Process for preparing cigarette expanded stem shreds

A preparation process and expansion stem technology, applied in the preparation of tobacco, tobacco, tobacco treatment, etc., can solve the problems of difficult screening, end falling, large miscellaneous gas, etc., and achieve good adsorption performance, good processing resistance, and stable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

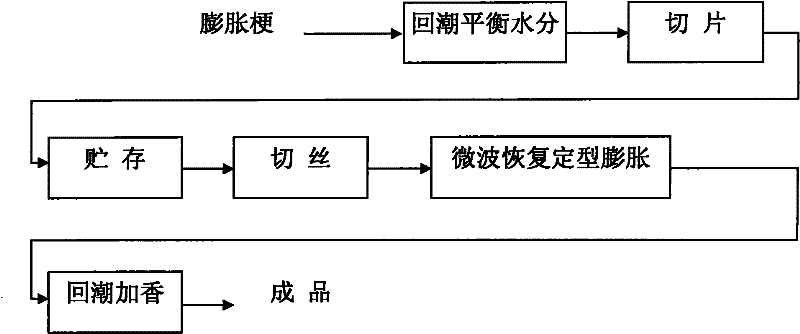

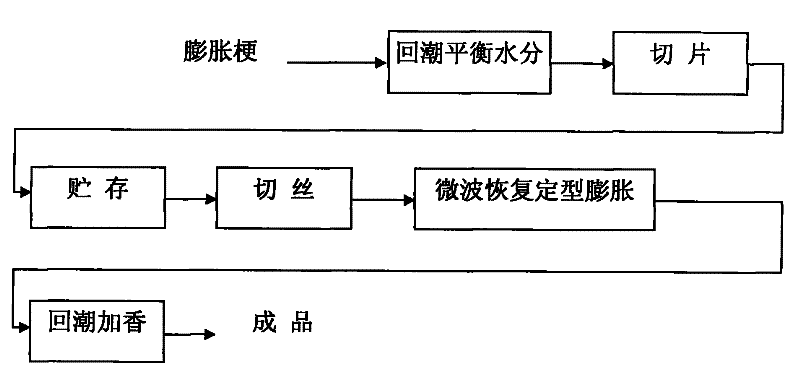

Image

Examples

Embodiment 1

[0032] The invention relates to a preparation process of cigarette expanded stalks. The expanded tobacco stalks with an expansion degree of more than 150% are rehydrated to balance the water content, sliced, stored, shredded, microwaved to restore the shape and expansion, rehydrated and flavored to obtain finished stalks. The specific process steps are as follows:

[0033] A. Moisture balance and moisture: rehydrate the expanded tobacco stems to 30% moisture in the moisture regain and balance moisture equipment and balance the moisture. The moisture deviation of the same batch is ≤3%.

[0034] B. Slicing: Cut the rehydrated expanded tobacco stem into expanded stem slices with a thickness of 0.2-0.4mm.

[0035] C. Storage: Store the expanded stalks in a storage cabinet for later use.

[0036] D. Shred: cut the expanded stalks in step C into stalks with a width of 0.2-0.4mm and a length of 5-6mm, that is, the cross-sectional size is 0.2-0.4mm×0.2-0.4mm, and the length is 5-6mm ...

Embodiment 2

[0041] Send the expanded stalks prepared according to the patent ZL03117228.8 "Tobacco stem pretreatment process" into the moisture conditioner to rehydrate to 15% moisture, and balance the moisture in the storage cabinet. The moisture deviation of the same batch of tobacco stems is ≤3%; The final expanded tobacco stems are continuously cut into thin slices with a thickness of 1.4-1.8mm on the shredder, and then sent to the storage cabinet for storage; they are continuously fed into the shredder and cut into thin strips with a width of 1.4-1.8mm, that is, the cross-sectional size is 1.4mm. ~1.8mm×1.4~1.8mm, 16~20mm in length; then the stalks are continuously sent to the microwave heating equipment through the quantitative tube to dry until the water content is 8~10%; finally sent to the moisture regain and flavoring machine Flavoring and regaining moisture, the finished product of expanded stalk shreds that can be directly added to cigarettes with a moisture content of 12%±1% i...

Embodiment 3

[0043] Tobacco stems with an expansion degree of more than 150% expanded by the dry ice method are rehydrated to 20% moisture in a moisture reconditioning machine, and the moisture is balanced in a storage cabinet. The moisture deviation of the same batch of tobacco stems is ≤ 3%; The expanded tobacco stems are sent to the continuous shredding machine and cut into thin slices with a thickness of 1mm±0.1mm, then sent to the storage cabinet for storage, and then continuously sent to the shredder to cut into 1mm±0.1mm wide and 10-15mm long stems Silk, that is, the cross-sectional size is (1±0.1)mm×(1±0.1)mm; then it is continuously sent to the microwave heating equipment through the quantitative tube to dry to 5-6% moisture; and finally sent to the moisture-resurrection and aromatherapy machine for moisture-resurrection and aromatherapy to 12% ± 1% moisture, to obtain expanded stem strips that can be directly added to cigarettes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com