Patents

Literature

47 results about "Low tar cigarette" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

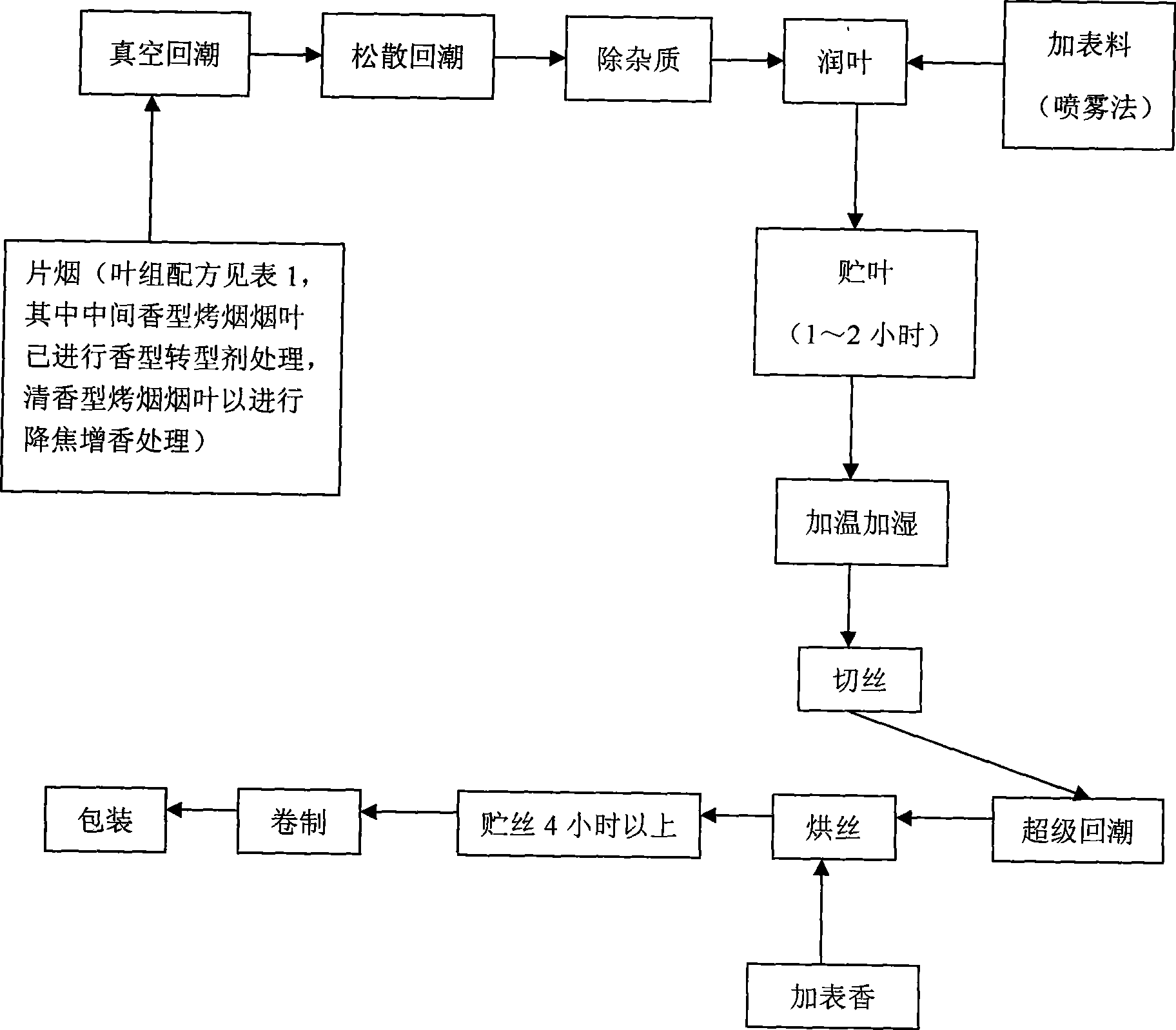

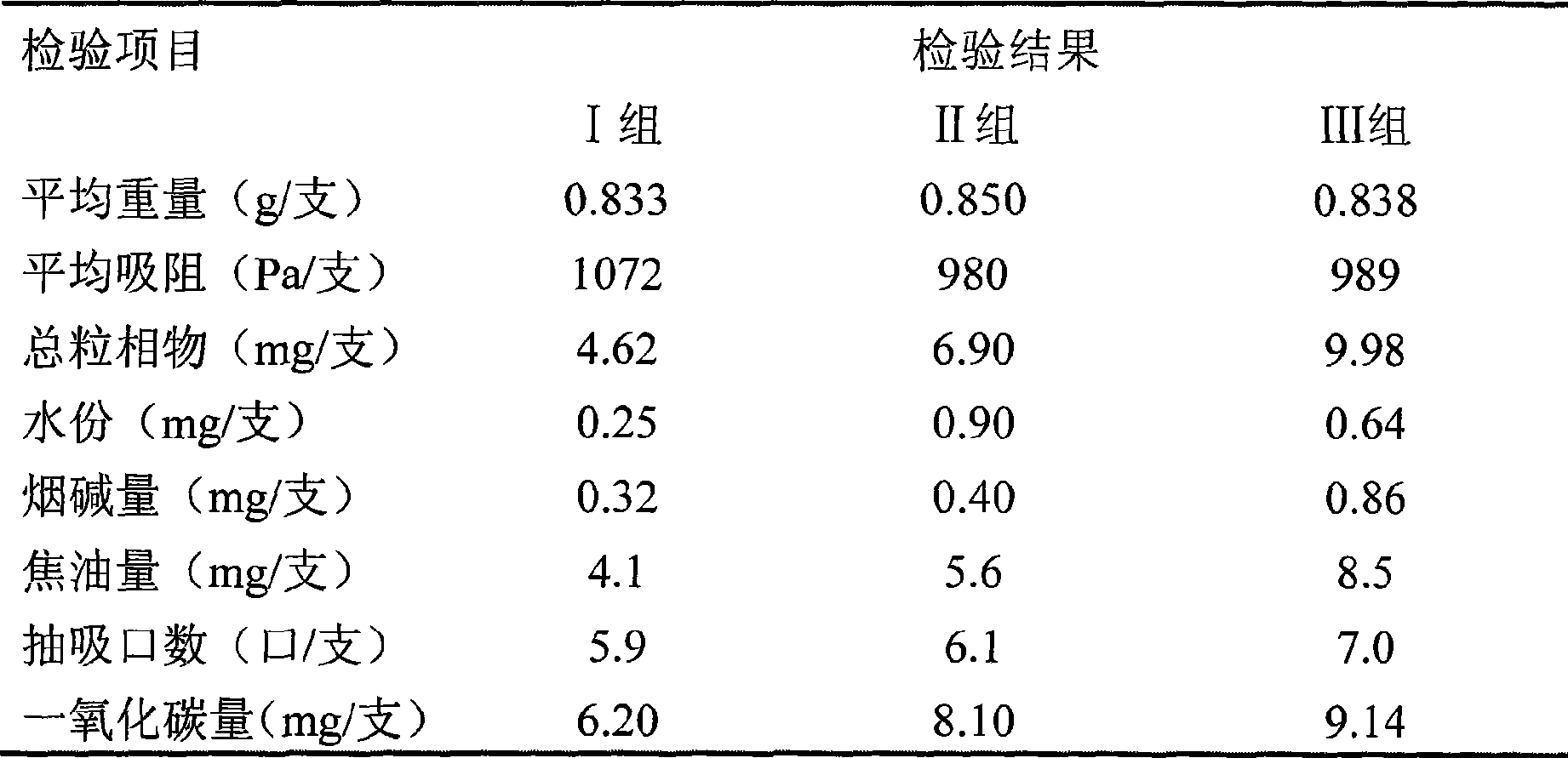

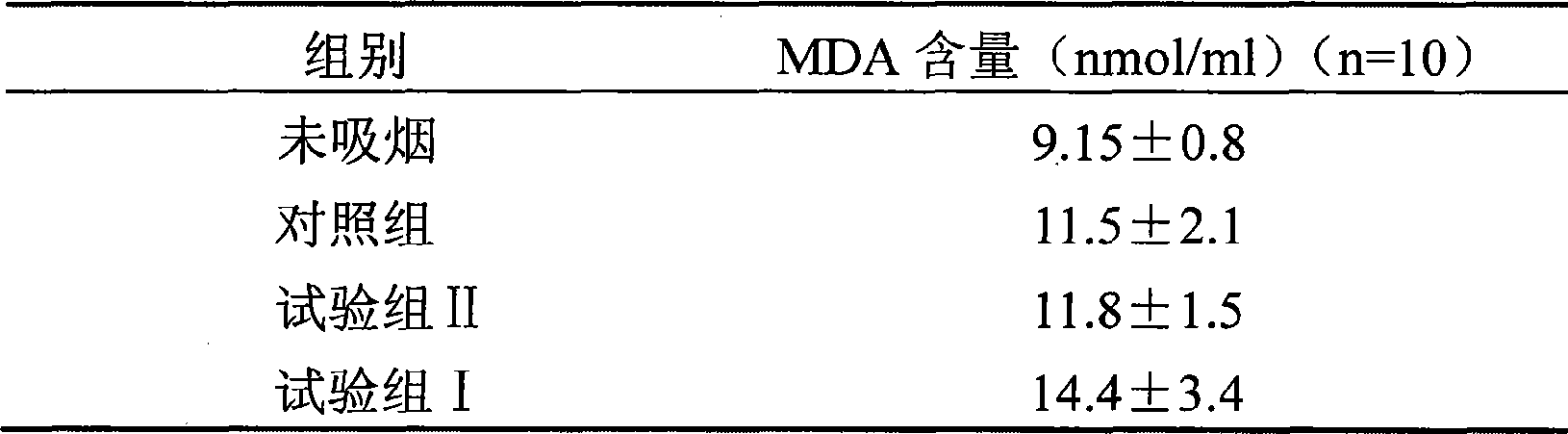

Fire-cured tobacco type low-coke tar cigarette and technique for preparing the same

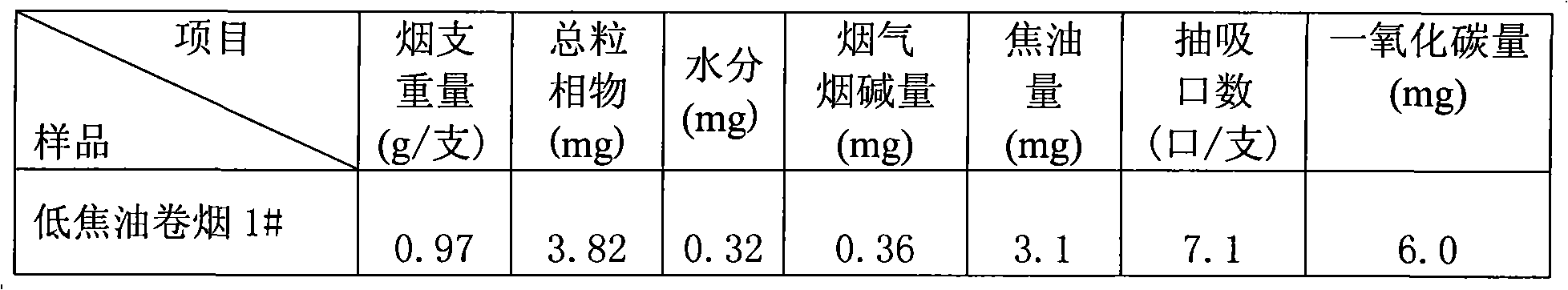

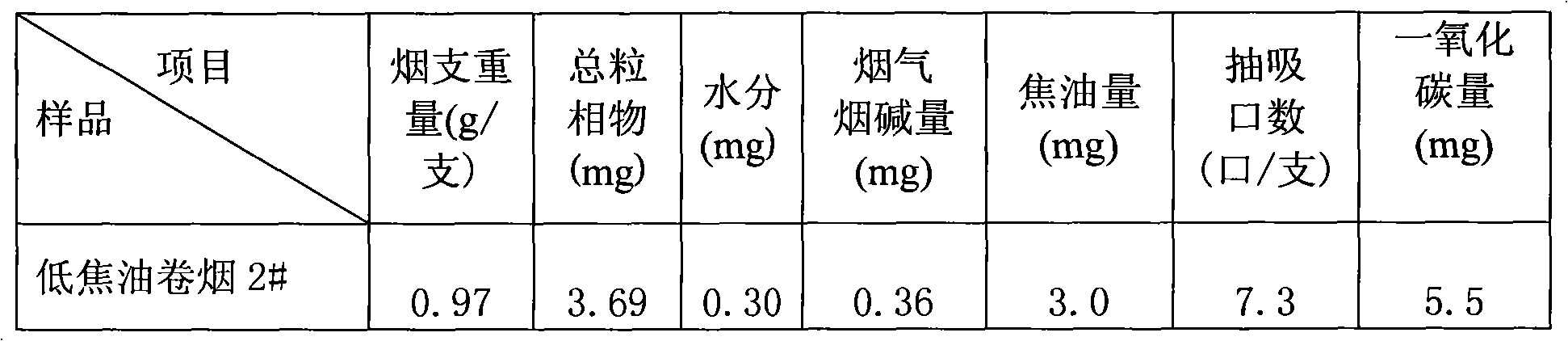

The invention discloses a cured tobacco type low-tar cigarette prescription and preparation thereof. The cured tobacco type low-tar cigarette comprises cut tobacco, a filter rod, and cigarette paper. The cut tobacco is prepared by: 15-22 by weight parts of faint scent type tobacco leaf, 28-40 by weight parts of aroma type tobacco leaf, 25-35 by weight parts of middle scent type tobacco leaf, 8-15 by weight parts of air-cured tobacco, 10-20 by weight parts of papermaking flake, 10-20 by weight parts of stalk. The middle scent type tobacco leaf in the prescription is processed by tobacco leaf scent type modifier, so as to add fragrance to tobacco leaves, and modify scent type. The faint scent type tobacco leaf in the prescription is processed by cured tobacco leaf tar lowering fragrance adding agent, so as to make faint scent feature more outstanding and lower tar releasing quantity. An odor-absorbing modifying agent and a fluid producing agent are added combined with perfuming in cigarette making process, and a safe cured tobacco type low-tar cigarette with fragrant, gentle smell, and obvious individual characteristic. Tar content of the cured tobacco type low-tar cigarette is 3mg-8mg per one cigarette.

Owner:延吉烟悦科技有限公司 +1

Tobacco component additive agent for compensating aroma to low tar cigarette

ActiveCN101129216AIncrease the amount of aromaImprove coordinationTobacco treatmentCyclopentenePropanoic acid

The invention discloses a tobacco component additive to compensate the perfume of low-tar cigarette, which comprises the following parts: 0. 1-2kg tobacco extract, 0-10g furfural, 1-5g 5-methyl-furfural, 1-10g 3-ethyl-2-hydroxy-cyclopentene-1-ketone, 1-10g hexadecyl methyl ester, 1-10g solanestone, 0-10g kiwi fruit lactone dihydroxide, 1-10g calicotone, 1-20g hugebean alkatrientone, 0-10g pyridine, 0-10g 2-methyl-pyridine, 0-100g acetic acid, 0-10g propionic acid, 0-10g benzene carbonic acid, 0-100g benzene carbonic acid, wherein the weight of the raw materials is 1-4 times as diluent. The invention uses tobacco extract and tobacco perfume material as raw material to improve the perfume content of low-tar cigarette, which has good harmonization with tobacco under convenient preparing method and wide resource of raw material.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Low-tar cigarette aroma compensation method

ActiveCN102423114AReduce drynessReduce volatilityTobacco preparationTobacco treatmentFlavor3-oxo-alpha-ionol

The invention relates to a method for compensating the aroma of low-tar cigarettes by utilizing tobacco flavor precursors, which belongs to the field of tobacco processing. The method is characterized in that: in the low-tar cigarette production process, one or more types of tobacco flavor precursors are added into cut tobacco or cigarette paper for the low-tar cigarettes; and the tobacco flavor precursor is any one or the mixture of glycolipid, glucoside, Amadori compound and 3-oxo-Alpha-ionol-related compound. By adding the tobacco flavor precursor, the method effectively increases the aroma of the low-tar cigarettes, harmonizes the cigarette aroma, decreases the dryness of smoke, and provides an effective approach for the development of high-aroma, low-tar cigarettes.

