Method for baking tobacco leaf of intelligentized miniature compact tobacco flue-curing house

A technology of flue-cured tobacco room and tobacco leaves, applied in the direction of tobacco, tobacco preparation, application, etc., to achieve the effect of eliminating fire hazards, uniform temperature, and good quality of tobacco leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

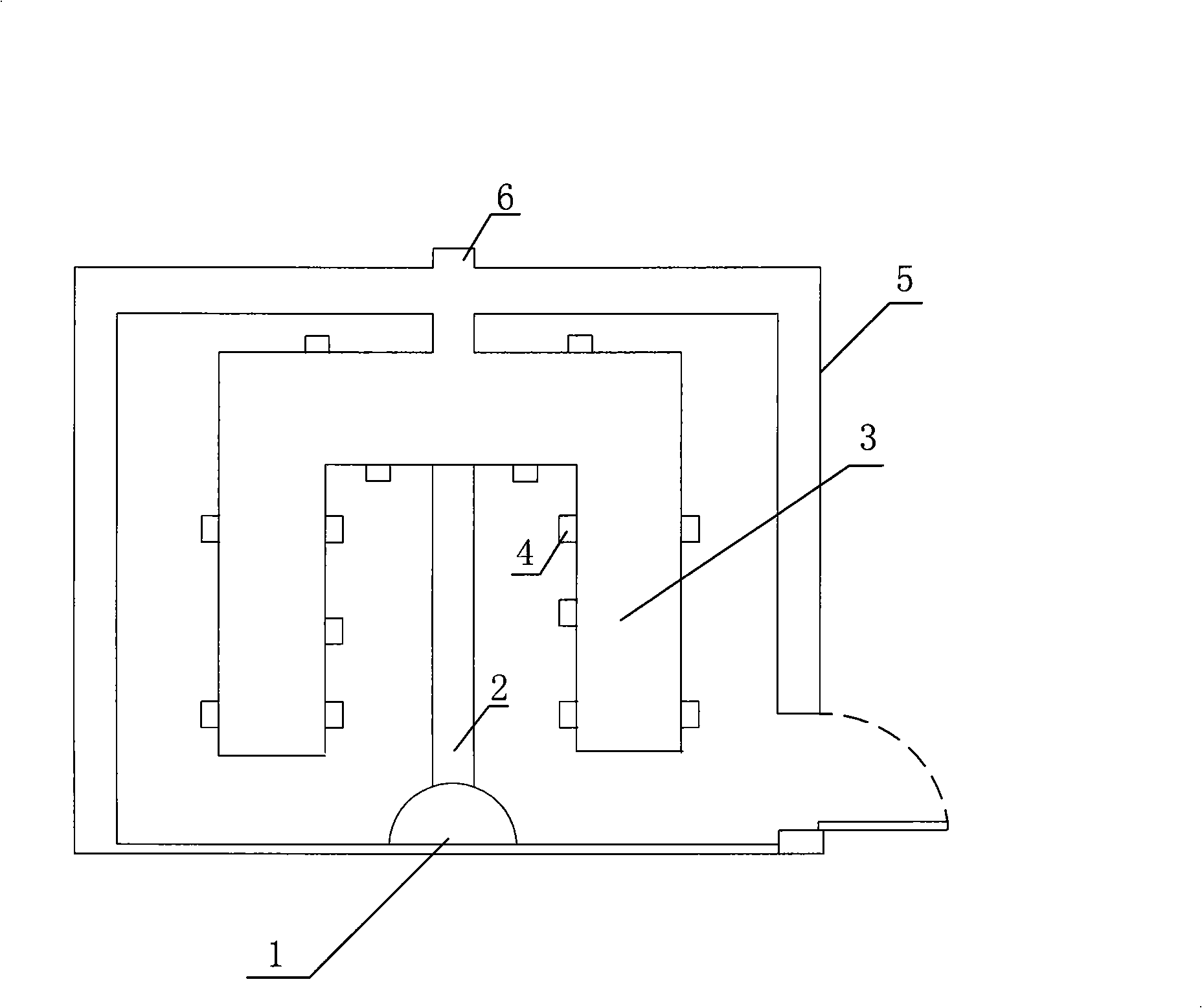

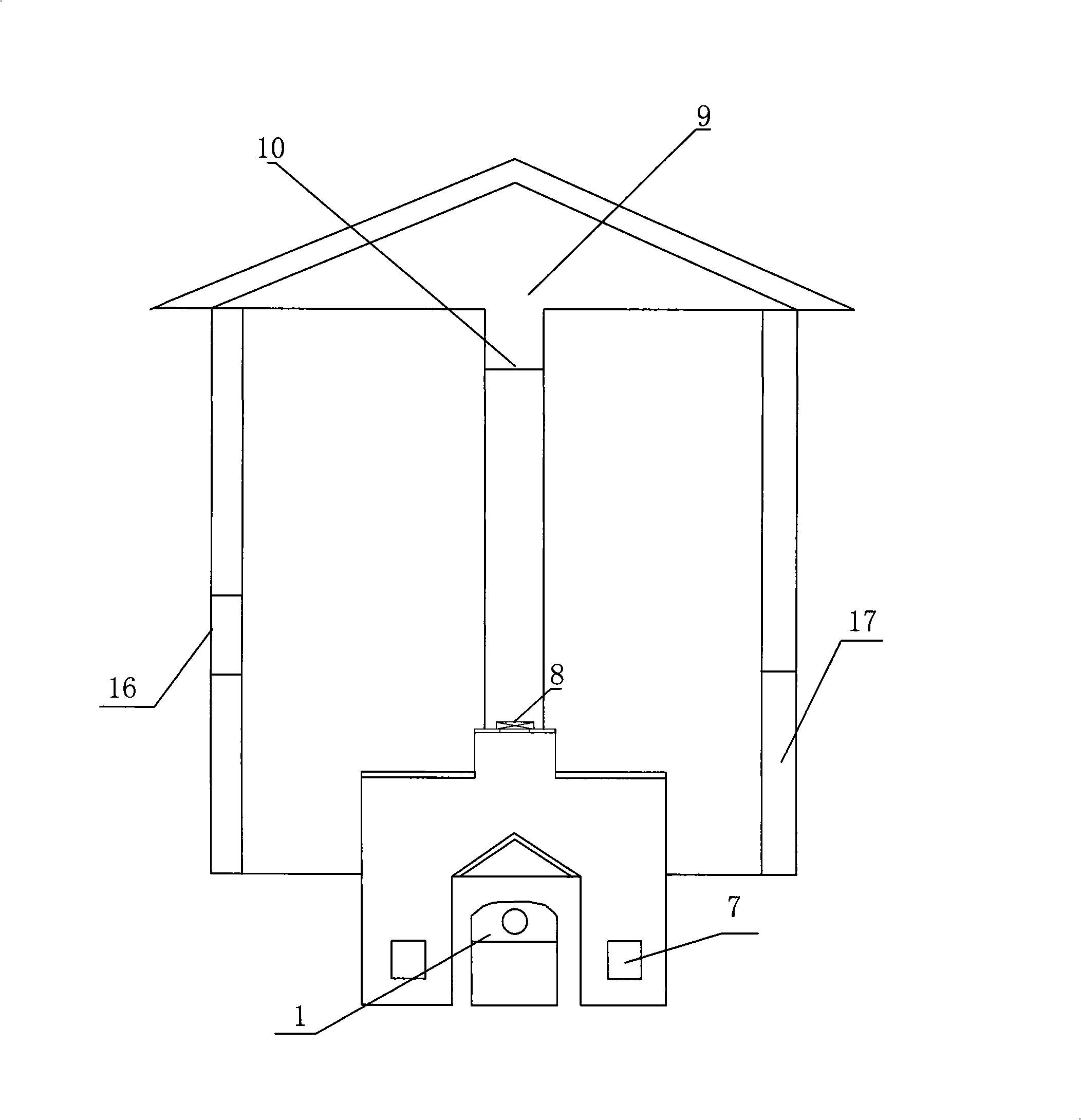

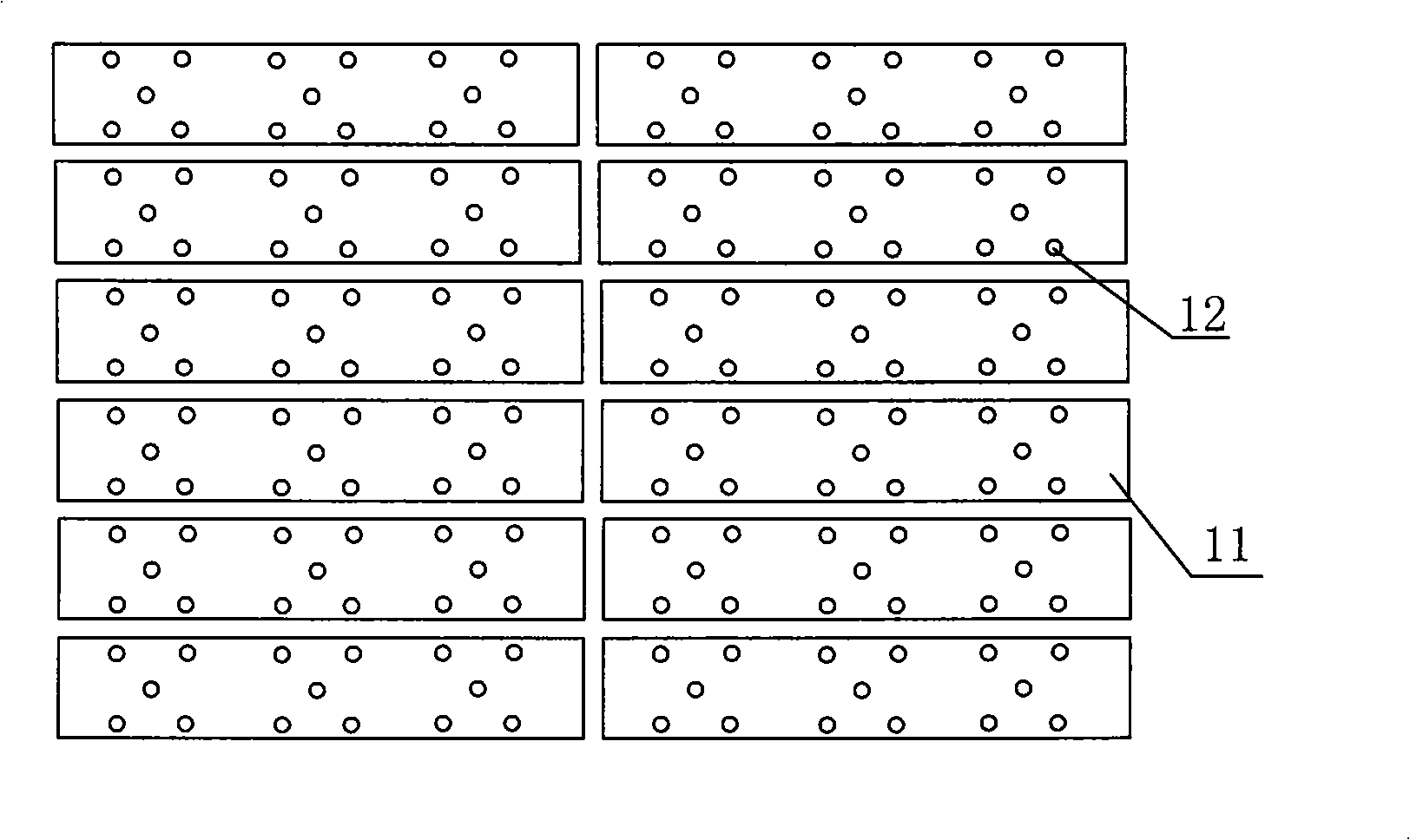

[0026] The specific implementation of the method for curing tobacco leaves in the intelligent small-scale intensive tobacco-curing room of the present invention is further described in detail with reference to the accompanying drawings: the structure of the intelligent small-scale intensive tobacco-curing room is composed of four walls 5, the ground and the roof In an indoor space, one side of the wall is provided with an access door 17 and an observation window 16, an air inlet 7 is respectively provided on both sides of the furnace, and a skylight 9 and a return air outlet 10 are provided on the top of the barn. On the ground level of the barn, it is composed of a furnace 1, a main fire pipe 2, a hot air duct 3, an air outlet 4, and a chimney 6 fire gate. The main fire pipe 2 is directly connected with the combustion chamber of the furnace 1, and the branch fire pipes are distributed in a circular shape after branching out from the main fire pipe 2, and the arrangement of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com