Axial shiftable type abrasive wheel and intelligent adjustment device thereof

An intelligent adjustment and grinding wheel technology, which is applied to the parts of grinding machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve the problems that the processing process does not meet the processing accuracy requirements, reduces work efficiency, and has a large amount of wear. Achieve the effect of improving the effective working area, ensuring the quality of processed parts, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

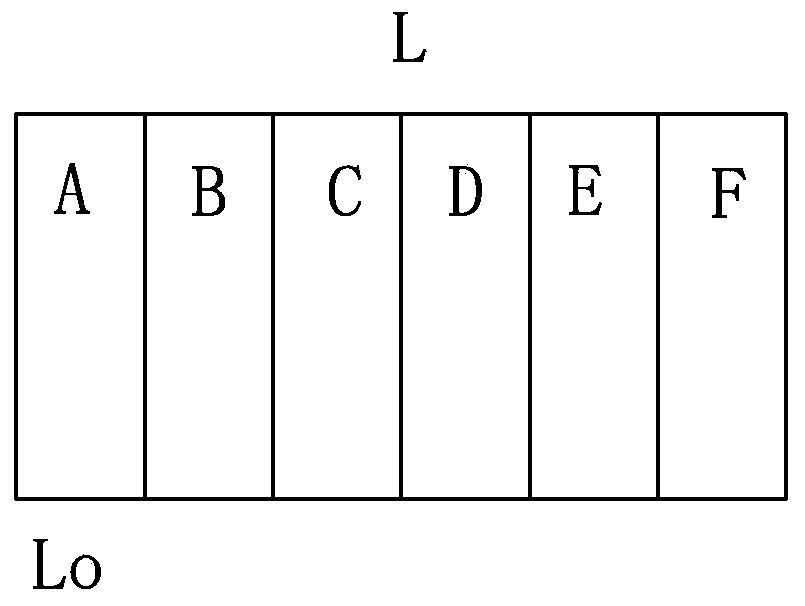

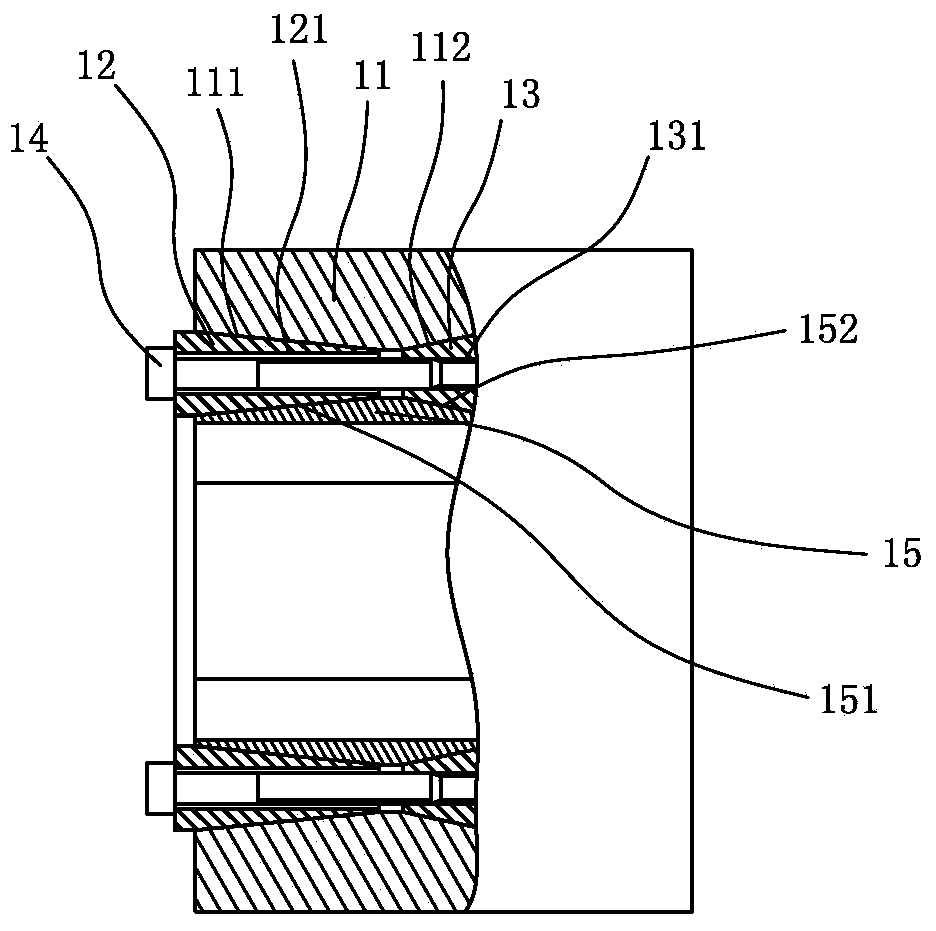

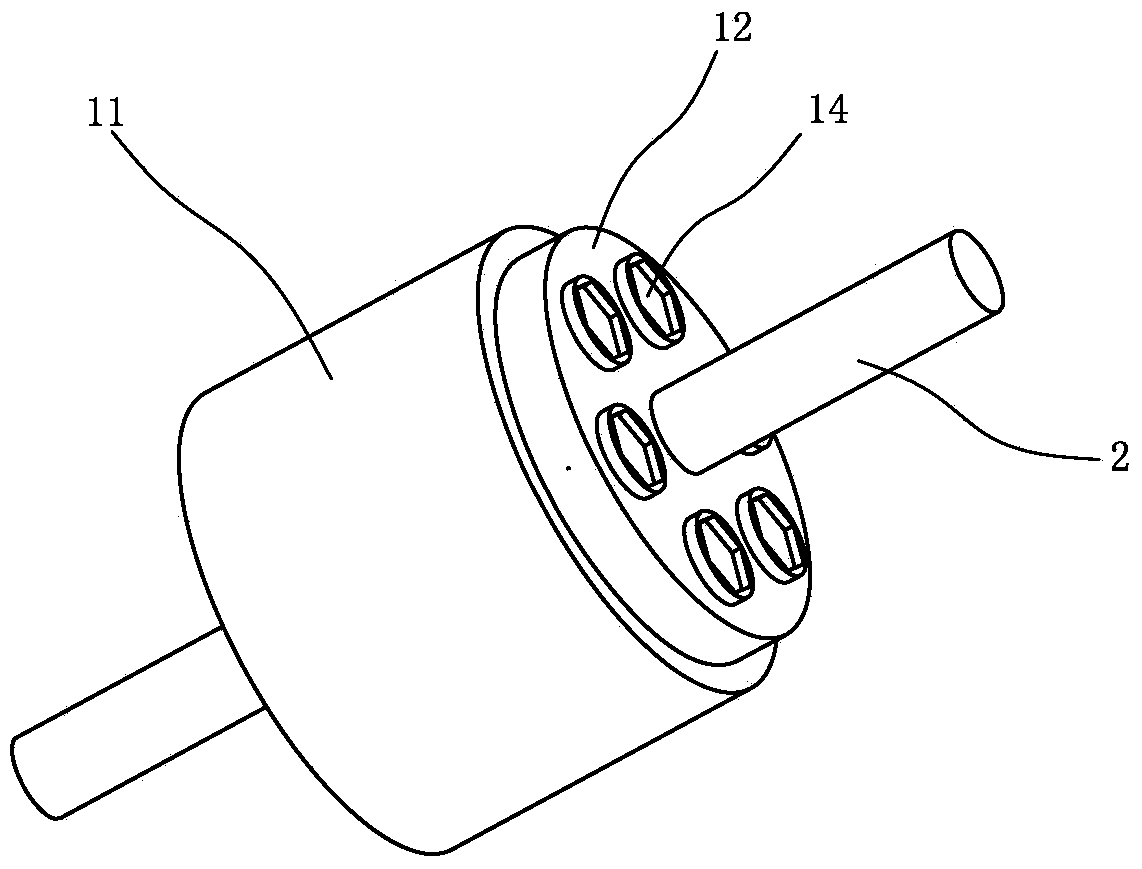

[0021] The theoretical basis of the present invention is as follows: with reference to figure 1 As shown, the grinding wheel with a total length of L is divided into six sections of A-F with axially equal lengths, and each section has a length of L0. After the grinding wheel is installed correctly and works normally for a period of time, the wear amount of the C, D, and E sections is the largest. It can be seen that these 3 sections are the working area, and the length is 3*L0. The wear of the B and F sections is small, and the A section is worn. Minimum amount. When the wear amount of C, D, and E section areas reaches the limit value, it is necessary to replace the new grinding wheel at this time to meet the production demand. However, the present invention pushes and adjusts the position of the grinding wheel on the main shaft through an intelligent adjustment device. Firstly, the F, E, and D section areas of the grinding wheel can be accurately positioned in the working ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com