Owner:HONGTA TOBACCO GRP

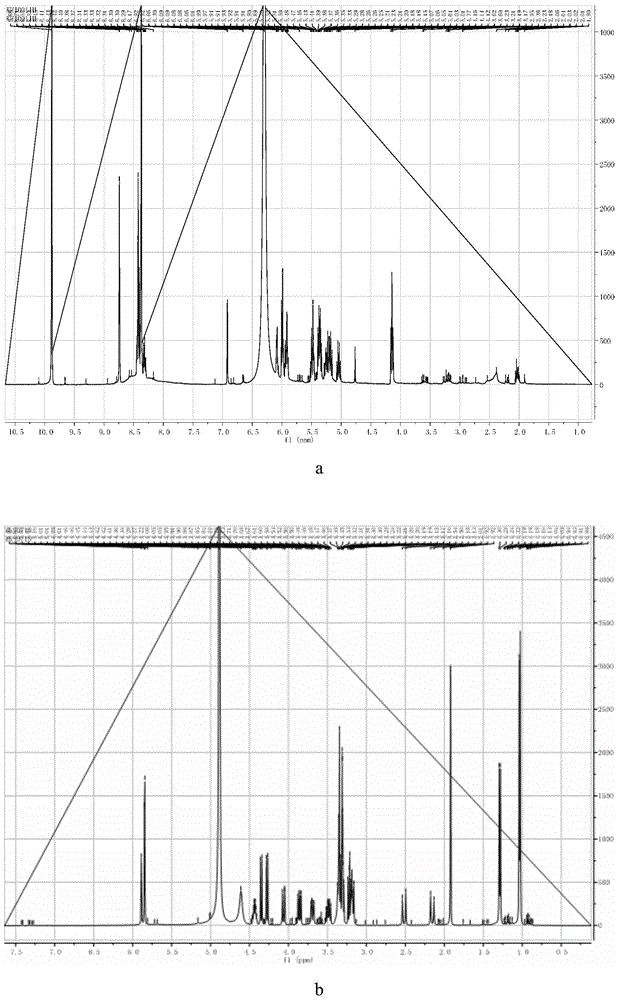

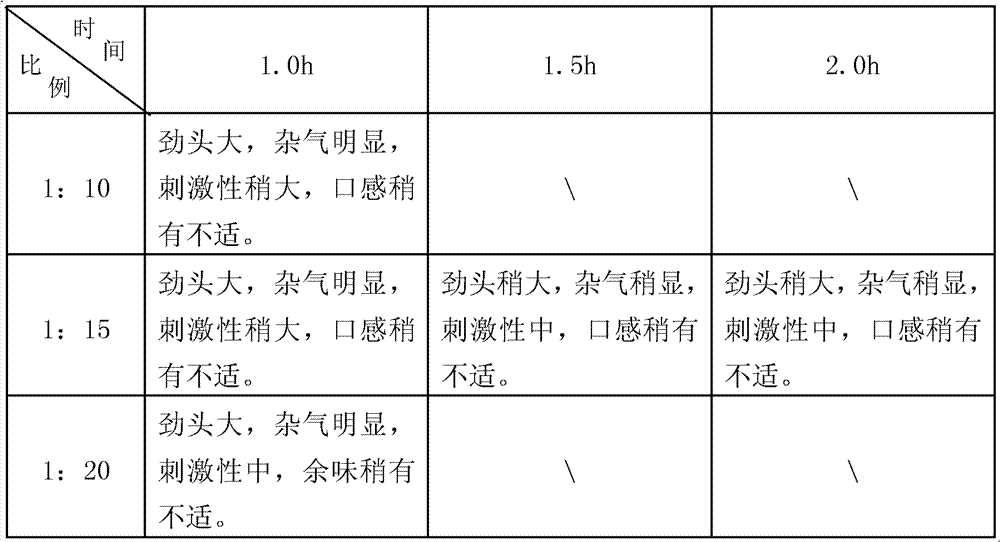

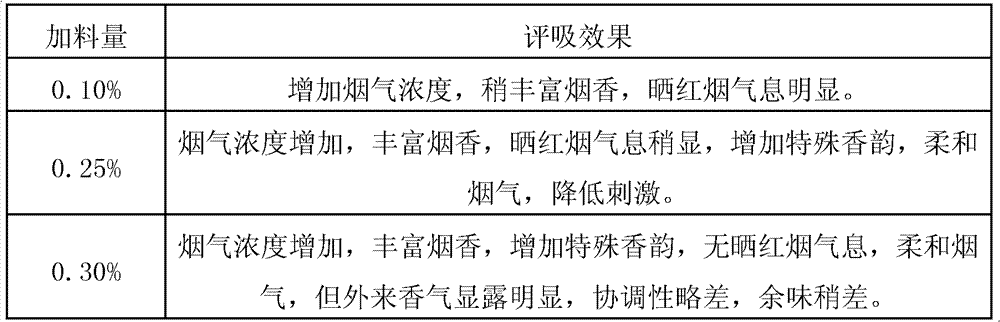

Preparation method for tobacco extract of dark sun-cured tobacco

ActiveCN105533793AIncrease the fragranceImprove the shortcomings of the lack of satisfactionTobacco treatmentMolecular distillationDistillationMass ratio

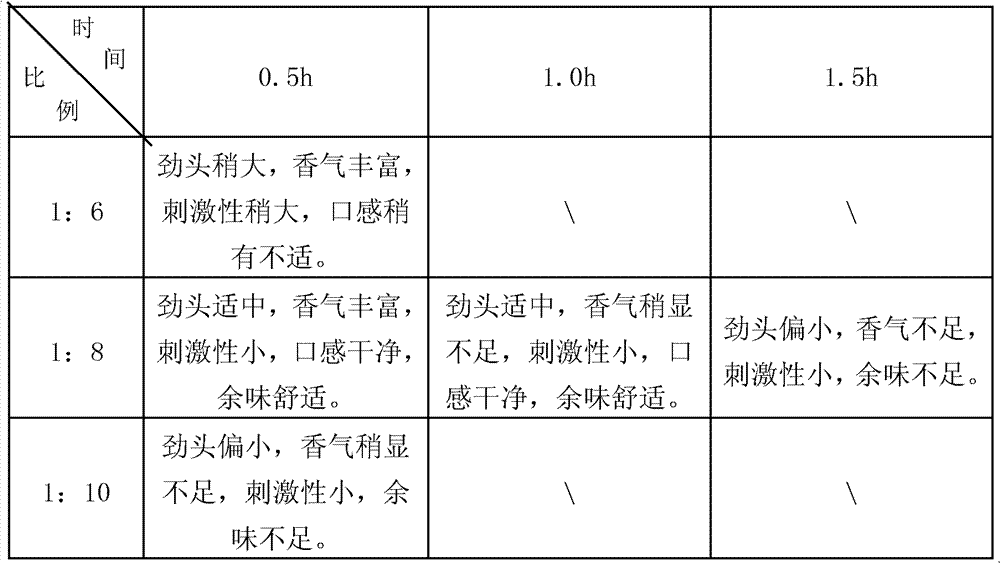

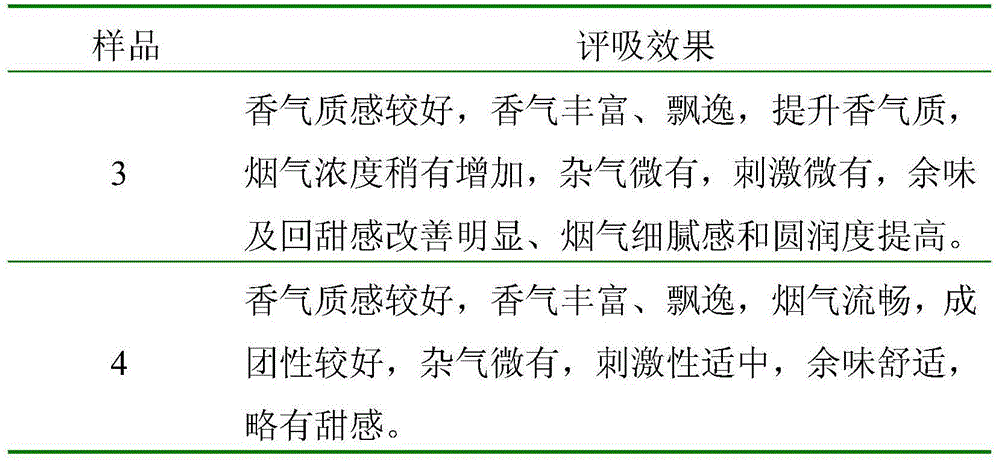

The invention relates to a preparation method for a tobacco extract of dark sun-cured tobacco. The method comprises the following steps: dark sun-cured tobacco leaves are dried, ground and sieved; tobacco powder is mixed with an alcoholic solution with the mass fraction of 65%-75% in a mass ratio of the tobacco powder to the alcoholic solution being 1:8-14, the mixture is subjected to extraction at the temperature of 55-65 DEG C for 1-2 h, solid-liquid separation is performed after extraction, and a product is concentrated; a primary extract is subjected to molecular distillation, second-level molecular distillation light components and fourth-level molecular distillation light components are assembled in the ratio being 1:0.8-2.4, and the final tobacco extract of the dark sun-cured tobacco is obtained. The prepared tobacco extract of the dark sun-cured tobacco can improve aroma of a low-tar blank cigarette, improve the smoke concentration, improve the aftertaste and reduce stimulation, an aroma enhancing purpose is achieved, and novel thought is provided for aroma enhancement of low-tar cigarettes.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

Method for compensating aroma of low tar cigarette

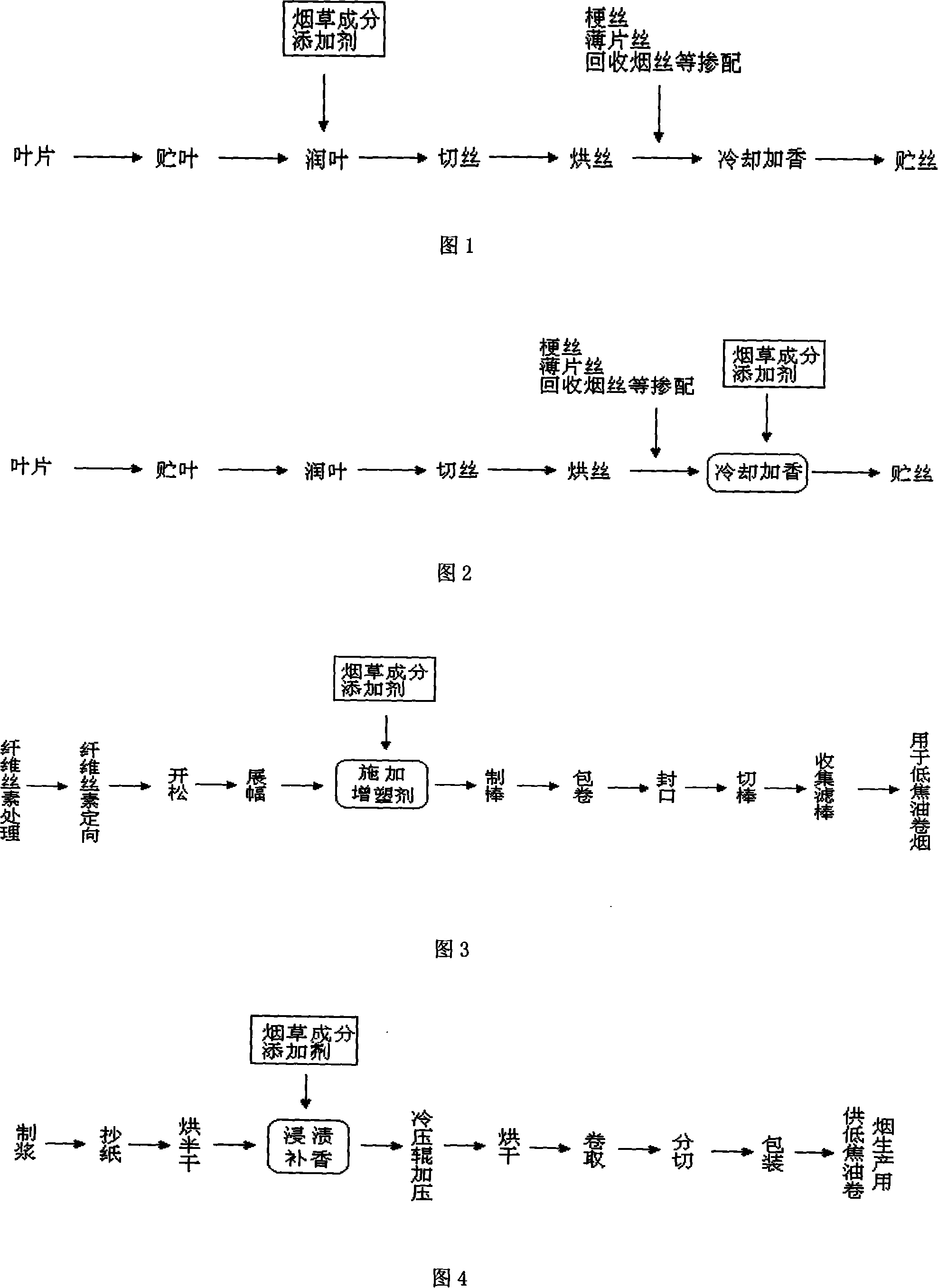

ActiveCN101129217AIncreased aroma absorptionIncrease the total amount of fragrance components in the granular phaseNon-fibrous pulp additionTobacco treatmentBobbinEngineering

The invention discloses a tobacco perfume compensating method, which is characterized by the following: adding tobacco component additive into one of cigarette material of tobacco piece of low-tar cigarette, dried cut tobacco of low-tar cigarette, filter bar of low-tar cigarette or bobbin of low-tar cigarette; adding additive into raw material of low-tar cigarette or auxiliary material to compensate the insufficiency of perfume in the low-tar cigarette; reaching the goal to compensate the perfume of low-tar cigarette.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

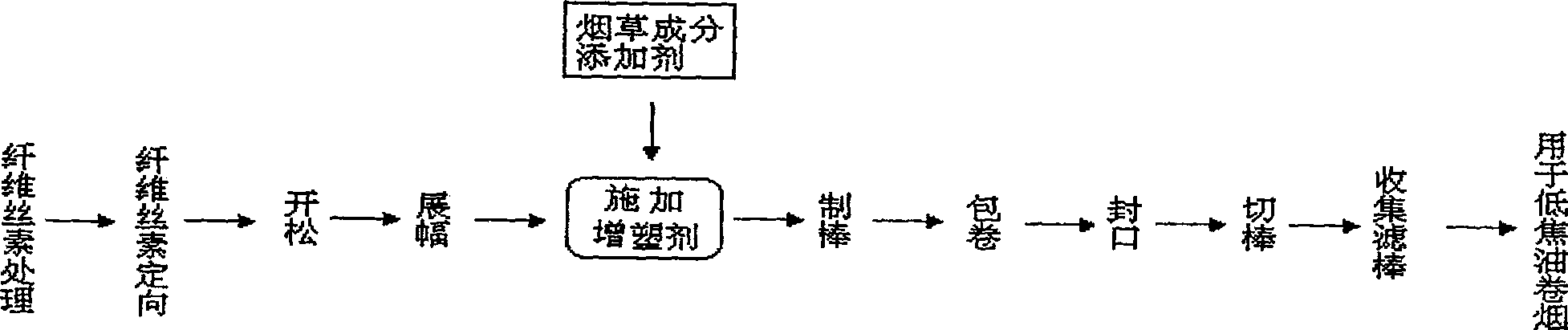

Paper cigarette filter stick and manufacturing method thereof

InactiveCN106617288AImprove the taste of smokingCause collapseTobacco smoke filtersPulp and paper industryPaper filter

The invention relates to a paper cigarette filter stick and a manufacturing method of the paper cigarette filter stick. The manufacturing method comprises the steps of pretreatment on tobacco raw materials, preparation of coating materials, preparation of plant fiber layers, spraying and drying, and the like. Compared with the traditional paper filter stick, the paper filter stick provided by the invention is free of paper taste and good in smoking mouthfeel, and has good moisture retention function, and the moist feel of smoke is promoted; the paper cigarette filter stick has the aroma enhancement function, so that the smoke has strong intrinsic aroma of tobacco, and is suitable for low-tar cigarettes; the paper cigarette filter stick has good appearance and special color, and thus certain visual impact can be formed.

