Automatic bag sleeving device

A bagging device and automatic technology, applied in packaging and other directions, can solve the problems of increased manufacturing cost, low work efficiency, increased failure rate, etc., and achieve the effects of saving energy and manufacturing costs, improving bagging efficiency, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

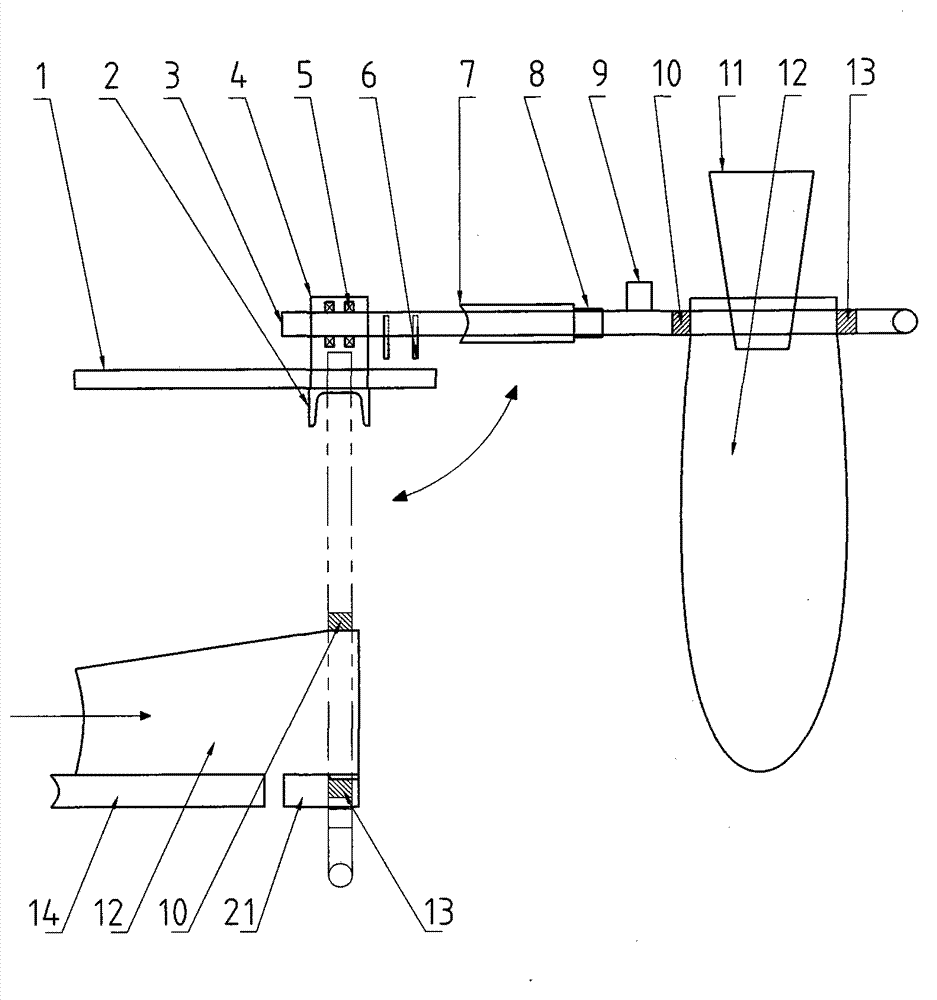

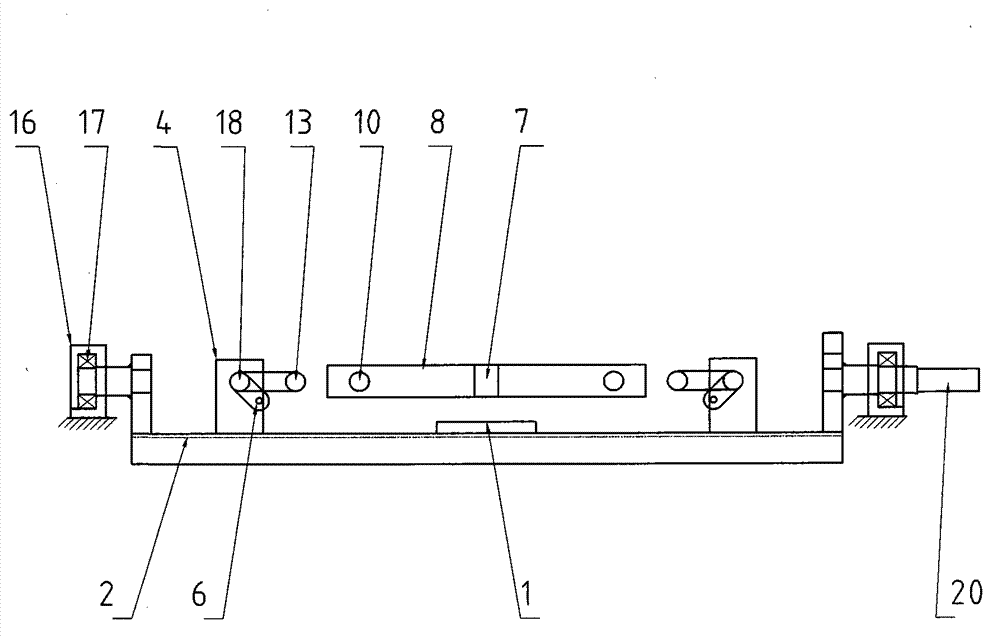

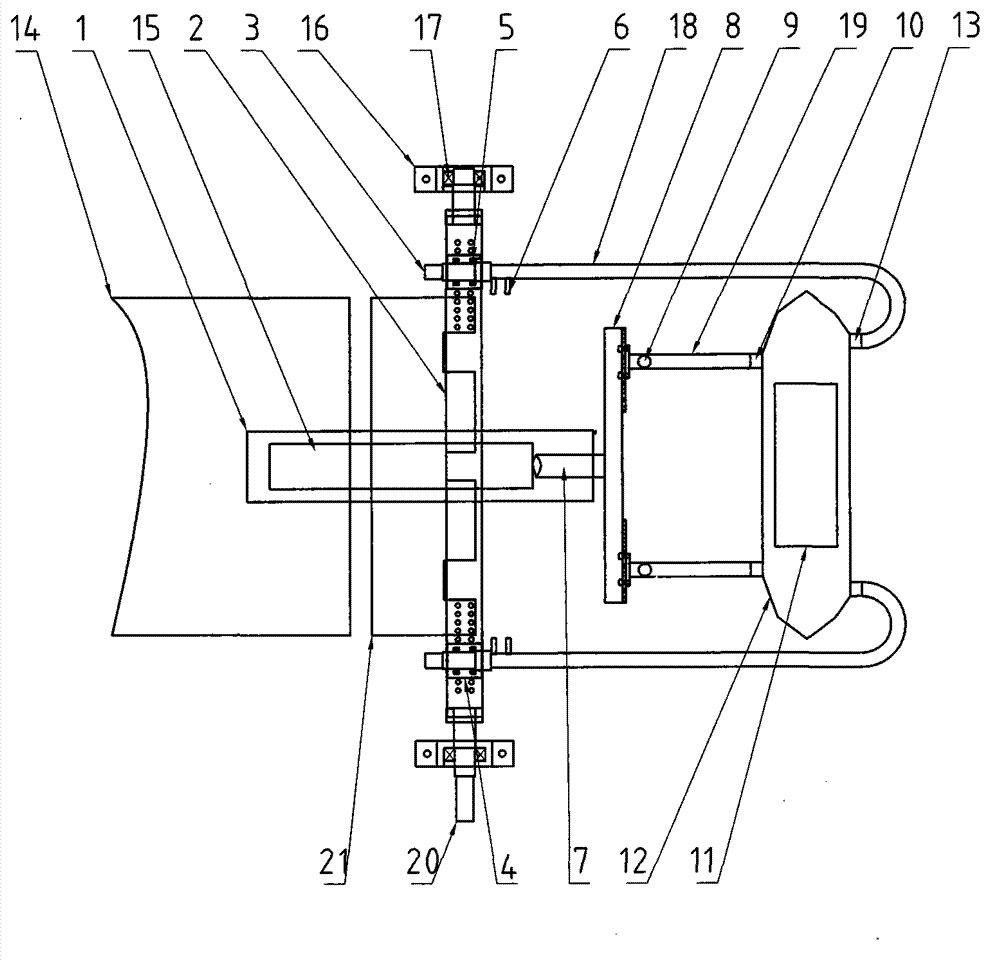

[0029] At first, explain: the inventive point of the present invention is in the bag-loading process, which is to complete the three processes of suction bag, bag opening (or being called as pulling the bag), and bagging (rotating bagging) as one station, and use simple Long and short rods 18 and 19 add suction heads 13 and 10 to realize this process.

[0030] see attached image figure 1 , the two sides of the frame correspond to the fixed bracket shaft bearing seat 16 and the bearing 17, see also Figure 2-Figure 3 , the two-sided symmetrical bearing 17 is equipped with a reciprocating 90° swing or a rotating shaft. The shaft here refers to the input shaft 20, and the inner ends of the input shaft 20 on both sides are connected to the fixed bracket shaft 2. There are three situations: one is that the inner ends of both sides of the input shaft 20 in the shaft are connected to the fixed bracket shaft 2, and the bracket shaft 2 is approximately in the shape of shape to reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com