Method for preparing aromatized tar reduction cut tobaccos

A technology of shredded tobacco and tobacco sheet, which is applied in the preparation of tobacco, tobacco, and application. It can solve the problems of weakened cigarette aroma, unsatisfied physiological experience, and unseen problems, so as to reduce irritation, reduce harm, and reduce coke consumption. The effect of improving filling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

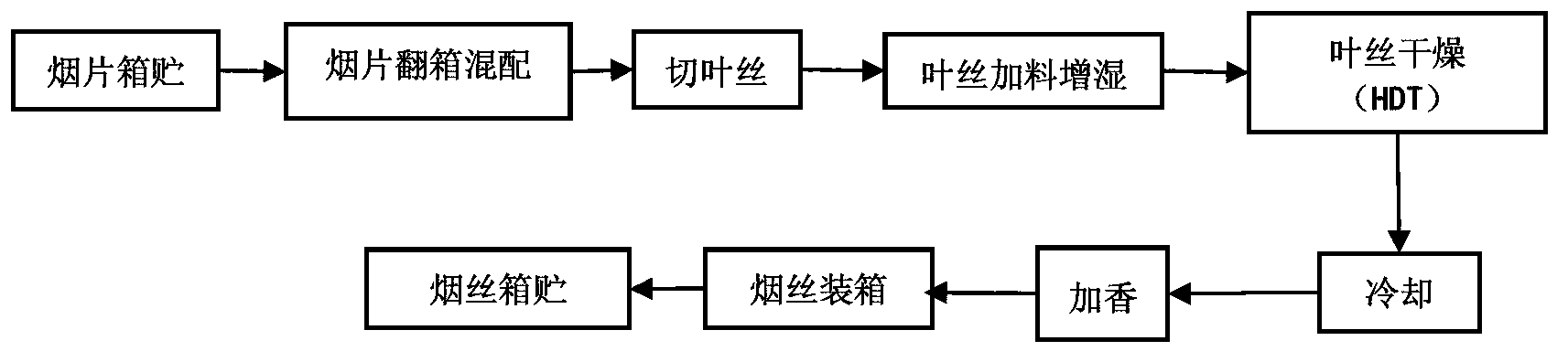

Method used

Image

Examples

Embodiment 1

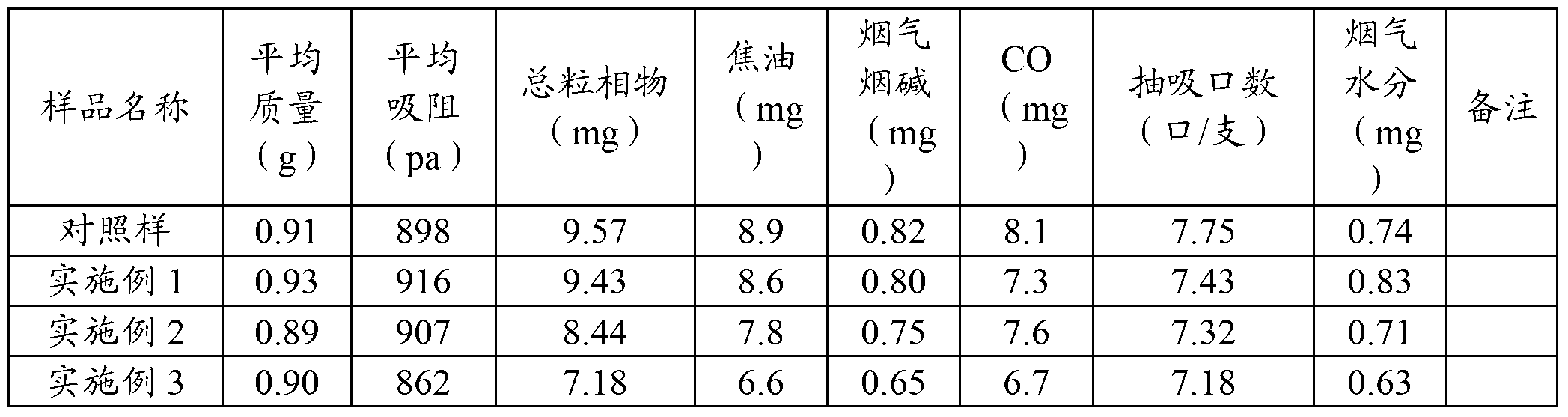

[0019] Burley tobacco flakes and flue-cured tobacco flakes were evenly mixed in a blending ratio of 1:19, cut into shredded tobacco with a width of 0.90 mm by a shredder, and fed and humidified through a shredding machine. The discharge temperature of shredded tobacco was 72°C, the moisture content of the shredded tobacco is 22%; the shredded tobacco after feeding and humidification is passed through the HDT hot air duct, and the hot air with a working air temperature of 190°C is used to control the moisture content of the shredded tobacco to 13.0%, and the temperature of the shredded tobacco is controlled The temperature is 62°C; the shredded tobacco is cooled and the moisture content of the shredded tobacco is kept at 12.5%, and the aromatized reduced-tar tobacco is obtained after adding surface aroma, which is used to produce low-tar cigarettes.

Embodiment 2

[0021] After the burley tobacco sheet and the flue-cured tobacco sheet are mixed evenly in a blending ratio of 1:9, cut into shredded tobacco with a width of 0.90 mm by a shredder, and then feed and humidify through a shredding machine, and the discharge temperature of the shredded tobacco is 73°C, the moisture content of the shredded tobacco is 22.5%; the mixed shredded tobacco after feeding and humidification is passed through the HDT hot air duct, and the hot air with a working air temperature of 210°C is used to control the moisture content of the shredded tobacco to 13.0%, and the temperature of the shredded tobacco is controlled The temperature is 62.5°C; the shredded tobacco is cooled and the moisture content of the shredded tobacco is kept at 12.5%, and the flavored reduced-tar tobacco is obtained after adding surface aroma, which is used to produce low-tar cigarettes.

Embodiment 3

[0023] Burley tobacco flakes and flue-cured tobacco flakes were evenly mixed at a blending ratio of 5:17, cut into shredded tobacco with a width of 0.90 mm by a shredder, and fed and humidified through a shredding machine. The discharge temperature of shredded tobacco was 74°C, the moisture content of the shredded tobacco is 23%; the mixed shredded tobacco after feeding and humidification is passed through the HDT hot air duct, and the hot air with a working air temperature of 230°C is used to control the moisture content of the shredded tobacco to 13.0%, and the temperature of the shredded tobacco is controlled 63°C; cool the shredded tobacco and keep the moisture content of the shredded tobacco at 12.5%. After adding the surface aroma, the flavored reduced-tar tobacco is obtained, which is used to produce low-tar cigarettes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com