New technology for curing red flower gold dollar tobacco leaf to be yellow and fragrant

A technology of safflower big gold and new technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of poor aroma, floating green, and green veins in tobacco leaves, so as to reduce the rate of green smoke, reduce blue veins, improve aroma quality and The effect of appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] For the Honghua Dajinyuan tobacco leaves from a certain origin in Sichuan Province, the following baking process is adopted:

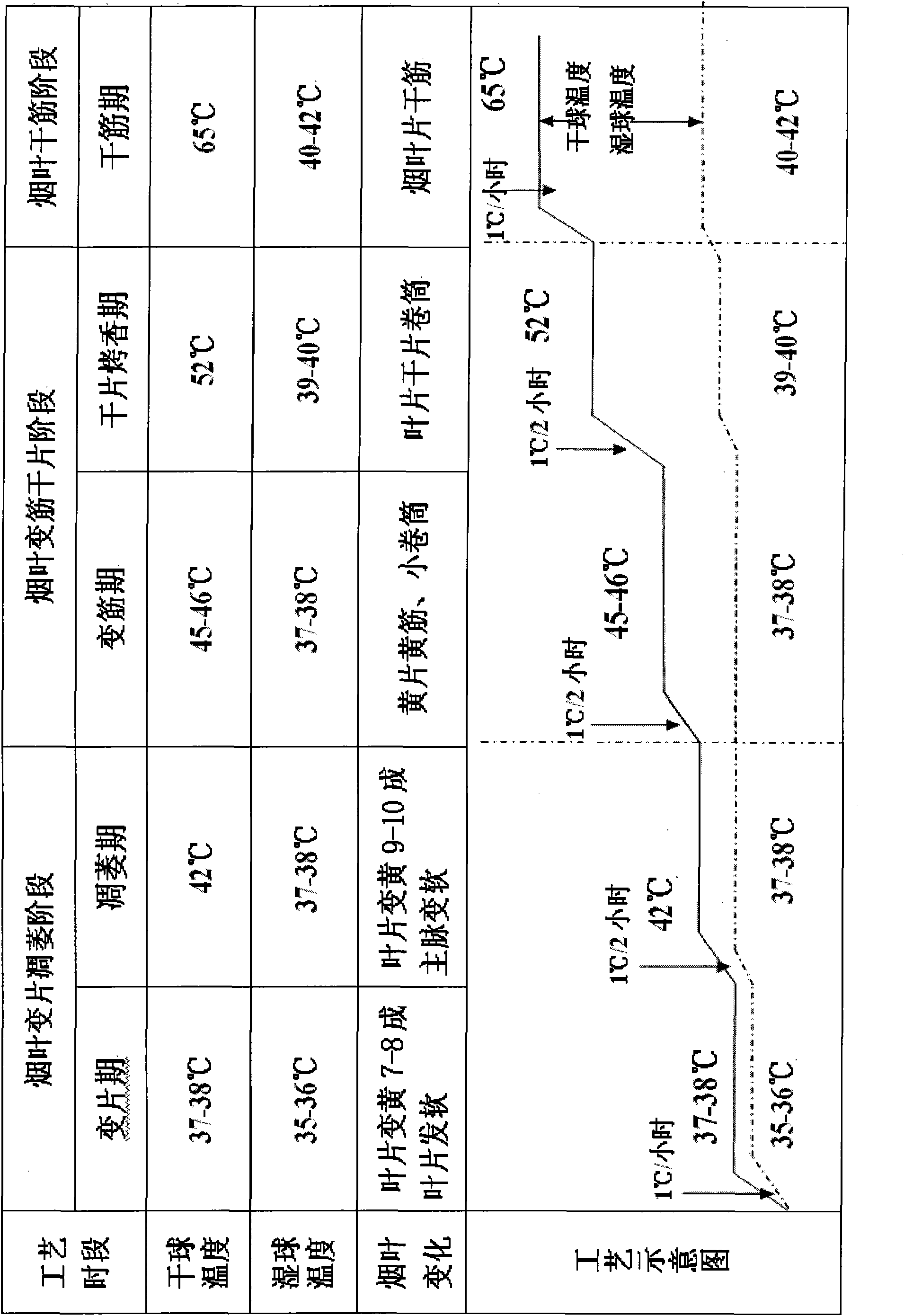

[0022] 1 Tobacco leaf changing and withering stage operation technology

[0023] After the field tobacco leaves are mature and harvested, they are loaded into the barn for baking, and enter the stage of tobacco leaves turning into sheets and withering.

