Patents

Literature

32results about How to "Does not take up production space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

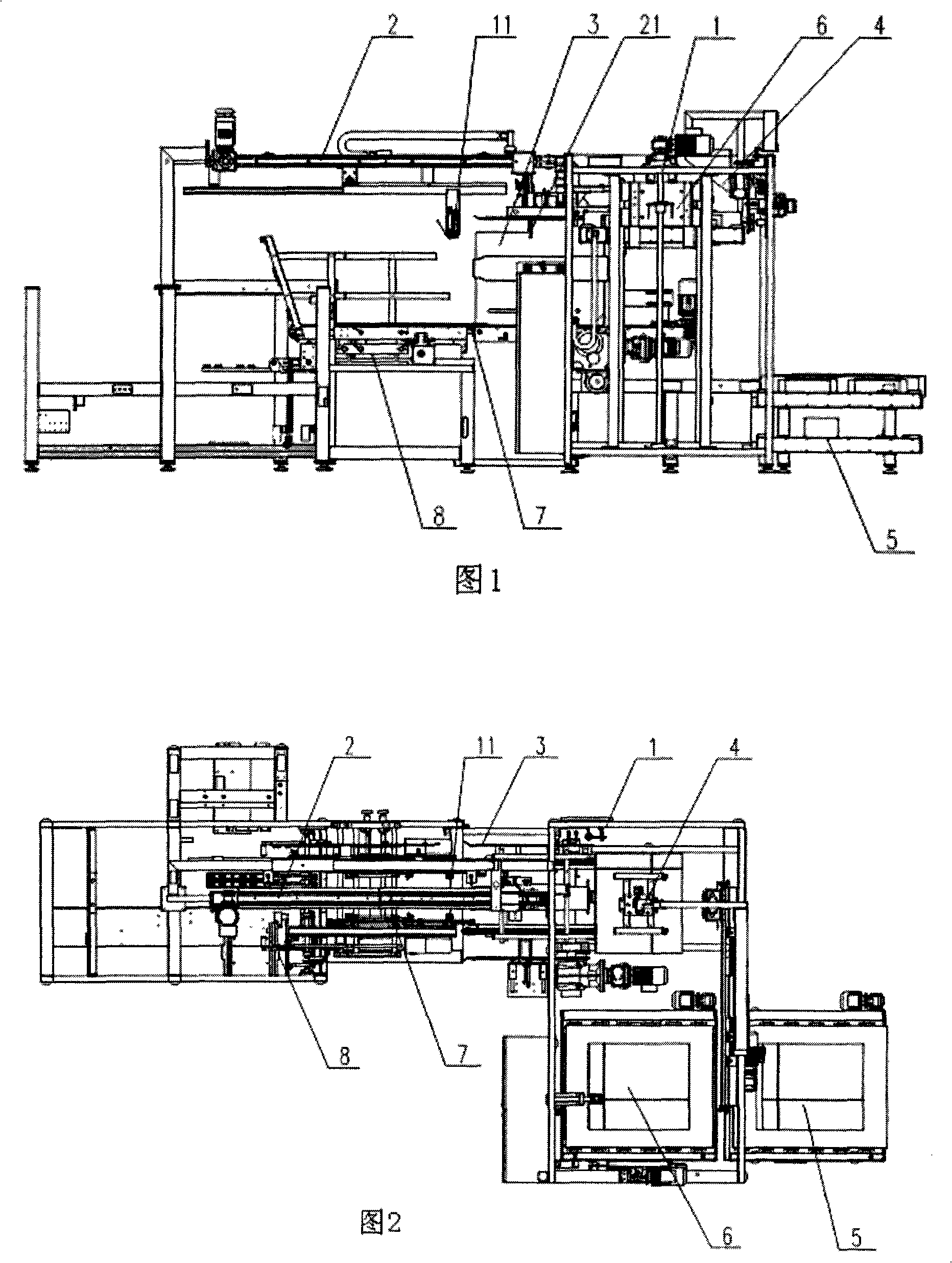

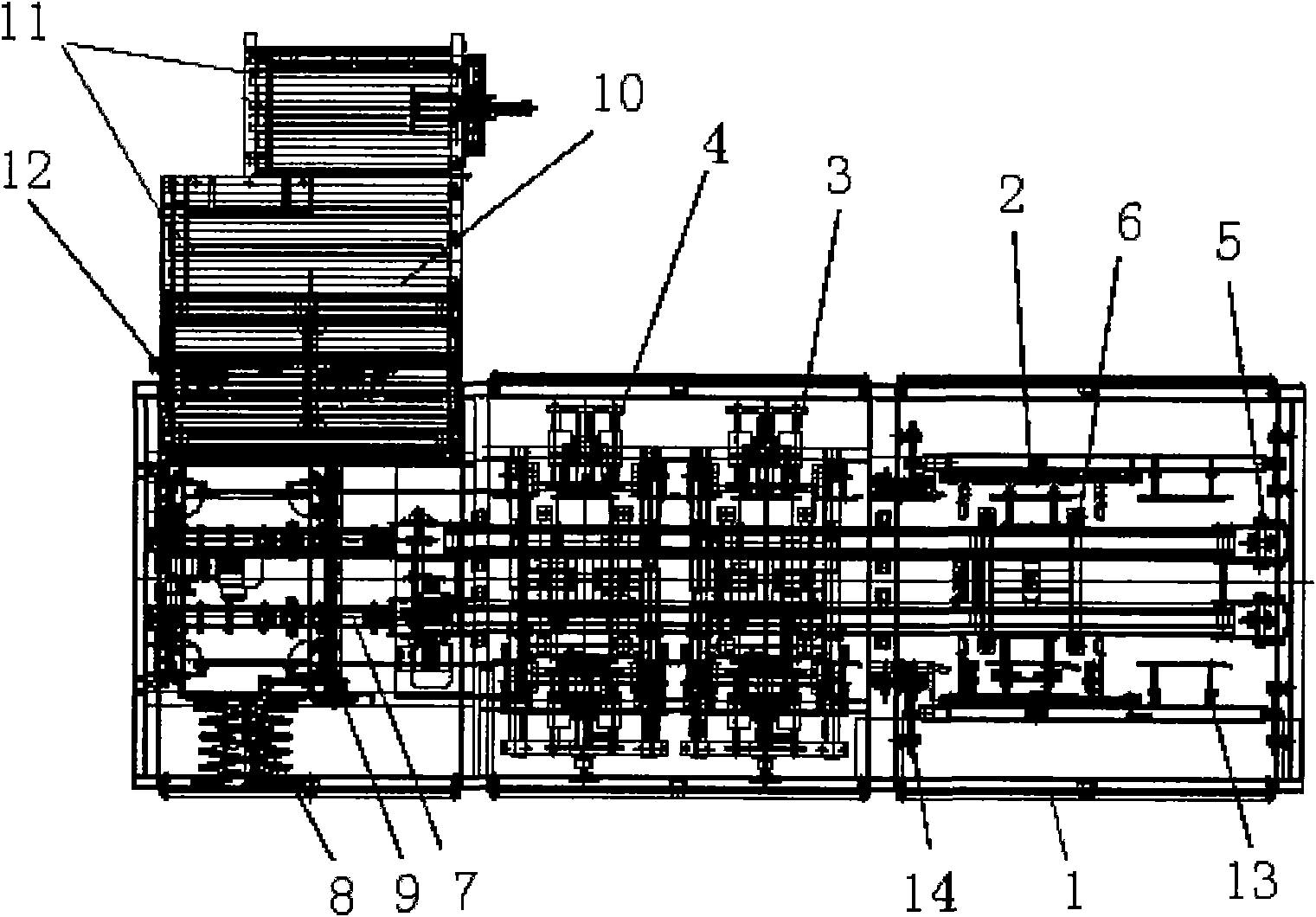

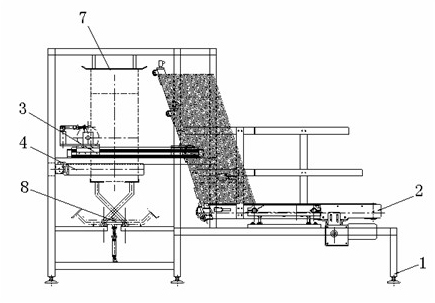

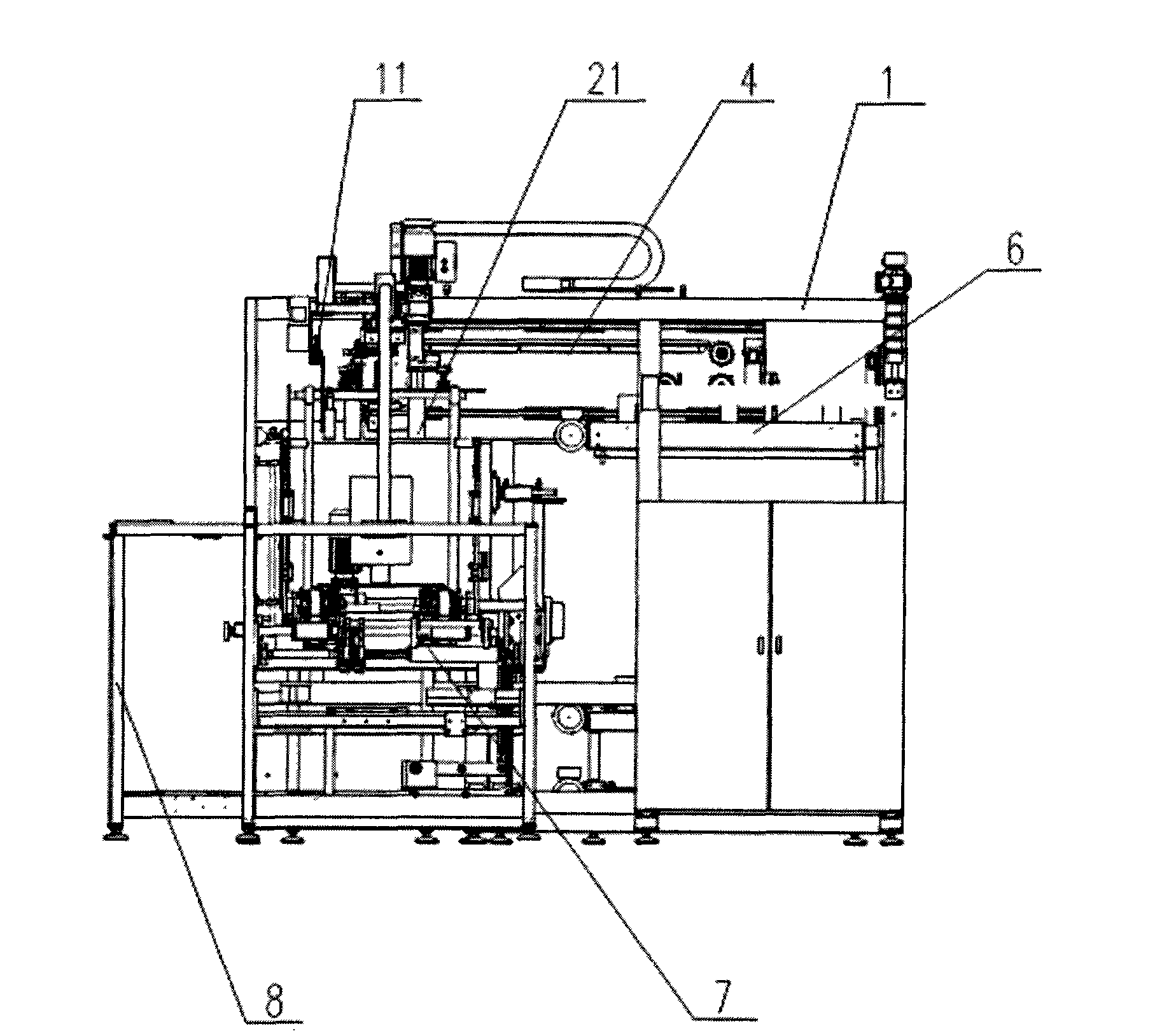

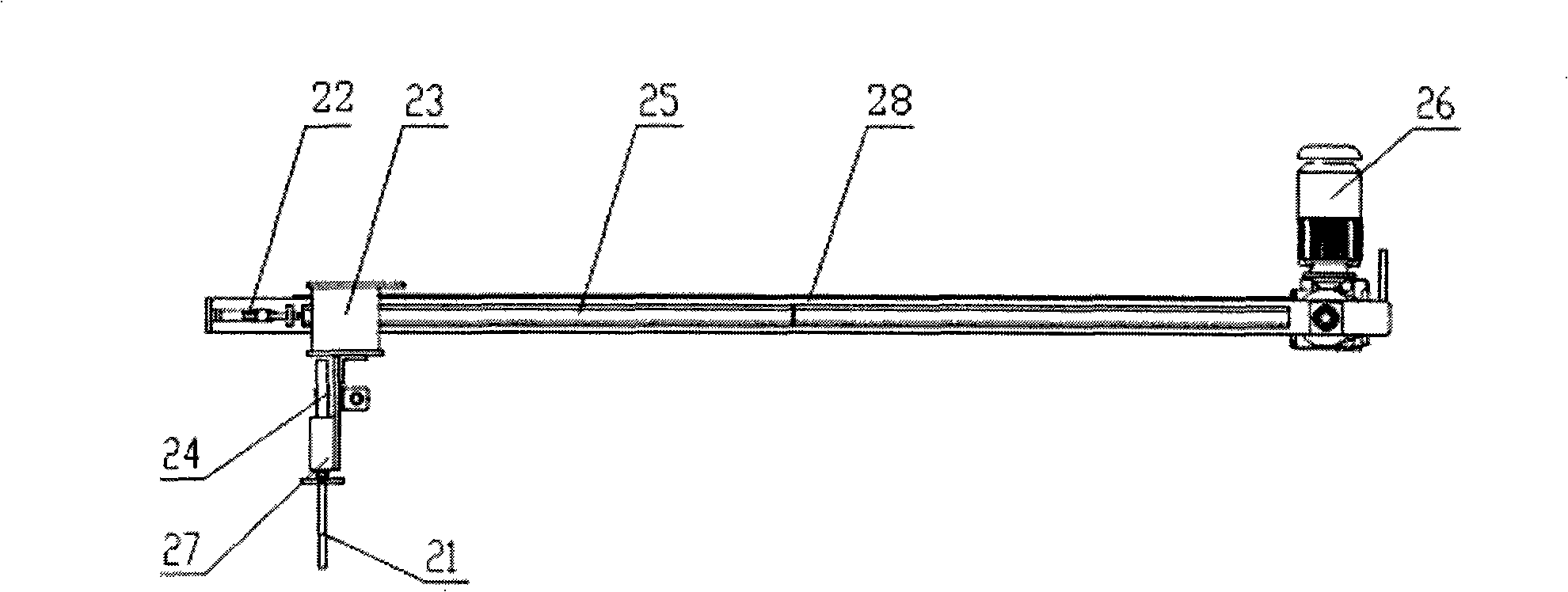

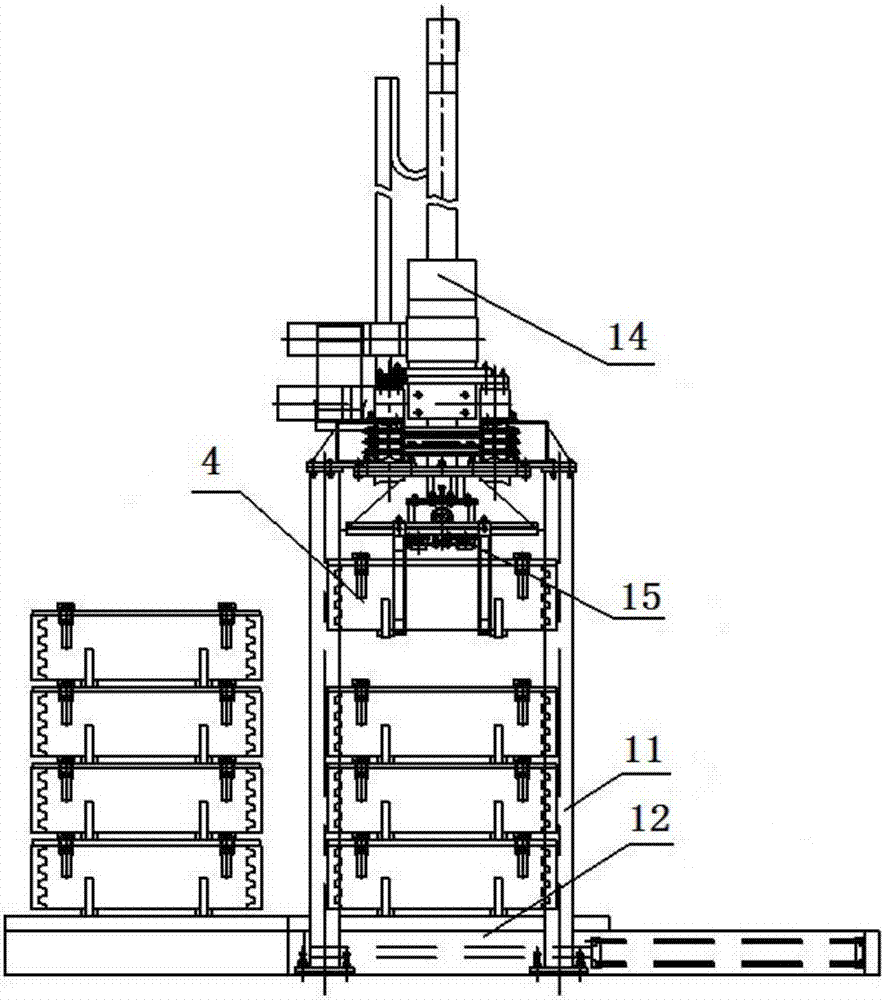

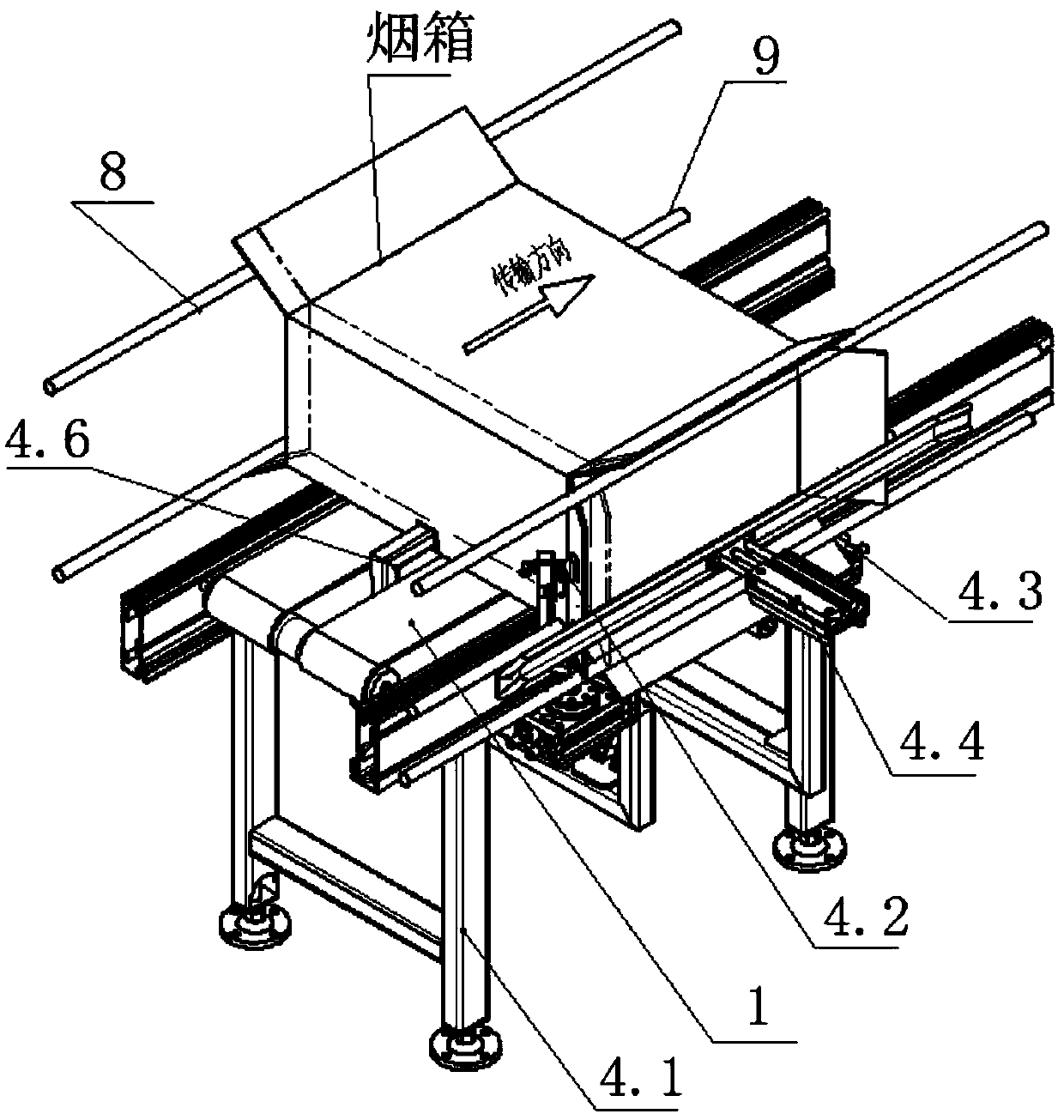

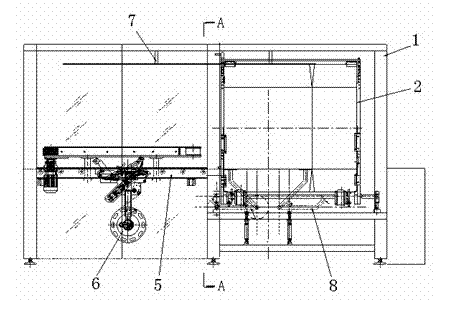

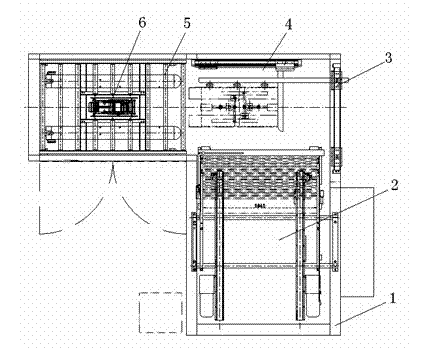

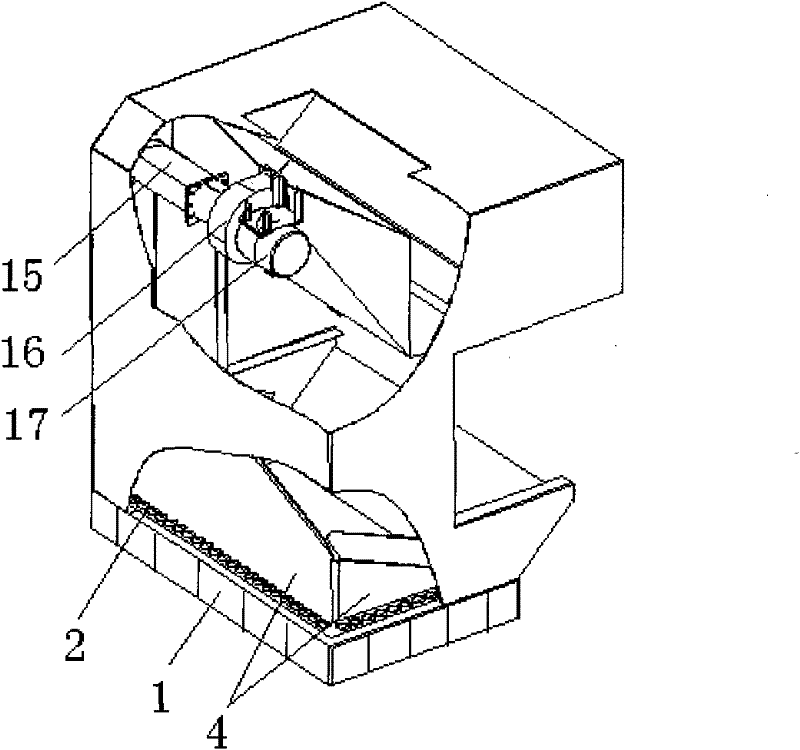

Automatic box feeding machine

ActiveCN101492104ARealize fully automated operationSolve the problems of high labor intensity and low work efficiencyOverturning articlesPackagingCartonFully automatic

The invention provides an automatic box feeding machine, which comprises a machine frame provided with a box inlet and a box outlet. The automatic box feeding machine is characterized in that the machine frame is provided with a lifting device which is connected with the box inlet; and the upper side of the lifting device is provided with a moving and rotating device, and the lower side of the moving and rotating device on one side of the lifting device is provided with a paper box aligning and stacking device which is connected with the box outlet. The automatic box feeding machine can completely achieve automatic box feeding, and overcome the defects of high labor intensity, low work efficiency, and the like, brought by feeding boxes by workers in the prior art. The automatic box feeding machine has the advantages of compact structure, reasonable layout and accurate and quick automatic box feeding, and does not occupy more production spaces. Proper automatic box feeding machine models can be selected according to different box sealing machine layouts of the prior art, so that the automatic box feeding machine also has the advantages of wide application range, convenient installation and investment conversation, and can provide guarantee for cigarette packing to achieve fully-automatic operation.

