Fire-cured tobacco type low-coke tar cigarette and technique for preparing the same

A preparation process, low-tar technology, applied in the field of tobacco products, can solve the problems of high irritation, unacceptable by consumers, dry aftertaste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

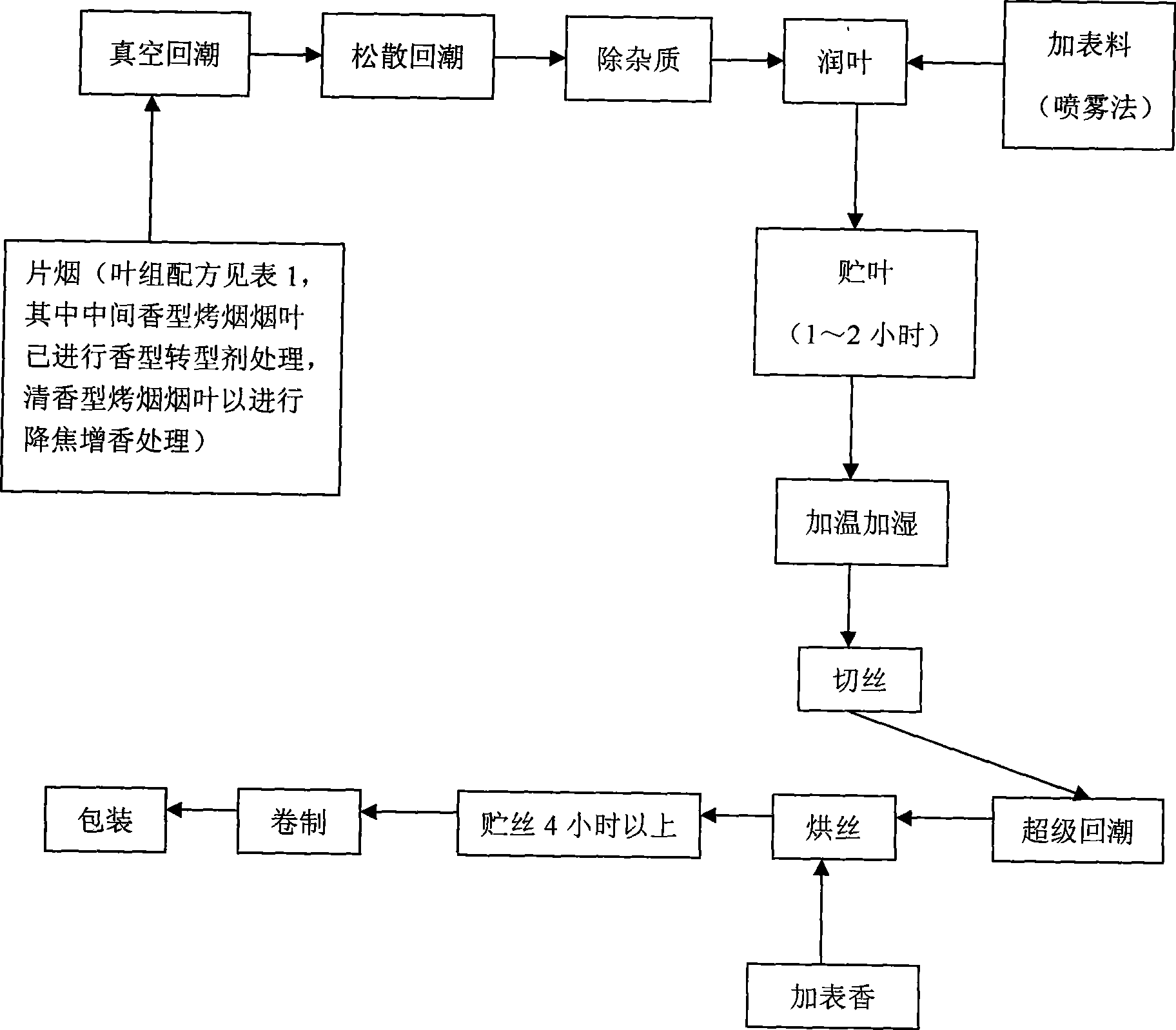

Method used

Image

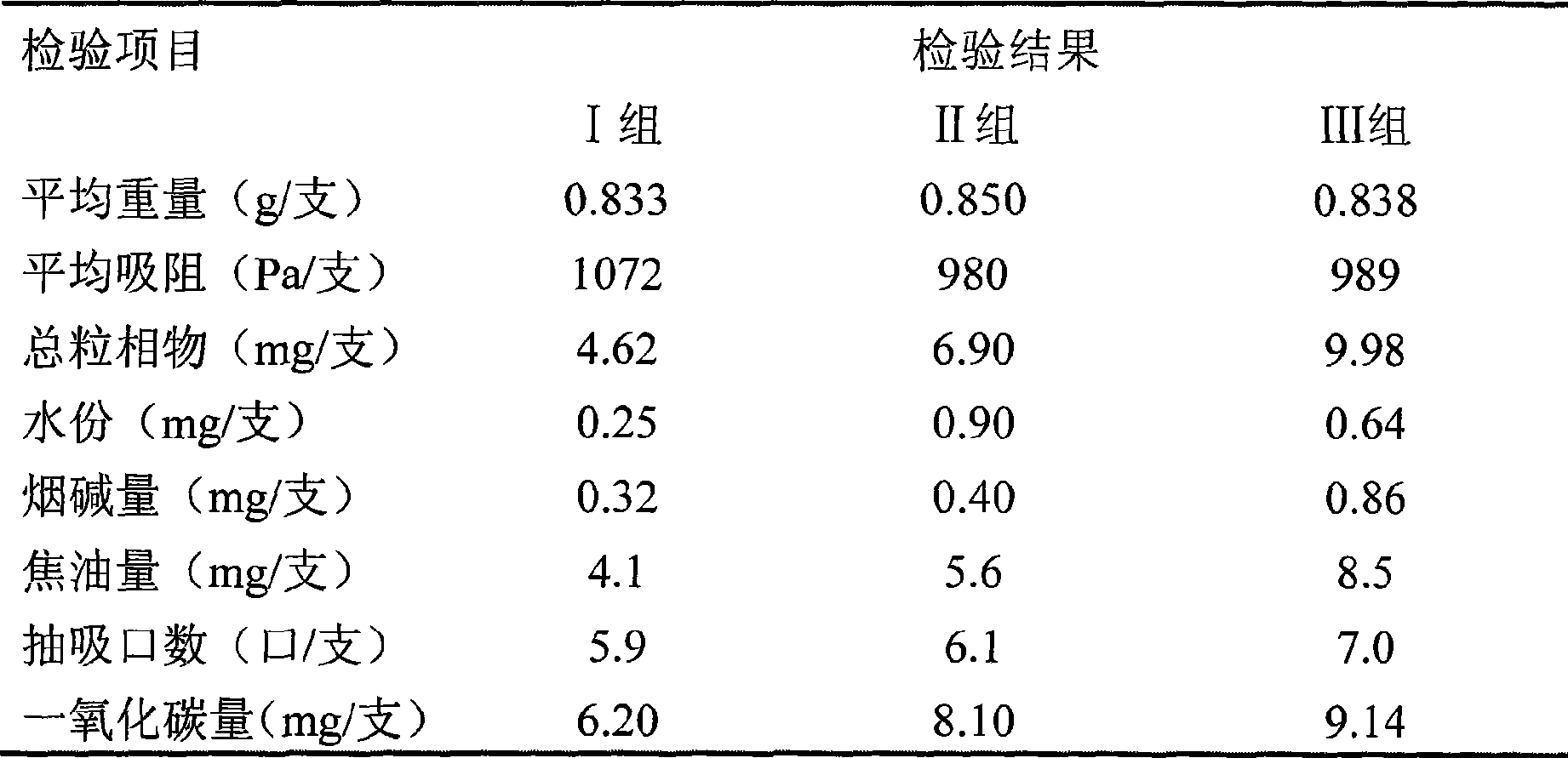

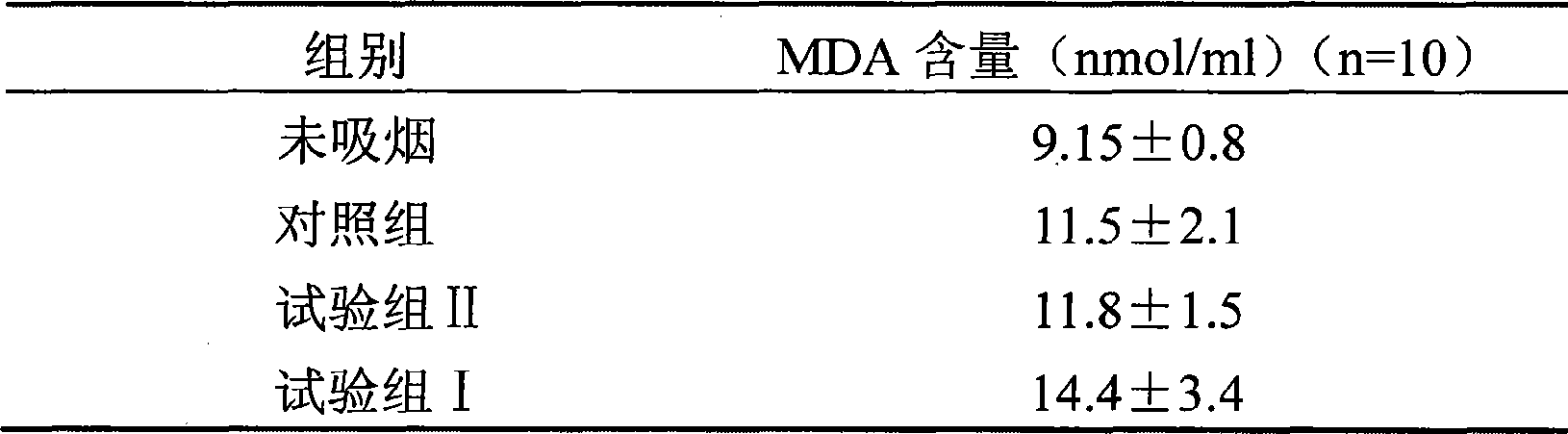

Examples

Embodiment 1

[0037] 1. Pretreatment of Fen-flavor flue-cured tobacco leaves

[0038] (1) Preparation of tar reducing and flavoring agent for flue-cured tobacco leaves

[0039](a) Houttuynia cordata, Dayflower grass, and Lobelia are dried and cut into pieces, and honeysuckle is made into fragments, and then the materials are taken according to the following weight ratio: 0.5 parts by weight of Houttuynia cordata, 0.5 parts by weight of Dayflower grass , Lobelia 1 weight part, honeysuckle 1 weight part. Put the raw materials of the above parts by weight into a ceramic container, add 40°C water of 2.5 times (7.5 parts by weight) of the raw materials, add cellulase in an amount of 0.3% (0.009 parts by weight) of