Method for preparing tobacco shreds capable of improving smoking satisfaction and low tar cigarette

A technology of satisfaction and shredded tobacco, which is applied in the directions of preparing tobacco, tobacco, and processing tobacco, can solve the problems of low-tar cigarettes being difficult to obtain consumers' recognition, reducing the release of harmful components, and reducing the satisfaction of smoking cigarettes, so as to improve smoking. The effect of suction power, improvement of smoke plumpness, and strong satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

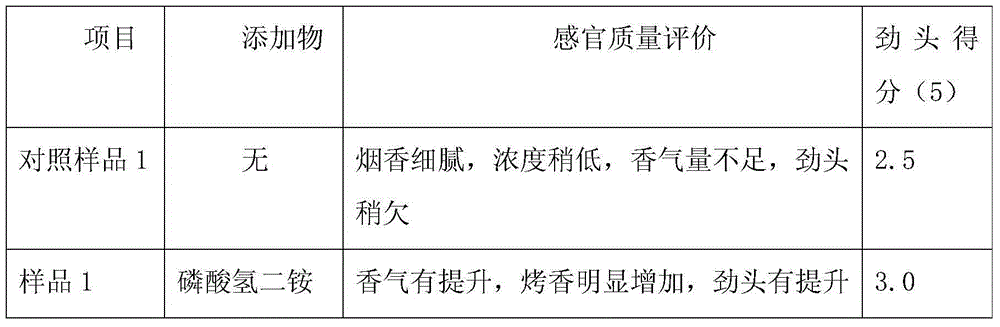

[0028] ① Diammonium hydrogen phosphate is dissolved in water, and added to the tobacco leaves at a rate of 0.2% by mass of the tobacco leaves, and then the tobacco leaves are alcoholized for 180 days; the alcoholized tobacco leaves are made into shredded tobacco, and the baking temperature is 120 ℃, the baking time is 5 minutes, the cut tobacco storage time is 3 hours, and the moisture content of the shredded tobacco is controlled to be 13%, which is the desired shredded tobacco of the cigarette.

[0029] ②According to the weight ratio of flue-cured tobacco: sun-cured tobacco=9:1, mix the composition of flue-cured tobacco and sun-cured tobacco, and then blend the above-mentioned shredded cigarette tobacco with the composition to prepare low-tar cigarette sample 1, the proportion of the above-mentioned shredded tobacco in the cigarette It is 40wt%, and the cigarette made of the above composition is used as the control sample 1, and the comparative smoking is carried out, and the...

Embodiment 2

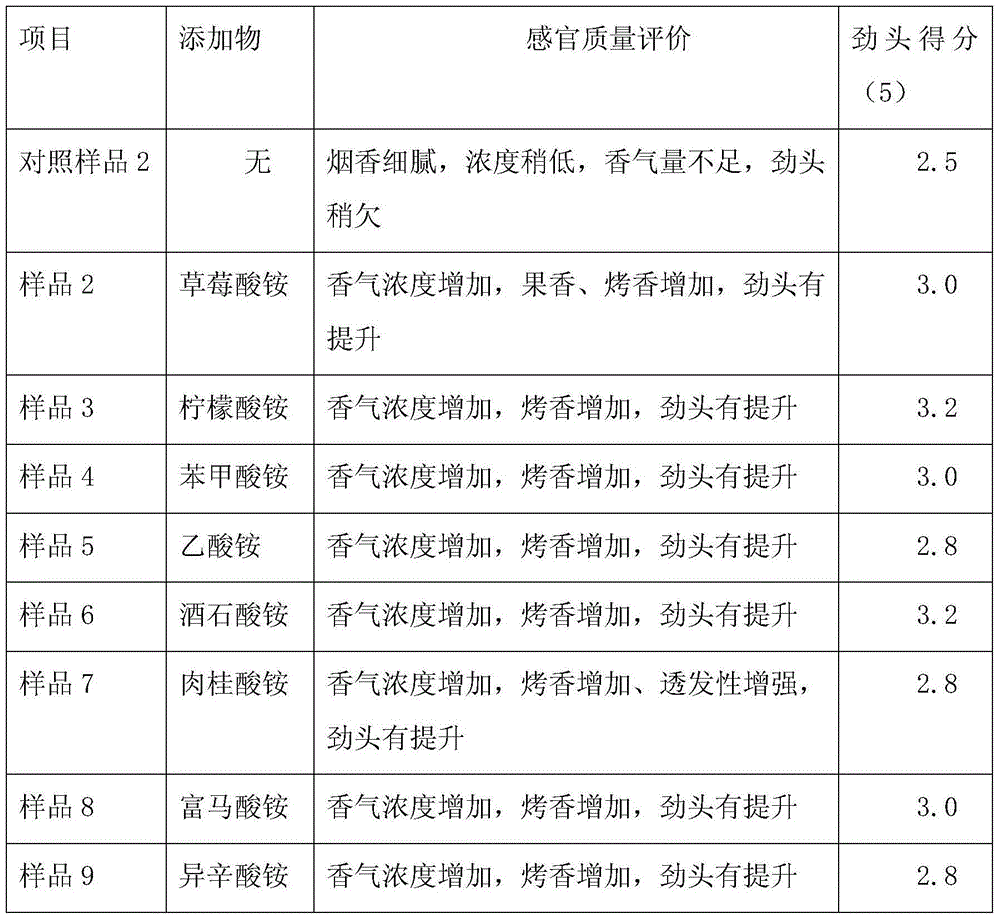

[0033] ① Prepare ethanol solutions of ammonium strawberry acid, ammonium citrate, ammonium benzoate, ammonium acetate, ammonium tartrate, ammonium cinnamate, ammonium fumarate, and ammonium isooctanoate, and spray them at a ratio of 0.5% of the mass of tobacco leaves on the tobacco leaves, and then alcoholize the tobacco leaves, the aging time is 90 days; the alcoholized tobacco leaves are made into shredded tobacco, the baking temperature is 120°C, the baking time is 5 minutes, the shredded storage time is 3 hours, and the moisture content of the shredded tobacco is controlled as 13%, which is the required shredded tobacco for cigarettes.

[0034] ②The shredded tobacco processed by the above technical scheme was blended with shredded flue-cured tobacco at a mass ratio of 20:80 to prepare low-tar cigarettes, which were named samples 2-9 respectively, and the cigarettes prepared entirely from shredded flue-cured tobacco were used as control sample 2 for comparison. The results ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com