Method for preparing cigarette flavor by microbial fermentation of coffee

A technology for microbial fermentation and tobacco flavors, applied in fermentation, essential oils/flavors, tobacco, etc., to achieve the effects of plumping smoke, reducing irritation, and enriching smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

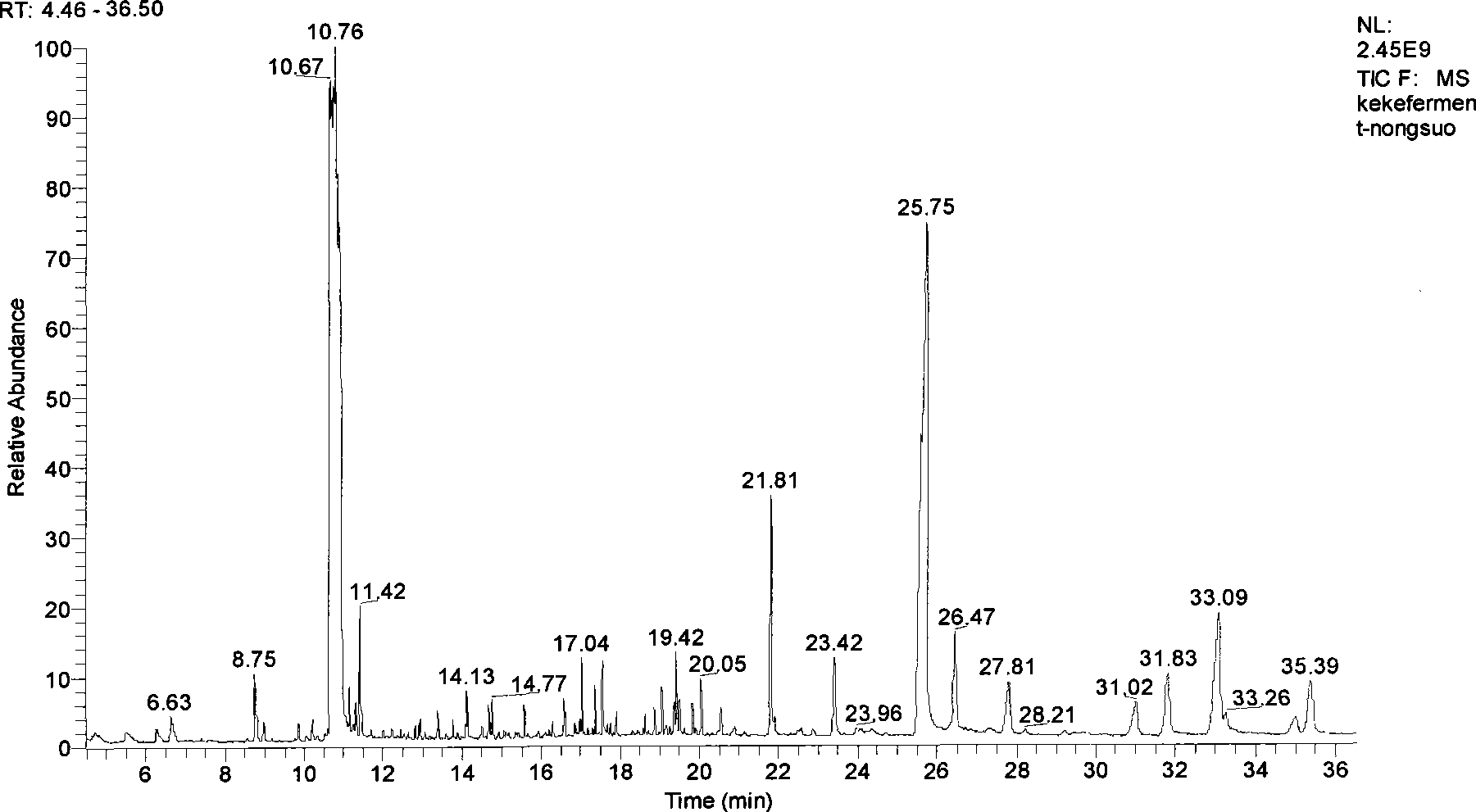

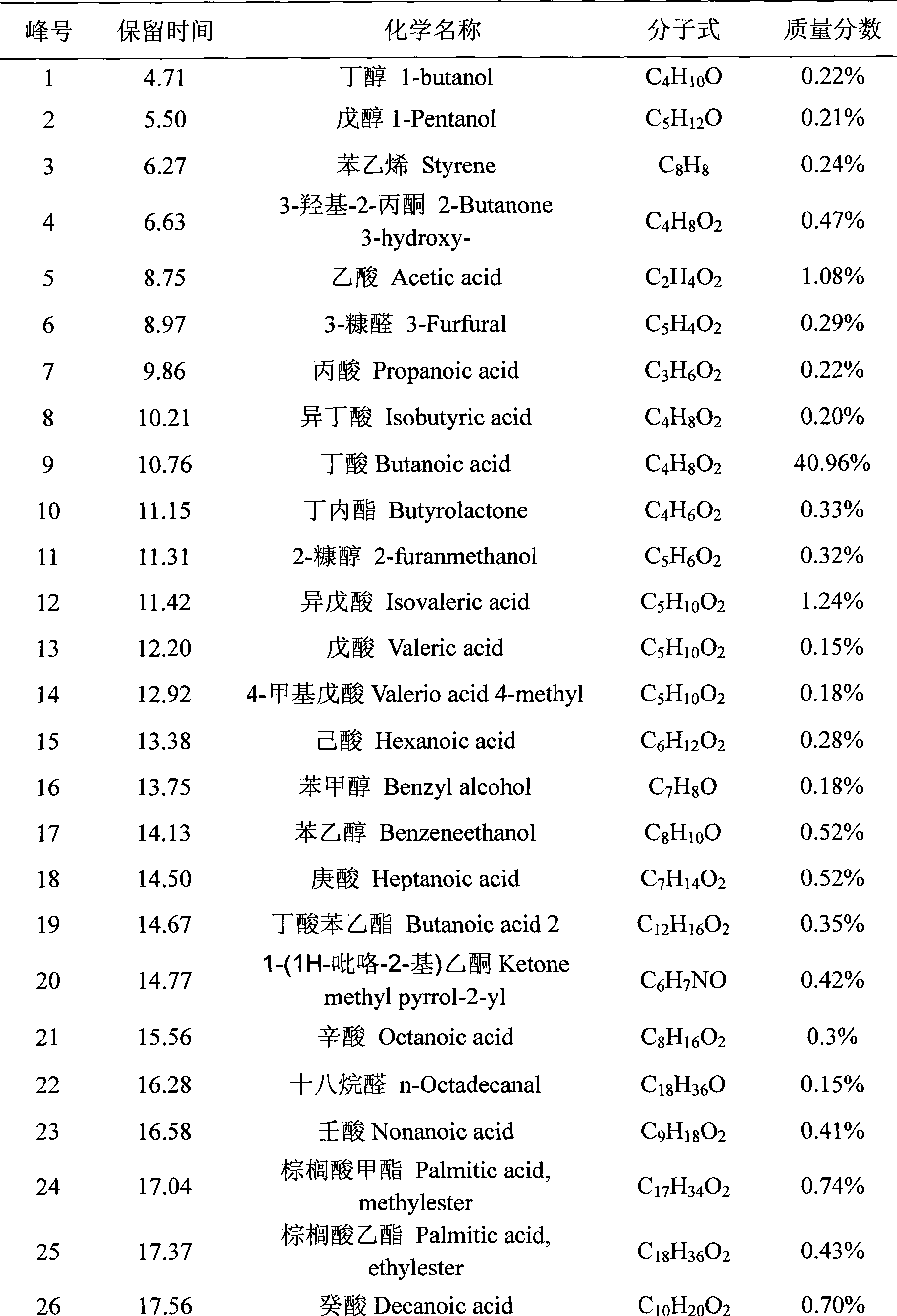

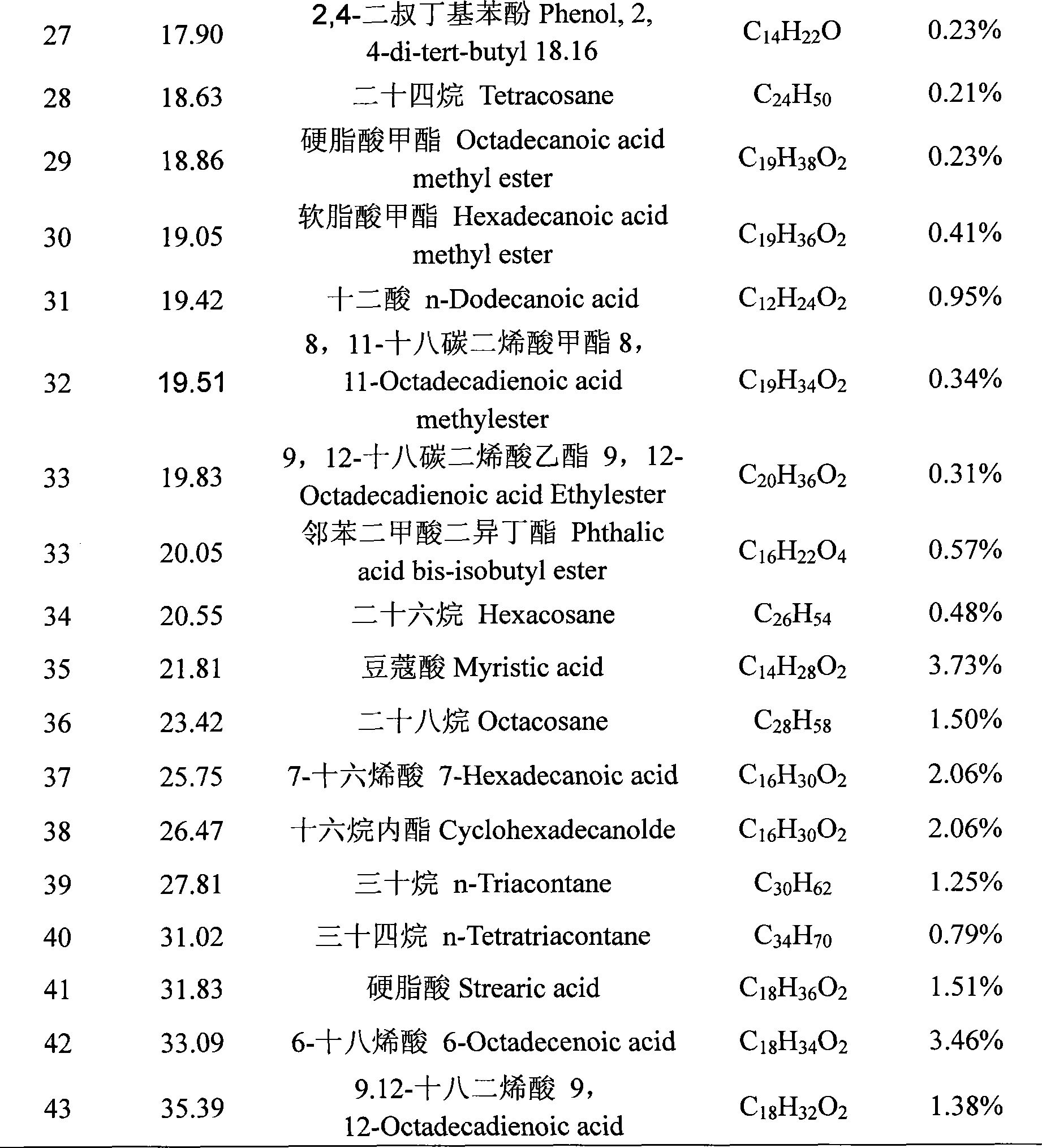

Image

Examples

Embodiment 1

[0032] Implementation Example 1: Prepare fermented coffee flavoring for tobacco by means of liquid fermentation.

[0033] ① Strain activation: Take Clostridium sporogenes, inoculate it on the slant of beef extract peptone medium, place it in a constant temperature incubator, cultivate it under anaerobic conditions at 30°C for 36 hours, then inoculate it into the deep basic liquid medium, and inoculate it at 30°C Cultivate for 24 hours to obtain activated seed solution.