Owner:GUANGDONG GOLDEN LEAF TECH DEV

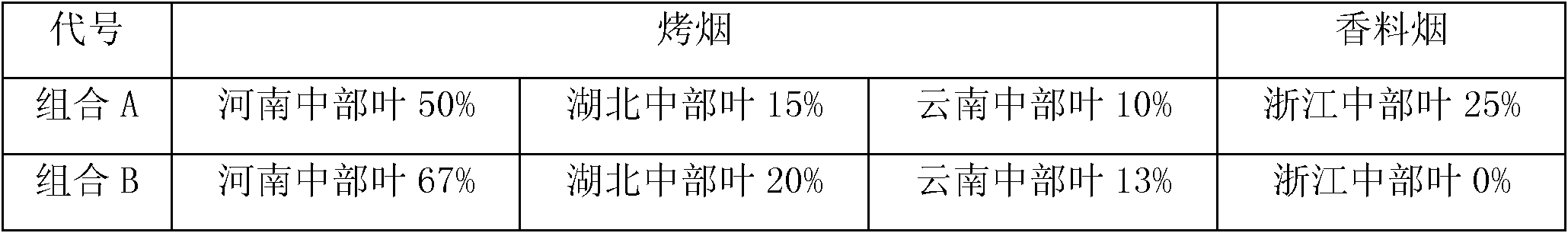

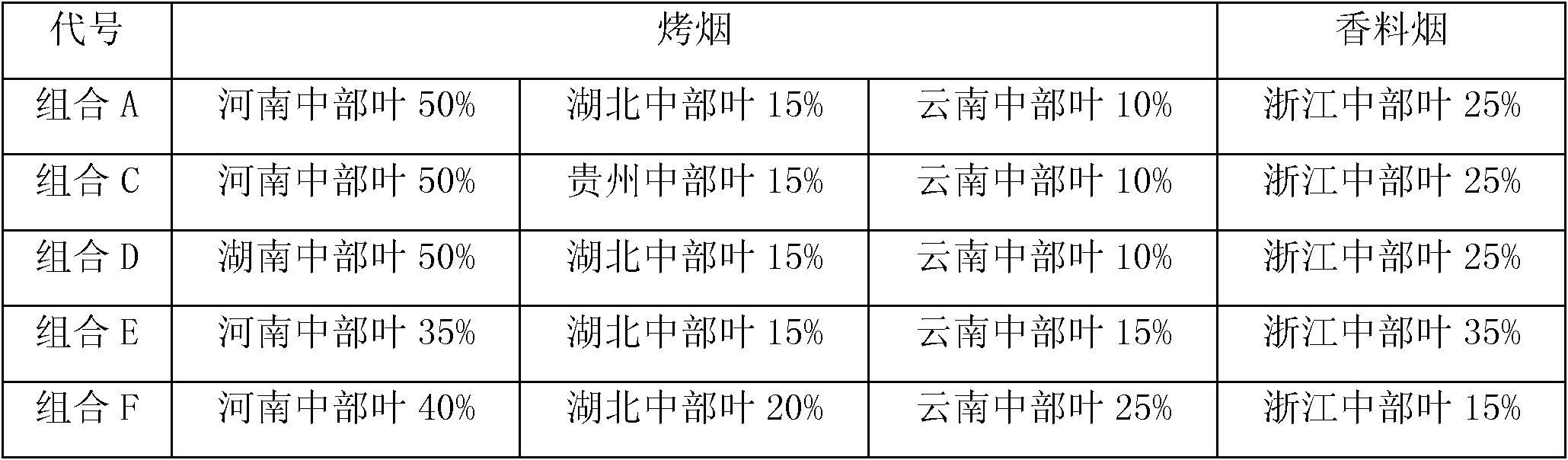

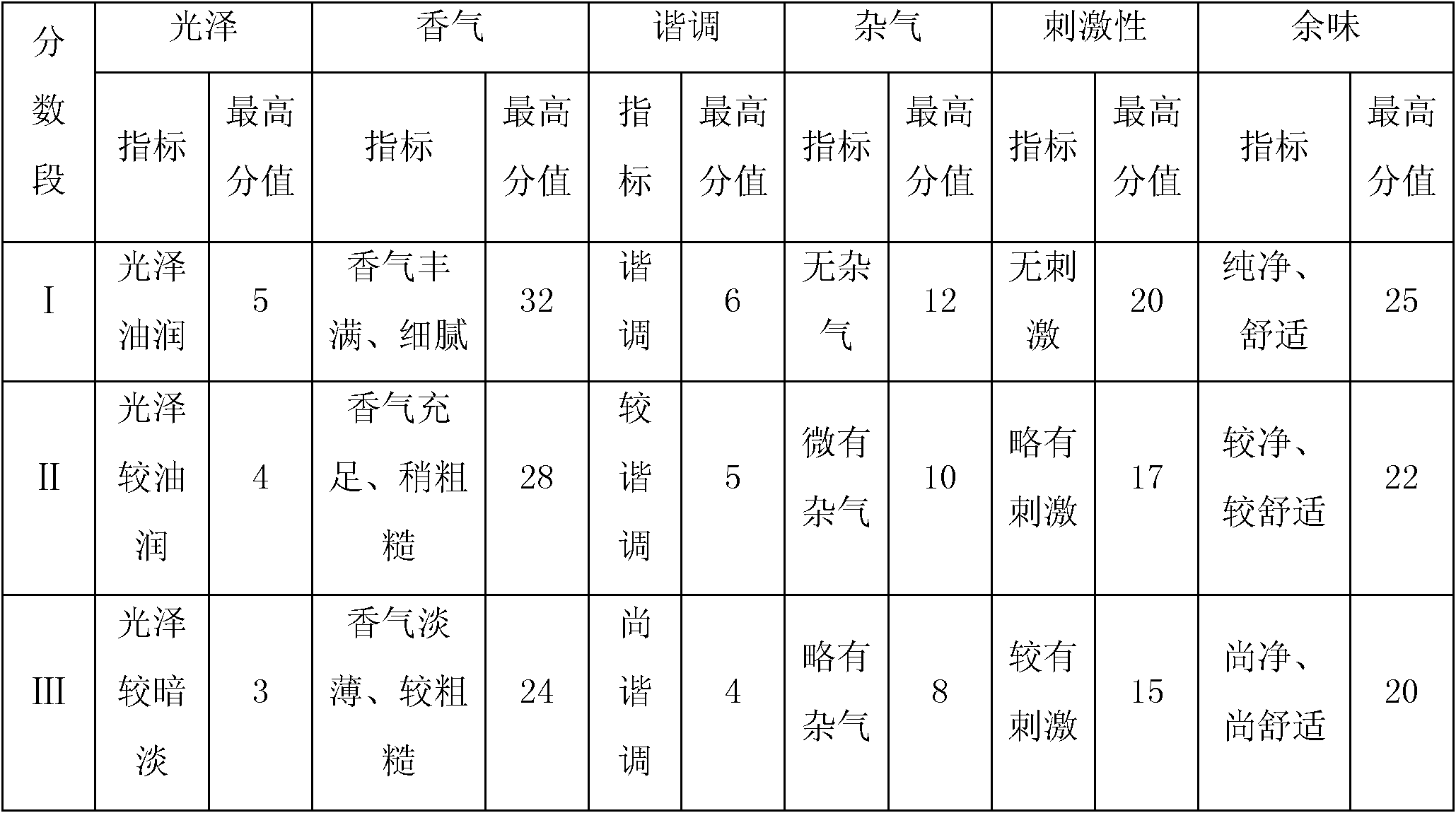

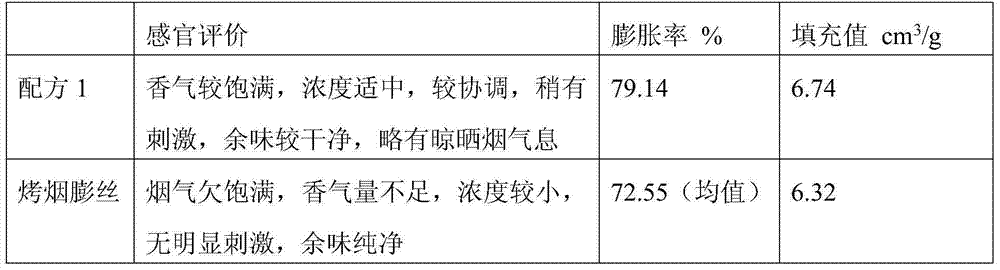

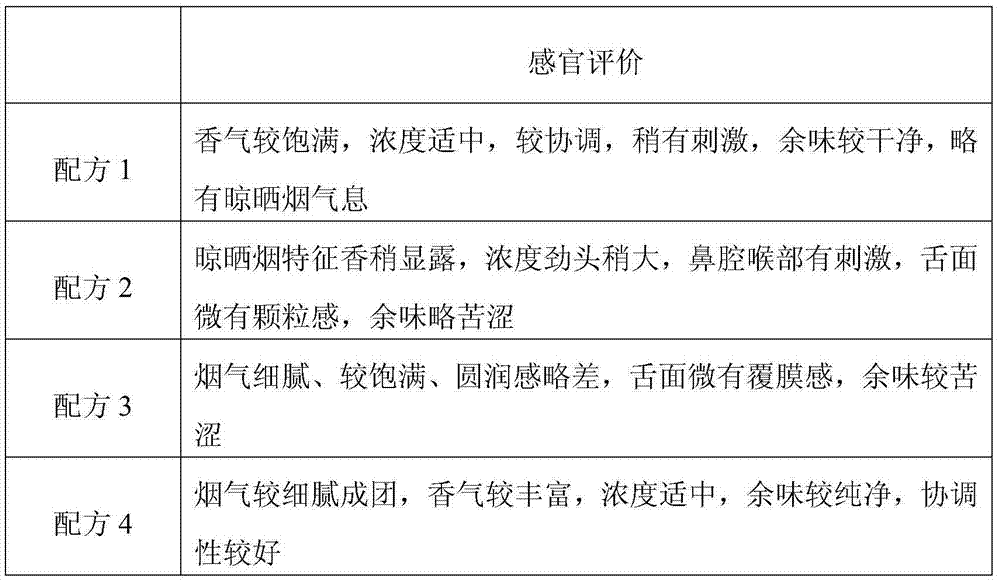

Expanded shredded tobacco composition of flue-cured tobacco and oriental tobacco and low-tar cigarette

The invention belongs to the technical field of cigarette leaf group formulations, and in particular relates to an expanded cut tobacco composition of flue-cured tobacco and oriental tobacco and a low-tar cigarette added with the expanded cut tobacco composition. The expanded shredded tobacco composition of flue-cured tobacco and oriental tobacco, the expanded shredded tobacco composition is composed of flue-cured tobacco and oriental tobacco in a weight ratio of 7.5-8:2.5-2, and the mixed expanded shredded tobacco is formed by carbon dioxide expansion technology. The fineness of the tobacco aroma of the present invention will increase slightly, the concentration will decrease slightly, and the aftertaste residue will slightly reduce. Through the combination of expanded oriental tobacco and flue-cured tobacco shreds, the characteristics of oriental tobacco at low concentrations are full and elegant, and at the same time, some To improve its defects such as thicker aroma, slightly greater stimulation, dry aftertaste and residue, etc., and blend it in low-focus products in a certain proportion, in order to achieve the effect of flavor compensation, and the inner quality can achieve full and elegant aroma and the characteristics of oriental tobacco The incense and flue-cured tobacco aroma are harmonious, the taste is pure, and there is no requirement for stimulation.

Owner:CHINA TOBACCO ZHEJIANG IND

Preparation method and application of tobacco additive deriving from burley tobacco

InactiveCN104188093ARich in aroma componentsIncrease the content of aroma substancesTobacco treatmentAlcoholSweet flavor

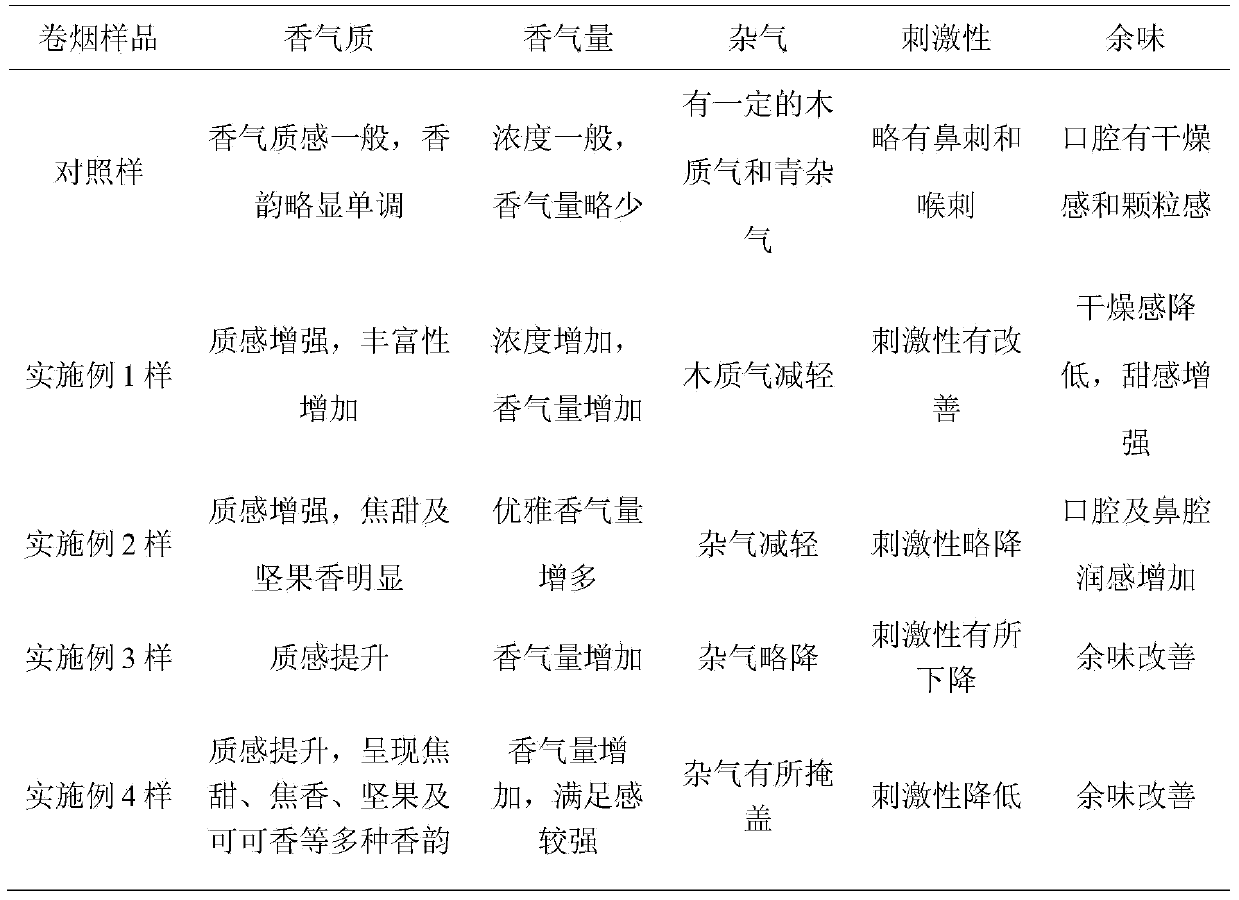

The invention discloses a preparation method and application of a tobacco additive deriving from burley tobacco. The preparation process includes the following steps of burley tobacco powder or tobacco smashing and drying, aqueous solution extraction, protease hydrolysis, solid-liquid separation, concentration, sugar and propylene glycol adding and heating reaction. Feed liquid which have different concentrations and is prepared by dissolving the prepared reaction solution in 95%ethyl alcohol is evenly sprayed on tobacco. The result of the smoke panel test shows that after the tobacco additive is added, richness of the cigarette flavor is increased, various flavors such as the caramel sweet flavor, the empyreumatique flavor, the nut flavor and the cocoa flavor are achieved, and in addition, the satisfaction, the remaining taste and the moistening feeling brought by cigarettes are enhanced. By means of the preparation method and the application, the smoking quality of low-tar cigarettes can be obviously improved, and good industrialized application prospects are achieved.

