Microwave treatment method for heating non-combustion tobacco shreds

A heat-not-burn and microwave treatment technology, which is applied in the treatment of tobacco, tobacco, application, etc., can solve the problems of small smoke volume, small smoke volume, lack of tobacco aroma, etc., and achieve moderate smoke temperature and smoke characteristics Increase, the effect that the aroma is rich

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

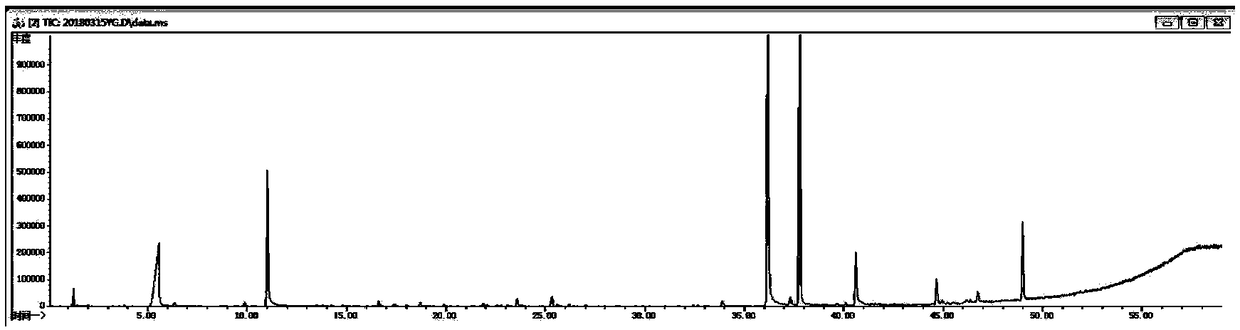

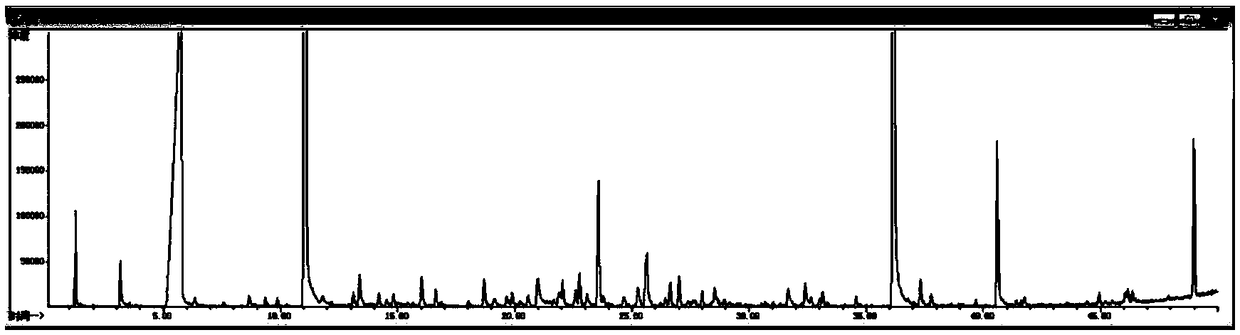

Image

Examples

Embodiment 1

[0015] Weigh 4 g of flue-cured tobacco shreds, mix evenly, the moisture content of the shredded tobacco is 12%, carry out microwave treatment, the microwave power is 600W, the set temperature is 150°C, the temperature is raised to the set temperature within 10 minutes and then reacted for 2h, after the reaction is completed, it is cooled and taken out.

[0016] The cut tobacco has a moisture content of 4%. According to the sensory evaluation, the smoke concentration is relatively high, the temperature of the smoke is moderate, the smoke is rich, the tobacco aroma is sufficient, and the burnt aroma is obvious.

Embodiment 2

[0018] Weigh 4g of flue-cured tobacco shreds, mix evenly, and carry out microwave treatment. The microwave power is 300W, and the set temperature is 120°C. The temperature is raised to the set temperature within 20 minutes, and then reacted for 2h. After the reaction is completed, it is cooled and taken out.

[0019] According to the sensory evaluation, the concentration of the smoke is relatively high, the temperature of the smoke is moderate, the smoke is rich, the aroma of tobacco is strong, and the burnt aroma is obvious.

Embodiment 3

[0021] Weigh 4g of flue-cured tobacco shreds, mix evenly, and carry out microwave treatment. The microwave power is 800W, the set temperature is 50°C, the temperature is raised to the set temperature within 10 minutes, and the reaction is carried out for 30 minutes. After the reaction is completed, it is cooled and taken out.

[0022] According to the sensory evaluation, the concentration of the smoke is relatively high, the temperature of the smoke is moderate, the smoke is rich, the aroma of tobacco is strong, and the burnt aroma is obvious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com