Fermentation method for increasing flavor components in fermented grains

A technology of aroma components and fermentation method, applied in the field of winemaking, can solve the problems of insufficient aroma ability of glutinous rice grains, non-uniform quality of glutinous rice grains, deviation of aroma of glutinous rice grains, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

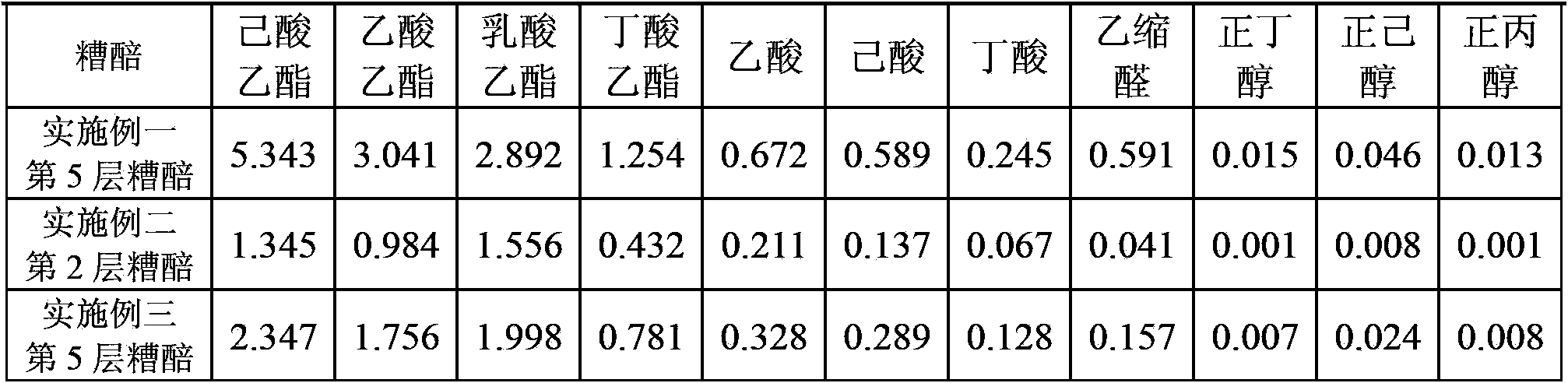

[0025] Taking a certain cellar as the research object, the cellar is divided into layers 1, 2, 3, 4, and 5 from top to bottom, and the cellar is filled with fermented grains for sealed fermentation. After 60 days of fermentation, the cellar is opened, and then Take out the 1st, 2nd, 3rd, and 4th layer of unstrained spirits, then take out the 5th layer of unstrained spirits at the bottom of the cellar for distillation, and then fill the original 4th, 3rd, 2nd, and 1st layer of unstrained spirits in the cellar from bottom to top. , and finally fill in a layer of fresh grains to be fermented for sealed fermentation. After 60 days of fermentation, the above steps are repeated, and the fifth layer of unstrained spirits at the bottom of the cellar is taken out again for distillation to obtain wine. After repeating the above steps 5 times, take the fifth layer of fermented grains at the bottom of the cellar for sensory aroma identification, and take a wine sample to detect the conten...

Embodiment 2

[0027] Taking the cellar of the same size and quality as the research object in Example 1, fill the cellar with fresh unstrained spirits of the same quality all at once, ferment for 60 days, and then take out all the unstrained spirits in the cellar from top to bottom for distillation fetch wine. Since the unstrained spirits of the whole cellar are taken out at the same time, but the quality of the unstrained spirits in the upper and lower layers of the cellar is different, in order to better reflect the quality of the unstrained spirits in each layer in the cellar, compare it with the unstrained spirits in Example 1 , then take the 5th layer of unstrained spirits samples and the 2nd layer of unstrained spirits samples at the same layer cellar position as in Example 1 for sensory aroma identification, and detect the content of aroma components in the distilled wine by conventional gas chromatography analysis. The results are shown in Table 1 and Table 2:

[0028] Table 1 Iden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com