Anti-vibration arrangement, tool using said anti-vibration arrangement and its method for cleaning working surface

A vibration-damping device and tool technology, applied in the direction of manufacturing tools, metal processing equipment, grinding machine parts, etc., can solve problems such as reducing the ability of the human body to eliminate vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

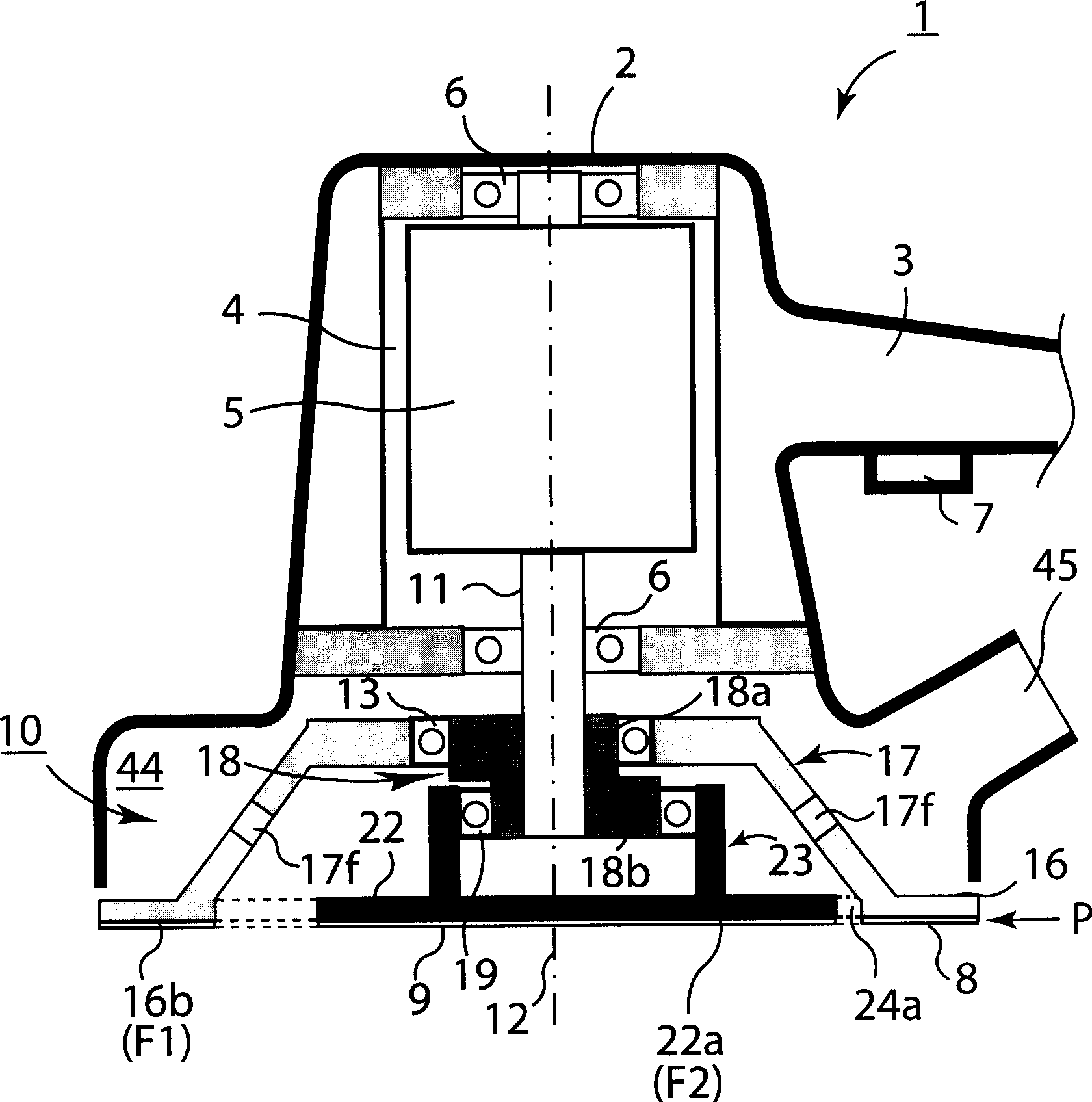

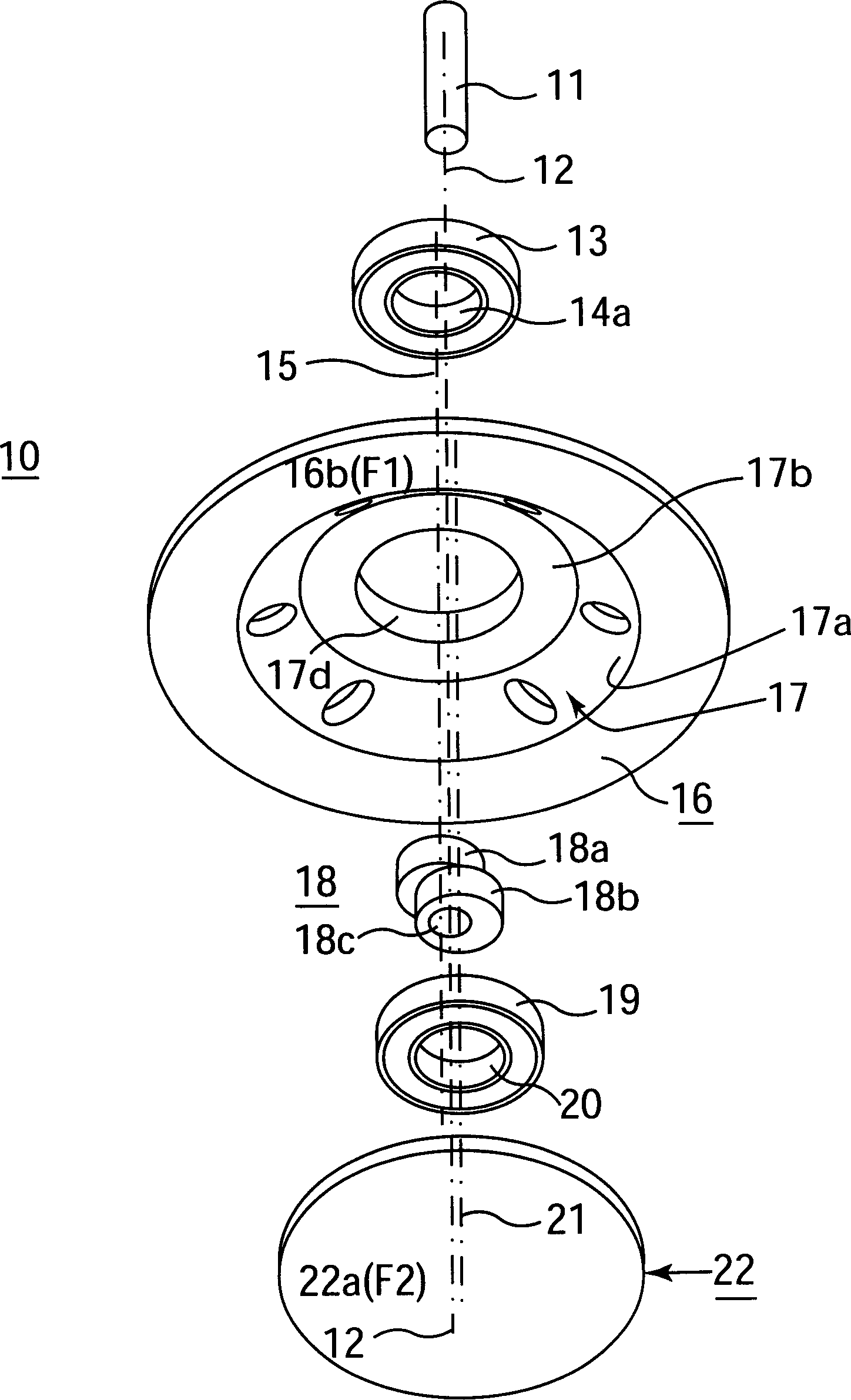

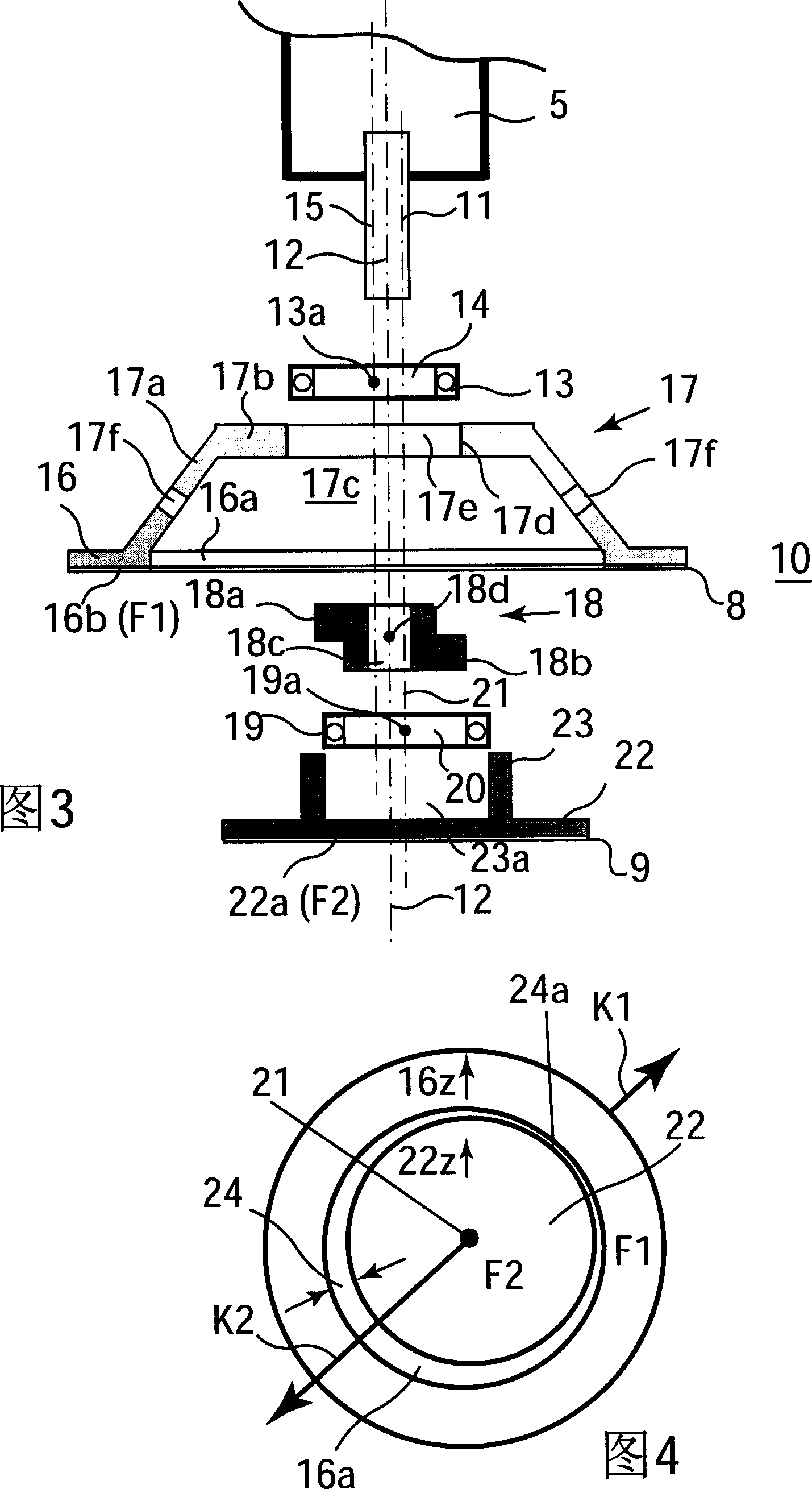

[0150] Refer to attached figure 1, discloses an eccentrically rotating and oscillating tool 1, such as a sander or a polishing machine, incorporating a vibration damping device according to an embodiment of the present invention.

[0151] Eccentrically rotating and oscillating tools 1 basically have a casing 2 with a handle 3 and an inner cavity 4 to accommodate a motor 5, such as a motor, with a motor shaft 11 and a longitudinal centerline 12. The motor shaft 11 is composed of a ball bearing and a needle bearing. Or oil bearing support. Motor 5 can not be electric, as also can be pneumatic. Axis 12 may also be referred to as the motor shaft centerline or axis of rotation. The motor 5 can work at any speed, even very high speeds. The typical design range of the rotational speed of the motor 5 is 2000-12000 revolutions per minute.

[0152] The power switch 7 is arranged on the handle 3 so that the operator is easy to operate, and it connects the motor 5 to the main power su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com