Pollution-free low-tar cigarette and manufacturing method thereof

A manufacturing method and low-tar technology, applied in the manufacture of cigarettes, cigars, tobacco, etc., can solve problems such as hazards, and achieve the effects of less dry distillation equipment, reduced harm, and simple dry distillation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

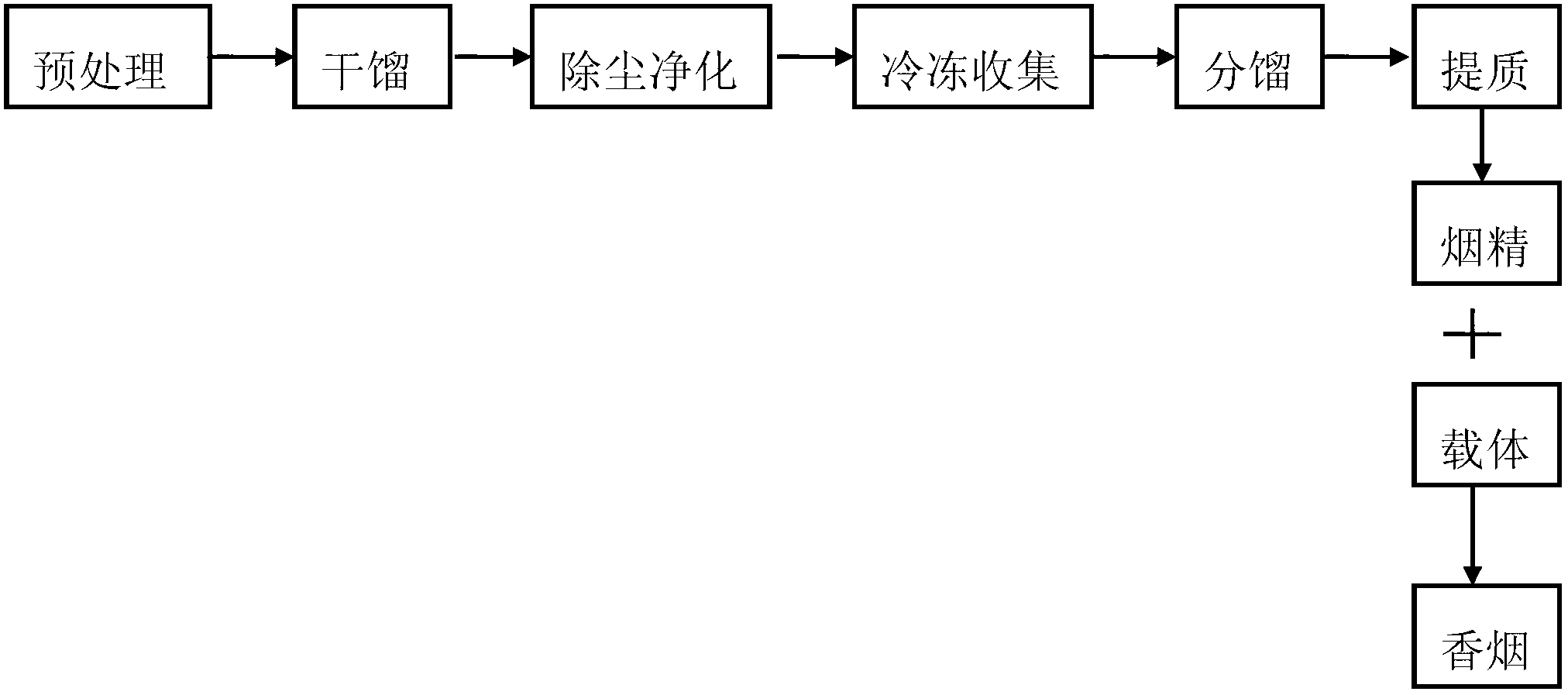

[0049] Such as figure 1 shown.

[0050] A kind of manufacture method of pollution-free low-tar cigarette, comprises steps as follows:

[0051] (1) Tobacco leaf pretreatment:

[0052] According to the prior art, the tobacco leaves are classified, stemmed, shredded, baked, aired and sun-dried;

[0053] (2) Dry distillation:

[0054] Carry out dry distillation on the tobacco leaves processed in step (1) by dry distillation technology: the dry distillation temperature is 900°C, and the dry distillation pressure is 0.1Mpa;

[0055] (3) Dust removal and purification:

[0056] Removing fine tobacco leaf particles, carbon monoxide, nitrogen oxides and formaldehyde during the dry distillation of tobacco leaves; the fine tobacco leaf particles are particles with a particle size ≧20 μm;

[0057] (4) Frozen collection:

[0058] cooling and collecting the product of dry distillation of tobacco leaves in step (3) with a cooling medium at a temperature of -30 to 0° C., to obtain a dry ...

Embodiment 2

[0066] A manufacturing method of a pollution-free low-tar cigarette as described in Example 1, the difference is that the dry distillation temperature is 600°C.

[0067] The heating carrier is a chemical heating carrier; when smoking, the chemical heating carrier atomizes the smoke essence through chemical heating to achieve the effect of smoking.

Embodiment 3

[0069] A manufacturing method of a pollution-free low-tar cigarette as described in Example 1, the difference is that the inert carrier is a non-heating carrier. The non-heating carrier is wood cellulose, cellulose acetate or propylene fiber, and the non-heating carrier is filled with tobacco essence. When smoking, the airflow enters to promote the volatilization of the tobacco essence in the non-heating carrier to achieve the effect of smoking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com