Cigarette tobacco leaf formulation design method

A design method and technology for cigarette leaves, which are applied in the directions of tobacco, tobacco preparation, tobacco processing, etc., can solve the problem that sensory quality, product style and smoke indicators cannot be guaranteed, optimal or sub-optimal combination of tobacco leaves cannot be guaranteed, and insufficient Using problems such as utilization, to achieve the effect of increasing the scope of use, reasonable leaf group formula, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

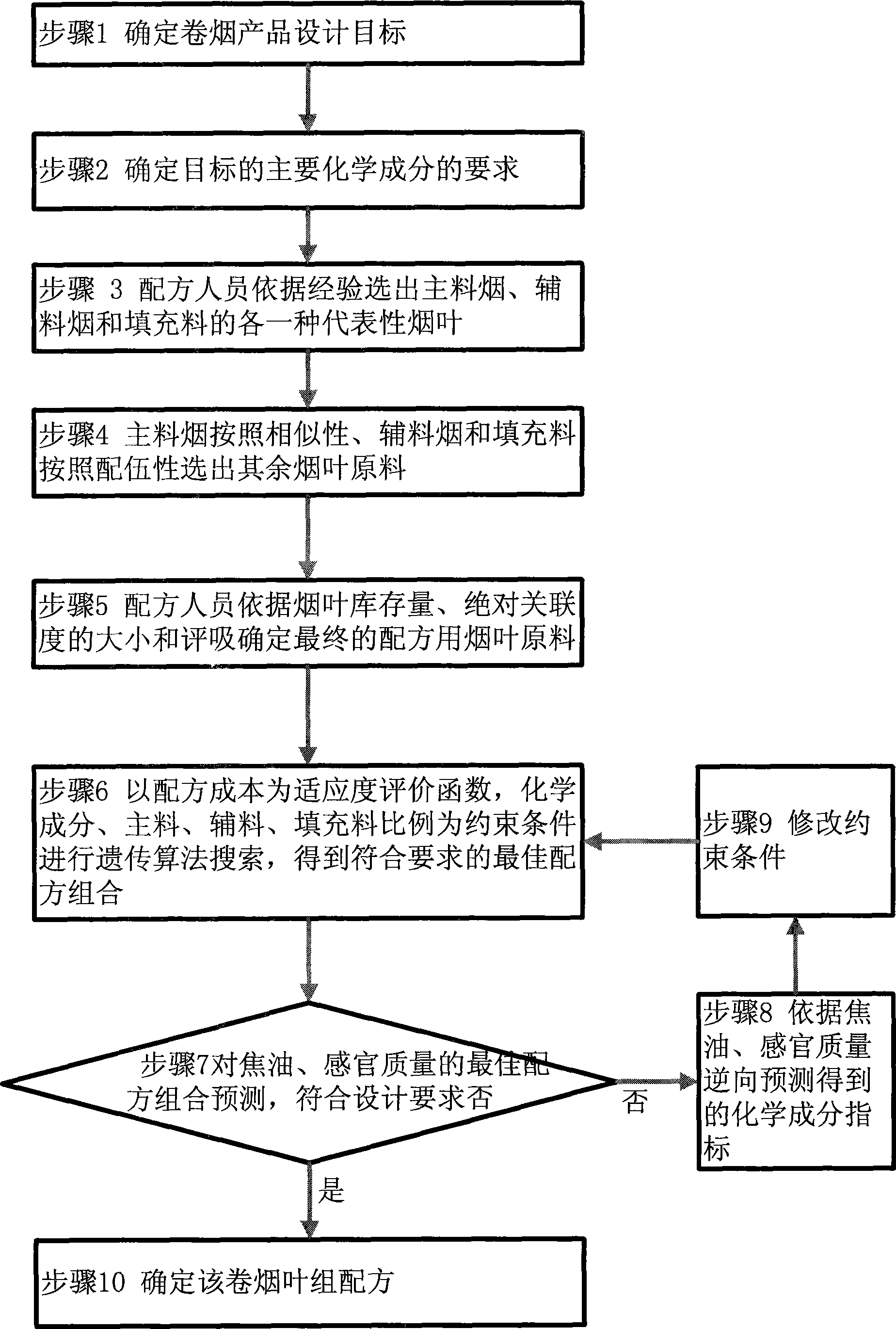

[0027] The present invention will be further elaborated below in conjunction with the accompanying drawings.

[0028] The chemical composition of cigarette tobacco leaves, including aroma components, is the intrinsic basis of cigarette sensory quality, product style and smoke composition. Therefore the present invention replaces the combination of the tobacco leaves of the cigarette with the combination of the chemical components of the tobacco leaves. And it is necessary to apply combination optimization technology to optimize the combination of selected tobacco leaves, and find the optimal combination that meets the requirements of the design goal.

[0029] The research object of gray system theory is the "small sample" and "poor information" uncertain system of "partial information is known and part information is unknown", which is suitable for nonlinear evaluation problems.

[0030] The present invention combines gray clustering and gray absolute correlation to carry out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com