Method for preparing tea flavored low-tar cigarette

A low-tar, cigarette technology, applied in the preparation of tobacco, tobacco, application, etc., can solve the problems of not being able to maintain high aroma, not recognized by consumers, not accepted by the market, etc., to achieve saving tobacco raw materials, smooth and elegant smoke, and good economy The effect of benefits and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

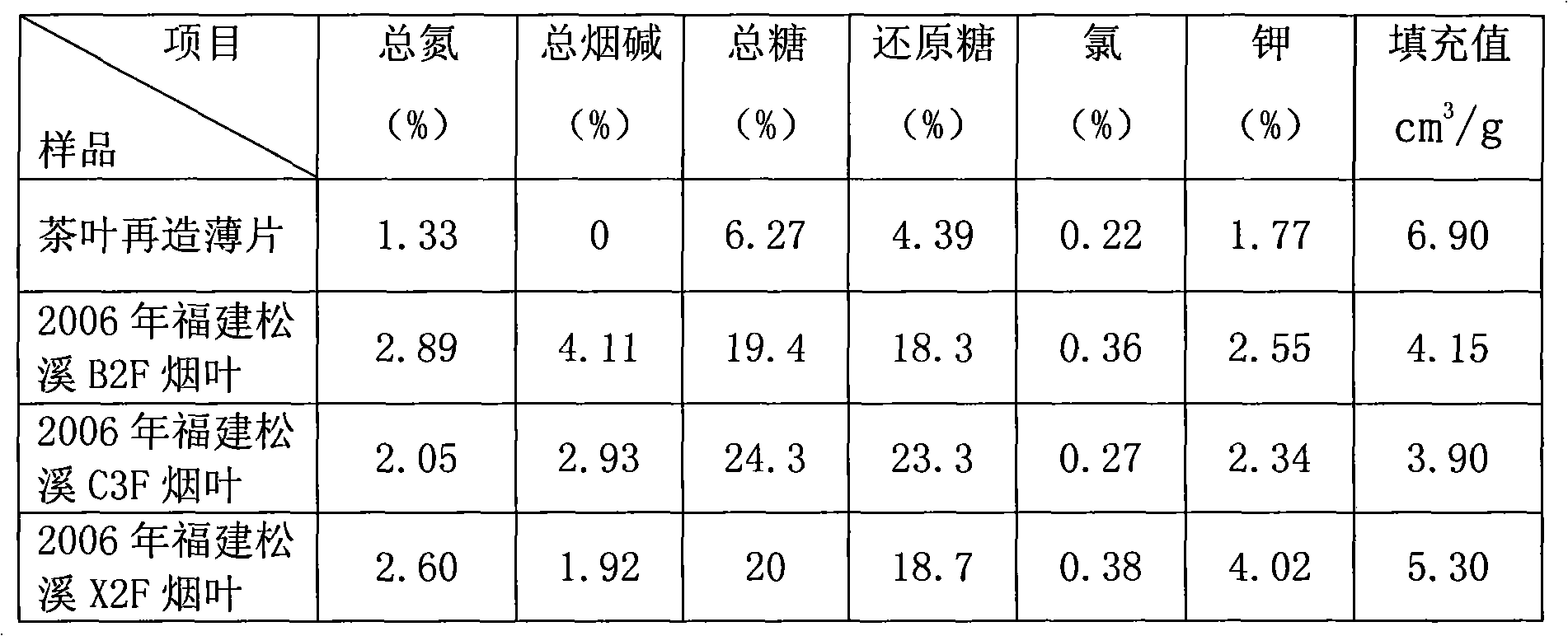

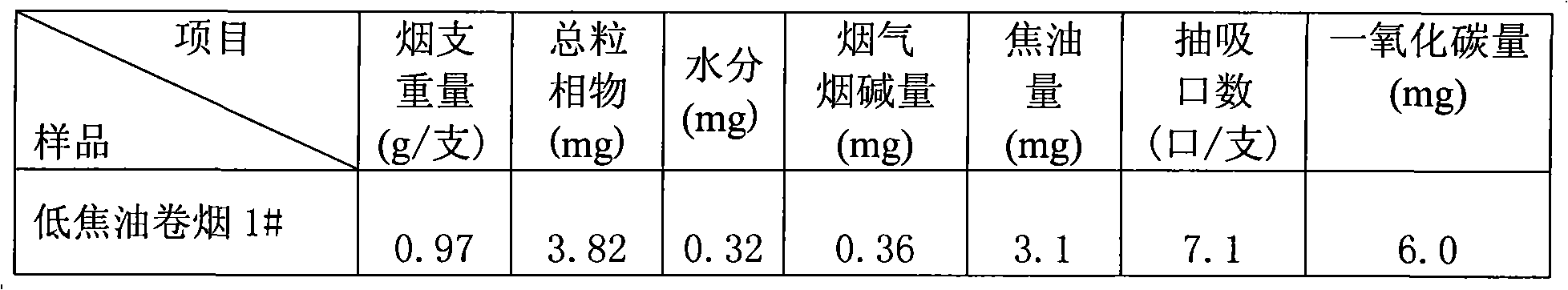

[0025] Embodiment 1 of the present invention, firstly, the tea reconstituted sheet and tobacco leaves are put into the moisture conditioning cylinder according to the weight ratio of 13:87 to loosen and regain moisture, so that the moisture content is about 18%. Send the loose and dampened raw materials into the feeding cylinder and add the necessary feed liquid, adjust the moisture content of the fed materials to about 20%, then send them into the leaf storage cabinet until the feed liquid is fully absorbed, and then heat and humidify the materials, adjust When the moisture reaches about 21%, use a shredder to cut the material into shreds, enter the drying drum to dry the shreds until the moisture content is about 12.5%, cool, store the shreds, and mix the shredded tobacco