[0034] 2. Pretreatment of raw materials: choose 100g dry ground coffee powder (coffee powder is a commercially available product, the same below) as raw material, add 100g of sucrose and 10g (NH 4 ) 2 SO 4 , 2gMgSO 4 , 5g KH 2 PO 3 , add 4000ml of purified water to prepare liquid fermentation broth, and sterilize at 115°C for 20min.

[0035] ③ Liquid fermentation: Inoculate 40ml of the activated seed solution into the sterilized coffee liquid medium, mix well, and place it in a constant temperature incub...

Embodiment 2

[0037]Example 2: Preparation of fermented coffee flavoring for tobacco by means of solid-state fermentation.

[0038] ① Strain activation: take yeast, inoculate it on the upper surface of solid PDA medium, place it in a constant temperature incubator at 28°C and cultivate it for 48 hours, then inoculate it in the PDA liquid medium that was inoculated again, and cultivate it at a constant temperature of 28°C for 48 hours. An activated seed liquid is obtained.

[0039] ② Raw material pretreatment: select 1000g of dried and pulverized coffee powder as raw material, and sterilize at 115°C for 20 minutes to obtain aseptic coarse coffee powder.

[0040] ③ Solid fermentation: Inoculate 100ml of the treated seed liquid into the above-mentioned sterile coffee powder, stir to make the coarse powder solid and seed liquid fully mixed evenly, and place the inoculated coffee powder in an incubator at 28°C for fermentation 7 days.

[0041] ④Extraction and refining: Add the fermented coarse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com