Owner:东方机器制造(昆明)有限公司

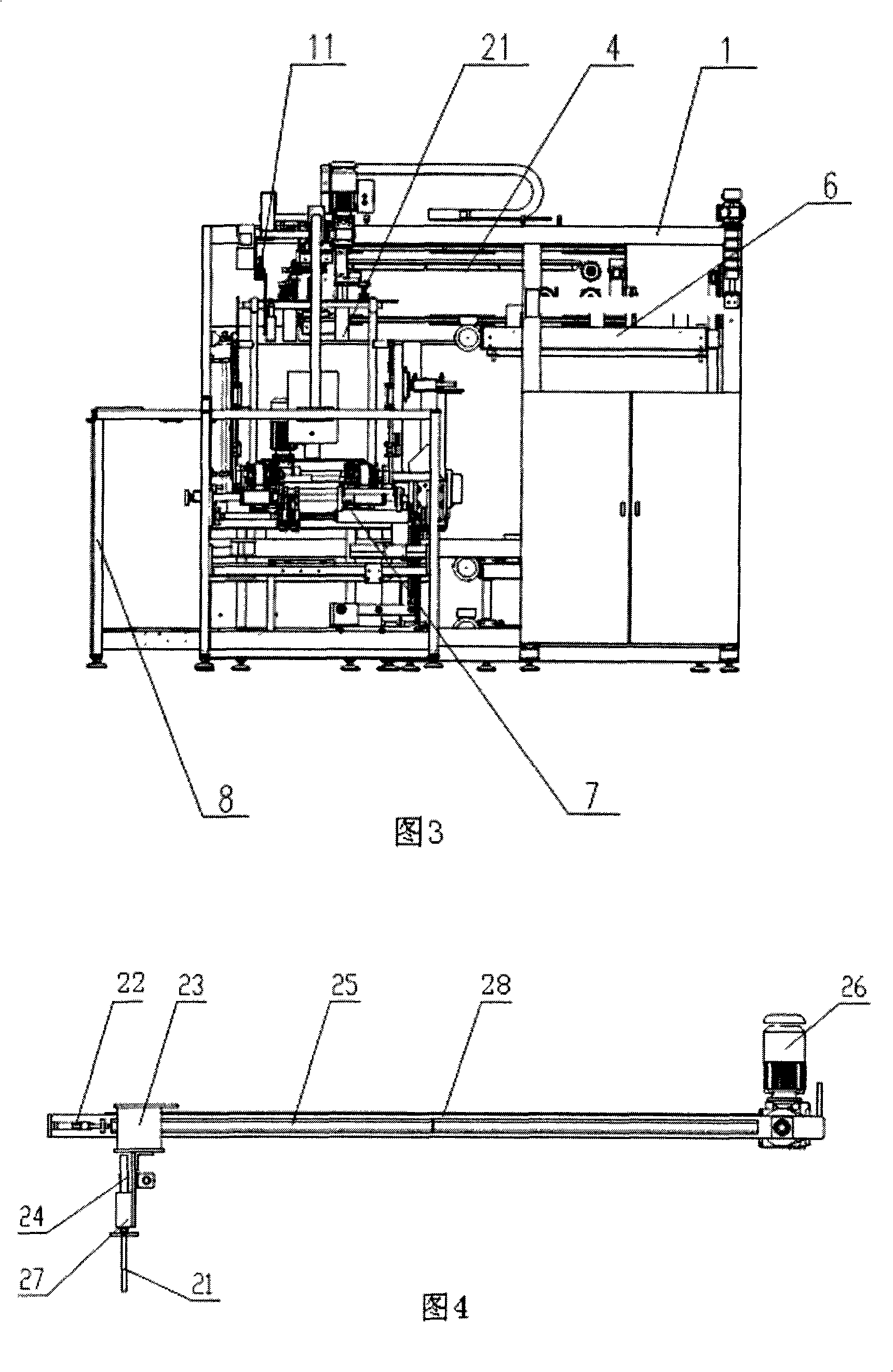

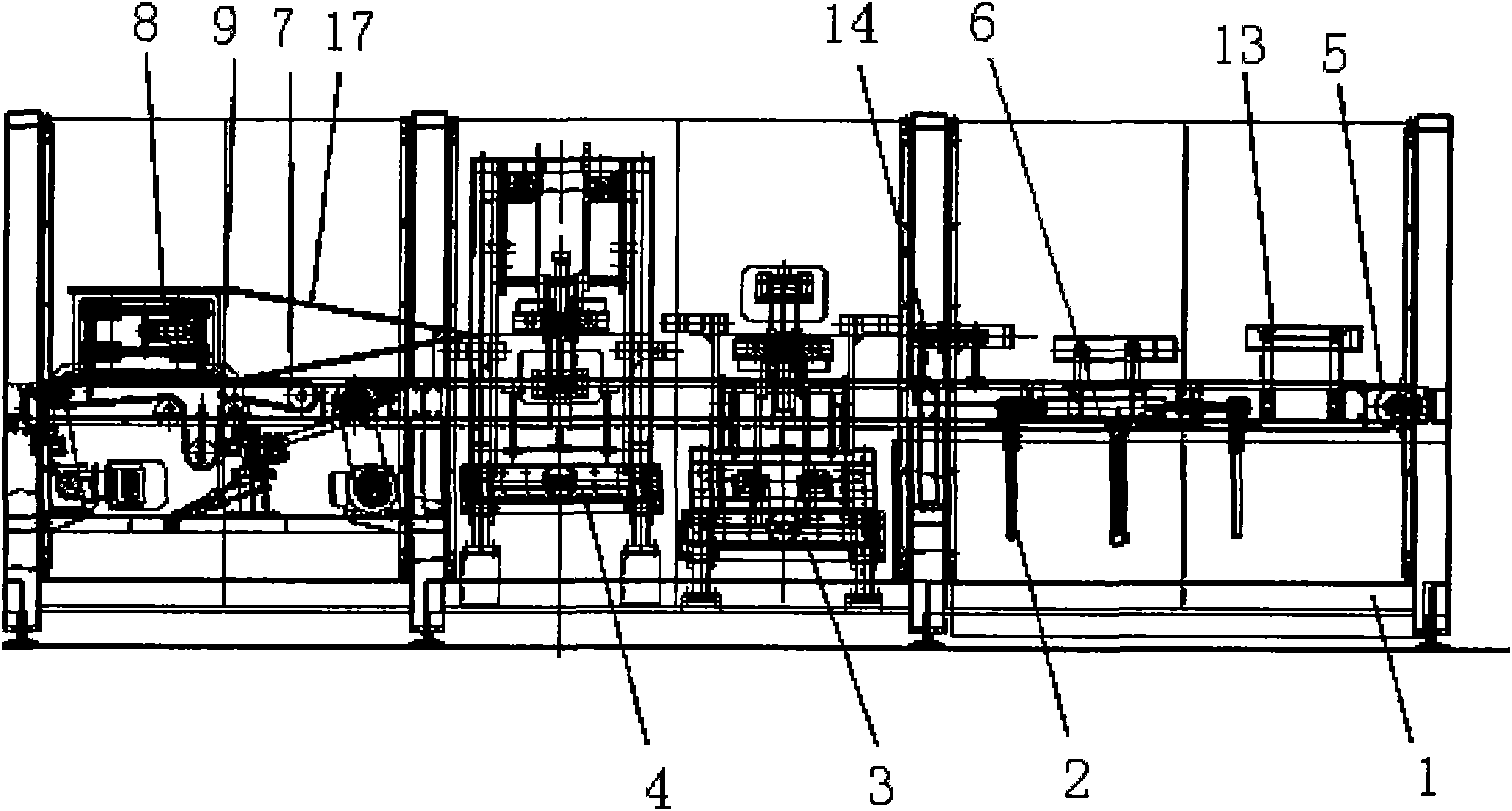

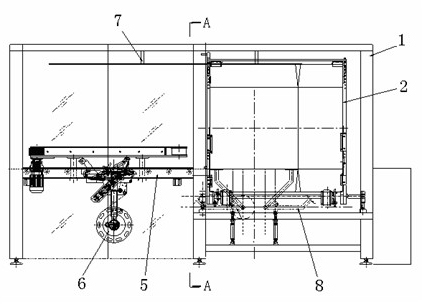

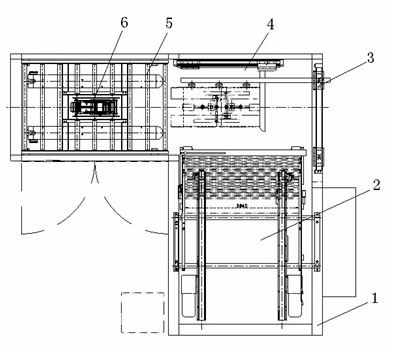

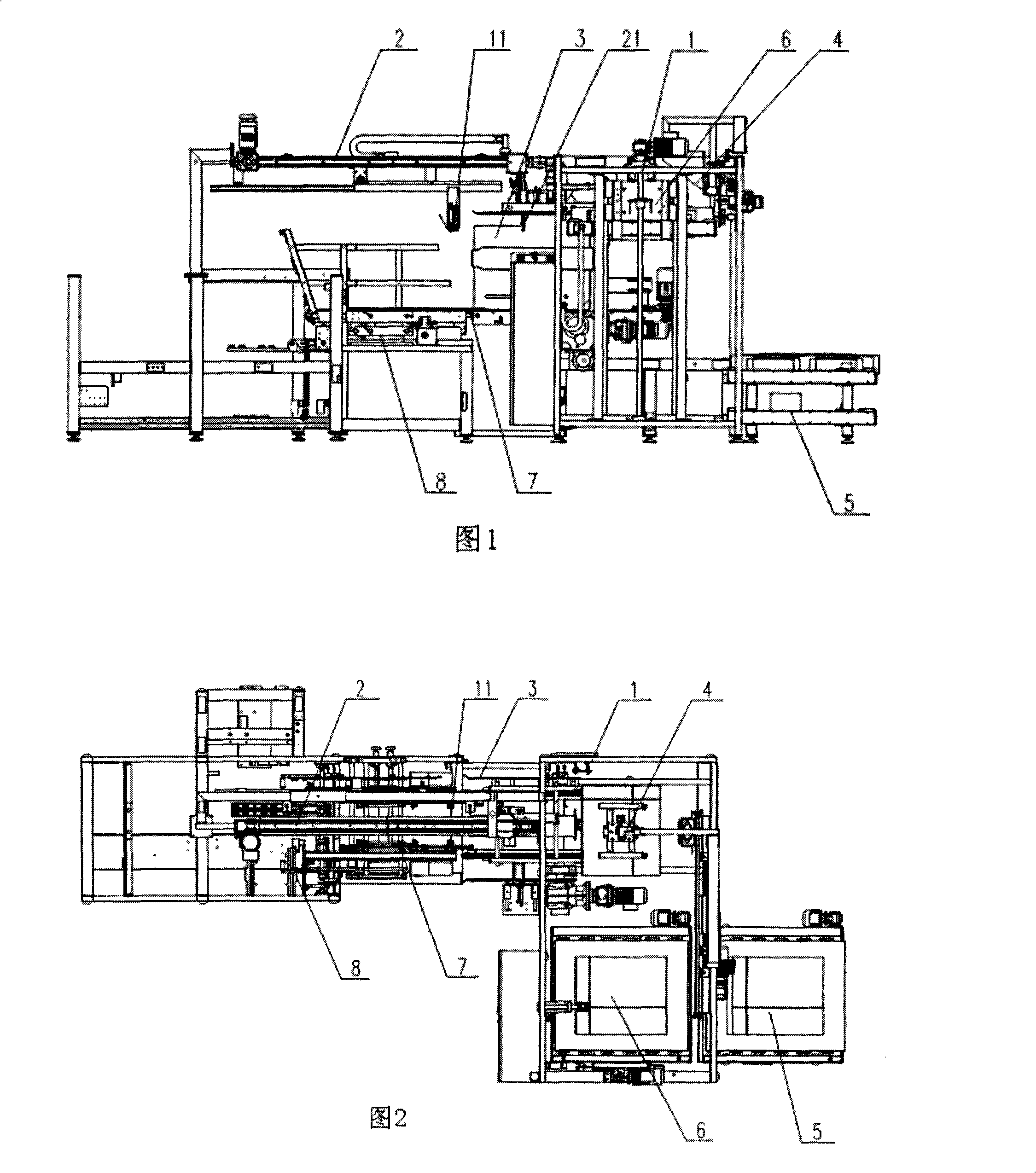

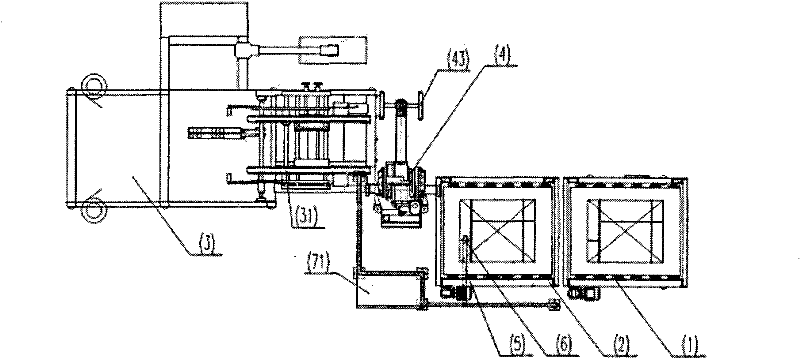

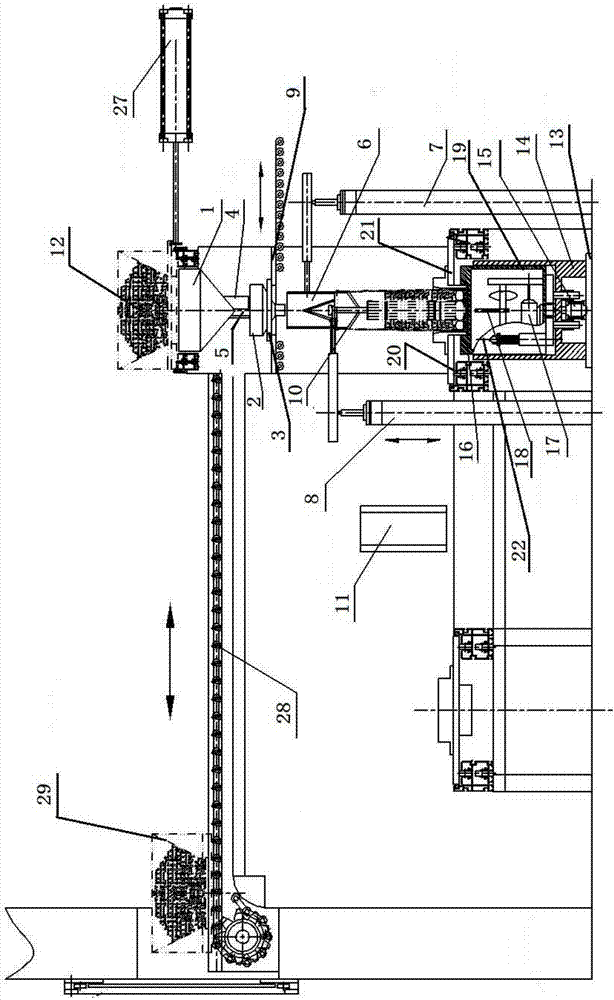

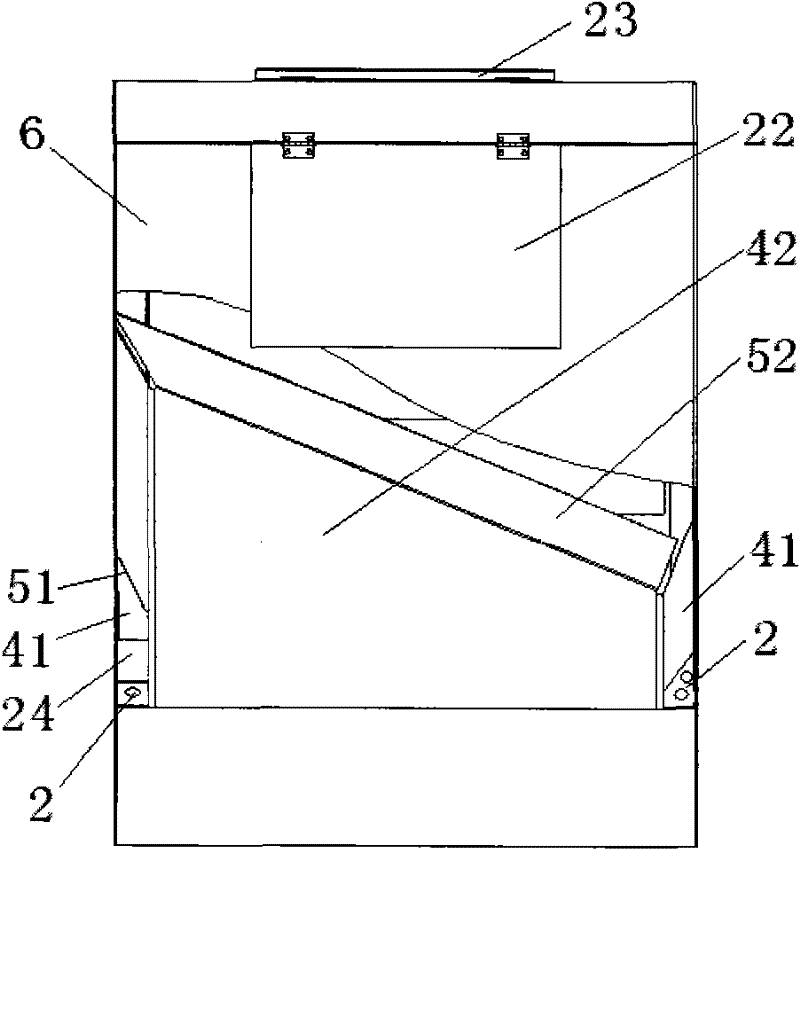

Automatic case unpacking machine

ActiveCN101792035ACompact structureReasonable layoutArticle unpackingLogistic distributionManufacturing engineering

The invention provides an automatic case unpacking machine, which comprises a conveyor and a cigarette case pre-locating mechanism, a cigarette case lift mechanism, a cigarette case upright cutting mechanism, a cigarette case cross cutting mechanism, a cigarette case lower cover opening mechanism, a cigarette case upper cover opening mechanism, a cigarette case side cover opening mechanism, a cigarette pushing mechanism, a distributary output mechanism and a transverse output mechanism which are arranged on the conveyor. The invention can realize full-automatic case unpacking, and thereby, the problems of high labour intensity, low work efficiency and the like brought by artificial case unpacking in the prior art are fundamentally solved. Moreover, the automatic case unpacking machine has compact structure, reasonable layout, accurate and rapid automatic case packing, wide applying range, convenient installation and investment saving, does not occupy more production space and can provide guarantee for the cigarette logistics distribution center to realize full-automatic operation.