Owner:CHINA TOBACCO ANHUI IND CO LTD

Yellow sun-cured tobacco and preparation method and low tar cigarette

ActiveCN103230093AIncrease the application ratioImprove inner qualityTobacco treatmentReflux extractionAlcohol

The invention discloses a yellow sun-cured tobacco which is prepared by the following steps of: (1) adding 10-16 times of 90-95 percent of alcohol into the threshed and aired yellow sun-cured tobacco, performing reflux extraction at the temperature of 85-95 DEG C for 2-3 hours, filtering after extraction, wherein the filtrate is subjected to vacuum concentration to form the concentrated solution with the density of 0.97-0.99g / cm<3>; (2) adding 8-12 times of 65-75 percent of alcohol into the filtered yellow sun-cured tobacco, performing reflux extraction at the temperature of 90-95 DEG C for 2.5-3.5 hours, and filtering after extraction; and (3) drying the filtered yellow sun-cured tobacco in the step (2) to the moisture content of 12-15 percent, spraying the concentrated liquid obtained in the step (1), adding the additive according to 0.6-1 percent of the weight of the yellow sun-cured tobacco, baking at the temperature of 40-60 DEG C for 20-40 minutes, and obtaining the yellow sun-cured tobacco. The interior quality of the yellow sun-cured tobacco is improved, the application ratio of the yellow sun-cured tobacco in the low tar cigarette is improved, and the interior quality of the low tar cigarette is improved.

Owner:HUBEI CHINA TOBACCO IND

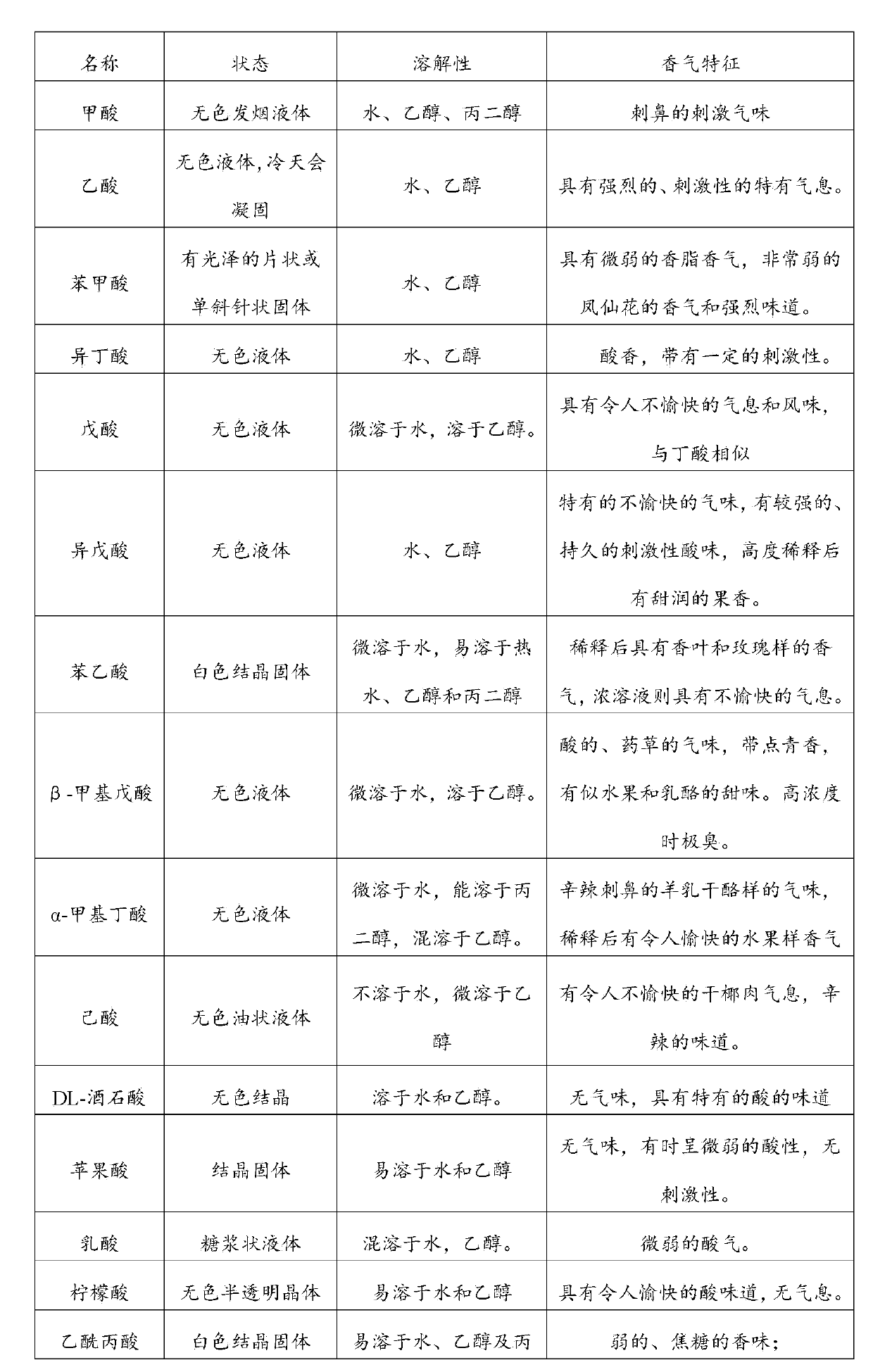

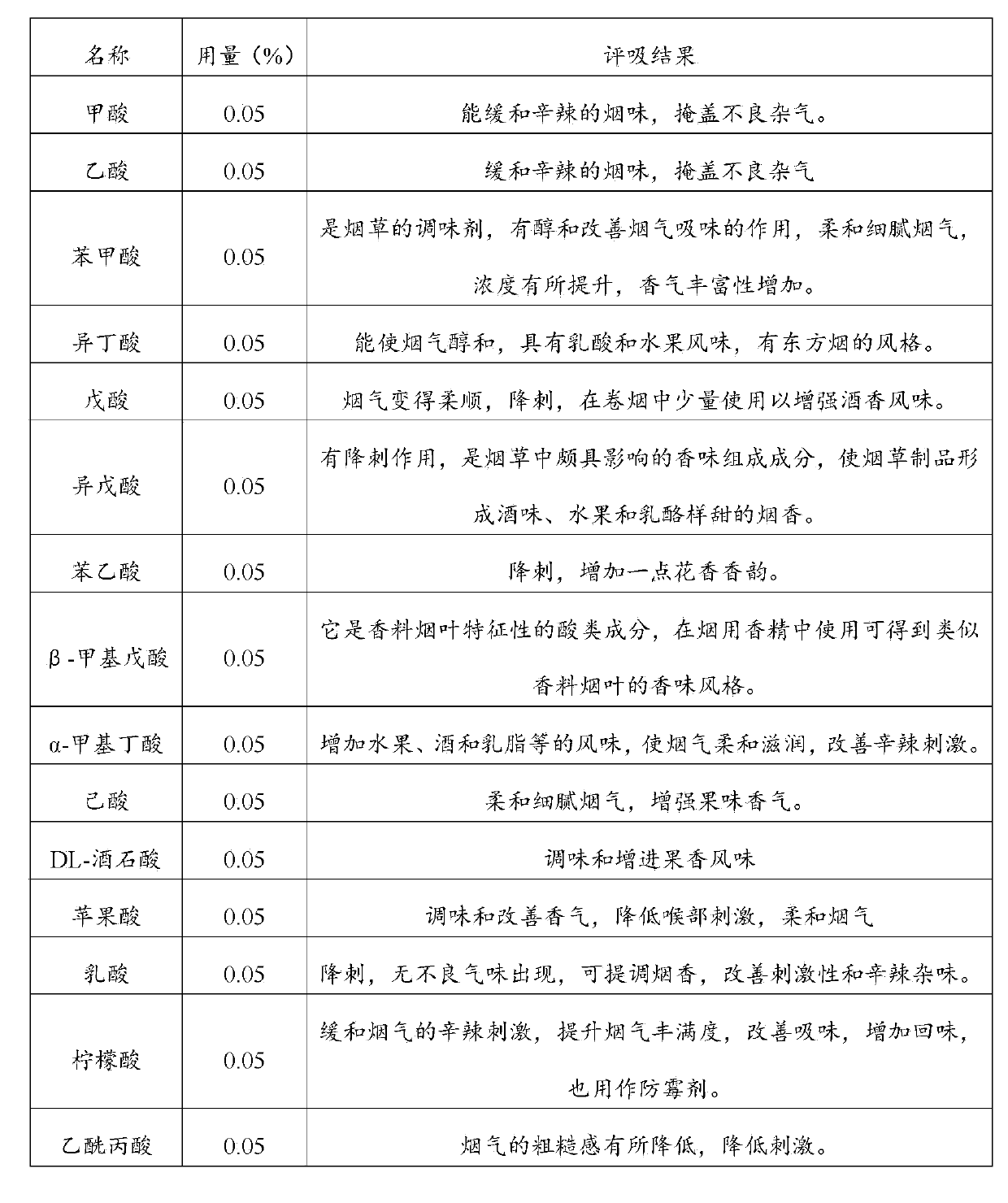

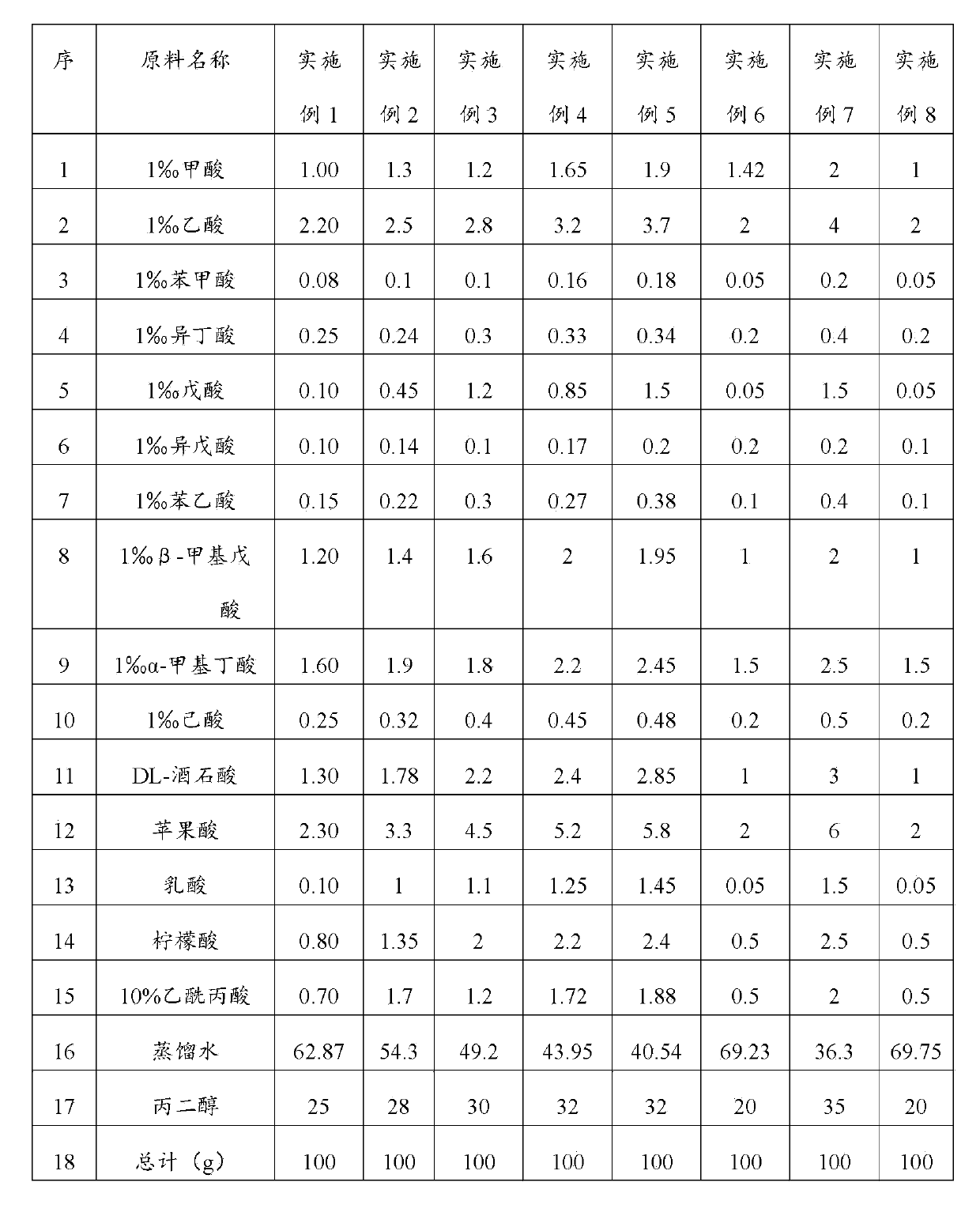

Low-tar cigarette flavoring essence with organic acids

ActiveCN103387876AGreat improvement in stimulationImprove smoke roughnessTobacco preparationEssential-oils/perfumesPhenyl acetic acidBenzoic acid

The invention discloses a low-tar cigarette flavoring essence with organic acids. The cigarette flavoring essence is a mixture of the following raw materials in percentage by weight: 1%-2% of 0.1% formic acid, 2%-4% of 0.1% acetic acid, 0.05%-0.2% of 0.1% benzoic acid, 0.2%-0.4% of 0.1% isobutyric acid, 0.05%-1.5% of 0.1% valeric acid, 0.1%-0.2% of 0.1% isovaleric acid, 0.1%-0.4% of 0.1% phenyl acetic acid, 1.0%-2.0% of 0.1% beta-mevalonic acid, 1.5%-2.5% of 0.1% alpha-methylbutyric acid, 0.2%-0.5% of 0.1% hexanoic acid, 1.0%-3.0% of DL-tartaric acid, 2.0%-6.0% of malic acid, 0.05%-1.5% of lactic acid, 0.5%-2.5% of citric acid, 0.5%-2.0% of 10% levulinic acid, 36.3%-69.75% of distilled water and 20%-35% of propylene glycol. Due to the use of organic acid raw materials, the effect of the blended essence is promoted greatly; the problems such as high irritation, rough smoke, uncomfortable aftertaste and insufficient aroma, existing in the existing low-tar cigarette, are covercome remarkably; the smoking quality of the low-tar cigarette is enhanced.

