Automatic grading system and method based on mass tobacco leaf data

A tobacco leaf and data technology, applied in the field of automatic grading system, can solve the problems that there are no equipment and technical inventions that can comprehensively detect and extract the characteristics of tobacco leaf automatic grading, and can not meet the actual requirements, so as to improve the speed, ensure the effectiveness, reduce the effect of complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] see figure 1 , the automatic grading system based on massive tobacco leaf data is characterized in that it includes the following components, connected through a gigabit switch (8):

[0054] Camera and video capture card (2): used to collect images of tobacco leaves (1);

[0055] PC1 image acquisition and processor (3): by using the camera (2) and video acquisition card to collect, preprocess and feature extract the real scene, construct the classification model of relevant tobacco leaves;

[0056] PC2 storage and search engine processor (4): responsible for system data query, storage and search of relevant tobacco images and feature data, and management of expert tobacco leaf grading rule base;

[0057] PC3 communication and system monitoring processor (5): it is the communication and control center of the system, and also completes tasks such as grading information audio output control, grading information display control, and hardware equipment status monitoring;

...

Embodiment 2

[0066] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0067] 1) The camera and video capture card (2): The LCH-P49A industrial camera of CBC Company is used, which has backlight compensation, automatic white balance, automatic gain control and other functions. Its camera uses 1 / 4"CCD (3.2×2.4mm), with a horizontal resolution of 500 lines. The parameters of the lens are adjustable, the focal length range is 4-9mm, the maximum aperture ratio is 1:1.6, and the horizontal viewing angle range is 51.8°- 23.8°, the adjustable range of vertical viewing angle is 38.3°-17.8°, the camera has many adjustable parameters, the resolution is high, and the image quality captured by it is very good, it is a choice that is more in line with the original design intention; for the camera, The Microview V211 video capture card is used, which is based on the PCI bus and collects two-way high-quality real-time professional image capture cards of PAL ...

Embodiment 3

[0074] see figure 2 , this automatic grading method based on massive tobacco leaf data, adopts the above-mentioned system to operate, and its characteristics are as follows:

[0075] 1): Image collection: use a camera and a video capture card (2) to collect images of tobacco leaves in the area to be detected;

[0076] 2): Feature acquisition: analyze and preprocess the tobacco leaf image, retain the image part of visual concern, remove noise, and then extract the relevant detailed features of the tobacco leaf to ensure the sparsity and relevance of the data;

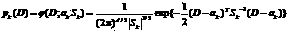

[0077] 3): Model construction: Obtain different types of tobacco leaf characteristic data from the tobacco leaf characteristic database, carry out model construction, and provide models for subsequent decision-making;

[0078] 4): Tobacco leaf grading: analyze the tobacco leaf image and characteristic data, obtain expert knowledge through the expert tobacco leaf grading rule base, and obtain the corresponding tobacco l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal viewing angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com