Owner:东方机器制造(昆明)有限公司

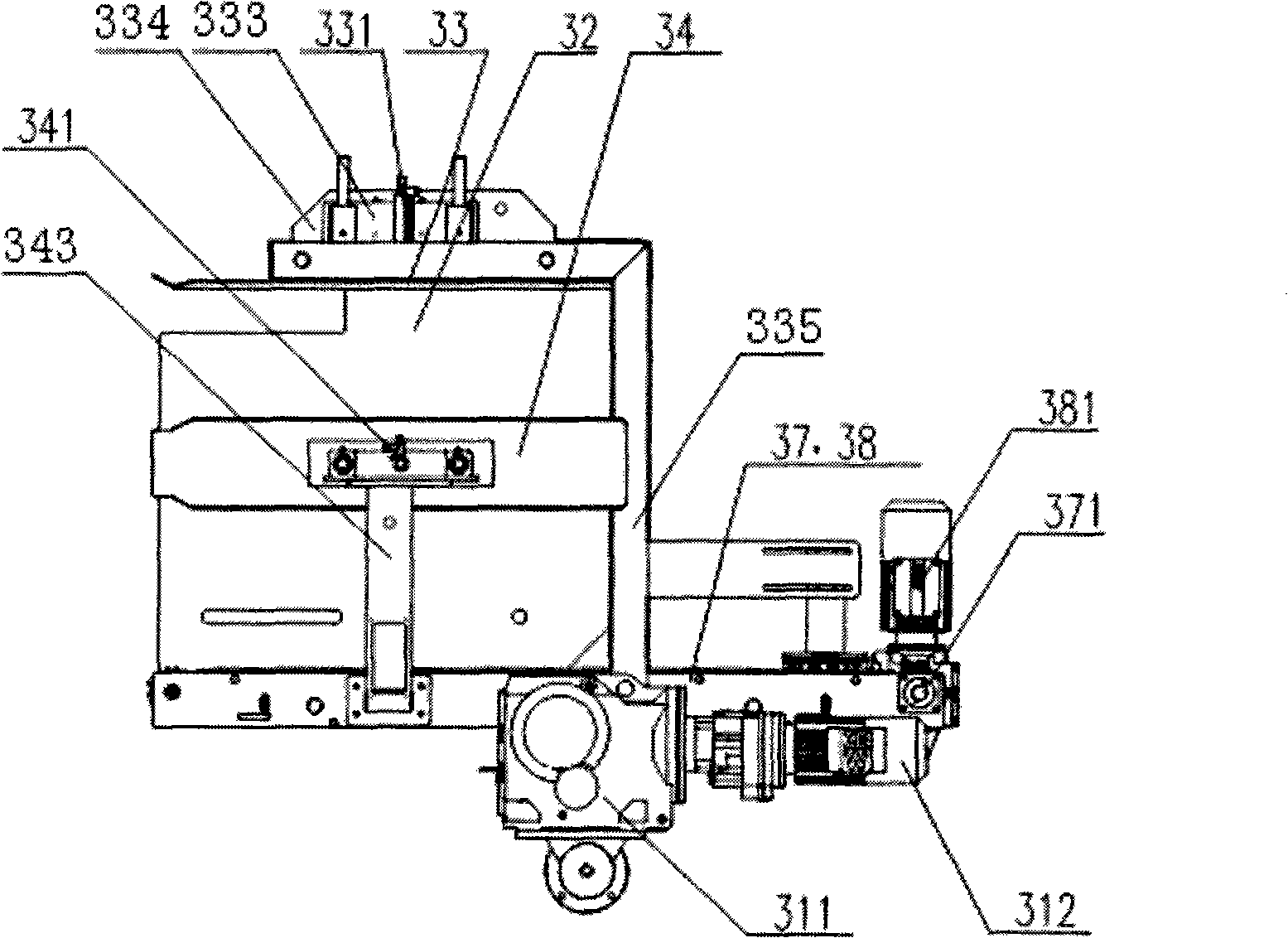

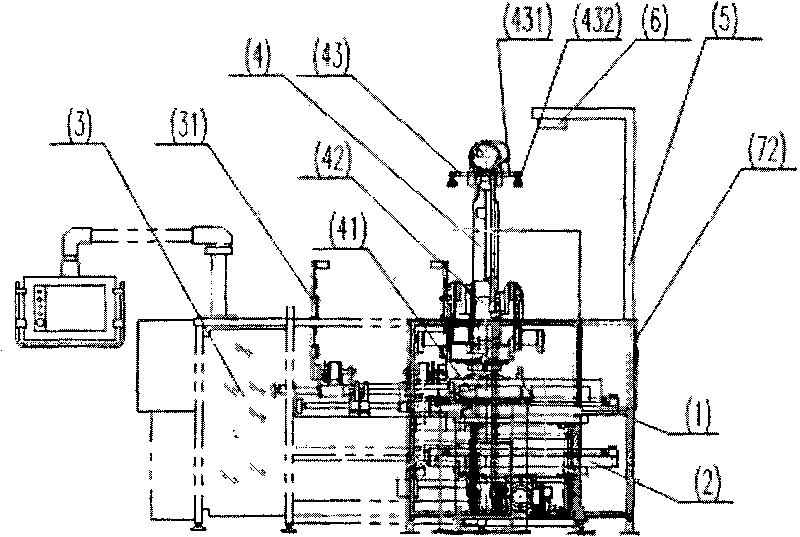

