Dynamic load type flexible polishing head

A flexible polishing and dynamic loading technology, which is applied to surface polishing machine tools, grinding/polishing equipment, and parts of grinding machine tools, etc., can solve the problems of easy deformation of airbag cylinders, and achieve simple structure, convenient assembly and disassembly, and tight connection solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

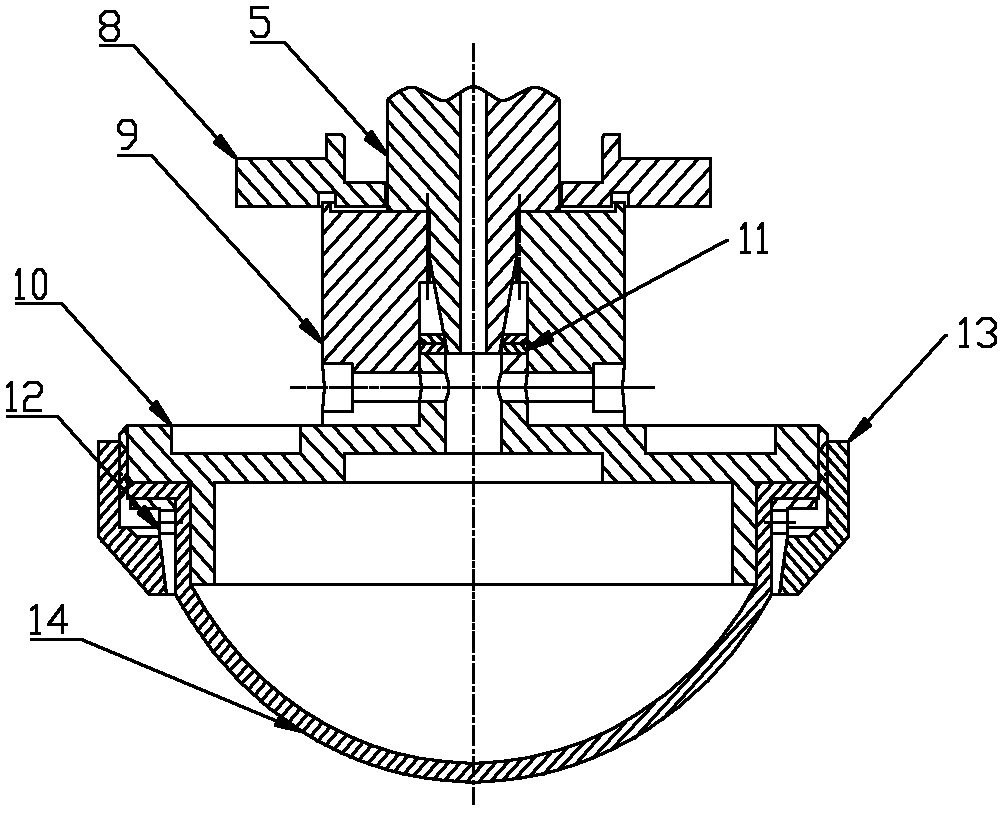

[0022] When working, the motor 1 drives the rotating shaft 5 to rotate through the shaft coupling 3, and the rotating shaft 5 drives the shaft front sleeve 9 to rotate. Rotate together to drive the polishing head for polishing. While rotating, gas can be filled into the airbag through the vent hole on the rotating shaft 5, and the internal pressure of the airbag can be controlled as required.

[0023] The technical solution of the present invention will be further elaborated below in conjunction with the accompanying drawings.

