Brewing process of high-quality red orange fruit wine

A high-quality, tangerine fruit wine technology, applied in the field of fruit wine brewing, can solve the problems of rotting red oranges, less nutrient components, waste of resources, etc., and achieve the effects of good taste and fruit flavor, simple brewing process, and improved economic value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

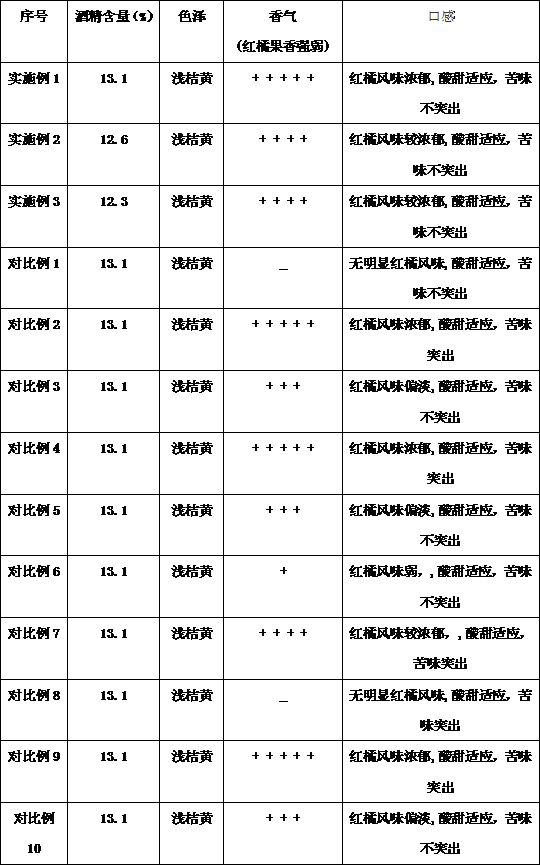

Examples

Embodiment 1

[0032] A brewing process of high-quality red orange fruit wine, comprising the following steps:

[0033] (1) Pretreatment: Peel and break the red orange to obtain broken red orange pulp, add pectinase (0.02% of the weight of the broken red orange pulp) and carry out enzymatic hydrolysis treatment (temperature is 33℃, time is 1.5h) Then, filter to obtain red orange juice;

[0034] (2) Component adjustment: Add partial potassium sulfite to the red orange juice (the amount added is SO 2 After being calculated as 100mg / L), adjust the sugar content of the red orange juice to 19% and the pH value to 4.5 to obtain fermentation raw materials;

[0035] (3) Fermentation: add yeast (0.12g / L) to the fermentation raw materials, stir evenly and then carry out fermentation treatment (temperature is 22°C, time is 12d), and the fermentation puree is obtained by filtration;

[0036] (4) Ageing: aging the fermented puree (the temperature is 7°C and the time is 8 months) to obtain the puree of ...

Embodiment 2

[0039] A brewing process of high-quality red orange fruit wine, comprising the following steps:

[0040] (1) Pretreatment: Peel and crush the red orange to obtain broken red orange pulp, add pectinase (0.01% of the weight of the broken red orange pulp) and carry out enzymatic hydrolysis treatment (temperature is 35 °C, time is 1 h) , filtered to obtain red orange juice;

[0041] (2) Component adjustment: Add partial potassium sulfite to the red orange juice (the amount added is SO 2After being calculated as 80mg / L), adjust the sugar content of the red orange juice to 20% and the pH value to 4 to obtain fermentation raw materials;

[0042] (3) Fermentation: add yeast (0.10g / L) to the fermentation raw materials, stir evenly and then carry out fermentation treatment (temperature is 25°C, time is 15d), and the fermentation puree is obtained by filtration;

[0043] (4) Ageing: aging the fermented puree (at a temperature of 5°C for 10 months) to obtain a puree of fruit wine;

[0...

Embodiment 3

[0046] A brewing process of high-quality red orange fruit wine, comprising the following steps:

[0047] (1) Pretreatment: Peel and break the red orange to obtain broken red orange pulp, add pectinase (0.03% of the weight of the broken red orange pulp) and carry out enzymatic hydrolysis treatment (temperature is 32°C, time is 2h) , filtered to obtain red orange juice;

[0048] (2) Component adjustment: Add partial potassium sulfite to the red orange juice (the amount added is SO 2 After being counted as 80mg / L), adjust the sugar content of red orange juice to 18% and pH value to 5 to obtain fermentation raw materials;

[0049] (3) Fermentation: add yeast (0.15g / L) to the fermentation raw materials, stir evenly and then carry out fermentation treatment (temperature is 18°C, time is 15d), and the fermentation puree is obtained by filtration;

[0050] (4) Ageing: aging the fermented puree (the temperature is 10°C, and the time is 6 months) to obtain the puree of fruit wine;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com