Cigarette flavor essence for heating non-combustion cigarette as well as preparation method and application of cigarette flavor essence

A heat-not-burn, cigarette technology, applied in the field of tobacco flavors and fragrances, can solve the problems of incomplete tobacco components, sensory quality differences, different aroma senses, etc., and achieve the effects of rich aroma, good satisfaction, and good suction power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~14

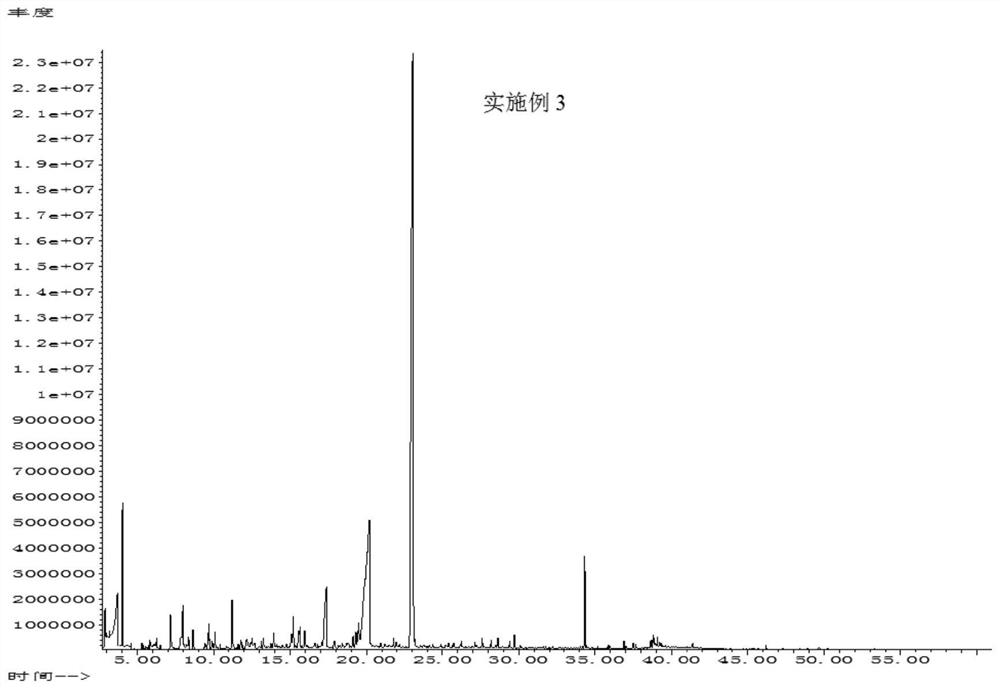

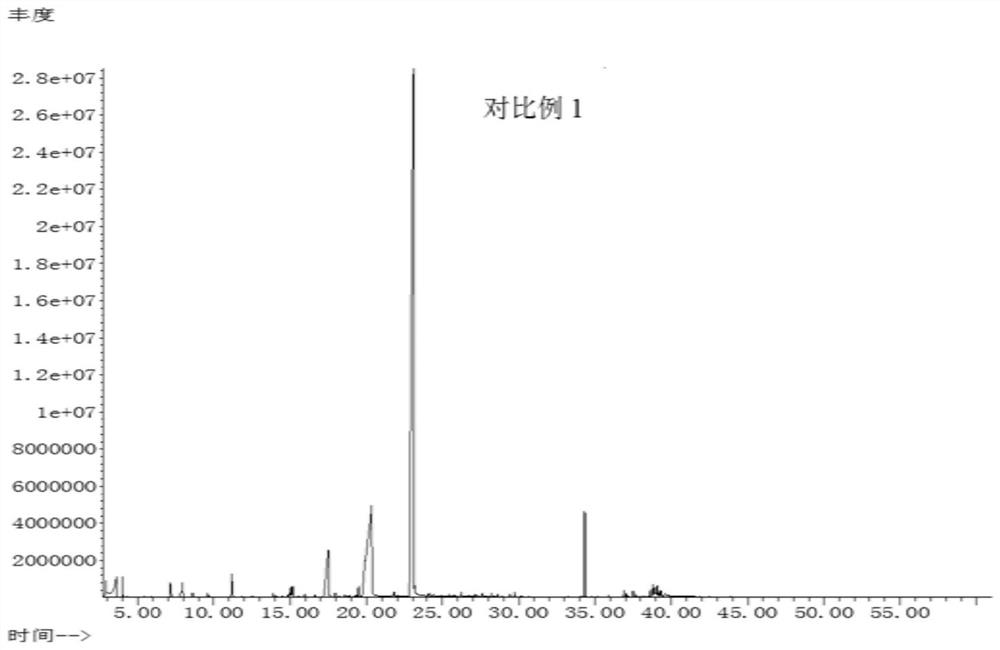

[0045] This example provides a series of flavoring essences for heat-not-burn cigarettes, which are prepared according to the formula in Table 1 as follows:

