Method for curing pit

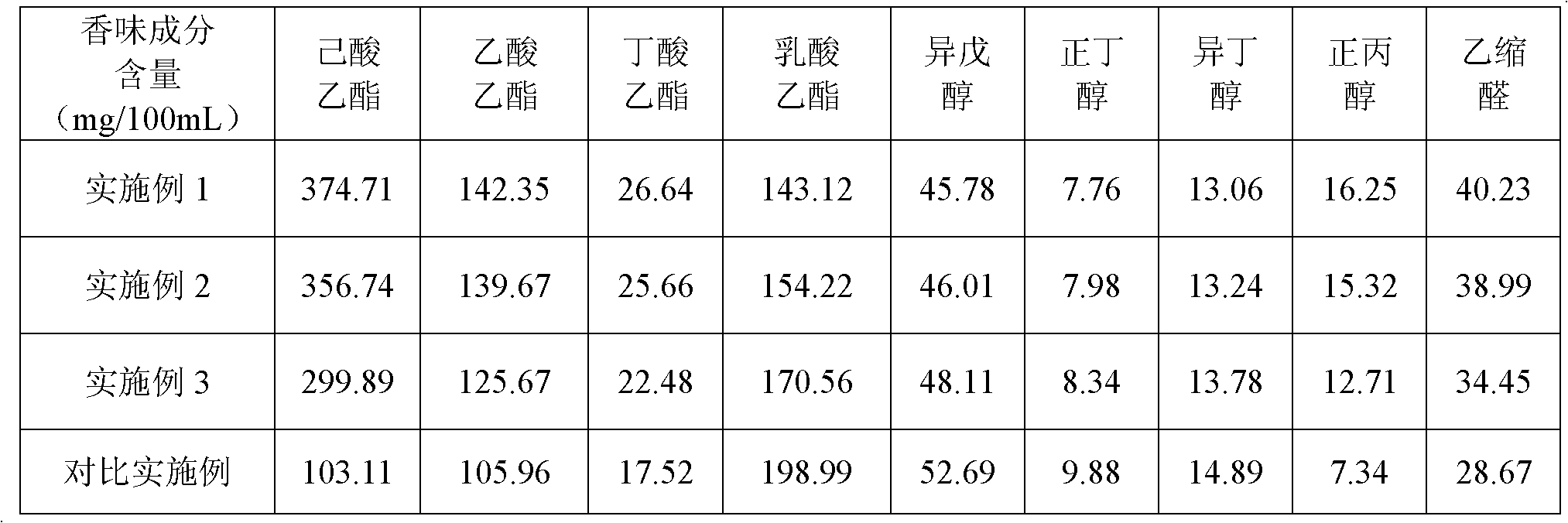

A technology of cellar pool and cellar wall, which is applied in the field of wine making, which can solve the problems of weakened aroma production ability of cellar mud, degradation of cellar wall mud, and lack of water and nutrients in cellar wall mud, so as to increase the flavor of aging and soft taste , acetal and n-butanol enhance the strong and long-lasting effect of pit mud fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 adopts the method of the present invention to carry out maintenance to cellar pool