Owner:HUBEI CHINA TOBACCO IND +1

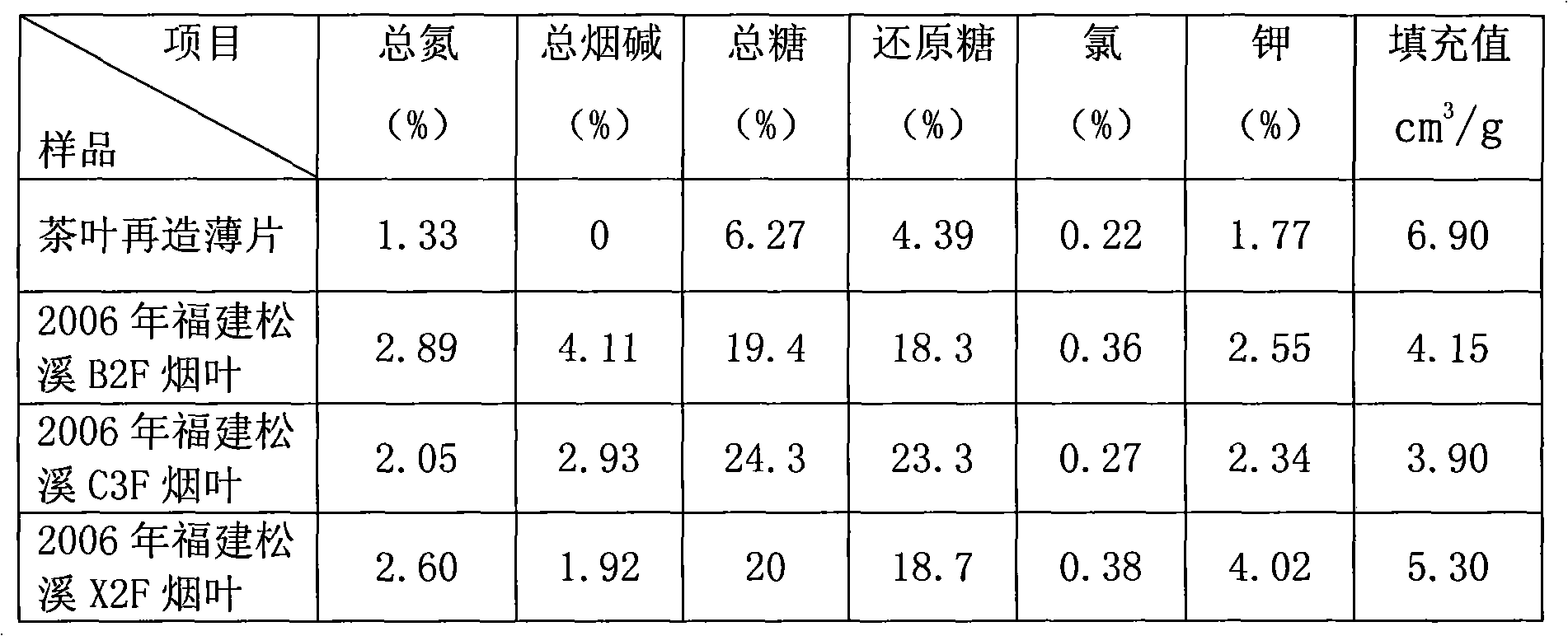

Method for preparing tea flavored low-tar cigarette

InactiveCN101919580ARich and elegant fragranceIn line with smoking habitsTobacco preparationFiberIndustrial equipment

The invention discloses a method for preparing a tea flavored low-tar cigarette. A reconstituted tea sheet prepared from a tea raw material and a non-tobacco substance such as wood fiber and the like is mixed with a tobacco raw material according to a certain proportion or all the raw material is the reconstituted tea sheet; the conventional cigarette industrial equipment is used for shredding; and a low-tar Chinese style cigarette with Chinese characteristics is prepared from the raw material and an auxiliary material by a matched process. Compared with the prior art, the tea flavored low-tar cigarette prepared by the method has the characteristics of smoking satisfaction, full embodiment of addiction and enjoyment of cigarette smoking and the like, and overcomes the general defects in sensory quality such as short and boring incense, thinness, dry throat and tongue, poor satisfaction and enjoyment and the like. The raw materials provided by the invention mainly comprise the reconstituted tea sheet, so the cigarette is slightly harmful to smokers, and can save the tobacco leaf raw material, perform value-added utilization of the wasted tea leaf raw material and bring high economic benefit and social benefit.

Owner:CHINA TOBACCO FUJIAN IND

Application of free-state and bonding-state aroma substance in fruits to cigarettes

ActiveCN104957761AReduce lossesImprove sensory qualityTobacco treatmentEssential-oils/perfumesFruit juiceDesorption

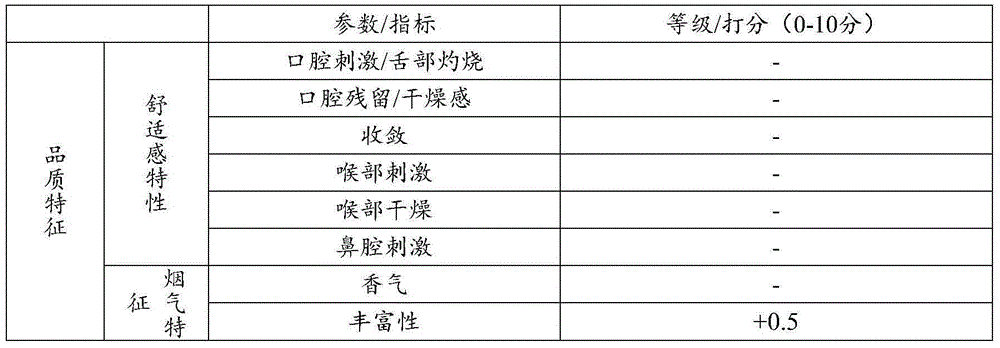

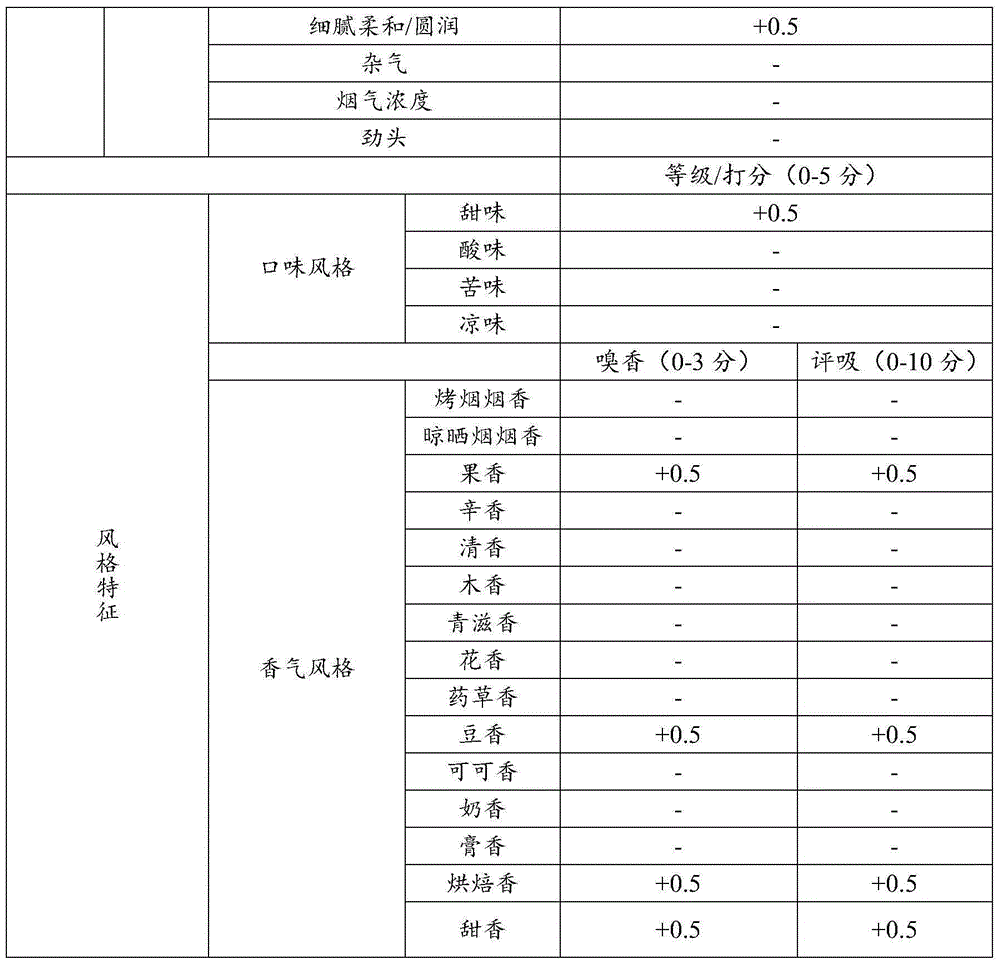

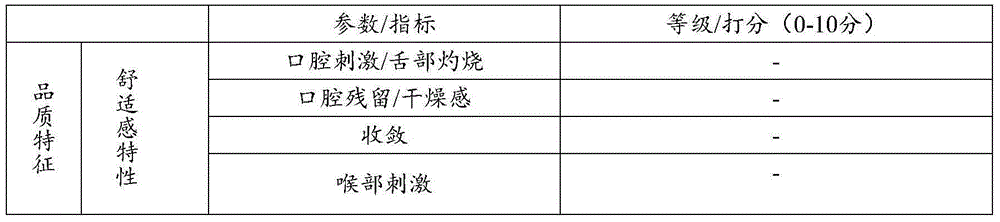

The invention discloses application of free-state and bonding-state aroma substance in fruits to cigarettes. An extraction method of the free-state and bonding-state aroma substance in the fruits includes the steps that the fruits are pulped and separated to obtain fruit juice, macroporous resin is used for absorption, an appropriate amount of eluant is used for desorption, and then components rich in free-state aroma substance and bonding-state aroma substance are obtained respectively. The extracted free-state aroma substance and the extracted bonding-state aroma substance are added into cut tobaccos of the cigarettes, and therefore the sensory quality of the low-tar cigarettes can be effectively improved; main expressions of the increase of the sensory quality comprise that the free-state aroma substance in the fruits has the better effect on the aspect of improving the aroma quality and the aroma amount; and the bonding-state aroma substance in the fruits has the better effects on improving offensive odors, softening smoke, reducing drying and increasing return sweet and remaining taste. In addition, raw materials are the natural fruits which are wide in source and low in cost, the separating method is simple, and industrial production is easily achieved.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Treatment method for sun-cured red tobacco and cigarette containing same

ActiveCN102894470AImprove the problem of insufficient aftertaste of cigarettesGreat tasteTobacco preparationTobacco treatmentReflux extractionAlcohol

The invention discloses a treatment method for sun-cured red tobacco. The treatment method comprises the following steps of: carrying out first reflux extraction reaction of sun-cured red tobacco after leaf tobacco threshing and sun-curing and alcohol aqueous solution with mass fraction of 60% according to the weight ratio of 1:(10-20), draining the alcohol aqueous solution after reacting for 1-2 hours, carrying out second reflux extraction reaction of the sun-cured red tobacco and alcohol aqueous solution with mass fraction of 80% according to the weight ratio of 1:6-10, draining the alcohol aqueous solution after reacting for 0.5-1.5 hours, drying until the moisture content is 12-15%, and finally adding essence and baking for 20-40 minutes at 60 DEG C to obtain treated sun-cured red tobacco. A low-tar cigarette containing the sun-cured red tobacco treated by the treatment method not only can be endowed with the flavor of the sun-cured red tobacco so as to improve the problem of insufficient aftertaste of the low-tar cigarette, but also can have the effects of reducing the irritating smell and smoke, doping masking and increasing the flavor so as to greatly improve the taste of the low-tar cigarette.

Owner:HUBEI CHINA TOBACCO IND

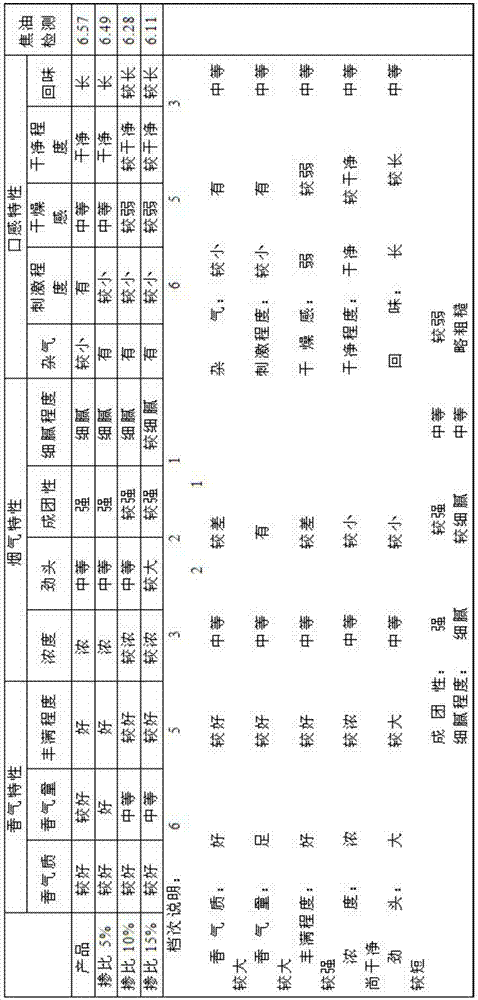

Low-tar mixed type expanded tobacco and application thereof in low-tar cigarettes

The invention discloses low-tar mixed type expanded tobacco and application of the low-tar mixed type expanded tobacco in low-tar cigarettes. The low-tar mixed type expanded tobacco is formed by mixing, by weight, 35 percent to 45 percent of burley tobacco, 25 percent to 45 percent of yellow sun-cured tobacco and 15 percent to 35 percent of aromatic tobacco through a carbon dioxide expansion technology. According to the application of the low-tar mixed type expanded tobacco in the low-tar cigarettes, the low-tar mixed type expanded tobacco accounting for five percent to 15 percent of the total weight of the tobacco used in tobacco curing is doped in the production process of cigarette products, and rolling is carried out. The mixed type formula expanded tobacco is low in tar, the filling value is good, the tobacco is added to the cigarettes, the aim of reducing the tar and harm is achieved, and the fragrance of the cigarettes can be richer.

Owner:HUBEI CHINA TOBACCO IND +1

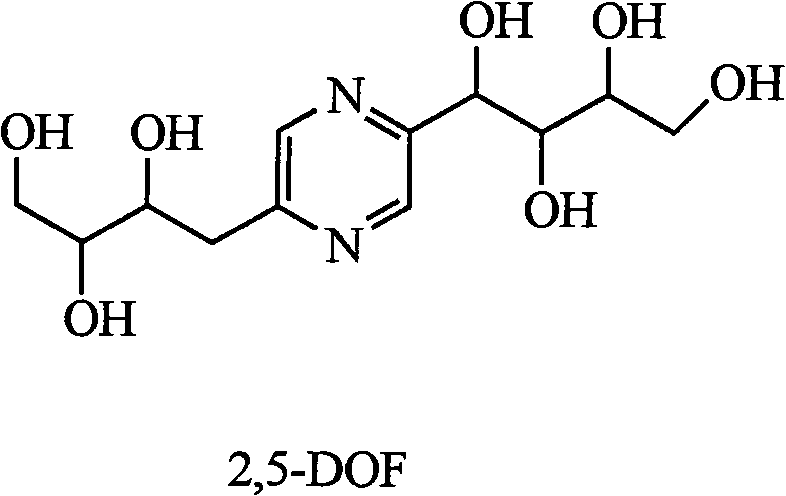

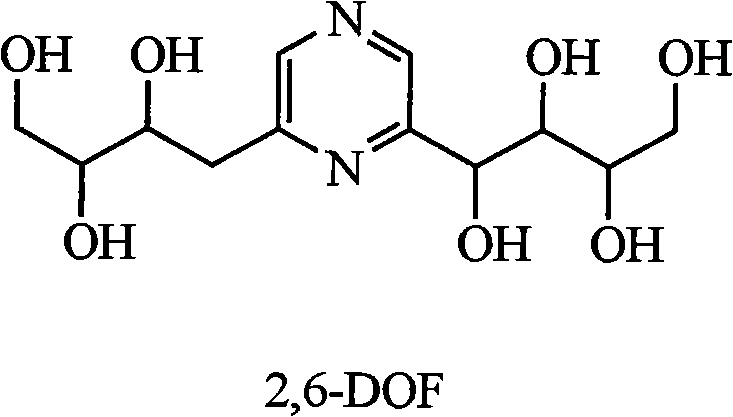

Deoxyfructosazine containing additive agent for fragrance compensation for low-coke tar cigarette

ActiveCN101317693AIncrease the amount of aromaImprove coordinationTobacco preparationNon-fibrous pulp additionCyclopentenePropanoic acid

