Non-Combustion Smoking Tool

a smoking tool and non-combustion technology, applied in the field of tools, can solve the problems of reducing work efficiency, reducing work time, and unsatisfactory smell of non-smokers in the room or car, and achieve the effects of reducing the amount of electric power used, increasing heat utilization efficiency, and small heaters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

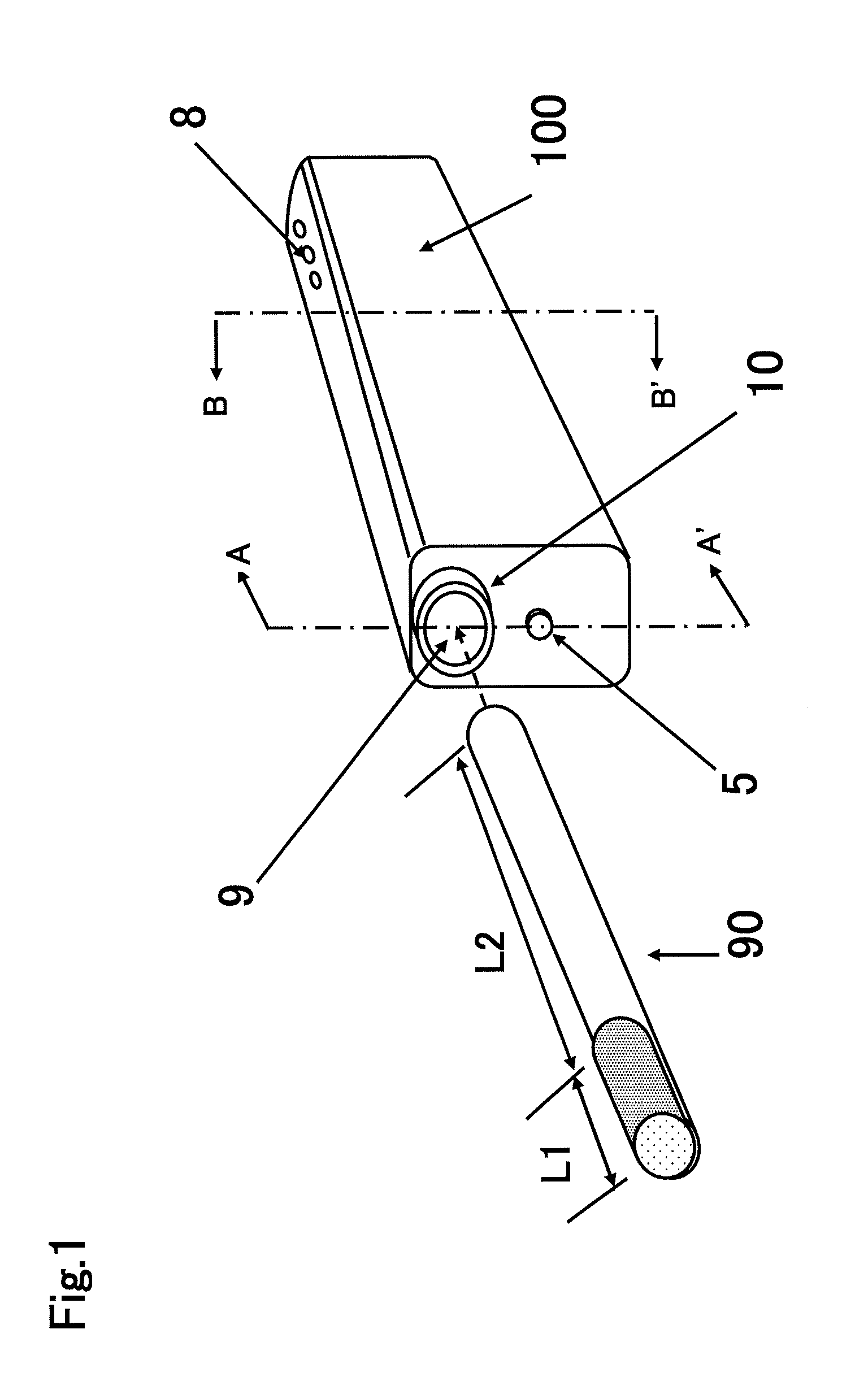

[0043]FIG. 1 shows appearance of an example of a tool according to the present invention. A tool 100 comprises: a tobacco insertion opening 9 for inserting a filter cigarette 90; a projection 10; an indicator 5 for indicating an operation state; a connector 6 (shown in FIG. 2) for receiving electric power from outside; an outside air inlet 8; and inner constituents shown in FIG. 2.

