Blended cut tobacco and preparation method thereof

A technology for shredded tobacco and tobacco leaves, which is applied in the field of mixed shredded tobacco and its preparation, which can solve the problems of waste of resource quality, failure to develop the quality characteristics of tobacco leaf raw materials, and single taste of the product, and achieve the effects of reducing quality alienation, rich taste, and reducing process loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is further described below in conjunction with an embodiment.

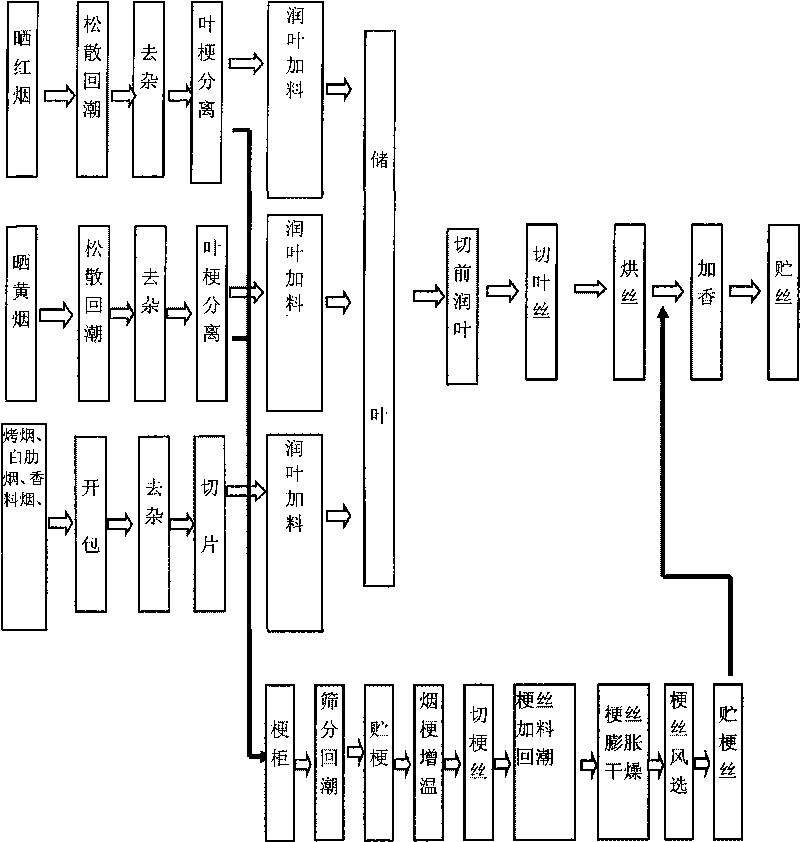

[0012] For a better description of the present invention, the process flow diagram of an embodiment is provided below:

[0013]

[0014] In combination with the above process flow chart, it can be seen that the preparation method of mixed shredded tobacco provided in this embodiment includes the following specific steps:

[0015] (1) First, treat red sun-cured tobacco, yellow sun-cured tobacco, flue-cured tobacco, burley tobacco or oriental tobacco as follows:

[0016] a. Perform loosening and rehydration, impurity removal, leaf stalk separation, and leaf moistening treatment on red sun-cured tobacco and yellow sun-cured tobacco respectively, to obtain red sun-cured tobacco leaves, yellow sun-cured tobacco leaves, red sun-cured tobacco stems, and sun-cured yellow tobacco stems;

[0017] b. Unpacking, removing impurities, slicing, moistening and adding materials to flue-cured tobacc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com