The invention discloses an additive containing deoxyfructosazine for applying fragrance compensation to low-tar cigarettes, which is characterized in that the additive comprises the following raw materials: 0.001 to 5 percent of deoxyfructosazine, 0 to 1 percent of furfural, 0.1 to 0.5 percent of 5-methyl-furfural, 0.1 to 1 percent of 3-ethyl-2-hydroxyl-2-cyclopentene-1-ketone, 0.005 to 5 percent of Peru concrete, 0.1 to 1 percent of methyl palmitate, 0.1 to 1 percent of damascenone, 0.1 to 2 percent of Megastigmatrieno, 0.1 to 3 percent of cocoa powder tincture, 0 to 1 percent of propionic acid, and 82 to 99 percent of ethanol containing 50 percent of water in weight percentages; the additive with a weight percentage of 0.1 to 5 percent is used for aromatizing tobacco leaves or coil paper of dark color, and can obviously improve the fragrance volume of high-tar and low-tar cigarettes and also has good compatibility with tobacco flavor, decreases stimulation and improves the comfort degree of nonnasality.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Method for preparing beta-carotene cigarette flavoring agent under ultrahigh pressure

InactiveCN102134527AImprove resource utilizationReduce pollutionTobacco preparationEssential-oils/perfumesFlavorLutein

The invention discloses a method for preparing a beta-carotene cigarette flavoring agent under ultrahigh pressure, and belongs to the technical field of flavor production. The method comprises the following steps of: dispersing 1 weight part of lutein in 50 to 1,000 weight parts of dispersing agent, and performing ultrahigh pressure treatment at the temperature of between 20 and 90DEG C under thepressure of between 50 and 900MPa for 5 to 50 minutes. By the method, the resource utilization rate of waste and inferior tobacco can be improved, the pollution is lightened, and a new way is provided for solving the problem of insufficient aroma of the conventional low-tar cigarettes. The method has the advantages of high efficiency, high speed and simple process.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

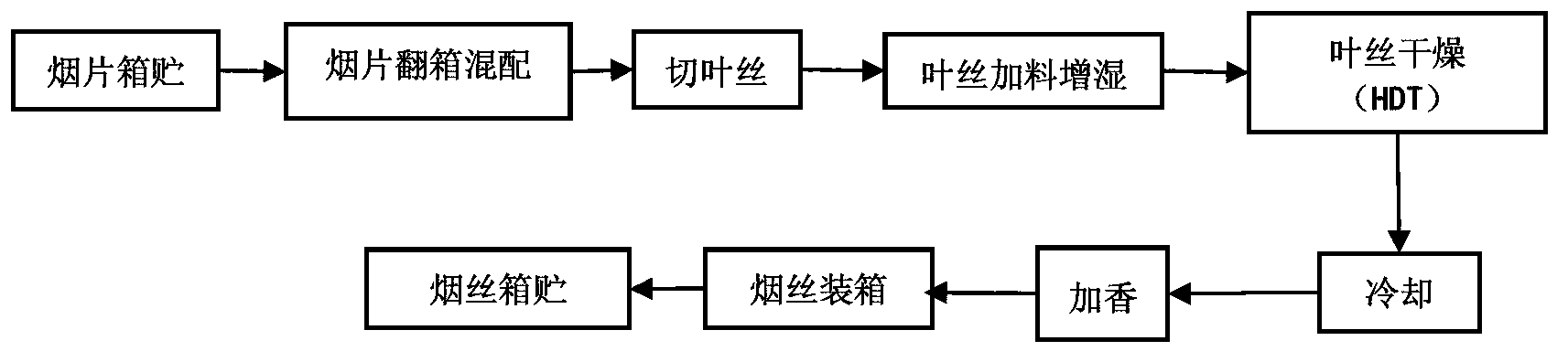

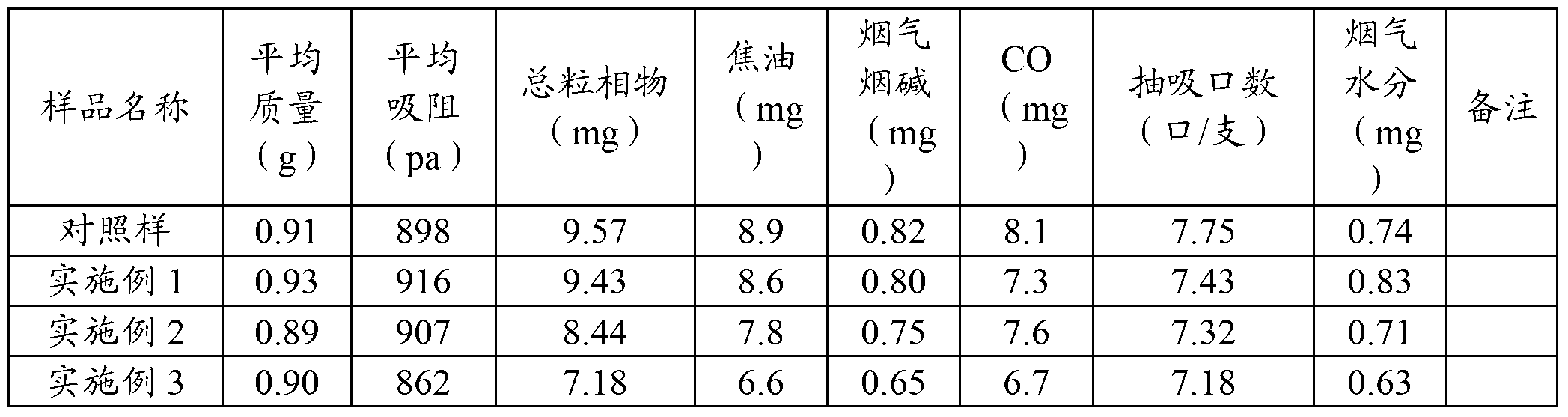

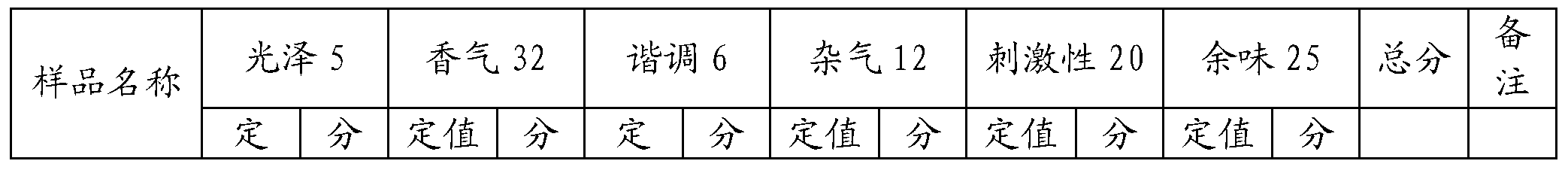

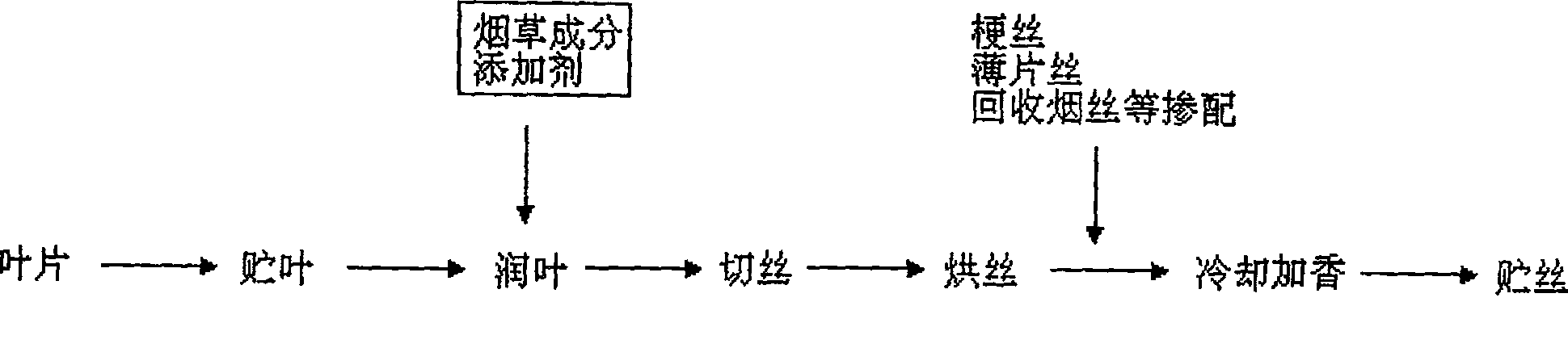

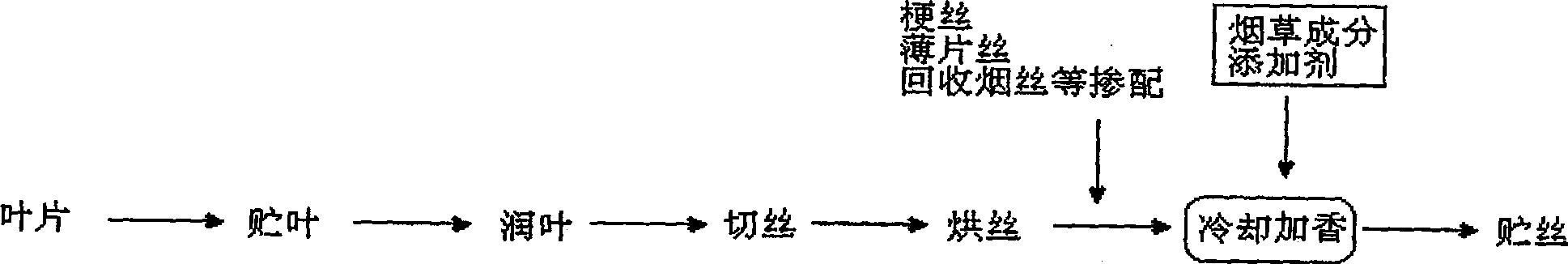

Method for preparing aromatized tar reduction cut tobaccos

InactiveCN103238920AImprove the effect of aroma enhancementReduce tar contentTobacco preparationPulp and paper industryMoisture

The invention discloses a method for preparing aromatized tar reduction cut tobaccos. Burley tobacco flakes and flue-cured tobacco flakes are uniformly mixed according to a certain proportion and then cut into cut tobaccos on a tobacco cutting machine, moisture in the cut tobaccos is controlled within the range of process requirements by the aid of working hot air with stable temperature in an HDT (heat distortion temperature) hot air pipeline after the cut tobaccos are fed and humidified by a tobacco wetting machine, and the cut tobaccos are packed and stored after cooled and applied with surface aroma, so that finished cut tobaccos applicable to low-tar cigarettes are produced. The method is ingenious in process combination, can simultaneously meet two requirements of the cigarettes for tar reduction, harm reduction and aroma enhancement and supplement, and can be used as a base for researching and developing the low-tar cigarettes.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

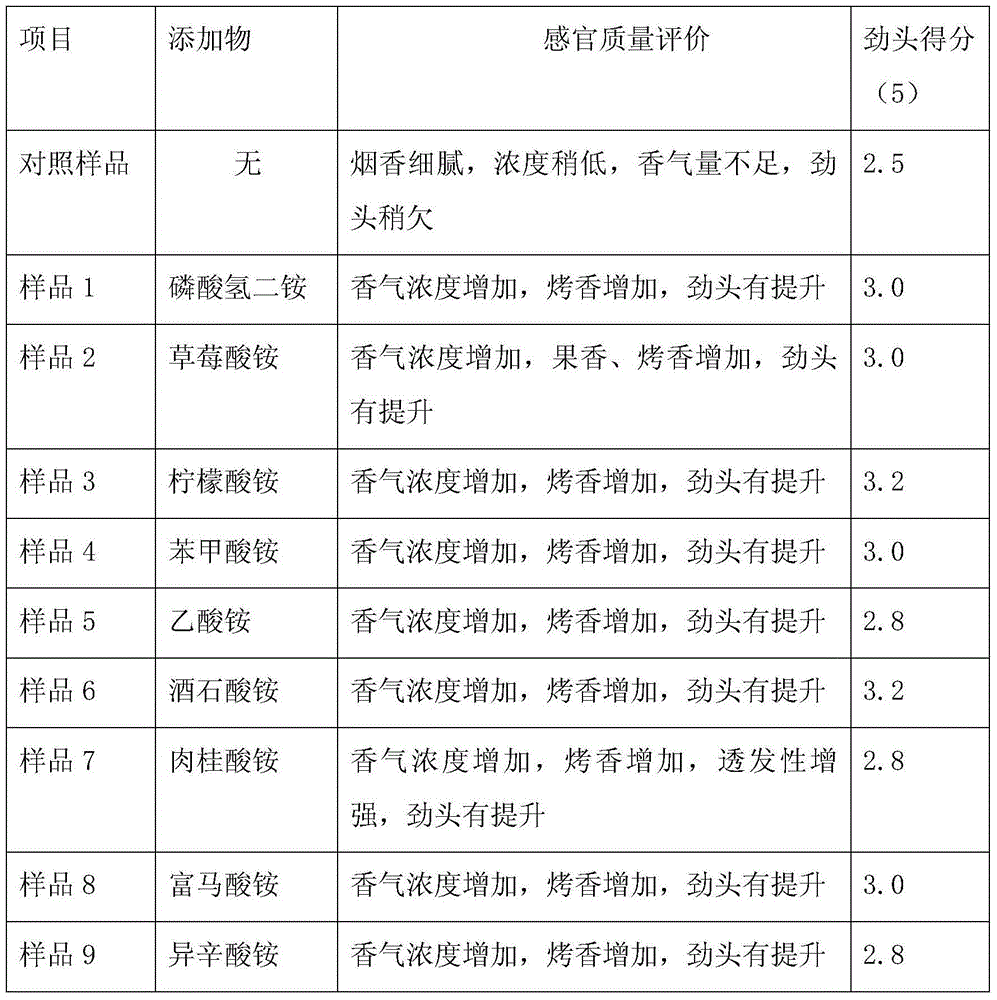

Method for preparing tobacco shreds capable of improving smoking satisfaction and low tar cigarette

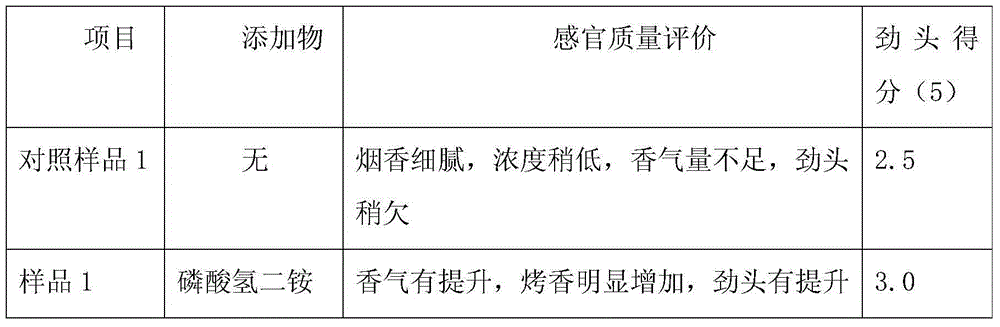

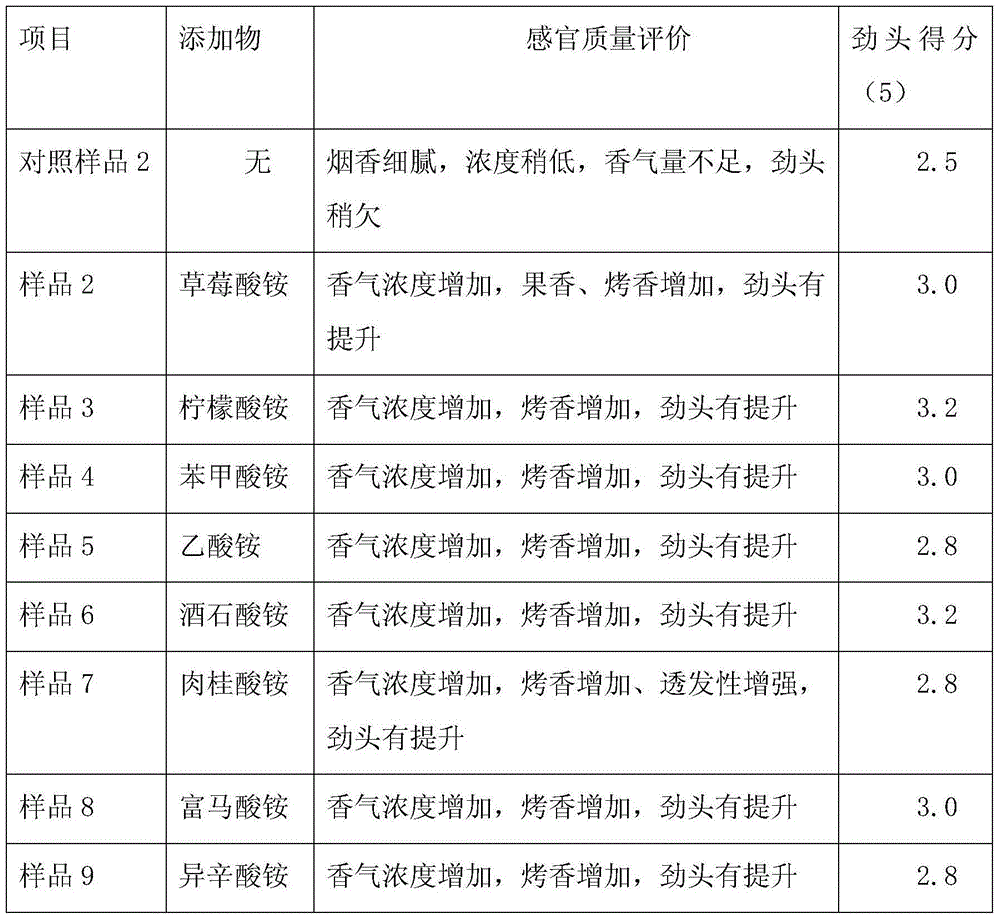

InactiveCN104432494AImprove smoke fullnessImprove suction powerTobacco preparationTobacco treatmentAlcoholHydrogen phosphate