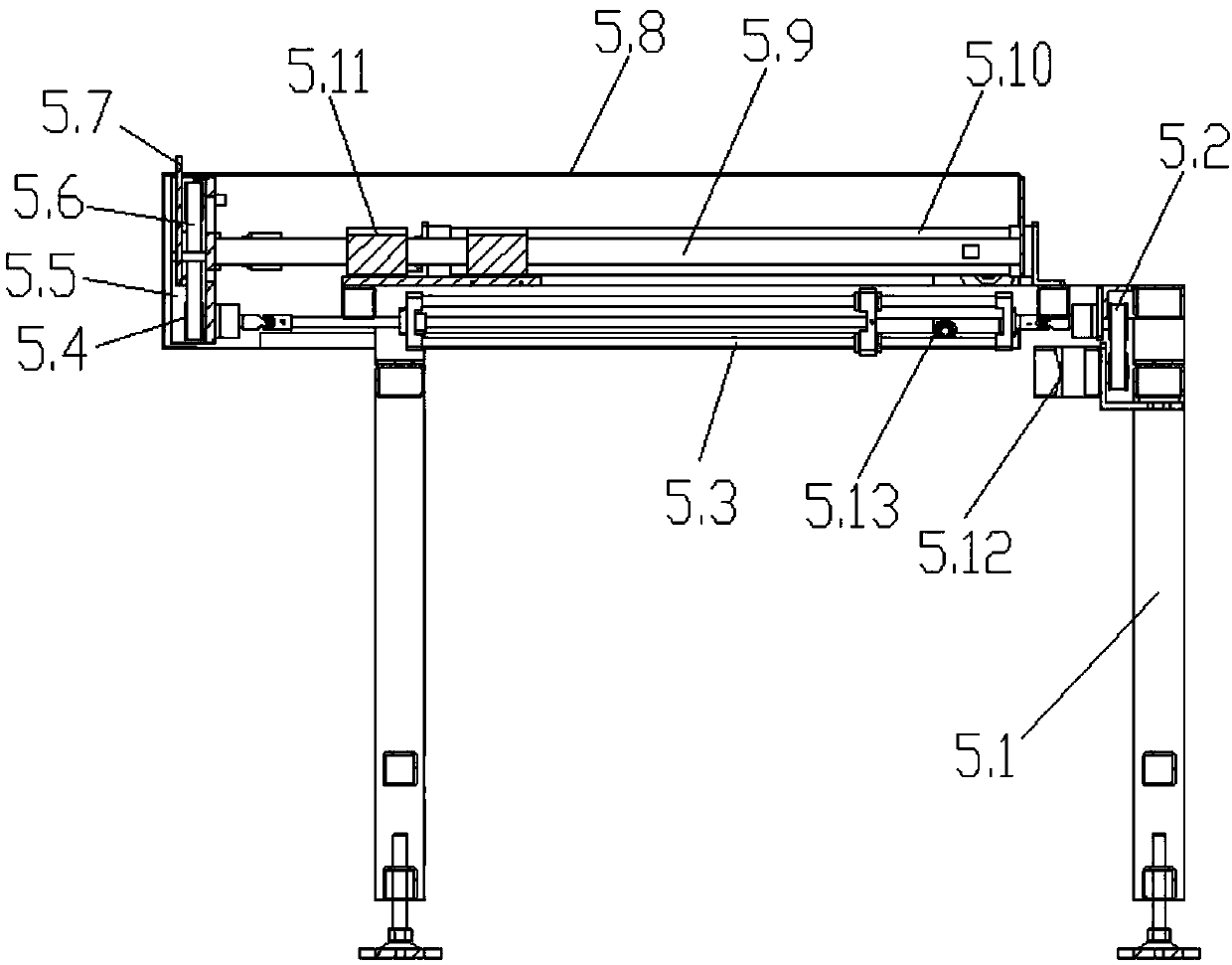

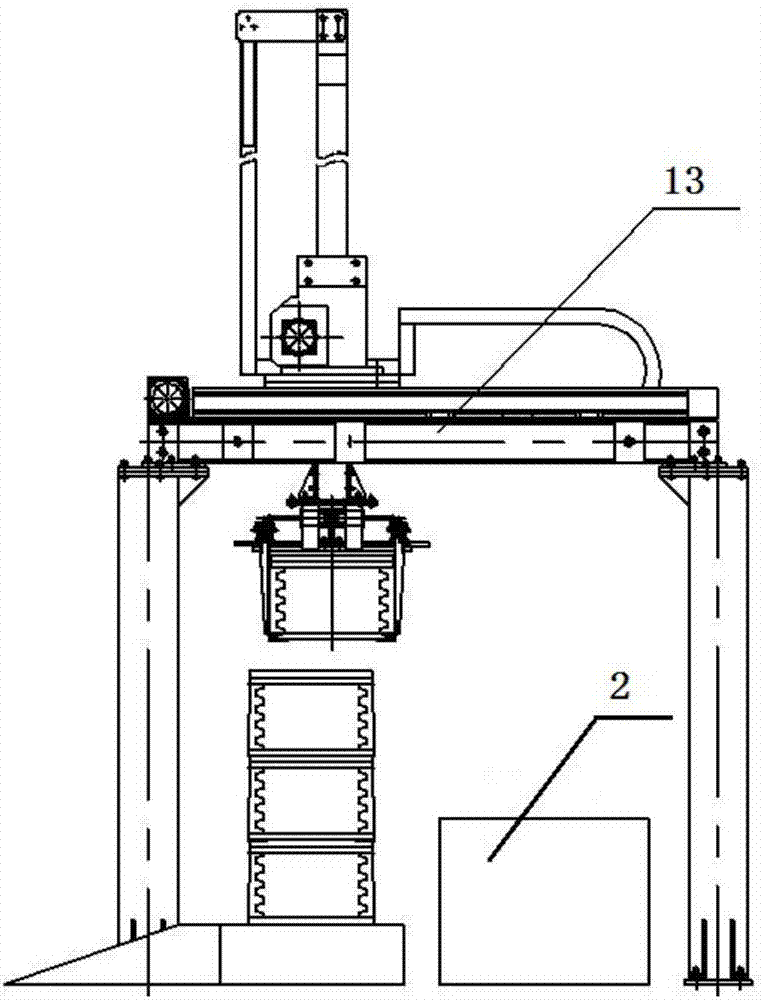

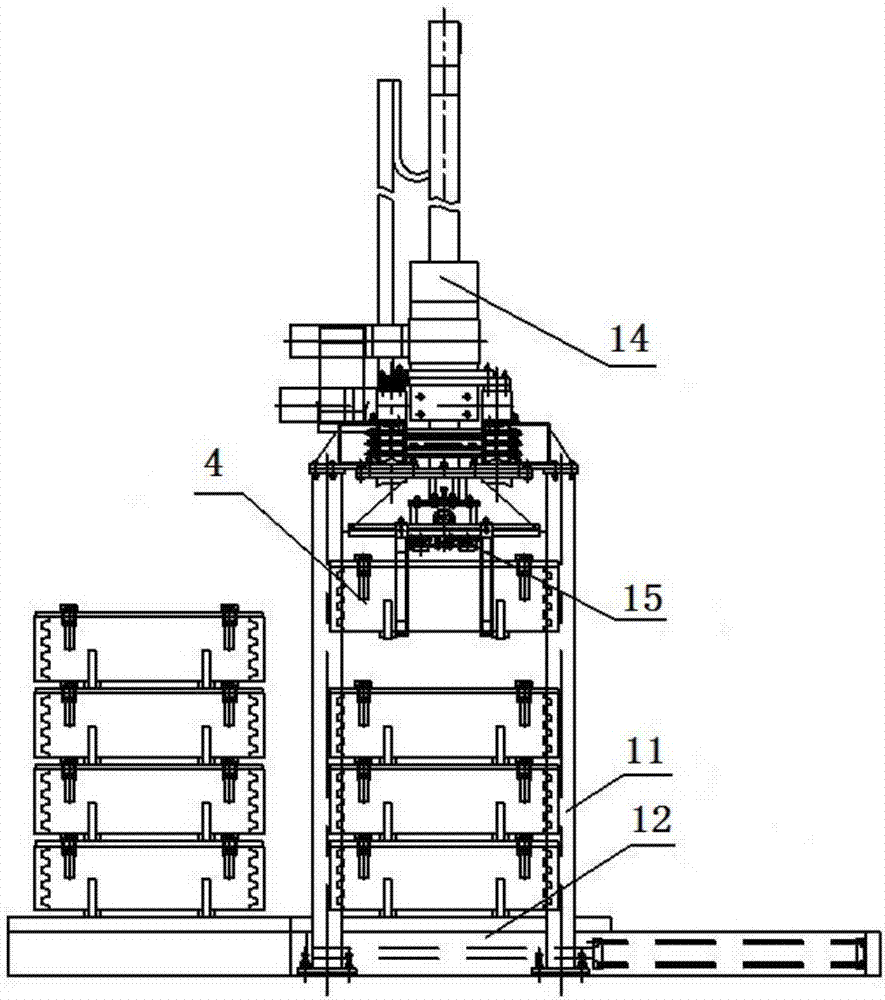

