Reconstructed tobacco coating liquid component-component group chemical kitchen combination, coupling preparation, and coupling preparation process

A technology for reconstituting tobacco leaves and coating liquid, which is used in the preparation of tobacco, tobacco, food science, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

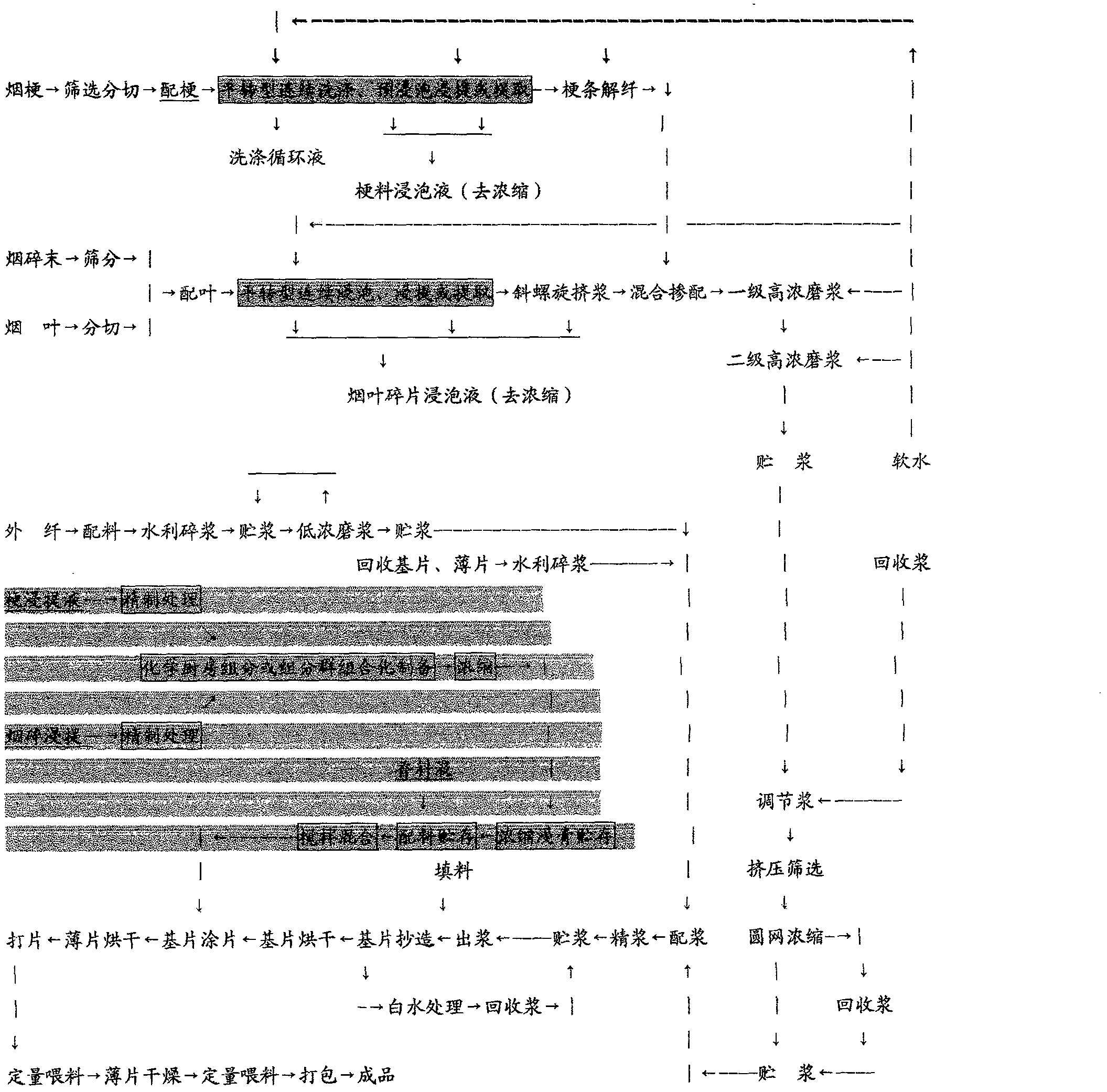

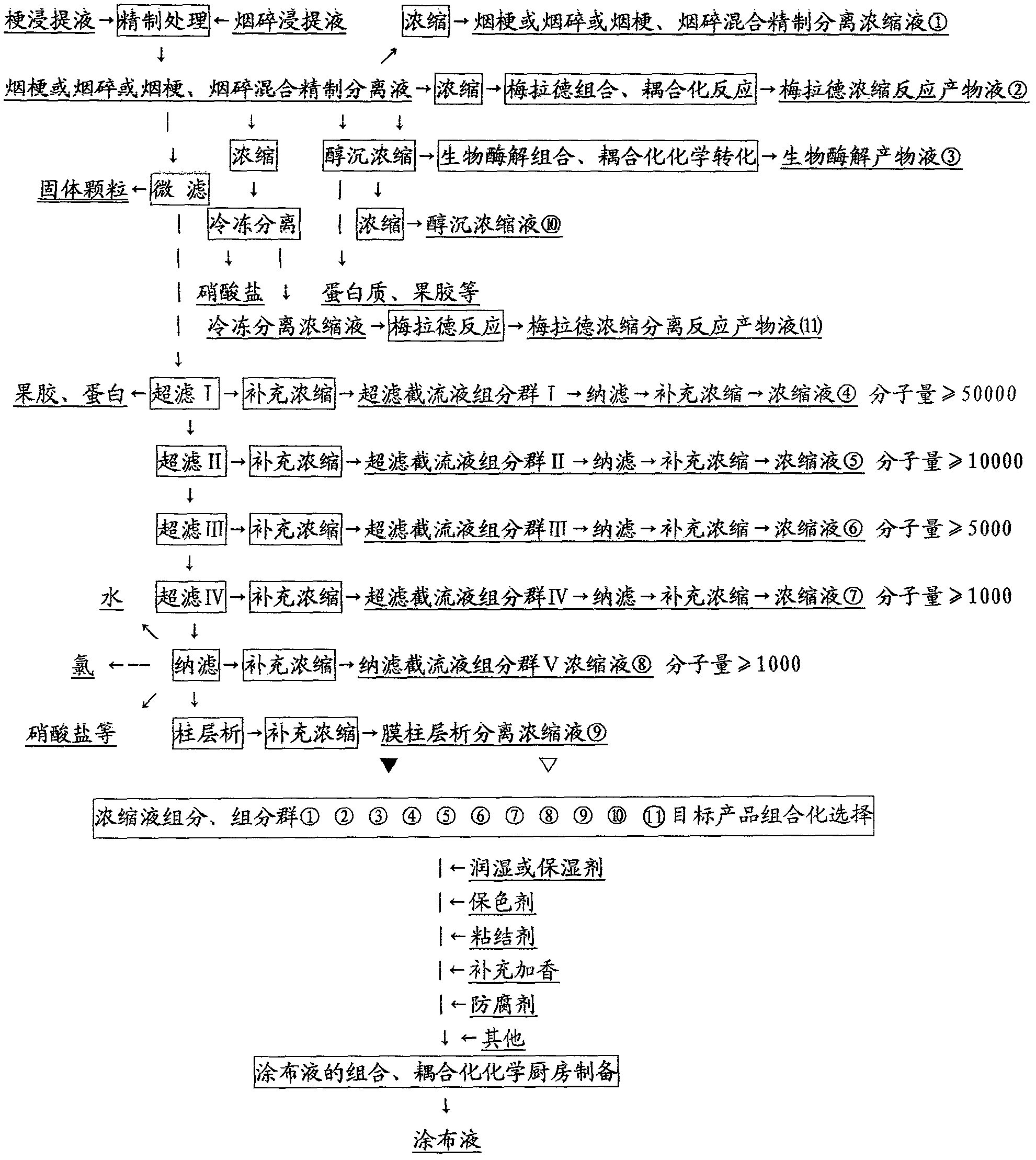

[0106] 1. A reconstituted tobacco leaf coating solution component and component group chemical kitchen combination, coupled preparation and process thereof, characterized in that it comprises the following steps:

[0107] The first step, composition of raw materials: Compatible raw materials according to the technical requirements of the target product of reconstituted tobacco leaves, consisting of tobacco stem mixture and tobacco leaf fragment mixture. The mixture of tobacco stems can be composed of short stems, tobacco stems, etc.; the mixture of tobacco leaf fragments can be composed of tobacco leaf fragments, tobacco powder, crushed tobacco rods, etc. Tobacco stem mixture:tobacco leaf fragment mixture=3~5:7~5. The moisture content of raw materials is 8-15%.