[0024] Operation requirements: At this stage, the tobacco leaves are mainly yellowing and withering period; the leaves of tobacco leaves are 70-80% yellowing in the leaf-changing stage, and the leaves are soft; The veins soften. Baking guide time in the stage of withering: 36-54 hours for the lower leaves, 48-72 hours for the middle and upper leaves.

[0025] Operation method: During the sheet-changing period, after the tobacco leaves are loaded into the barn, ignite and bake, and rise to 34-35°C at 1°C per hour, keep the difference between dryness and humidity at about 2°C, and stabilize the ...

Embodiment 2

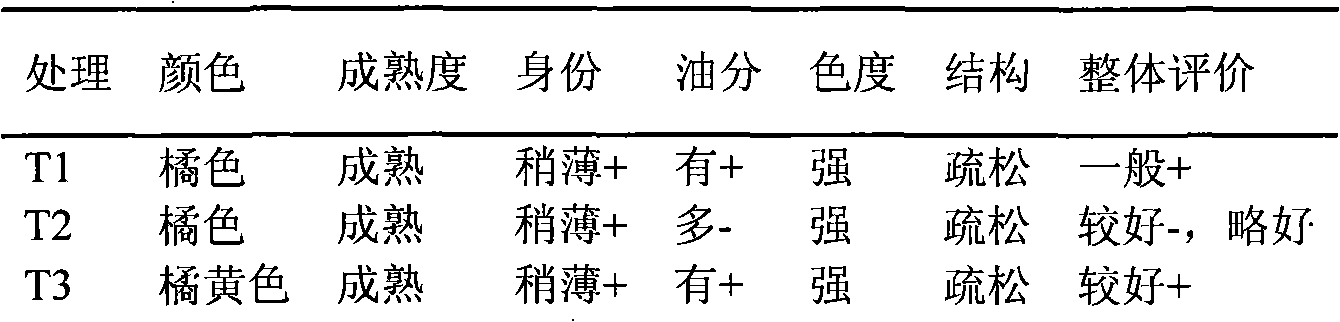

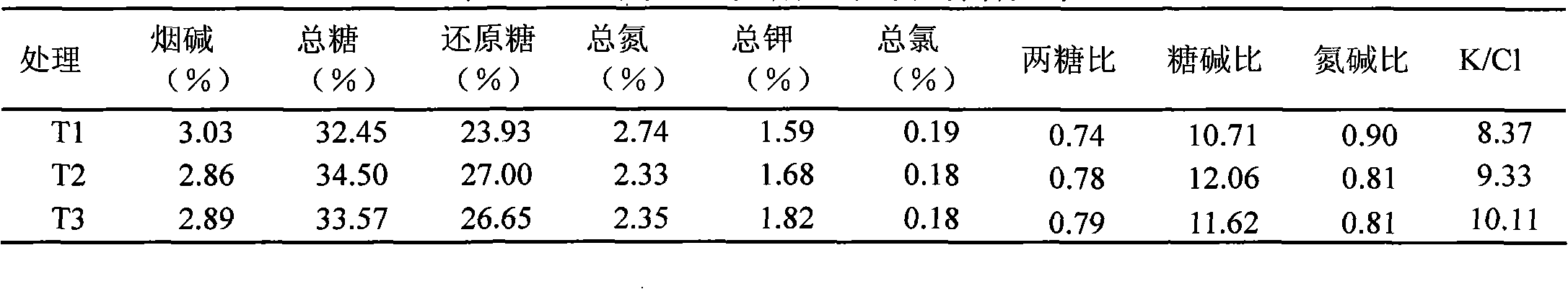

[0033] For Honghua Dajinyuan tobacco leaves from a place in Sichuan Province, the following three curing processes are set up: T1: three-stage curing (commonly used process in the prior art), T2: three-stage five-step curing (patent 021101884 process) , and T3 (technique of the present invention), three sections of five periods of baking process. Comparison of appearance quality, chemical composition, sensory quality evaluation, grade and economic properties of cured tobacco leaves. The results are shown in Table 1-4.

[0034] Table 1 Comparison of appearance quality of middle tobacco leaves with different curing processes

[0035]

[0036] Table 2 Comparison of chemical components in middle tobacco leaves with different curing processes

[0037]

[0038] Table 3 Comparison of sensory evaluation and smoking of middle tobacco leaves with different curing processes

[0039]

[0040] Table 4 Tobacco leaf grades and economic properties after different curing processes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com