Deoxyfructosazine containing additive agent for fragrance compensation for low-coke tar cigarette

A technology of deoxyfructosazine and aroma compensation, which is applied in the direction of non-fiber pulp addition, tobacco, and tobacco preparation, can solve problems such as lightening of smoke flavor, lack of aroma, and reduction of mainstream particle phase aroma components in cigarettes, achieving reduced irritation, The effect of increasing the amount of aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

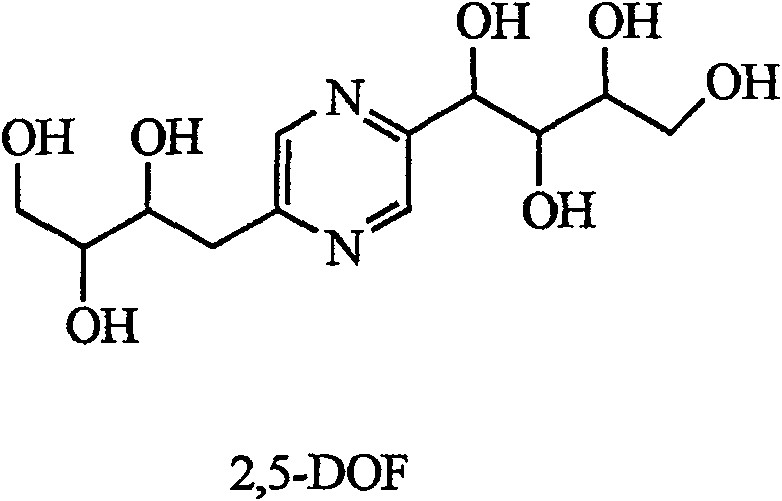

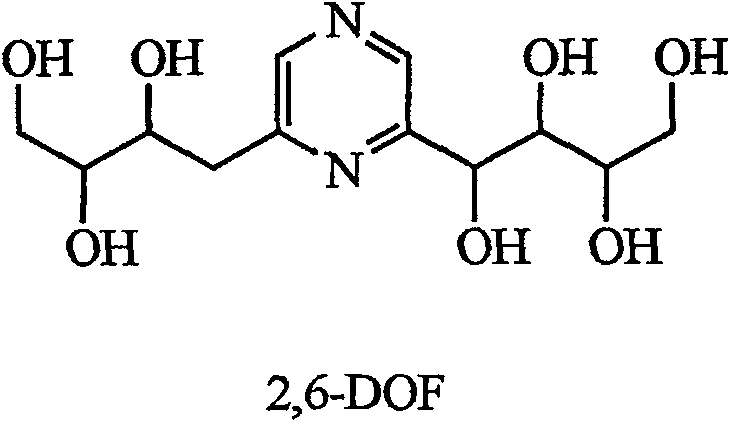

Method used

Image

Examples

Embodiment 1

[0023] Take 0.2% deoxyfructosine, 0.1% furfural, 0.1% 5-methyl-furfural, 0.2% 3-ethyl-2-hydroxyl-2-cyclopenten-1-one, 0.5% Peruvian extract by weight, 0.2% of methyl palmitate, 0.2% of damascenone, 0.3% of macrostigmatrienone, 0.5% of cocoa powder tincture, 97.7% of ethanol containing 50% of water, and the above raw materials are mixed to prepare the additive of the present invention, The additive is added in the feeding link with an amount of 5% relative to the weight ratio of the tobacco leaf of the low-tar cigarette.

Embodiment 2

[0025] Take 1% of deoxyfructosine, 0.1% of 5-methyl-furfural, 0.2% of 3-ethyl-2-hydroxy-2-cyclopenten-1-one, 5% of Peruvian extract, and methyl palmitate by weight 0.2% of ester, 0.2% of damascenone, 0.3% of macrostigmatrienone, 0.1% of propionic acid, 0.1% of cocoa powder tincture, 92.8% of ethanol containing 50% of water, and the above raw materials are mixed to prepare the additive of the present invention , the additive is added in the feeding link with an amount of 0.1% relative to the weight ratio of the tobacco leaves of the low-tar cigarette.

Embodiment 3

[0027] Take 3.5% deoxyfructosine, 0.1% furfural, 0.2% 5-methyl-furfural, 0.1% 3-ethyl-2-hydroxyl-2-cyclopenten-1-one, 0.8% Peruvian extract by weight, 0.5% of methyl palmitate, 0.1% of damascenone, 0.2% of macrostigmatrienone, 2% of cocoa powder tincture, 0.1% of propionic acid, 92.4% of ethanol containing 50% of water, and the above raw materials are mixed to prepare The additive of the present invention is added in the flavoring link with an amount of 0.2% relative to the weight ratio of the cured shredded tobacco (tobacco leaf) of the low-tar cigarette.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com