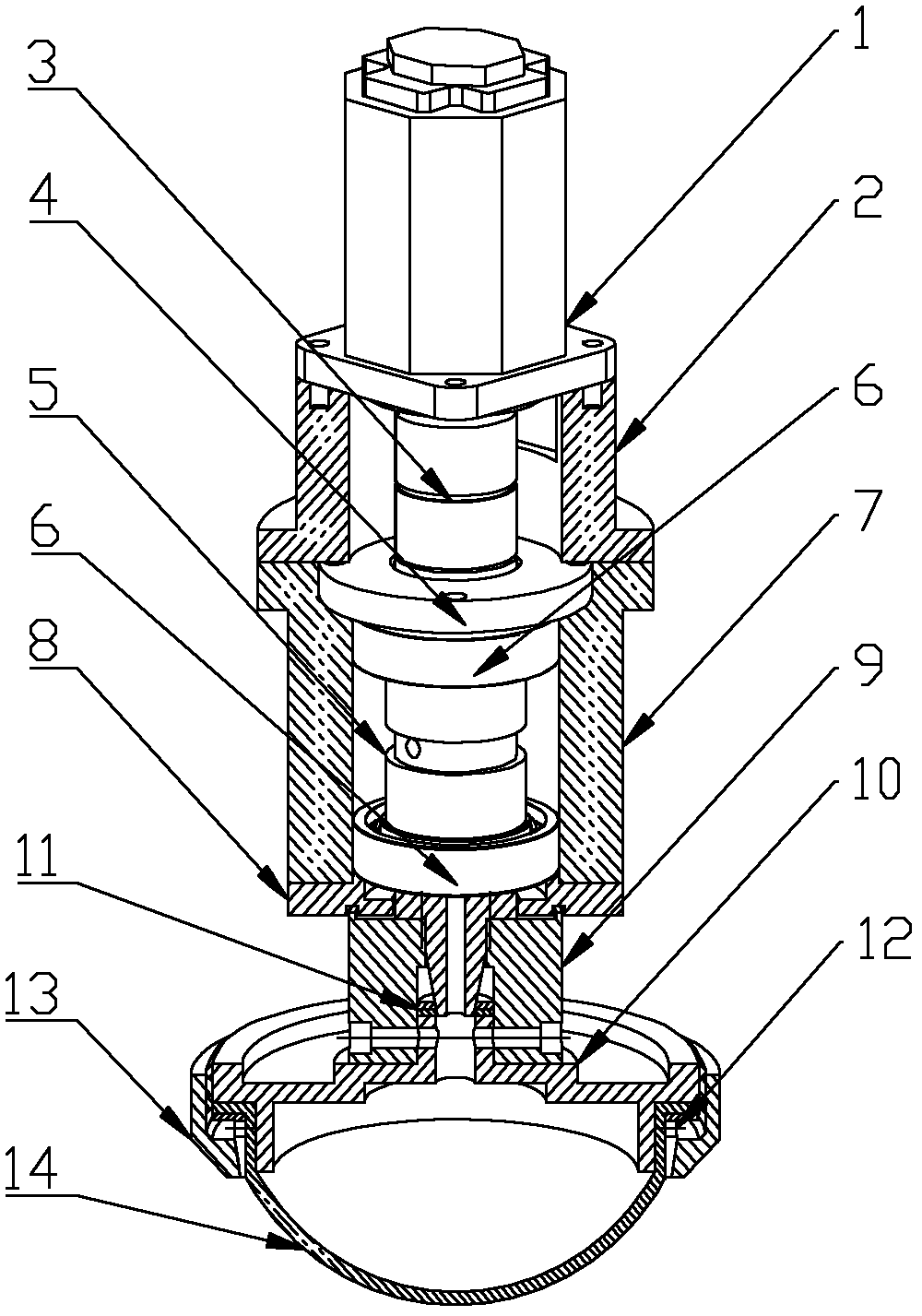

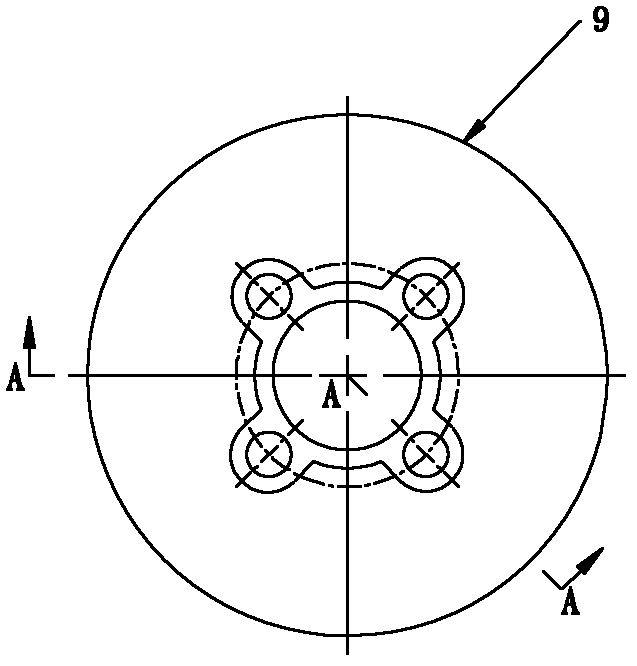

[0024] Such as Figure 1-7 As shown, the embodiment of the present invention is provided with a motor 1, a motor base 2, a shaft coupling 3, an upper end cover 4, a rotating shaft 5, a bearing 6, a box body 7, a lower end cover 8, a shaft front sleeve 9, a shaft end connector 10, Washer 11, elastic sleeve 12, locking sleeve 13 and air bag 14; the motor 1 is fixedly connected with the motor base 2 through screws, the box body 7 is connected under the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com