Additive for compensating aroma of low tar cigarette

An additive and low-tar technology, applied in the direction of non-fiber pulp addition, tobacco, application, etc., can solve the problems of lightening the smoke taste and reducing the aroma components of the mainstream particle phase of cigarettes, and achieve the effect of increasing the aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

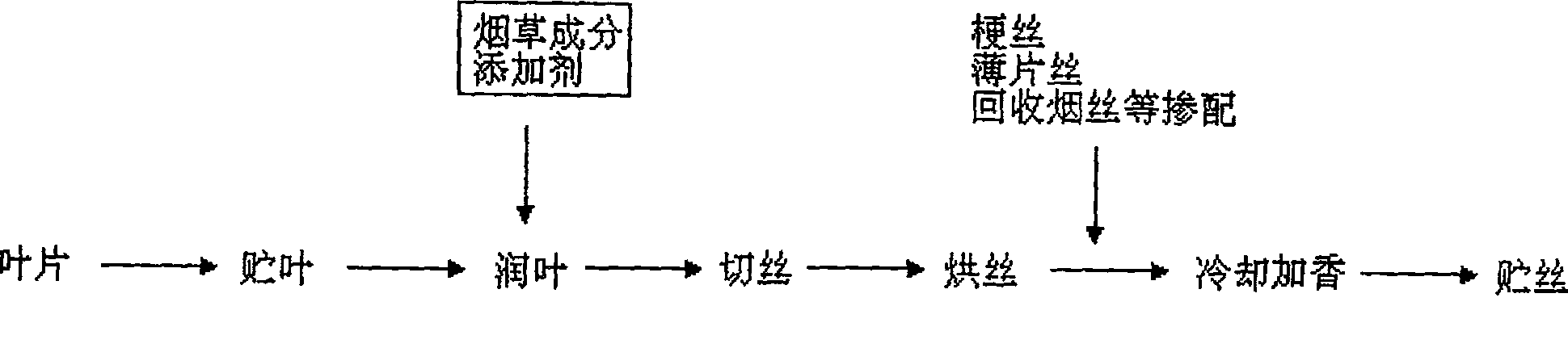

[0038] Such as figure 1 As shown, 0.5 kg of tobacco extract, 1 g of furfural, 1 g of 5-methyl-furfural, 2 g of 3-ethyl-2-hydroxy-2-cyclopenten-1-one, and 200 g of neophytadiene , 2 grams of methyl palmitate, 3 grams of solanone, 4 grams of dihydroactinolactone, 5 grams of damascenone, 8 grams of macrostigmatrienone, 50 grams of acetic acid, 2 grams of propionic acid, and 3 grams of benzoic acid , 40 grams of palmitic acid, 1 gram of 2-methyl-pyridine, 2 grams of indole, diluted with 2 kilograms of ethanol and added in the tar cigarette leaf moistening process, its addition is 6% of the weight of the tobacco leaf, and the rest are the same normal process.

Embodiment 2

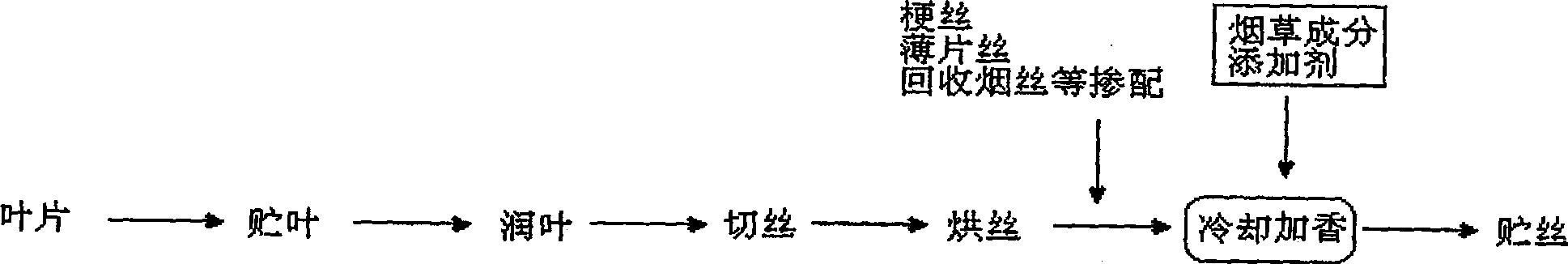

[0040] Tobacco extract 0.5 kg, furfural 4 g, 5-methyl-furfural 3 g, 3-ethyl-2-hydroxy-2-cyclopenten-1-one 5 g, neophytadiene 300 g, palmitic acid 4 grams of methyl esters, 8 grams of solanone, 8 grams of dihydroactinolactone, 5 grams of damascenone, 15 grams of macrostigmatrienone, 70 grams of acetic acid, 6 grams of propionic acid, 5 grams of benzoic acid, palmitic acid 50 grams and 6 grams of pyridine are diluted with 2 kilograms of ethanol and added in the cooling and perfuming process after drying shredded tar cigarettes. The amount added is 5% of the shredded tobacco weight.

Embodiment 3

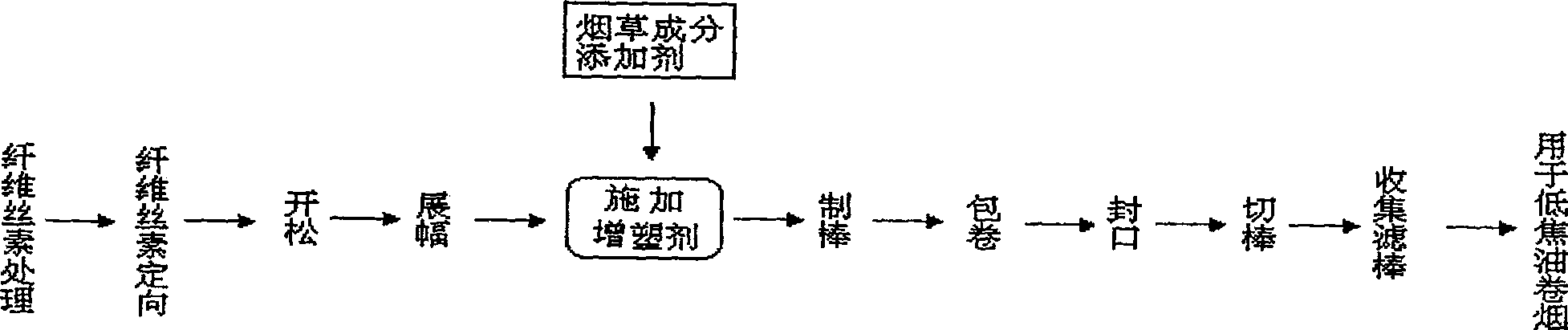

[0042] 1 kg of tobacco extract, 6 g of furfural, 1 g of 5-methyl-furfural, 8 g of 3-ethyl-2-hydroxy-2-cyclopenten-1-one, 100 g of neophytadiene, 7 grams of methyl ester, 8 grams of solanone, 3 grams of dihydroactinolactone, 2 grams of damascenone, 15 grams of macrostigmatrienone, 80 grams of acetic acid, 3 grams of propionic acid, 3 grams of benzoic acid, sixteen 40 grams of acid and 6 grams of 2-methyl-pyridine are diluted with 4 kilograms of ethanol and added to the dark-colored disc paper in an amount of 2%, and the rest are the same as the normal process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com