The invention relates to a method for preparing tobacco shreds capable of improving the smoking satisfaction. The method includes the following steps that (1) a carboxylic acid ammonium or diammonium hydrogen phosphate aqueous solution or an alcoholic solution is sprayed to tobacco leaves; (2) the tobacco leaves are subjected to alcoholation; (3) the tobacco leaves which are subjected to alcoholation are made into the tobacco shreds. The invention further relates to a low tar cigarette capable of improving the smoking satisfaction. The low tar cigarette is a blending object of the tobacco shreds which are prepared through the above method and can improve the smoking satisfaction, flue-cured tobacco shreds, and burley tobacco shreds or yellow sun-cured tobacco shreds. The tobacco shreds which are obtained through the above method and can improve the smoking satisfaction have the advantages of being rich in cigarette flavor, capable of improving cigarette energy, suitable for the low tar cigarette so as to improve the smoking satisfaction, and the like.

Owner:CHINA TOBACCO YUNNAN IND

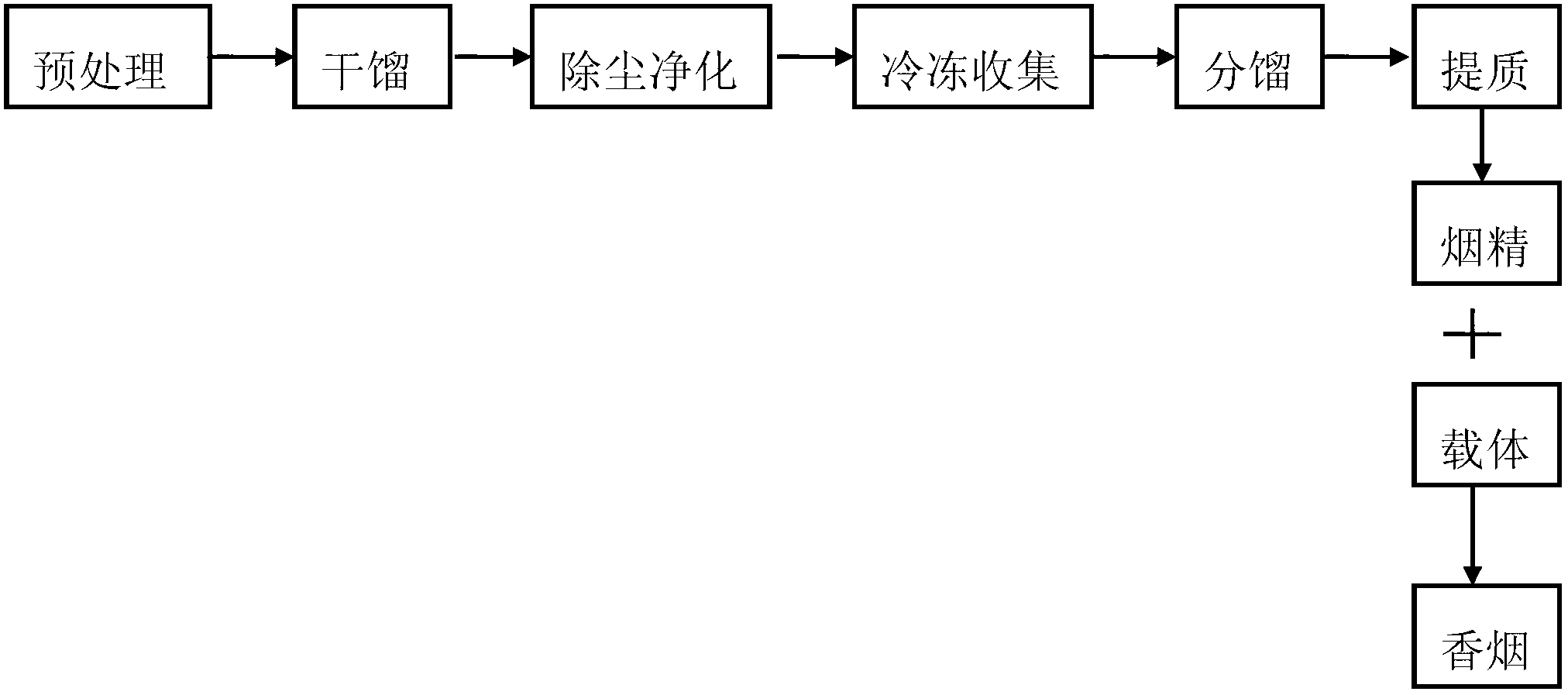

Pollution-free low-tar cigarette and manufacturing method thereof

ActiveCN103315395ARaw material requirements are simpleEasy to handleCigar manufactureCigarette manufactureFire riskPassive smoking

The invention relates to a pollution-free low-tar cigarette and a manufacturing method thereof. The manufacturing method comprises the following steps of pre-processing tobacco leaves, distilling in a dry mode, removing dust, purifying, refrigerating, collecting, distilling in a fractional mode, upgrading, combining tobacco extract with inertia carriers, processing and assembling the tobacco extract and the inertia carriers into a cigarette holder, and preparing the pollution-free low-tar cigarette. The manufacturing method has the advantages that the requirement for raw materials is simple, and the tobacco leaves of the same grade or class can be used and do not need to be refined. Moreover, the raw materials are treated simply and the problems of the three wastes are not caused. According to the cigarette, harm of passive smoking to other people and environment in the smoking process is small, the open fire of smoking can be avoided, and fire risks can be reduced.

Owner:SHANDONG UNIV

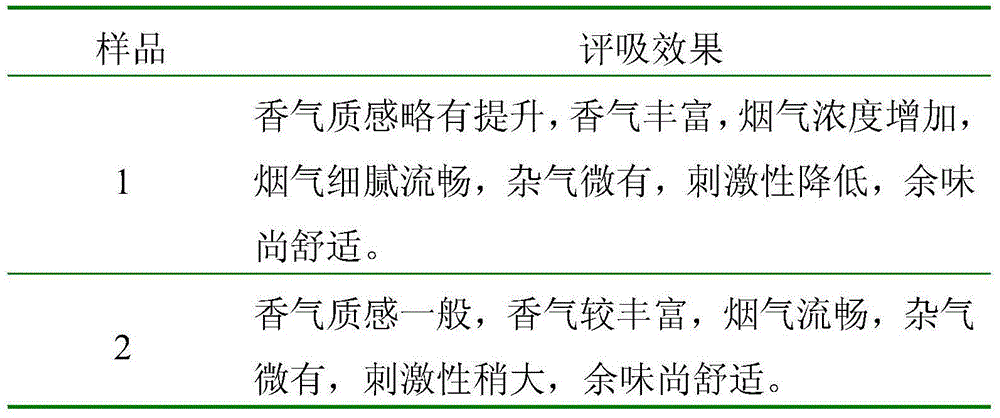

Preparation method of burley tobacco extract

The invention relates to a preparation method of a burley tobacco extract. The preparation method comprises the following steps of adding water into burley tobacco according to the weight ratio of 1:12, and obtaining volatile oil A by adopting a water vapor distillation method; extracting and filtering the volatile oil, obtaining filter liquor B for standby, adding water into filter residues according to the weight ratio of 1:10 to backflow and extract for 2.0+ / -0.1h, filtering while hot, and obtaining filter liquor C for standby, wherein the filter residues can be directly applied in paper-making process reconstituted tobacco production; merging the filter liquor B and C, concentrating to the density of 1.200+ / -0.006g / cm<3> at the temperature of 30-45 DEG C, and obtaining the burley tobacco extract D; adding ethyl alcohol with the mass fraction of 95 percent into the burley tobacco extract D, then settling, filtering, vacuum concentrating the filter liquor to the density of 0.930+ / -0.006g / cm<3>, and obtaining a burley tobacco concentrate E, wherein the weight of the ethyl alcohol is threes times that of the burley tobacco extract D; adding the burley tobacco volatile oil A into the burley tobacco concentrate E, and uniformly mixing to obtain the burley tobacco extract. The burley tobacco extract prepared by the invention has more obvious effects in stimulation reduction, aroma enhancement, smoke smoothness, smoke concentration increase and the like, the residual taste of cigarettes can be improved, and the low-tar cigarette sensory quality can be obviously improved.

Owner:HUBEI CHINA TOBACCO IND

Additive for compensating fragrance of low-tar cigarettes

InactiveCN105054287AAdd sweetnessAdds a roasted aromaTobacco treatmentTobacco smoke filtersMaillard reactionFermentation

The invention provides an additive for compensating fragrance of low-tar cigarettes. Plant extracts containing abundant furfural components are taken as raw materials, and then the plant extracts are mixed with an organic acid and propylene glycol according to a certain proportion to form the additive. The plant extracts containing abundant furfural components comprise red date maillard reaction product red date alcohol extract, fenugreek microwave extract, tamarind fruit alcohol extract and apple juice fermentation extract. The invention also provides an application of the above additive in flavour addition of cigarettes. 1% by weight of the additive is added into low-tar cigarette tobacco, or 0.5-5% by weight of the additive is added into low-tar cigarette filters, or 0.5-5% by weight of the additive is added into cigarette paper. The additive can effectively supplement micromolecule low-boiling aroma substance such as furfural substance in low-tar cigarettes, and can supplement fragrance of low-tar cigarettes specifically.

Owner:HUBEI CHINA TOBACCO IND

Additive for compensating aroma of low tar cigarette

ActiveCN100542439CIncreased aroma absorptionIncrease the total amount of fragrance components in the granular phaseNon-fibrous pulp additionTobacco treatmentFlavorCigarettes low tar

A method for flavor compensation of low-tar cigarettes, characterized in that: the method is in the production process of low-tar cigarettes, through the tobacco blades of low-tar cigarettes, cut tobacco after drying of low-tar cigarettes, filter of low-tar cigarettes It is realized by adding tobacco component additives to any cigarette raw material in the low-tar cigarette wrapping paper. The method of the present invention can effectively compensate the lack of flavor of low-tar cigarettes by adding additives to low-tar cigarette raw materials or auxiliary materials, and achieve the purpose of flavor compensation for low-tar cigarettes.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

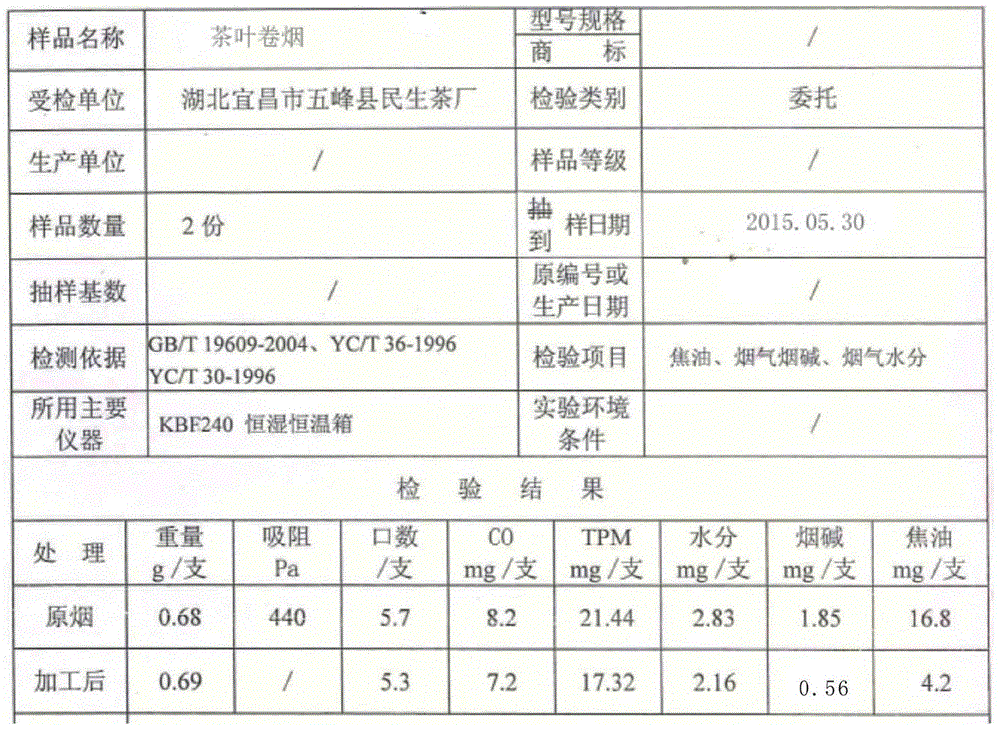

Production method of low-tar cigarette cut tobacco and cigarette with low-tar cigarette cut tobacco

A production method of low-tar cigarette cut tobacco includes the steps of 1, selecting and drying a material; 2, performing massing; 3, performing shredding; 4, performing first soaking; 5, changing warm water in a warm water pool; 6, performing second soaking; 7, mixing cut tea material made in the step 6 and cut burley tobacco 10-12% in water content, adding Fei Yi Qing powder, and performing uniform mixing to obtain mixed cut tobacco; sealing the mixed cut tobacco in a plastic bag to obtain the low-tar cigarette cut tobacco. According to the production method of the low-tar cigarette cut tobacco and a cigarette with the low-tar cigarette cut tobacco, the tea leaf and cut burley tobacco are used as raw materials to produce the low-tar cigarette cut tobacco, the existing cut burley tobacco can be completely replaced, and the low-tar cigarette cut tobacco is free of bitter, has mild and soft smoke, meets the needs of smokers, further has reduced tar content and nicotine content in the smoke so that smoking harm is greatly reduced, and has certain health effect for smokers.

Owner:五峰土家族自治县民生茶厂

Low-tar cigarette aroma compensation method

ActiveCN102423114BReduce drynessReduce volatilityTobacco preparationTobacco treatment3-oxo-alpha-ionolFlavor

The invention relates to a method for compensating the aroma of low-tar cigarettes by utilizing tobacco flavor precursors, which belongs to the field of tobacco processing. The method is characterized in that: in the low-tar cigarette production process, one or more types of tobacco flavor precursors are added into cut tobacco or cigarette paper for the low-tar cigarettes; and the tobacco flavor precursor is any one or the mixture of glycolipid, glucoside, Amadori compound and 3-oxo-Alpha-ionol-related compound. By adding the tobacco flavor precursor, the method effectively increases the aroma of the low-tar cigarettes, harmonizes the cigarette aroma, decreases the dryness of smoke, and provides an effective approach for the development of high-aroma, low-tar cigarettes.

