then spray atomized water vapor onto the surface of the tobacco stem, and pass The negative pressure inside the tobacco stem draws the atomized water vapor on the surface of the tobacco stem into the cells of the tobacco stem, so that the inside and outside of the tobacco stem can be evenly infiltrated, and the tobacco stem can achieve preliminary puffing after absorbing moisture. The channel is opened, the moisture absorption capacity of the tobacco stem is strengthened, and the defect of insufficient moisture increase in the traditional tobacco stem treatment process is overcome. The sand and other impurities in it are easy to fall off. After the tobacco stem vacuum rehydration treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com