Culturing method of one-ridge double-row flue-cured tobacco dislocation

A flue-cured tobacco and timely technology, which is applied in field preparation methods, botanical equipment and methods, horticulture, etc., achieves the effects of low ridge height, improved space utilization of tobacco fields, and guaranteed income of tobacco farmers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

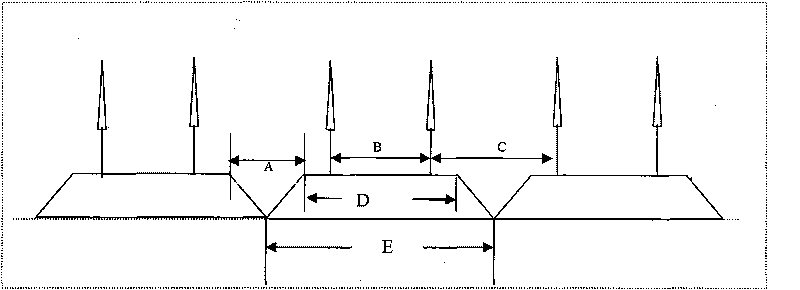

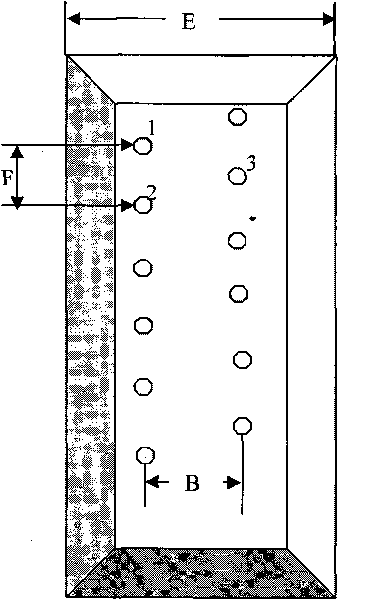

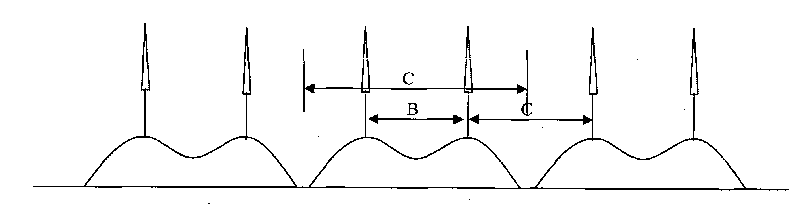

[0026] as attached Figure 1-3 A ridge of flue-cured tobacco is cultivated in two rows, wherein: the distance A between the furrows is 0.4m, the row spacing B between the two rows of tobacco on the ridge is 0.75-0.8m, and the row spacing C between the two rows of tobacco between the ridges is 1.0-1.05m. The width D of the ridge body is 1.4m, the distance E between the ridges is 1.8m, and the distance between two tobacco plants is F. Three adjacent flue-cured tobacco plants form an isosceles triangle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com