Production method of low-tar cigarette cut tobacco and cigarette with low-tar cigarette cut tobacco

A low-tar and shredded tobacco technology, applied in tobacco, tobacco processing, application, etc., can solve the problems of limited additive dosage, complicated process, and harm reduction effect, and achieve the effects of reducing harm, simplifying the preparation process, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

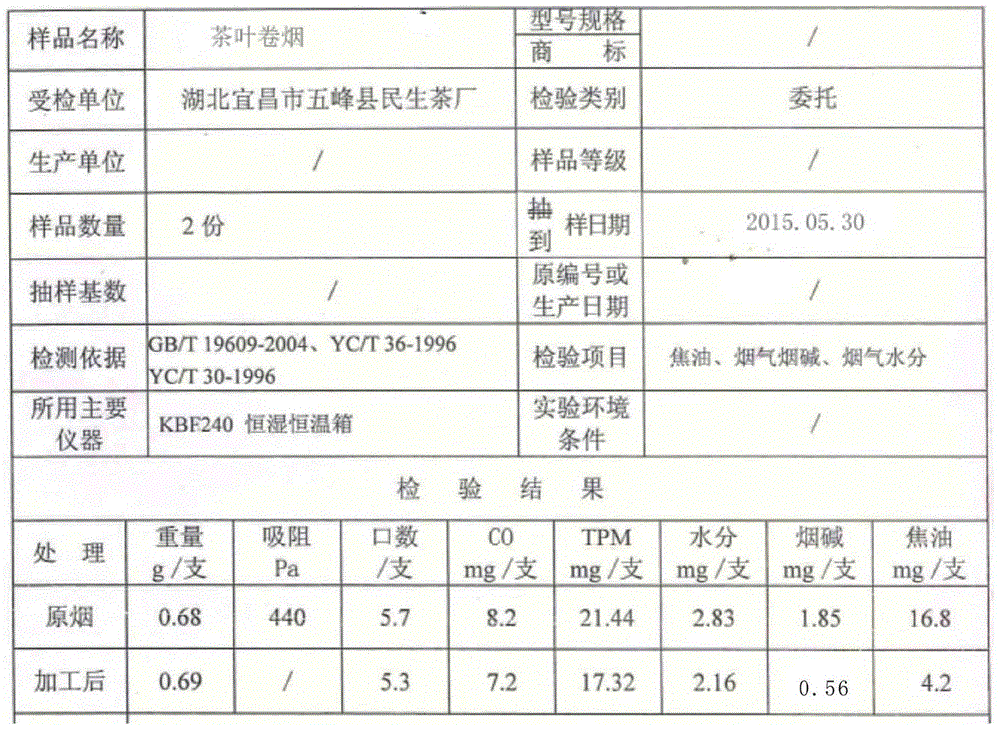

Embodiment 1

[0043] A method for preparing shredded tobacco of low-tar cigarettes, the method comprising the following steps:

[0044] 1) Material selection and drying: From June 30th to October 30th every year, the fresh tea leaves with a single leaf length ≥ 5 cm are picked as raw materials, and they are cleaned and dried until the water content is 10-20%. To prepare cut tobacco raw material;

[0045] 2) block making: put the shredded tobacco raw material prepared in step 1) into a mold for pressing to obtain a rectangular block raw material with a thickness of 5-15 cm and a length of 45-55 cm;

[0046] 3) shredding: shredding the rectangular block raw material obtained in step 2) to obtain shredded tobacco raw material for tea;

[0047] 4) Brewing for the first time: putting the tea shredded tobacco raw material prepared in step 3) into a warm water pool for brewing, the weight parts of the tea shredded tobacco raw material and warm water are:

[0048] 30 parts by weight of tea shredd...

Embodiment 2

[0061] A method for preparing shredded tobacco of low-tar cigarettes, the method comprising the following steps:

[0062] 1) Material selection and drying: From June 30th to October 30th every year, the fresh tea leaves with a single leaf length ≥ 5 cm are picked as raw materials, and they are cleaned and dried until the water content is 10-20%. To prepare cut tobacco raw material;

[0063] 2) block making: put the shredded tobacco raw material prepared in step 1) into a mold for pressing to obtain a rectangular block raw material with a thickness of 5-15 cm and a length of 45-55 cm;

[0064] 3) shredding: shredding the rectangular block raw material obtained in step 2) to obtain shredded tobacco raw material for tea;

[0065] 4) Brewing for the first time: putting the tea shredded tobacco raw material prepared in step 3) into a warm water pool for brewing, the weight parts of the tea shredded tobacco raw material and warm water are:

[0066] 70 parts by weight of tea shredded...

Embodiment 3

[0079] A method for preparing shredded tobacco of low-tar cigarettes, the method comprising the following steps:

[0080] 1) Material selection and drying: From June 30th to October 30th every year, the fresh tea leaves with a single leaf length ≥ 5 cm are picked as raw materials, and they are cleaned and dried until the water content is 10-20%. To prepare cut tobacco raw material;

[0081] 2) block making: put the shredded tobacco raw material prepared in step 1) into a mold for pressing to obtain a rectangular block raw material with a thickness of 5-15 cm and a length of 45-55 cm;

[0082] 3) shredding: shredding the rectangular block raw material obtained in step 2) to obtain shredded tobacco raw material for tea;

[0083] 4) Brewing for the first time: putting the tea shredded tobacco raw material prepared in step 3) into a warm water pool for brewing, the weight parts of the tea shredded tobacco raw material and warm water are:

[0084] 50 parts by weight of tea shredd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com