Fully automatic pipe material saw cutting machine

A fully automatic, sawing machine technology, used in metal sawing equipment, sawing machine devices, metal processing equipment, etc., can solve the problems of waste of tailings and low transportation efficiency, and achieve a high degree of automation and compact structure with reduced waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

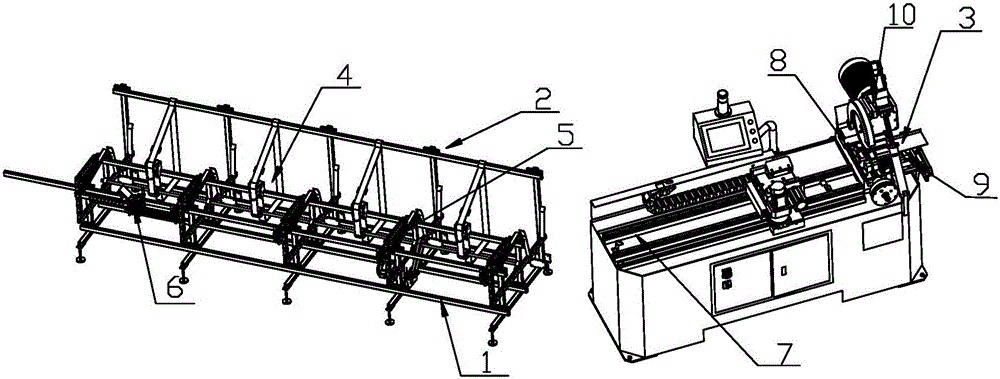

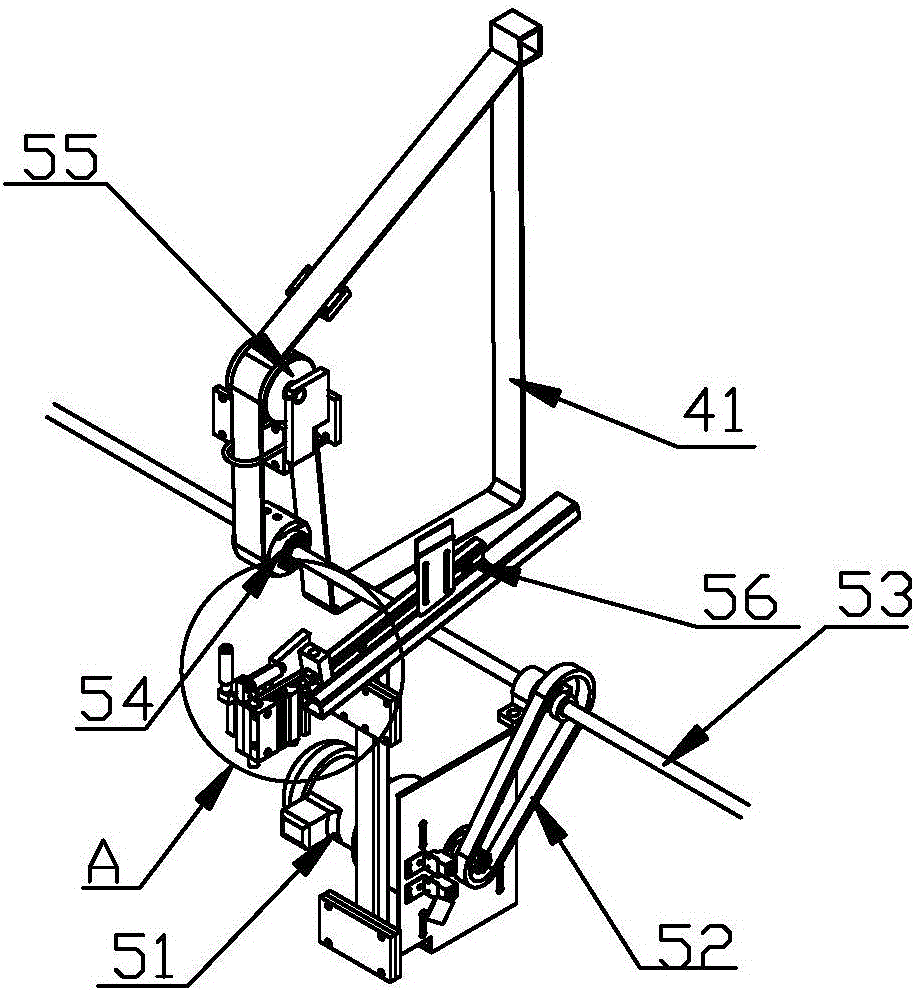

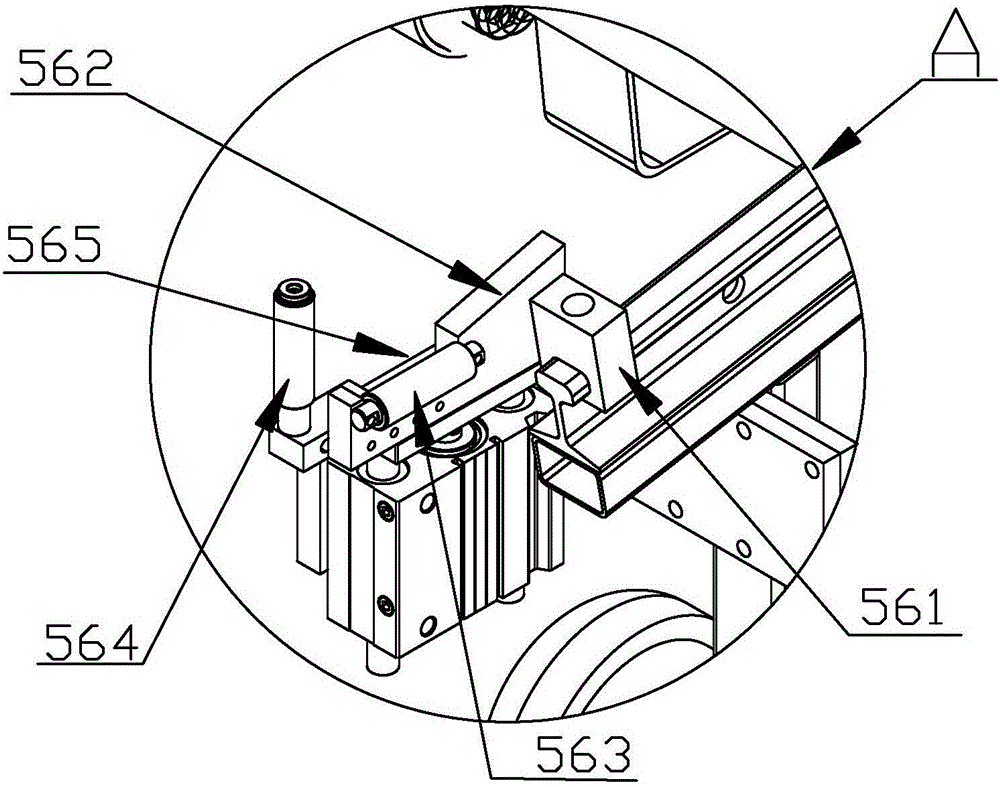

[0046] Such as Figure 1-8As shown, a fully automatic pipe sawing machine includes a frame 1, and also includes an automatic feeding device 2, a cutting device 3 and a feeding device arranged in sequence. The automatic feeding device 2 includes a storage mechanism 4, a pre-loading The feeding mechanism 5 and the feeding mechanism 7, the pipes are loaded sequentially through the storage mechanism 4, the pre-feeding mechanism 5 and the feeding mechanism 7. Mechanism 72, the cutting device 3 is arranged behind the feeding mechanism 7, including the main clamp seat assembly 8, the tail material clamp seat moving assembly 9 and the sawing mechanism 10, the main clamp seat assembly 8 is fixedly installed on the frame 1 On the upper side, the tailing clamp seat moving assembly 9 is arranged side by side behind the main clamp seat assembly 8 and can move back and forth relative to the main clamp seat assembly 8 along the pipe conveying direction. The sawing mechanism 10 is hinged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com