Cigarette processing and shredded tobacco making method and apparatus for loosening shredded tobacco

A shredded tobacco and loose technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of affecting the moisture uniformity of shredded tobacco, large fluctuations in the inlet flow of shredded tobacco drying process, and entanglement and agglomeration of shredded tobacco

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

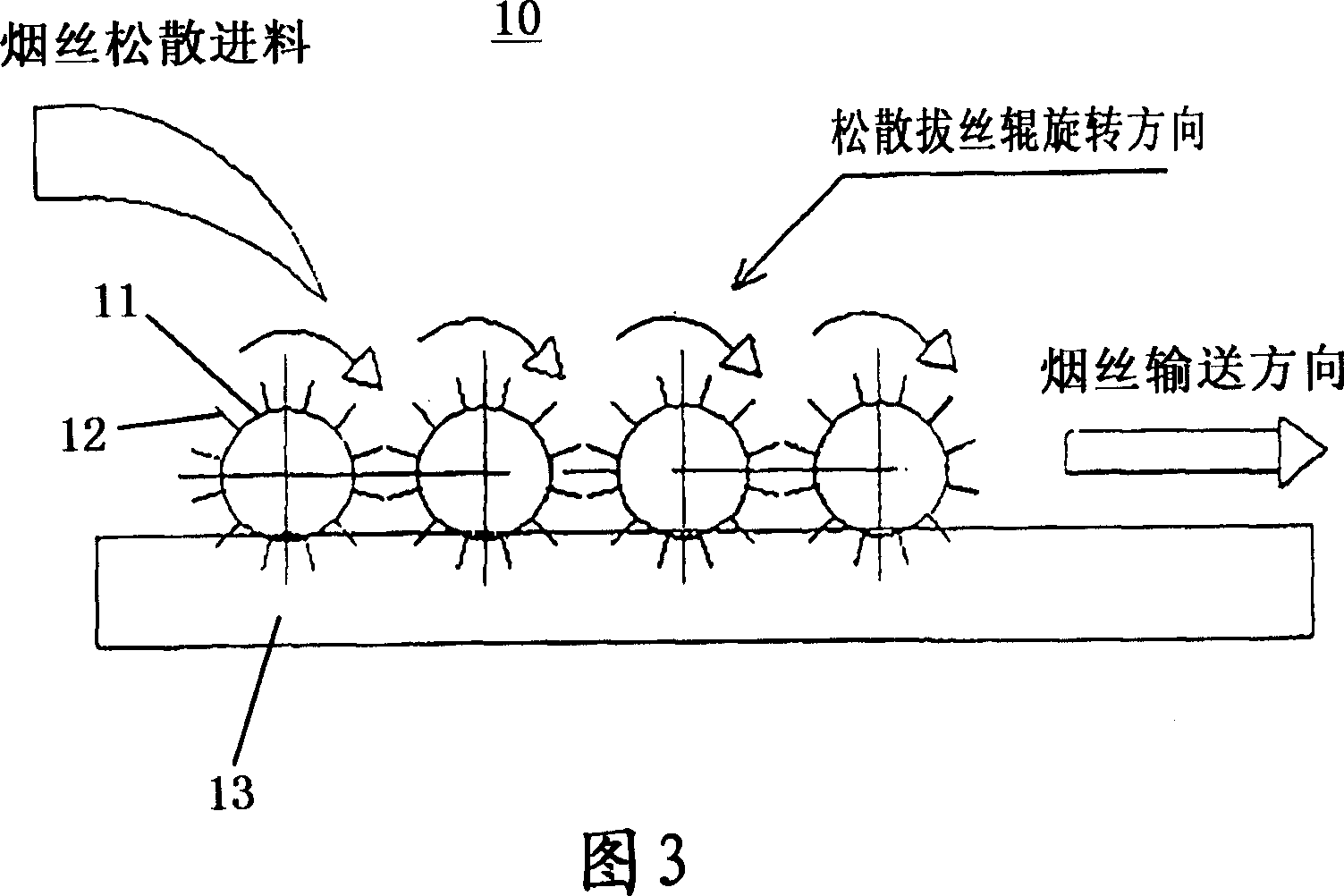

[0018] Embodiments of the present invention will be described below with reference to the drawings. In addition, in the drawings of the present invention, the same reference numerals as those in the prior art are assigned the same symbols, and their detailed descriptions are omitted.