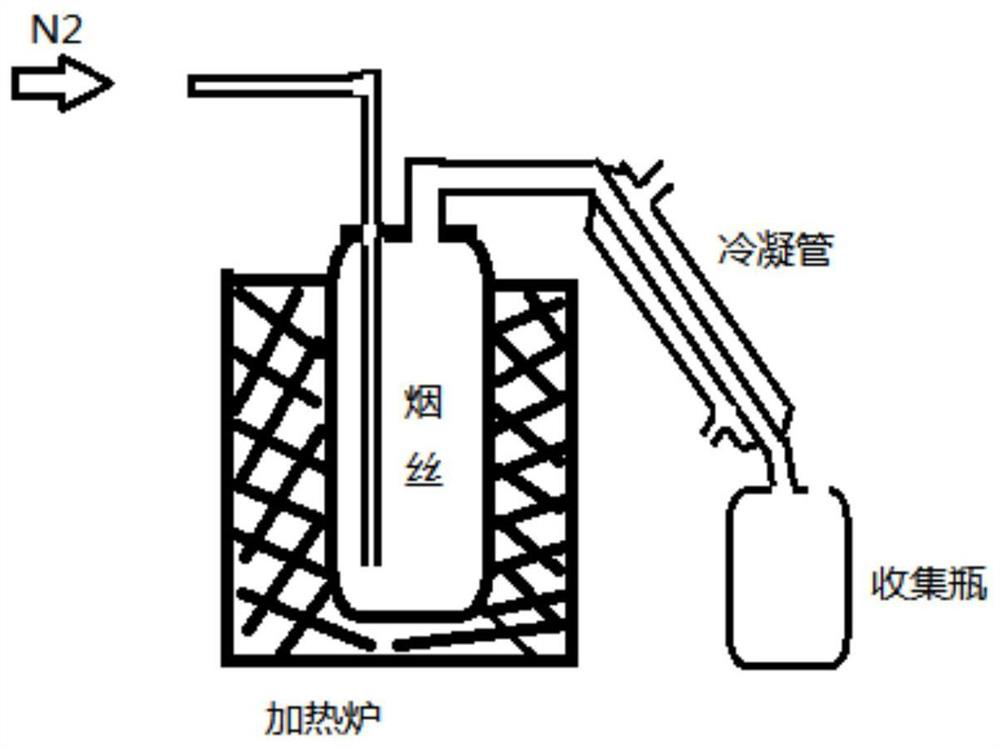

[0046] After the tobacco raw material, organic solvent, reducing sugar and amino acid are mixed evenly, they are placed in a heating box with a stainless steel liner that can precisely control the temperature (the schematic diagram of the preparation device is shown in figure 1 shown), set the heating temperature, feed nitrogen at the same time, carry out dry distillation, condense and collect through a condenser tube filled with water, until no liquid flows out, and then the tobacco flavor essence for heat-not-burn cigarettes is obtained.

[0047] Table 1 Composition (parts by weight) of flavoring essence for heat-not-burn cigarettes

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com