evenly, then add a certain amount of flavoring liquid, add the flavoring liquid The shredded tobacco enters the silk storage cabinet, and after the aroma liquid is fully absorbed, it is rolled and packaged w...

Embodiment 2

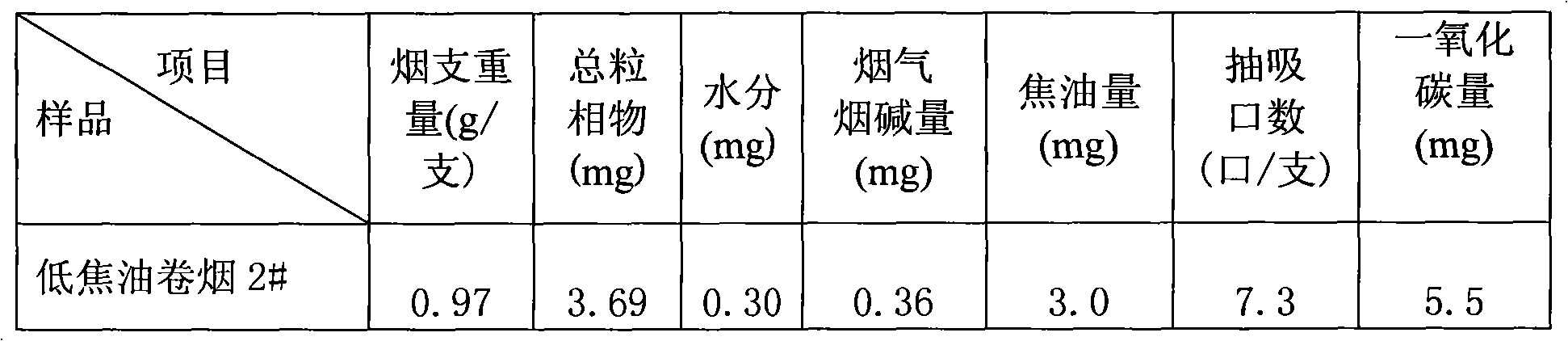

[0029] In the second embodiment of the present invention, firstly, the tea flakes and tobacco leaves are put into the dampening cylinder according to the weight ratio of 15:85 to loosen and regain moisture, so that the moisture content is about 18%. Send the loose and rehydrated raw materials into the feeding cylinder and add the necessary feed liquid. Adjust the moisture content of the material to about 20% and enter the leaf storage cabinet until the feed liquid is fully absorbed. Then heat and humidify the material and adjust the moisture content to about 21%. Use a wire cutter to cut the material into shreds, enter the drying drum to dry the shreds until the moisture is about 12.5%, cool, store the shreds, and mix the shredded tobacco evenly. After the fragrance liquid is fully absorbed, it is rolled and packaged with rolling and packaging equipment.

[0030] The rolled cigarettes were subjected to smoke chemical analysis; the results were as follows:

[0031]

[0032]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com