Owner:HONGTA TOBACCO GRP

A kind of preparation method of red sun-cured tobacco extract

ActiveCN105533793BGood aroma effectGreat tasteTobacco treatmentMolecular distillationMass ratioDistillation

The invention relates to a preparation method for a tobacco extract of dark sun-cured tobacco. The method comprises the following steps: dark sun-cured tobacco leaves are dried, ground and sieved; tobacco powder is mixed with an alcoholic solution with the mass fraction of 65%-75% in a mass ratio of the tobacco powder to the alcoholic solution being 1:8-14, the mixture is subjected to extraction at the temperature of 55-65 DEG C for 1-2 h, solid-liquid separation is performed after extraction, and a product is concentrated; a primary extract is subjected to molecular distillation, second-level molecular distillation light components and fourth-level molecular distillation light components are assembled in the ratio being 1:0.8-2.4, and the final tobacco extract of the dark sun-cured tobacco is obtained. The prepared tobacco extract of the dark sun-cured tobacco can improve aroma of a low-tar blank cigarette, improve the smoke concentration, improve the aftertaste and reduce stimulation, an aroma enhancing purpose is achieved, and novel thought is provided for aroma enhancement of low-tar cigarettes.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

Low-tar cigarette and manufacturing method thereof

ActiveCN104886769AImprove applicabilityEasy to organize productionCigar manufactureCigarette manufactureFiberOrganoleptic

The invention provides a manufacturing method of a low-tar cigarette. The manufacturing method includes the following steps: pneumatic drying and dry ice swelling are carried out on tobacco leaves respectively; a certain number of expanded cut stems and a certain number of recombined tobacco leaves are doped into the tobacco leaves obtained after pneumatic drying and dry ice swelling are carried out so as to manufacture cut tobaccos; the cut tobaccos are wrapped with rapidly-burning cigarette paper to form a tobacco rod; the rapidly-burning cigarette paper is matched with an acetate fiber high-transmittance filter stick to enable the ventilation rate of the tobacco rod to range from 40% to 50%; an fragrance invigorating agent is applied to the acetate fiber high-transmittance filter stick; the tobacco rod is connected with the acetate fiber high-transmittance filter stick through tipping paper wrapping outside the tobacco rod and the acetate fiber high-transmittance filter stick; and a flavoring agent is applied to the contact part of the tipping paper and the lip. The invention further provides the low-tar cigarette. By means of the manufacturing method, the fragrance and the physiological satisfaction of the low-tar cigarette can be promoted, the effect of improving the taste perception of the contact parts such as the oral cavity and the lip is achieved, the shortcoming of insufficient sensual pleasures of the low-tar cigarette is offset, the effects of increasing milk sweet taste and baking sweet taste are achieved, and the insufficient tobacco smell sense is offset.

Owner:HUBEI CHINA TOBACCO IND

Ultrahigh pressure preparation method of lutein cigarette flavoring agent

InactiveCN102154063AImprove resource utilizationReduce pollutionTobacco preparationEssential-oils/perfumesLuteinResource utilization

The invention discloses an ultrahigh pressure preparation method of a lutein cigarette flavoring agent, belonging to the technical field of spice production. The preparation method comprises the following steps: dispersing 1 part by weight of lutein in 20-500 parts by weight of dispersing agent; and carrying out ultrahigh pressure processing for 5-100 minutes at the temperature of 20-80 DEG C andthe pressure of 50-800 MPa. By using the preparation method, the resource utilization of waste tobacco can be improved, the pollution is reduced, and a novel way is provided for solving the problem that the aroma of low tar cigarettes is poor. The method has the advantages of high efficiency, rapid speed and simple process.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Bacillus amyloliquefaciens DGY 18 for degrading nicotine and application method thereof

ActiveCN106119176ALower nicotine levelsImprove usabilityBiocidePlant growth regulatorsBacillus amyloliquefaciensEconomic benefits

The invention discloses bacillus amyloliquefaciens DGY 18 for degrading nicotine and application method thereof. The conservation series number is CGMCC NO.11900. The bacillus amyloliquefaciens DGY 18 acts on a healthy tobacco plant, and within 20 days of a test, the degradation rate of nicotine in tobacco leaves on the upper portion is 30-40%. Bacillus amyloliquefaciens DGY 18 is used for degrading nicotine, which saves time and labor and has obvious economic benefits; the content of nicotine in the tobacco leaves on the upper portion can be controlled more effectively, a guarantee of the tobacco leaf raw material higher in usability is provided for development of low-tar cigarette products, usability of the tobacco leaves is improved, and therefore bacillus amyloliquefaciens DGY 18 has wide application prospects in tobacco processing and environment protection.

Owner:CHINA TOBACCO HUNAN INDAL CORP

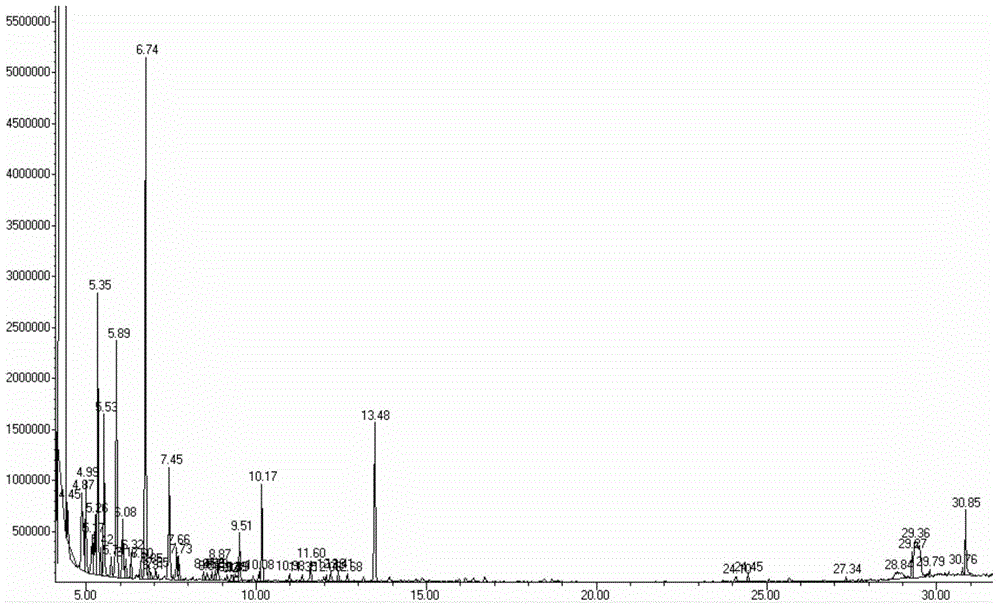

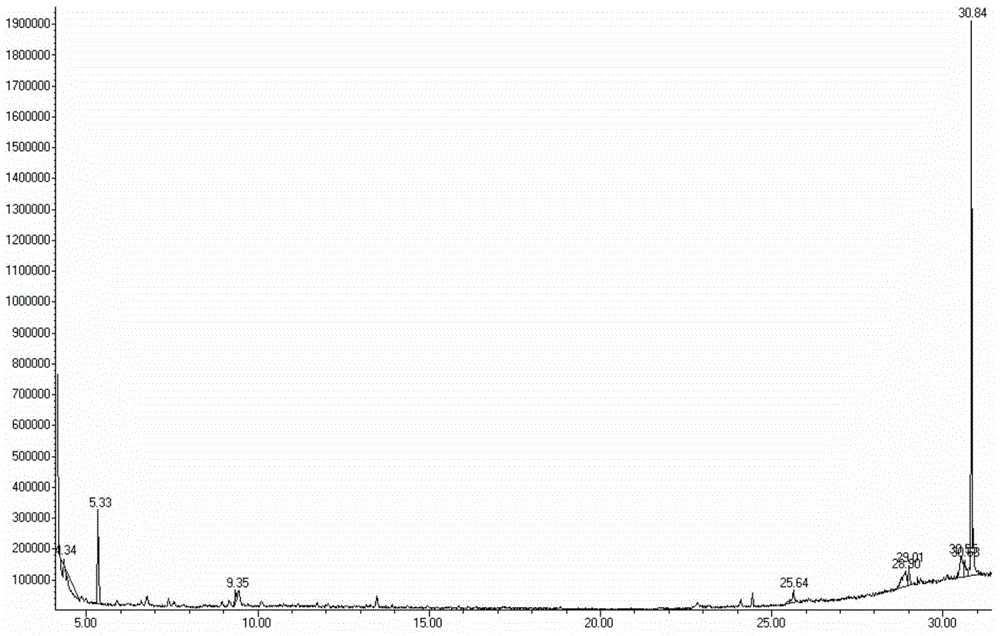

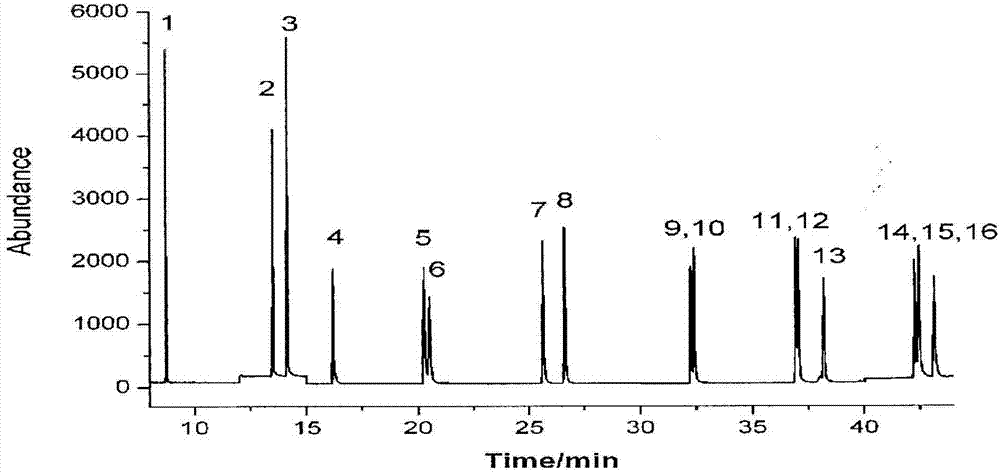

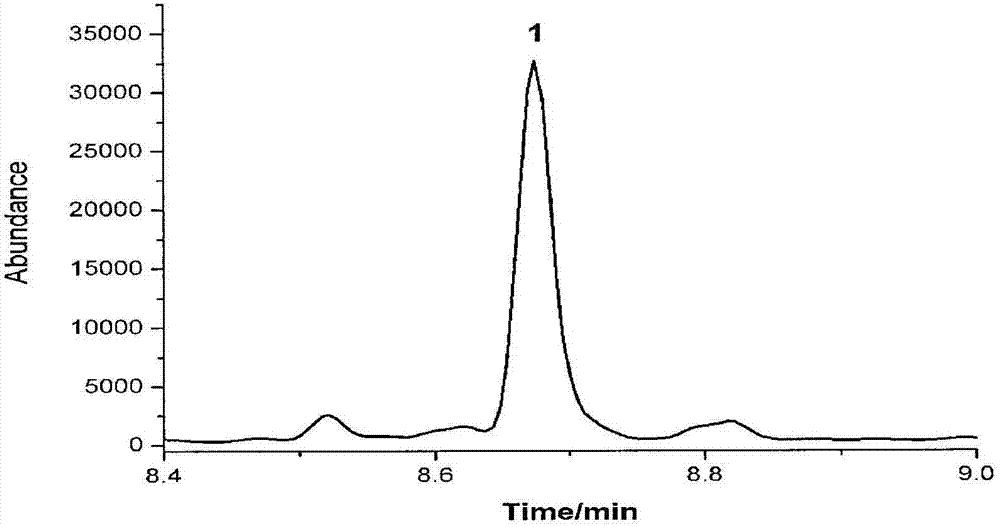

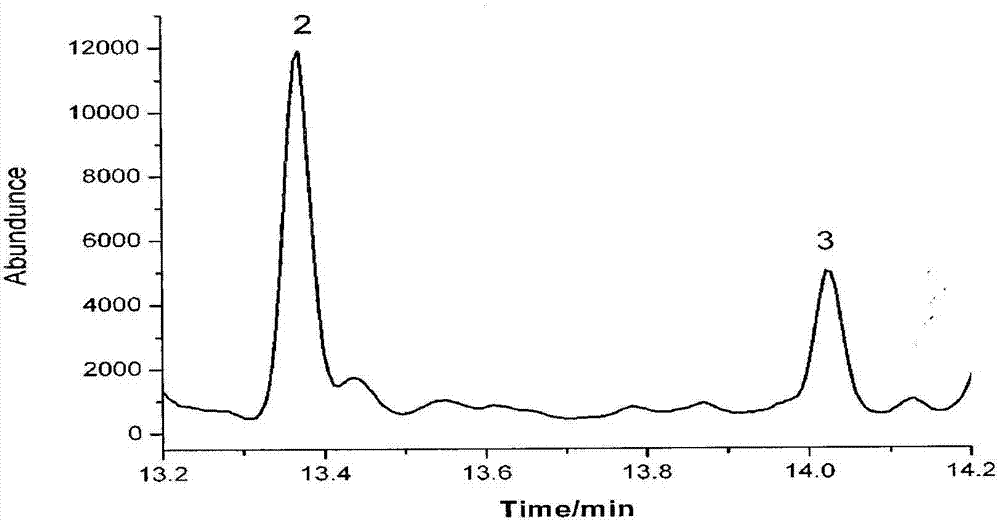

Simultaneous determination of 16 polycyclic aromatic hydrocarbons in mainstream cigarette smoke

The invention discloses a method for simultaneously measuring 16 polyaromatic hydrocarbons in mainstream smoke of cigarettes. The method comprises the following steps of (1) trapping dry particulate matters in the mainstream smoke of the cigarettes through a Cambridge filter, then transferring the Cambridge filter into an extraction container, adding an internal standard mixed solution, and then adding methyl alcohol for oscillation extraction to obtain a methyl alcohol extracting liquid; (2) diluting the methyl alcohol extracting liquid through super-pure water to obtain a diluent, and performing selective extraction on the diluent through an immersion type solid phase microextraction technology to obtain a smoke sample; (3) detecting the smoke sample through a GC-MS (gas chromatography-mass spectrometer) to detect the smoke sample, and detecting the content of the 16 polyaromatic hydrocarbons through an internal standard quantification method. The method can be used for simultaneously measuring the content of the 16 polyaromatic hydrocarbons in the mainstream smoke of the cigarettes by the GC-MS method, has the advantages of high detection speed, high sensitivity, high selectivity and high precision and is suitable for measurement of the content of polyaromatic hydrocarbon in smoke of low-tar cigarettes.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Cigarette paper capable of improving suction satisfaction

InactiveCN104452437ASmell is not affectedImprove smoke fullnessPaper coatingCoatingsCarboxylic saltSolvent

The invention relates to a piece of cigarette paper capable of improving suction satisfaction. Ammonium carboxylate or diammonium phosphate is added into the cigarette paper, and the addition amount accounts for 0.0001-1 percent of the mass of the cigarette paper, wherein ammonium carboxylate is selected from 2-methyl-2-pentenoic acid ammonium, ammonium citrate, ammonium benzoate, ammonium acetate, ammonium tartrate, ammonium cinnamate, ammonium fumarate or ammonium iso-octoate. The invention also relates to a method for preparing the cigarette paper capable of improving suction satisfaction, and the method comprises the steps of dissolving ammonium carboxylate or diammonium phosphate in water or a mixed solvent of ethanol and water to prepare a solution, then spraying the solution on the cigarette paper according to the addition amount, and drying to obtain the cigarette paper capable of improving suction satisfaction. The cigarette paper prepared according to the method disclosed by the invention can adjust the pH value of smoke gas under combustion condition, increases the release ratio of dissociative nicotine in main smoke gas, and is used in low-tar cigarettes for improving suction strength and satisfaction.

Owner:CHINA TOBACCO YUNNAN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com