Preparation method of burley tobacco extract

A Burley tobacco fine extraction technology, applied in the field of preparation of Burley tobacco fine extract, can solve the problems of weak aroma and texture of low-tar cigarettes, unsuitable for flue-cured tobacco, and reduced cigarette aroma, so as to increase fine smoke, The effect of increasing the concentration of flue gas and easy operation and implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A preparation method of burley tobacco extract, comprising the following steps:

[0016] (1) Take Burley tobacco, add water at a weight ratio of 1:12, and extract volatile oil by steam distillation to obtain Burley tobacco volatile oil A.

[0017] (2) After extracting the volatile oil, filter, filtrate B for later use, add water to the filter residue at a weight ratio of 1:10 for reflux extraction, reflux for 2.0 hours, filter while hot, and filtrate C for later use, and the filter residue can be directly used in the production of reconstituted tobacco leaves by the papermaking process.

[0018] (3) Filtrates B and C are combined and concentrated at 42°C to a density of 1.202g / cm 3 , to obtain Burley tobacco extract D.

[0019] (4) After adding 3.0 times the weight of ethanol with a mass fraction of 95% to the Burley tobacco extract D, settling and filtering, the filtrate was concentrated under reduced pressure to a density of 0.926 g / cm 3 , to obtain Burley tobacco c...

Embodiment 2

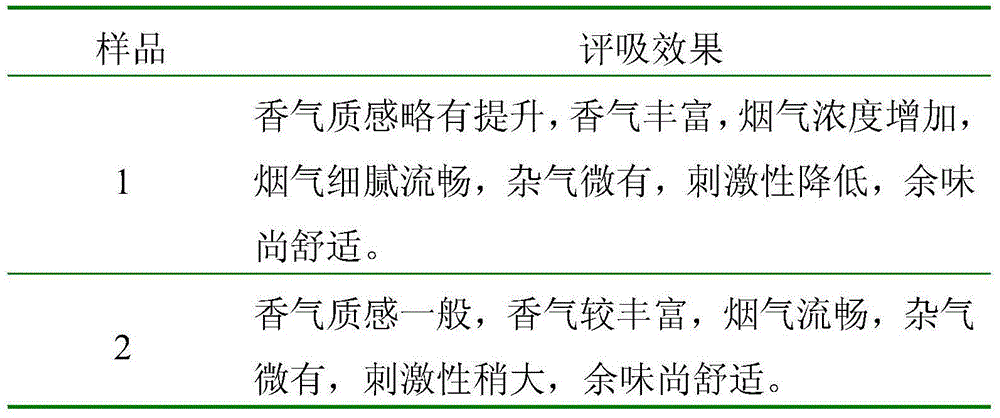

[0022] Weigh burley tobacco extract and add 0.06% to the low-tar cigarette leaf group formula (6mg / cigarette) with a price of 10 yuan, adjust the moisture content of shredded tobacco to about 12.5%, roll it into cigarettes, and put it in at a temperature of 22°C±1 , The relative humidity is 60% ± 2% in a constant temperature and humidity box for more than 48 hours to balance as sample 1 of the present invention, please evaluate the suction group to evaluate the suction. Under the same conditions, the same shredded tobacco was sprayed with the same amount of distilled water, and rolled into cigarettes as sample 2 of the blank control. Please refer to Table 1 below for the evaluation results.

[0023] Table 1 Sample 1 and sample 2 evaluation comparison

[0024]

[0025] The results in Table 1 show that the extraction of the burley tobacco extract obtained in the present invention and added to the 10 yuan low-tar cigarette has the effects of reducing thorns, increasing flavor...

Embodiment 3

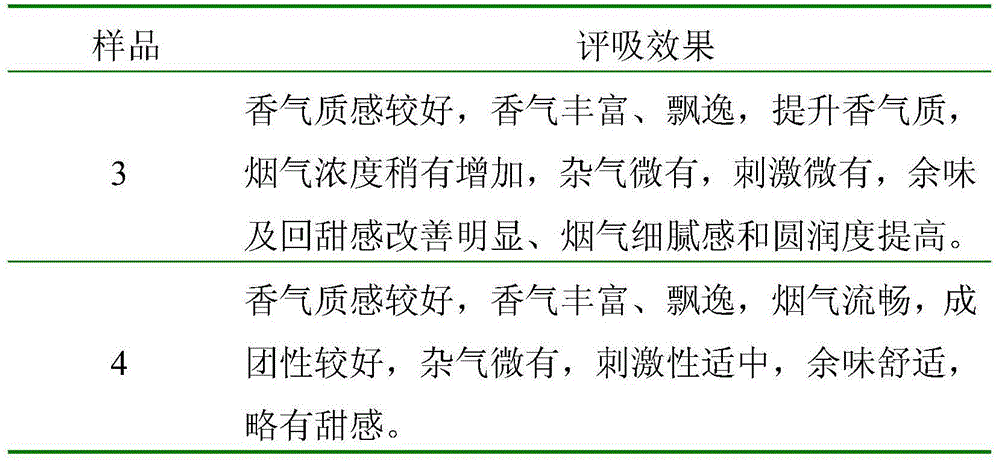

[0027] Weigh 0.06% of Burley tobacco essence and add it to the low-tar cigarette leaf group formula (6mg / stick) at the price of 40 yuan, adjust the moisture content of cut tobacco to about 12.5%, roll it into cigarette sticks, and put them in at a temperature of 22°C±1 1. The relative humidity is 60% ± 2% in a constant temperature and humidity box for more than 48 hours to balance as sample 3 of the present invention, and the evaluation group is invited to evaluate the suction. Under the same conditions, the same shredded tobacco was sprayed with the same amount of distilled water, and rolled into cigarettes as sample 4 of the blank control. Please refer to Table 2 below for the evaluation results.

[0028] Table 2 Sample 3 and sample 4 evaluation comparison

[0029]

[0030] The results in Table 2 show that the extraction of burley tobacco essence obtained in the present invention and added to 40 yuan low-tar cigarettes has the effects of reducing thorns, refining smoke, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com