Preparation of low temperature fraction with aromatizing function applied to heated cigarette and its use in heated cigarette

A low-temperature, distillate technology, applied in the field of heated cigarettes, to achieve the effect of increasing the concentration, characteristic aroma, rich and elegant aroma, and good texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

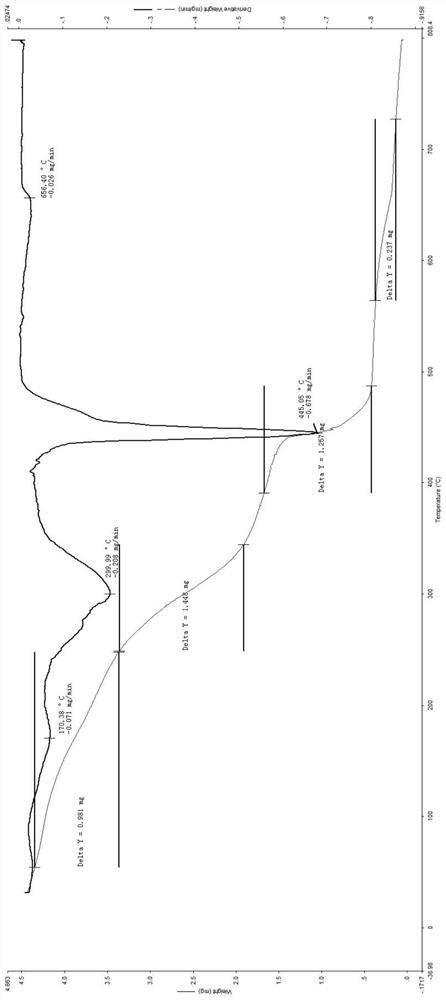

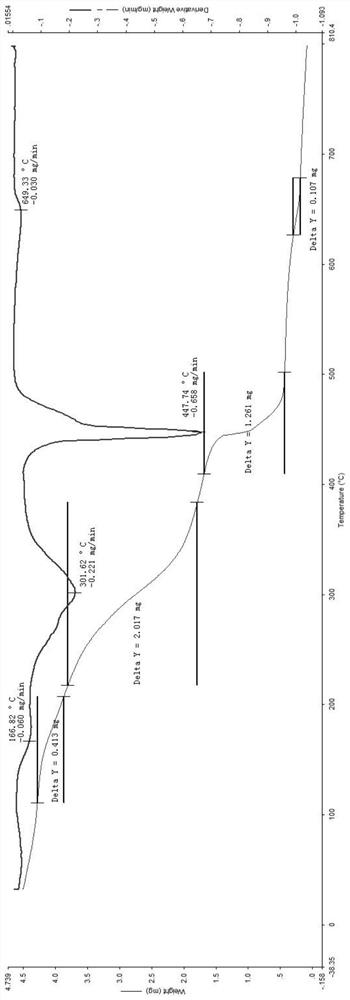

Examples

Embodiment 1

[0032] A preparation method of a low-temperature fraction with aroma-enhancing function, the preparation method comprises the following steps:

[0033] 1. The formula design of the aroma module leaf group

[0034] Tobacco material was prepared according to the following formulation.

[0035] Table 1 Formula design of aroma module leaf group

[0036]

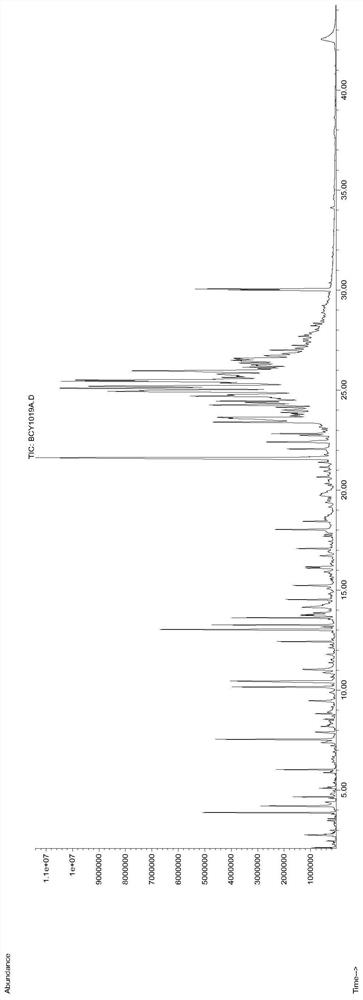

[0037] 2. Flavoring module microwave extraction

[0038] Wet the above tobacco raw material with an appropriate amount of water, put it into a microwave extraction device, maintain a certain extraction power for extraction, and collect the extract in the separation kettle after the extraction is completed. Crude extract of cryogenic fraction;

[0039] Among them, the ratio of tobacco raw material to water is 1:2.5, the extraction time is 65min, and the power of the microwave extraction device is 520W.

[0040] Extraction yield = low temperature fraction (g) / tobacco raw material (g) × 100%

[0041] The average extraction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com