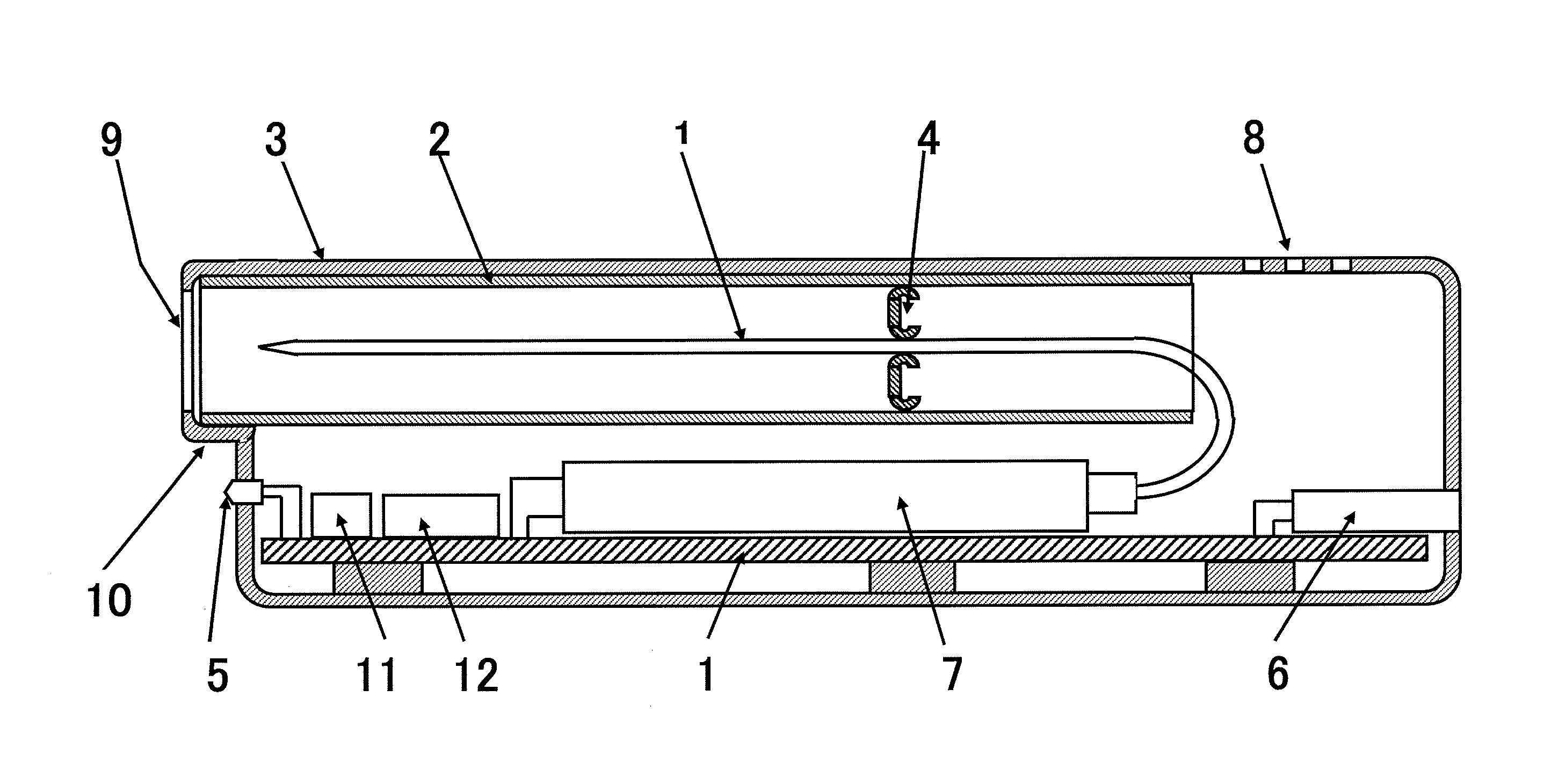

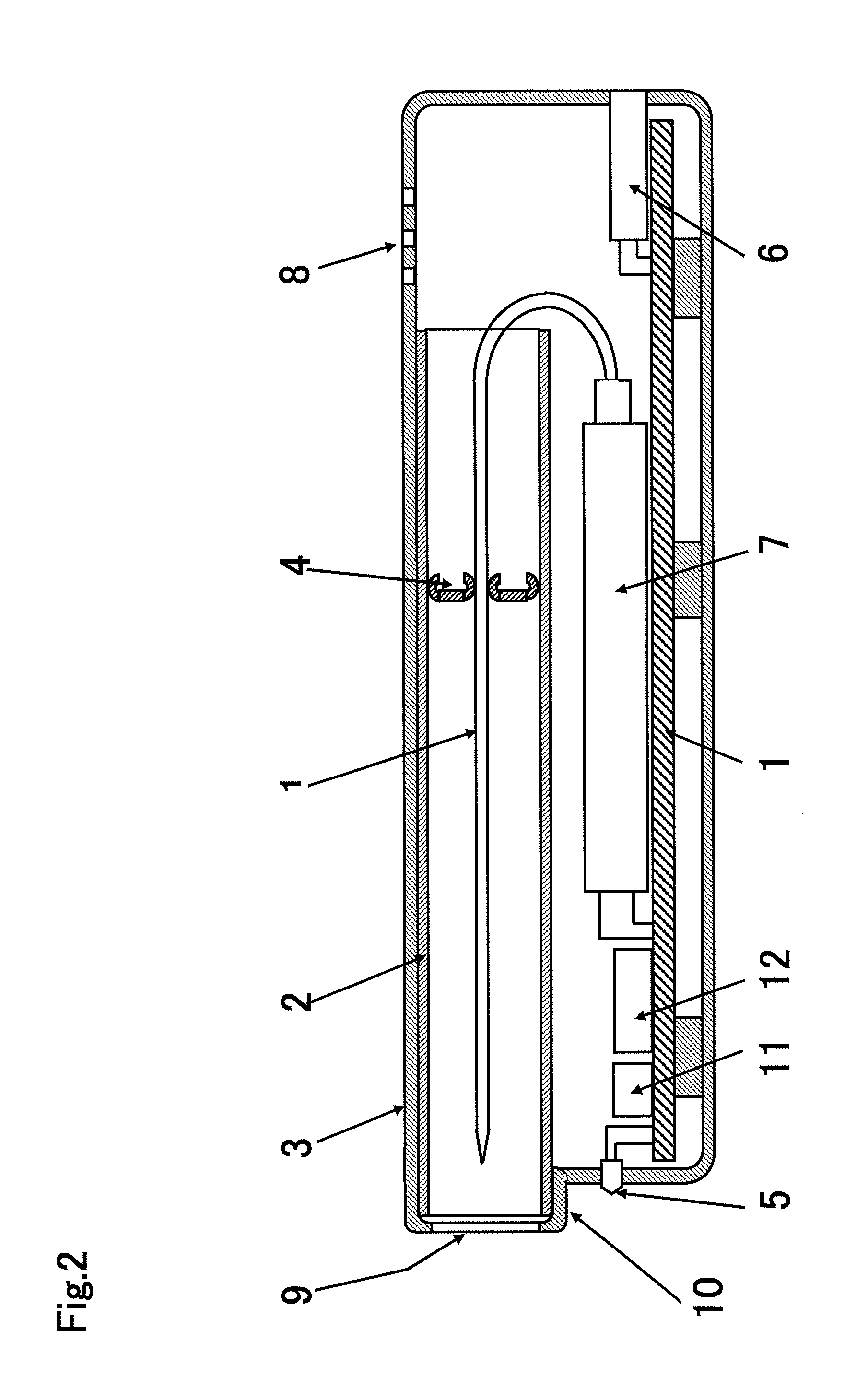

[0044]FIG. 2 is a view for explaining the inner structure along section line A-A′ of FIG. 1. The tool of the present invention basically comprises: a slender heater 1 with a heater sleeve 7; a thermal insulation pipe 2 for preventing heat of the heater 1 from being transferred to an outer case 3; the outer case 3 with the outside air inlet 8; a stopper 4 for fixing an insertion stop position of the filter cigarette; the indicator 5 for indicating the operation state of the tool; and the connector 6 for receiving electric power from outside. The heater sleeve 7 includes a sealing portion 28 for securing lon...

example 2

[0058]Hereinafter, a slender heater 1 having a sharp end to be used for the present invention will be described in detail.

[0059]Approximate dimensions of a general filter cigarette 90 are tobacco portion L2=58 mm, filter portion L1=26 mm, and diameter=8 mmΦ.

[0060]Insertion of a slender heater into the filter cigarette 90 is not easy. First of all, it is required to have a sharp end as a condition.

[0061]FIG. 5 shows a cross-sectional view of an inner structure of a general slender heater 1. A metal tube 22 is sealed with an end sealing portion 21 to prevent moisture from entering inside. The metal tube 22 has inside a resistance heating wire 24 (which portion is heated to serve as a heater) and an inner lead wire 25 connected to the resistance heating wire 24 by welding, and contains magnesium oxide powder 23 filled inside. The inner lead wire 25 which extends from the heater sleeve 7 is in turn connected on the outside to a lead wire 8 made of a solderable wire. While the end sealin...

example 3

[0066]Next, tobacco leaves of a real filter cigarette were taken out, and the components vaporized from the tobacco leaves were analyzed, using a gas chromatography mass spectrometer, by putting only the tobacco leaves in a vessel and heating the vessel. Here, a focus was placed on the amount of nicotine produced among the components vaporized from the tobacco leaves, and its data were obtained. Table 2 shows the results. The heating time was 5 minutes.

TABLE 21Heating temperature = 70° C.1000 μg2Heating temperature = 150° C.3600 μg3Heating temperature = 200° C.4300 μg4Heating temperature = 230° C.4300 μg5Heating temperature = 250° C.3060 μgLeaves get combusted.6Heating temperature = 280° C.1027 μgLeaves get combusted.

[0067]An encyclopedia says that nicotine is oily liquid with a boiling point (decomposition) of 247° C. The reduction in the analyzed data amount when the heating temperature reaches 250° C. is presumably because decomposition of nicotine vaporized out of the tobacco le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com