Dry distillation equipment for dynamic circulation extraction of spices

A dynamic circulation and fragrance technology, applied in the direction of essential oil/fragrance, fat production, etc., can solve the problems of inability to obtain water-soluble volatile components, single dry distillation environment, and loss of top fragrance, so as to facilitate research and analysis and achieve high yield , full-bodied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

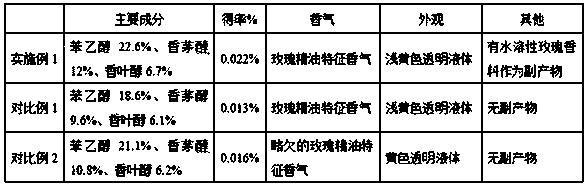

Embodiment 1

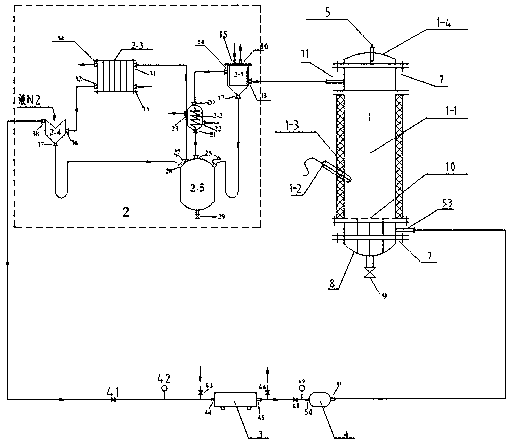

[0036] As shown in the figure, the dry distillation equipment for dynamic circulation extraction of spices includes a dry distillation extraction kettle 1, a multi-stage condensation recovery device 2, an air pump 3 and a gas preheating device 4; The far-infrared heating jacket 1-3 on the outer wall of the warehouse 1-1, the temperature probe 1-2 inserted in the raw material warehouse 1-1, the air outlet Ⅰ11 set on the upper part of the raw material warehouse 1-1, and the The air inlet I53 in the lower part, the temperature probe 1-2 is used to observe the temperature in the cylinder; the multi-stage condensation recovery device 2 includes an air condenser 2-1, a water condenser 2-2, and a spice collection tank connected by pipelines in sequence 2-5. Refrigerated liquid condenser 2-3 and liquid N 2 cold trap 2-4; the gas outlet I11 of the raw material bin 1-1 is connected to the air inlet II13 of the air condenser 2-1 through a pipeline, and the liquid N 2 The gas outlet 38 o...

Embodiment 2

[0055]Extracting the agarwood fragrance: open the charging cover 1-4 of the dry distillation extraction kettle 1, load 20 kg of agarwood debris, and cover the charging cover 1-4. Open the passage valve I41, close the intake valve 43, open the exhaust valve 46, close the passage valve II48, start the air pump 3, and vacuum the system. When the vacuum degree no longer rises, turn off the air pump 3 and close the exhaust valve 46. Open channel valve II48. Use the negative pressure of the system to inhale nitrogen from the intake valve 43 to reduce the vacuum degree of the vacuum pressure gauge I42 to 0Mpa. Then close the intake valve 43, start the air pump 3, and the system circulates under nitrogen gas phase and normal pressure conditions. Turn on the condensation system of the multi-stage condensation recovery device ②, turn on the gas preheating device 4, turn on the far-infrared heating switch of the dry distillation extraction kettle 1, and control the temperature at 260°C....

Embodiment 3

[0062] Tobacco flavor extraction: open the charging cover 1-4 of the dry distillation extraction kettle 1, load 15 kg of tobacco leaf fragments, and cover the charging cover 1-4. Open the passage valve I41, close the intake valve 43, close the exhaust valve 46, open the passage valve II48, start the air pump 3, and the system circulates under the condition of air gas phase and normal pressure. Turn on the condensing system of the multi-stage condensation recovery device 2, turn on the gas preheating device 4, turn on the heating switch of the far-infrared jacket 1-3 of the dry distillation extraction kettle 1, and control the temperature at 360 ° C. Under the action of heating, the moisture and spices of the tobacco leaves are brought into the multi-stage condensation recovery device 2 by the circulating gas and condensed and recovered into the spice collection tanks 2-5. In the first 30 minutes, due to the presence of oxygen, the tobacco leaves are partially burned, and the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com