Robot automatic carton loading machine

A robotic and automatic technology, applied in the direction of automatic packaging control, manipulator, packaging, etc., can solve the problems of low work efficiency, high labor intensity, fully automatic operation of difficult cigarette packaging, etc., to solve the problems of high labor intensity, reasonable layout and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

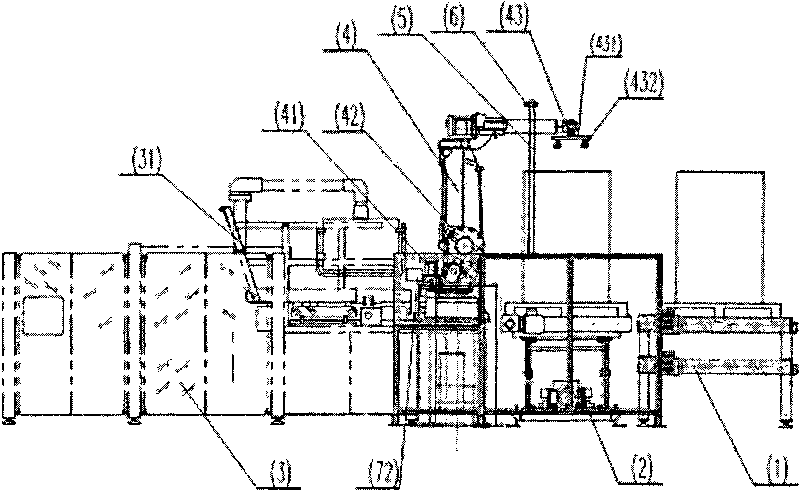

[0033] The robot automatic case loading machine provided by the invention comprises a carton conveyor (1) and a case packing and sealing machine (3), and also includes:

[0034] Carton lifting conveyor (2) - located between the carton conveyor (1) and the carton sealing machine (3), and its input end is connected with the output end of the carton conveyor (1), so as to complete the horizontal conveying of the carton Simultaneously, complete the vertical lifting conveyance of carton; The upper and lower guide rails (221), (224) that are arranged on the bottom seat body (223) and the top conveyor (21), and the two cross-links (222) whose middle part is hinged by the hinge shaft (226), the two One end of the connecting rod (222) is respectively fixed on the bottom base body (223) and the top conveyor (21), and the other end is slidably arranged on the bottom base body (223) and the top conveyor (21) by a pulley. On the guide rails (221), (224), one of the connecting rods is prov...

Embodiment 2

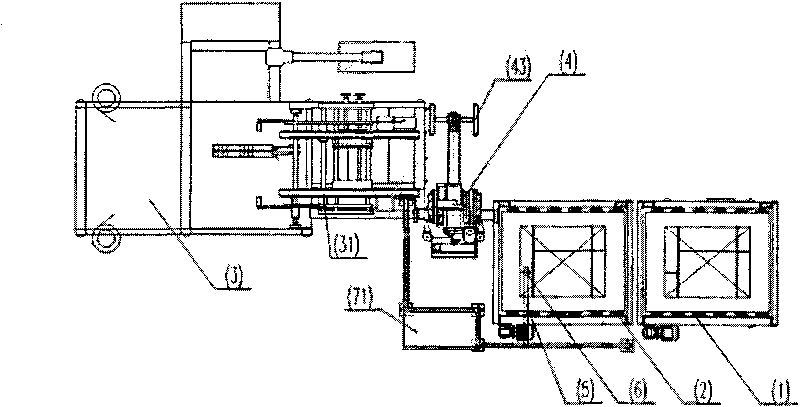

[0040] Another robot automatic box loading machine provided by the present invention comprises a carton conveyor (1), a carton lifting conveyor (2) connected thereto, a packing and sealing machine (3), and a carton lifting conveyor (2) and a packing A robot (4) between the case sealers (3), consisting of Figure 7 ~ Figure 9 It can be seen that, except that the layout is different from Embodiment 1, all other structures are the same as Embodiment 1.

Embodiment 3

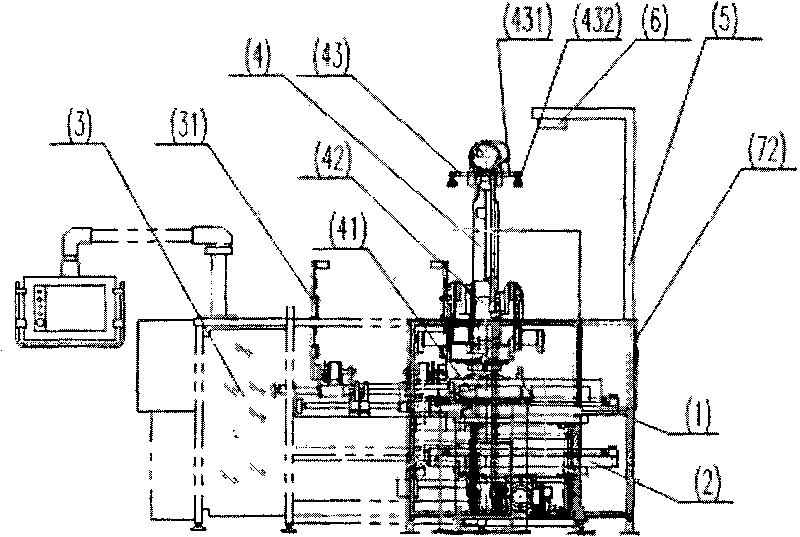

[0042] Another robotic automatic box loading machine provided by the present invention comprises a carton conveyor (1), a carton lifting conveyor (2) connected thereto, a packing and sealing machine (3), and a carton lifting conveyor (2) and a packing A robot (4) between the case sealers (3), consisting of Figure 10 ~ Figure 12 It can be seen that, except that the layout is different from Embodiment 1, all other structures are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com