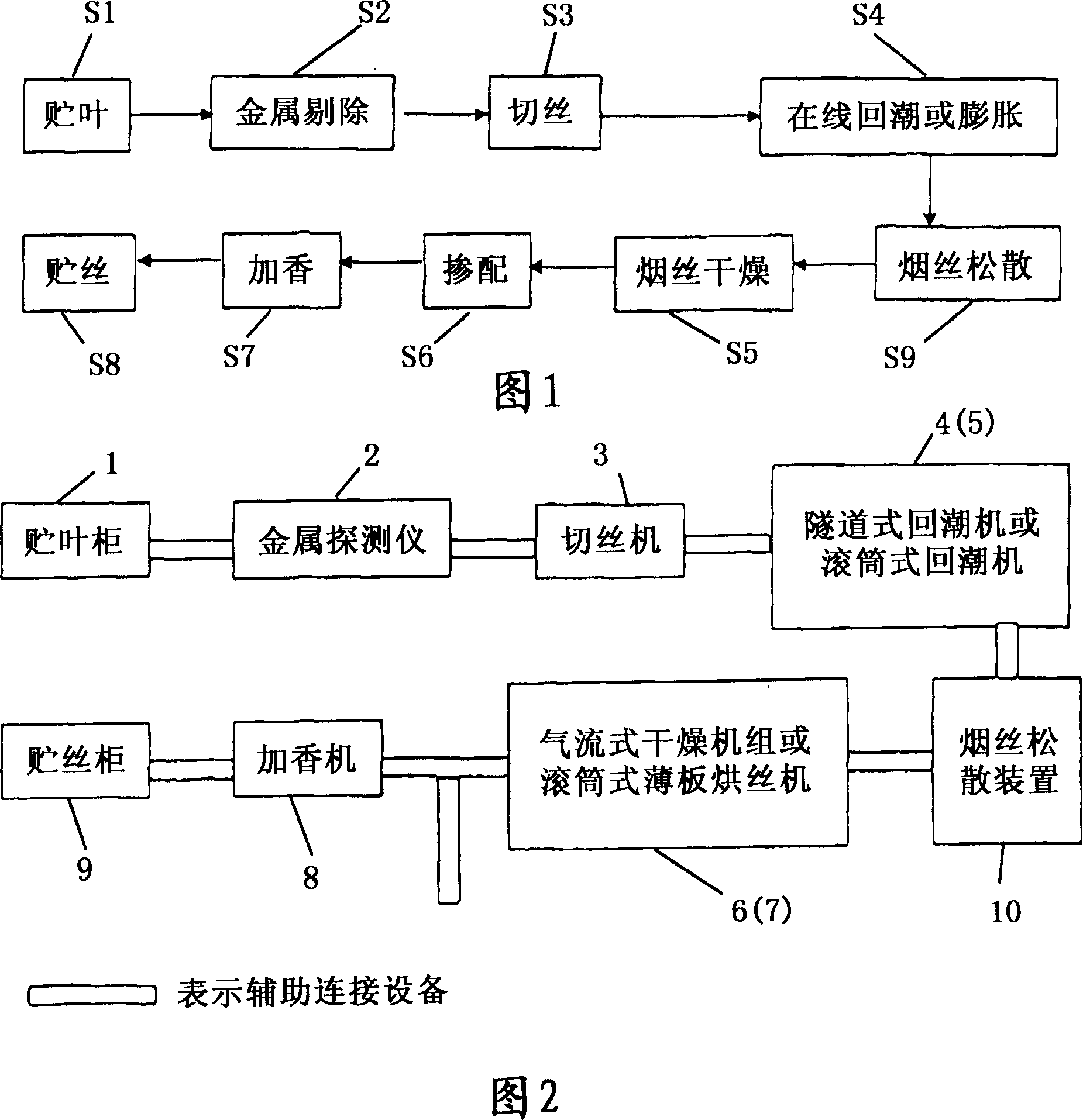

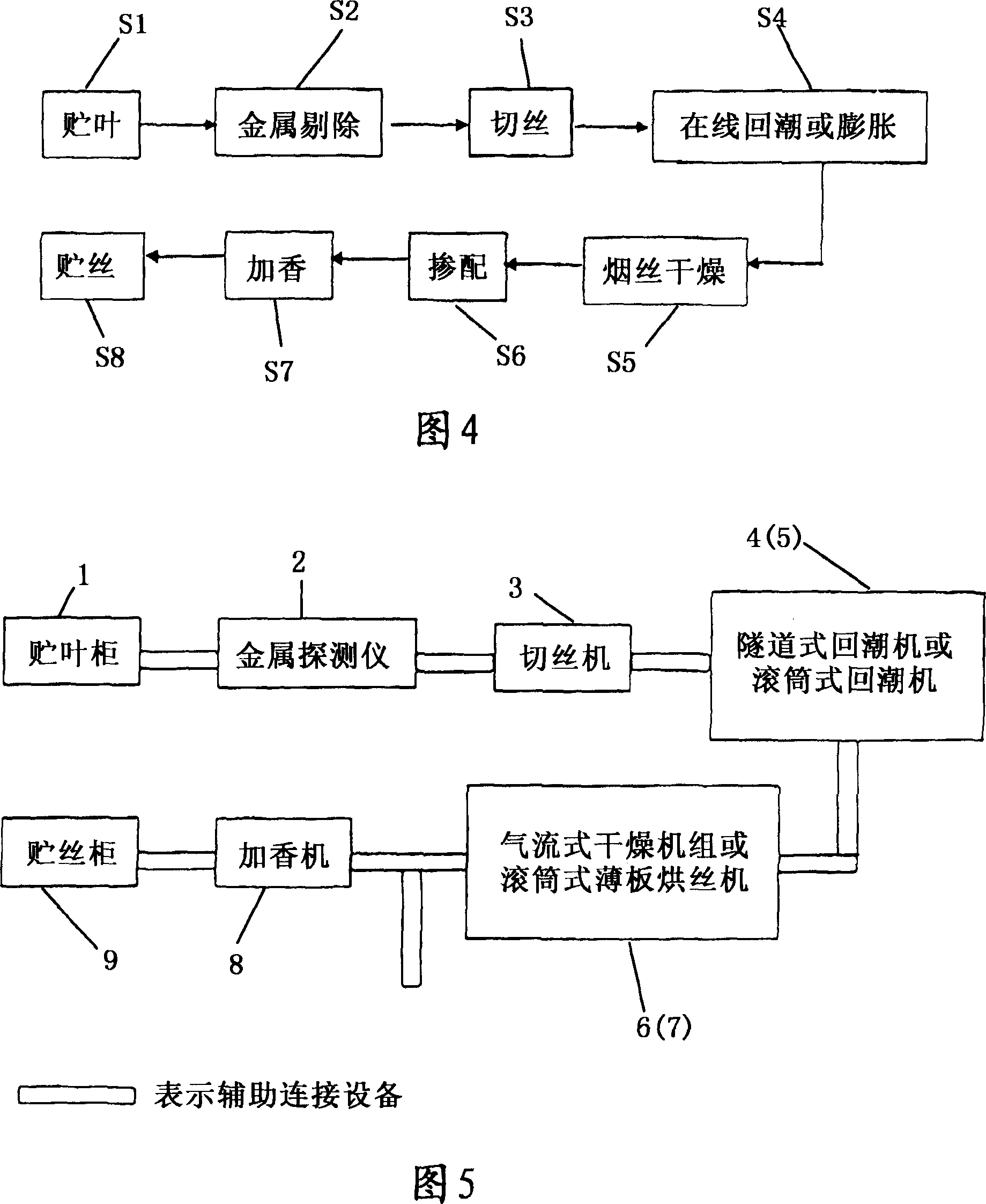

[0019] As shown in Figure 1, the cigarette processing and shredded method of the present invention includes: a leaf storage process S1 for storing the treated tobacco leaves; a metal removal process S2 for removing metal impurities in the tobacco leaves; a cutting process for cutting the tobacco leaves into qualified shredded tobacco. Cutting process S3; process S4 of online rehydration or expansion of cut tobacco; process S5 of drying online rehydrated or expanded tobacco; blending process S6; flavoring process S7; and storage of processed tobacco Process S8: These processes are the same as the existing cigarette processing and shredding process, but the cigarette processing and shredding metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com