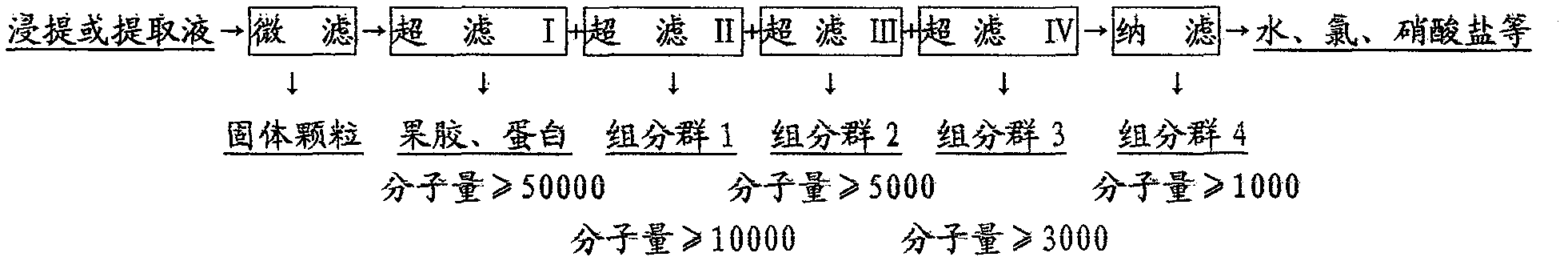

[0108] The second step is water washing, pre-soaking, leaching or extraction, enzymatic hydrolysis combination, coupling preparation and process of the washing stem material: after metering and water washing, the tob...

Embodiment 2

[0168] A process of water washing, presoaking, enzymatic hydrolysis combination, coupled extraction or extraction of tobacco stem material: after metering and water washing, the tobacco stem mixture is presoaked, extracted or extracted according to the process requirements of the target product of reconstituted tobacco leaves, enzymolysis. Stem washing solvent: soft water, washing water temperature: 30-40°C, washing time 30-50 seconds; pre-soaking solid-liquid ratio controlled at 1:2.5-4, pre-soaking temperature controlled at 50-90°C, pre-soaking time 20-50 seconds 30min; the leaching or extraction process can be two-step or three-step countercurrent leaching or extraction or horizontal type continuous leaching or extraction. The leaching or extraction solvent is generally soft water, and the solid-liquid ratio of the leaching or extraction is controlled at 1:4~ 8. The leaching or extraction temperature is controlled at 60-95°C, and the leaching or extraction time is 30-90min / ...

Embodiment 3

[0173] Pre-soaking, leaching or extraction, enzymatic hydrolysis combination, coupling preparation and its process of tobacco leaf fragments: according to the product process requirements, the mixture of tobacco leaf fragments is compatible, and pre-soaking, leaching or extraction, enzymatic hydrolysis, and leaching are carried out after metering. The process can adopt two-step or three-step countercurrent leaching or extraction or horizontal type continuous leaching or extraction. The leaching solvent is soft water, the solid-liquid ratio is controlled at 1:5-10, the pre-soaking temperature is controlled at 50-75°C, and the pre-soaking temperature is controlled at 50-75°C. The soaking time is 20-30min; the leaching or extraction temperature is controlled at 60-90°C, and the leaching or extraction time is 30-90min / step; the amount of enzyme added is 0.05%-5% of the mass of tobacco, and the enzymatic hydrolysis temperature is 20-70 °C, the stirring speed is 10-60rmp, the water c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com