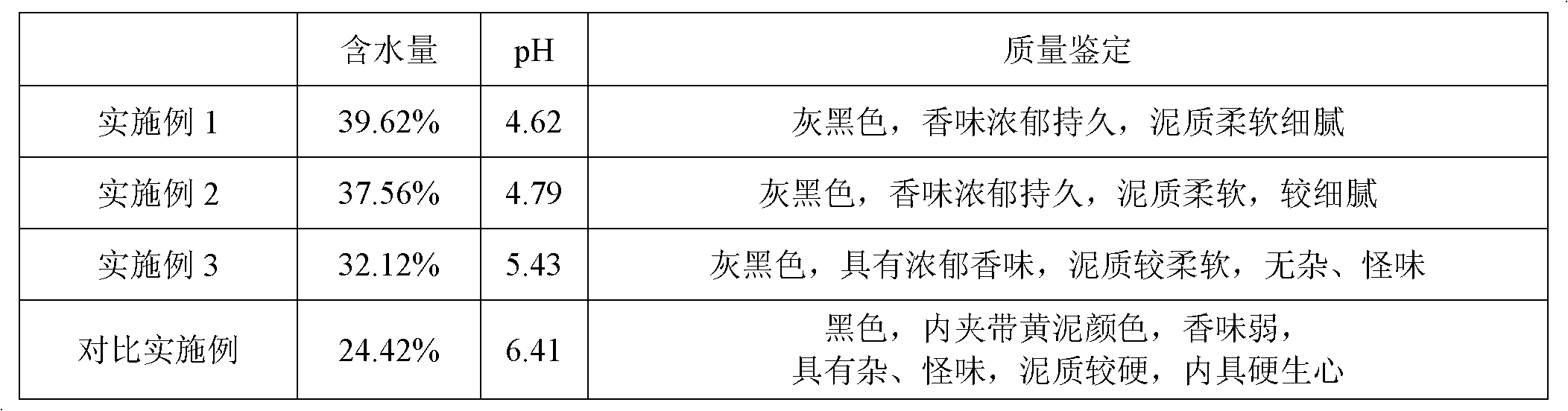

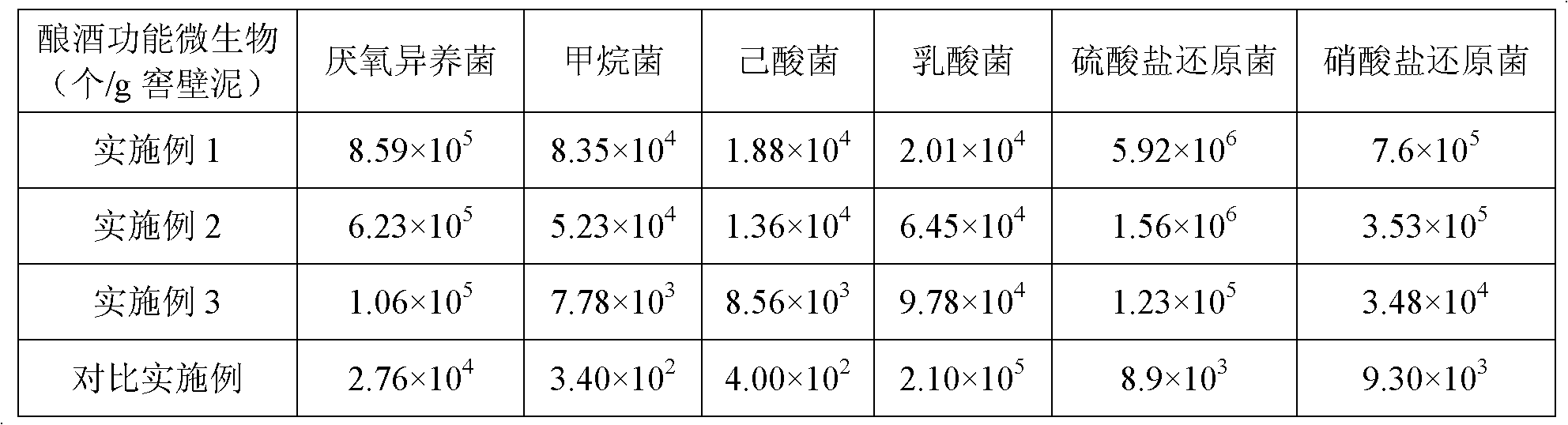

[0039] When the fermentation is completed and the cellar is opened, the cellar wall is fully cleaned to expose the cellar wall mud, and then the cellar wall is sprinkled with wine tails, 2kg / m 2 Cell wall, and cover the cellar pool with a film. When the temperature reaches above 30°C, the wine tail is sprayed once every 4 hours. When the temperature is lower than 20°C, sprinkle the wine tail once every 24 hours. After sprinkling the wine tail for the last time, evenly sprinkle medium-high temperature daqu on the cellar wall, 1kg / m 2Fill the cellar wall with fermented grains, then step on the fermented grains tightly along the cellar wall, sprinkle yellow water along the cellar wall after filling, 10kg / m 2 cellar wall. Taking 60 days as the fermentation period, after 1 year of continuous cycle brewing production, the quality and physical and chemical indicators of the pit...

Embodiment 2

[0040] Embodiment 2 adopts the method of the present invention to carry out maintenance to cellar pool

[0041] When the fermentation is completed and the cellar is opened, the cellar wall is fully cleaned to expose the cellar wall mud, and then the cellar wall is sprinkled with wine tails, 1.5kg / m 2 Cell wall, and cover the cellar pool with a film. When the temperature reaches above 30°C, the wine tail is sprayed once every 4 hours. When the temperature is lower than 20°C, sprinkle the wine tail once every 24 hours. After the last sprinkling of the wine tail, evenly sprinkle medium-high temperature Daqu on the cellar wall, 0.75kg / m 2 Fill the cellar wall with fermented grains, then step on the fermented grains tightly along the cellar wall, sprinkle yellow water along the cellar wall after filling, 7.5kg / m 2 cellar wall. Taking 60 days as the fermentation period, after 1 year of continuous cycle brewing production, the quality and physical and chemical indicators of the pi...

Embodiment 3

[0042] Embodiment 3 adopts the method of the present invention to carry out maintenance to cellar pool

[0043] When the fermentation is completed and the cellar is opened, the cellar wall is fully cleaned to expose the cellar wall mud, and then the cellar wall is sprinkled with wine tails, 1kg / m 2 Cell wall, and cover the cellar pool with a film. When the temperature reaches above 30°C, the wine tail is sprayed once every 4 hours. When the temperature is lower than 20°C, sprinkle the wine tail once every 24 hours. After sprinkling the tail of wine for the last time, sprinkle medium-high temperature Daqu evenly on the wall of the cellar, 0.5kg / m 2 Cell wall, then fill the cellar with fermented grains, step on the cellar wall to tighten the fermented grains, after filling, sprinkle yellow water along the cellar wall, 5kg / m 2 cellar wall. Taking 60 days as the fermentation period, after 1 year of continuous cycle brewing production, the quality and physical and chemical indic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com