Preparation method and application of tobacco additive deriving from burley tobacco

A technology for preparing additives and burley tobacco, which is applied in the field of cigarette flavors and fragrances, can solve the problems of low yield of flavor substances in the extract, affecting the quality of cigarette smoking, and high protein content, and achieves good industrial application prospects, increased richness, and high protein content. The effect of rich aroma components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

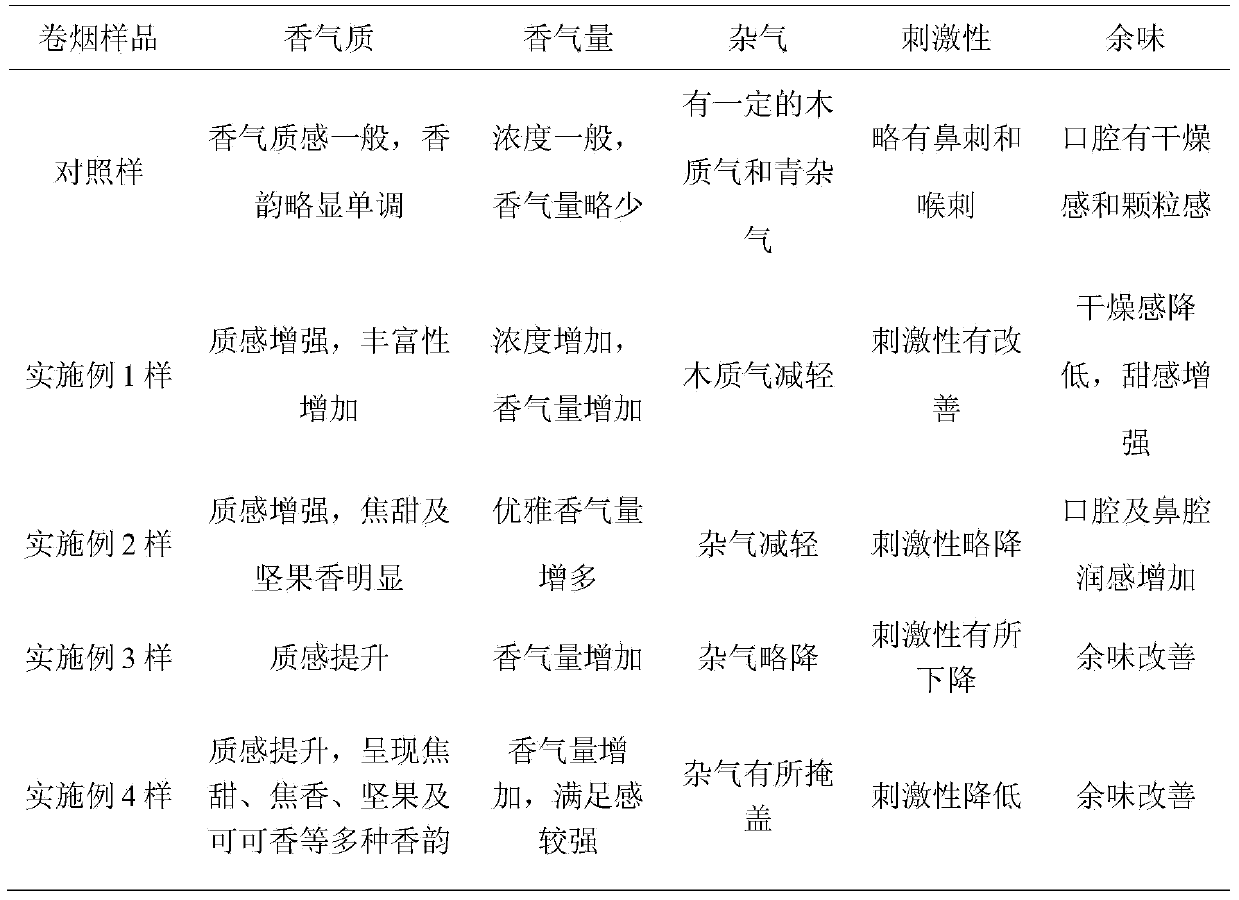

Embodiment 1

[0024] Dry and crush 50 g of burley tobacco powder produced in the process of leaf threshing and re-roasting, after sieving, add 2500 g of deionized water and vibrate and extract on a shaker for 1 hour, then add 0.9 g of papain, adjust the pH of the aqueous solution to 6, at 40 Heating and hydrolyzing at ℃ for 1 hour, and then performing solid-liquid separation to obtain a brown water extract, concentrating under reduced pressure to remove part of the water solvent, so that the water content accounts for 30% of the total, add 0.1g glucose, and then add 20% of the volume of the concentrated solution After the propylene glycol is mixed evenly, it is heated to a temperature of 80° C. for 2 hours to obtain a tobacco additive product derived from Burley tobacco.

[0025] After diluting the above additives with 95% ethanol, they are evenly added to the shredded tobacco of low-tar cigarettes in an amount of 0.2% by weight of shredded tobacco. The texture and richness of the finished c...

Embodiment 2

[0027] After drying and crushing 20g of low-grade Burley tobacco leaves produced in the storage process, sieve, add 400g of deionized water, shake and extract on a shaker for 1 hour, add 0.42g of neutral protease, adjust the pH of the aqueous solution to 7, and heat at 50°C Hydrolyze for 6 hours, then carry out solid-liquid separation to obtain a brown water extract, concentrate under reduced pressure to remove part of the water solvent, add 0.04g fructose, and then add propylene glycol accounting for 20% of the volume of the water extract and mix evenly so that the water content accounts for the total 50% of the mixture was heated to a temperature of 100° C. for 3 hours to obtain a tobacco additive product derived from Burley tobacco. After diluting the additive with 95% ethanol, it is evenly added to the shredded tobacco of low-tar cigarettes in an amount of 0.1% by weight of the shredded tobacco. The texture and richness of the finished cigarette product are significantly im...

Embodiment 3

[0029] Dry, pulverize and sieve 10 g of burley tobacco powder produced during leaf threshing and redrying, add 300 g of deionized water and place it in an ultrasonic extraction device for 20 minutes of ultrasonication, add 0.155 g of neutral protease, and adjust the pH of the aqueous solution to 8. Heat and hydrolyze at 45°C for 1 hour, then separate solid and liquid to obtain a brown water extract, concentrate under reduced pressure to remove most of the water solvent, add 0.02g fructose, and then add propylene glycol accounting for 30% of the volume of the water extract and mix evenly to make the water The content accounts for 70% of the total amount, and it is heated to a temperature of 120° C. for 5 hours to obtain a tobacco additive product derived from burley tobacco. After the additive is diluted with 95% ethanol, it is uniformly added to the shredded tobacco of low-tar cigarettes in an amount of 0.05% by weight of shredded tobacco, and the finished cigarette product has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com