the raw materials, and put it in at a temperature of 40°C The incubator was kept warm for 1 hour, taken out, heated in a microwave oven for 1 minute, filtered, and the filtrate was collected and allowed to stand for 24 hours, and the precipitate was discarded to obtain the supernatant...

Embodiment 2

[0058] 1. Pretreatment of intermediate flue-cured tobacco leaves

[0059] (1) Preparation of flue-cured tobacco leaf aroma transformation agent

[0060] (a) crush schisandra chinensis and pass through a 20-mesh sieve to make a coarse powder, remove impurities from the blueberry pressed residue obtained by brewing blueberry wine, and take the blueberry seed shell to dry. Put 1.5 parts by weight of the schisandra coarse powder obtained above and 2.0 parts by weight of the blueberry seed husk into a dipping device, add 60% ethanol that is 2.5 times the weight of the raw material (8.75 parts by weight), seal the dipping device, and heat the dipping device at a temperature of 30 ° C. Immerse under water for 3 days, stir 3 times in the middle to extract the ingredients, filter, and let the collected filtrate stand for 24 hours, discard the precipitate, and the obtained supernatant is concentrated into a paste by vacuum distillation at 35°C and 80Kpa;

[0061] (b) adding ethanol of ...

Embodiment 3

[0079] 1. Pretreatment of Fen-flavor flue-cured tobacco leaves

[0080] (1) Preparation of tar reducing and flavoring agent for flue-cured tobacco leaves

[0081] (a) Houttuynia cordata, Dayflower grass, and Lobelia are dried and cut into pieces, and honeysuckle is made into pieces, and then the materials are taken according to the following weight ratio: 2.0 parts by weight of Houttuynia cordata, 2.0 parts by weight of Wild dayflower , lobelia 4.0 parts by weight, honeysuckle 4.0 parts by weight. Put the raw materials of the above parts by weight into a ceramic container, add 40°C water of 3.0 times the weight of the raw materials (36 parts by weight), add cellulase in an amount of 0.5% of the raw materials (0.06 parts by weight), and put it in at a temperature of 40°C The incubator was kept warm for 1 hour, taken out, placed in a microwave oven, heated for 3 minutes, filtered, and the filtrate was collected and allowed to stand for 24 hours, and the precipitate was discarde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com