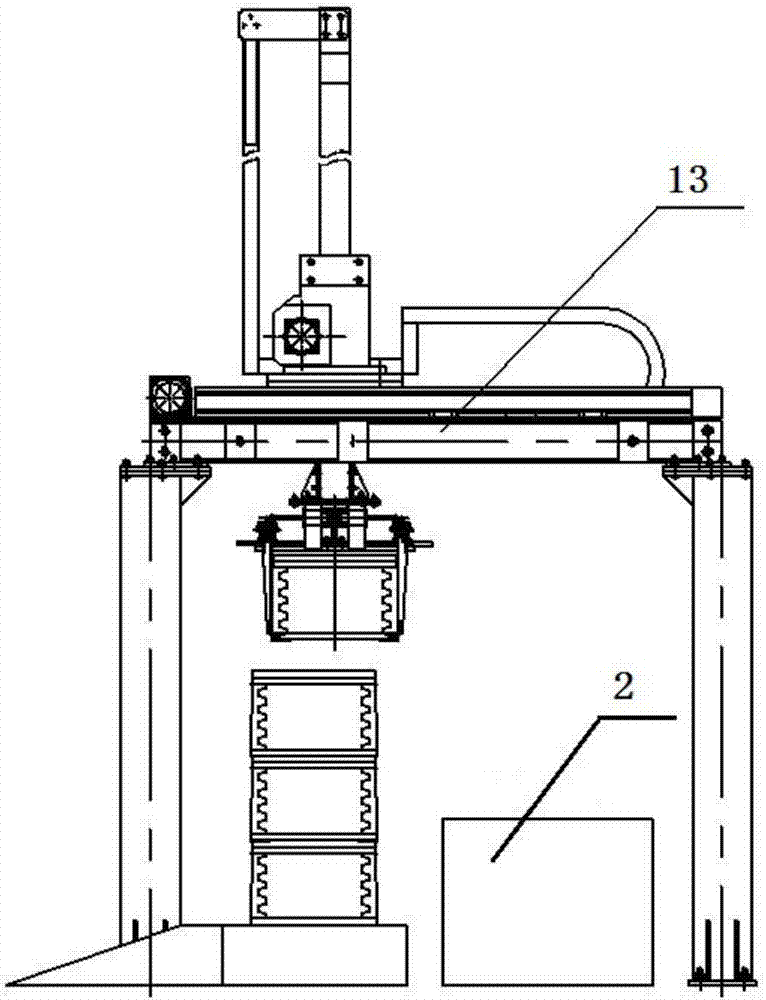

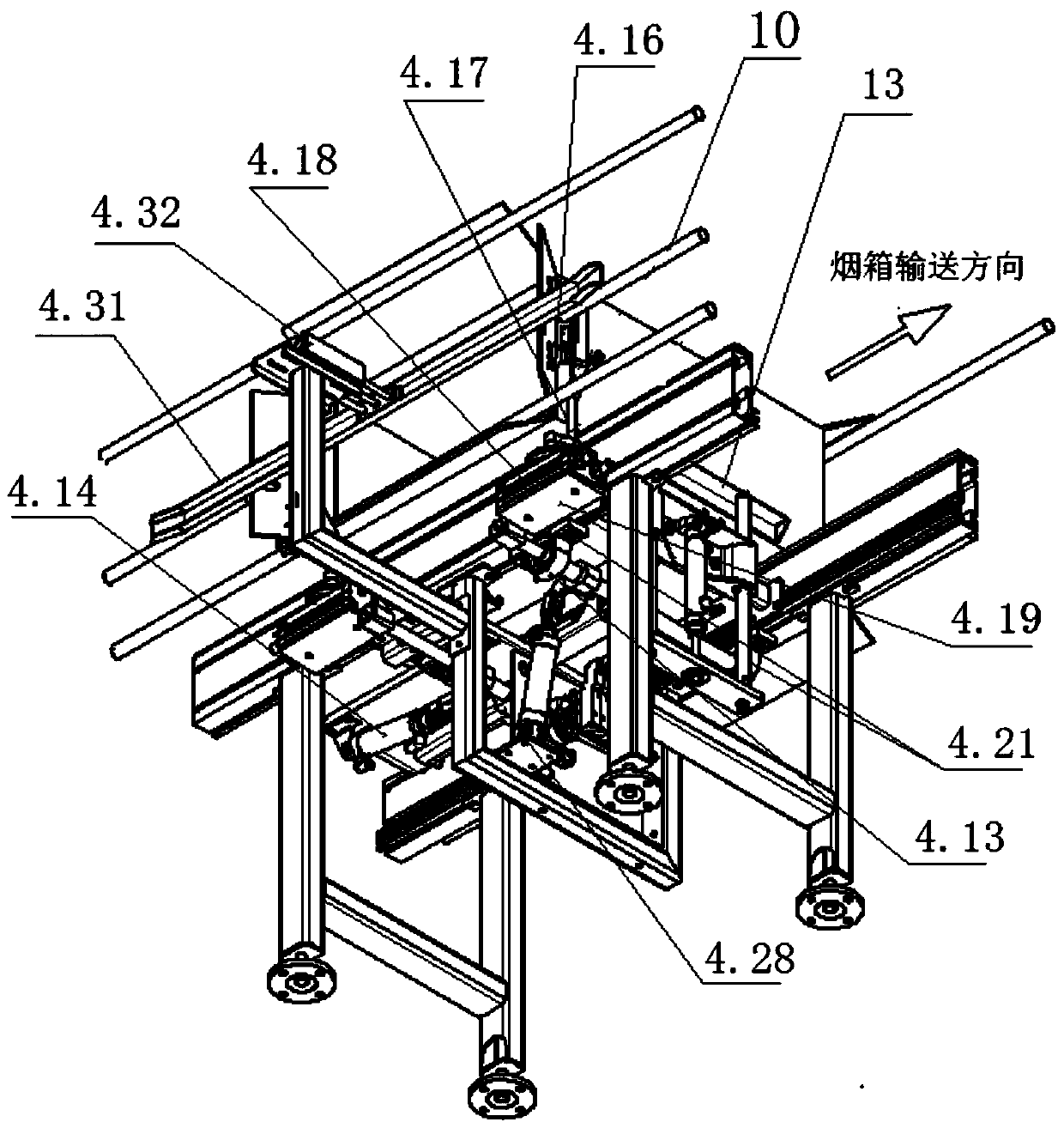

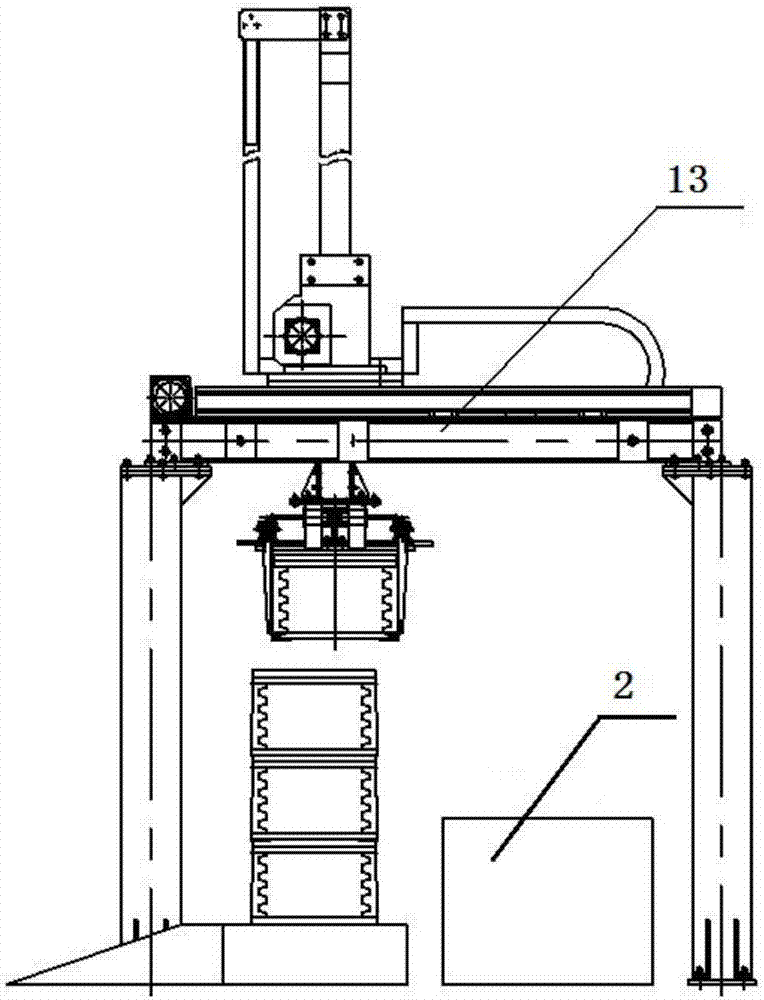

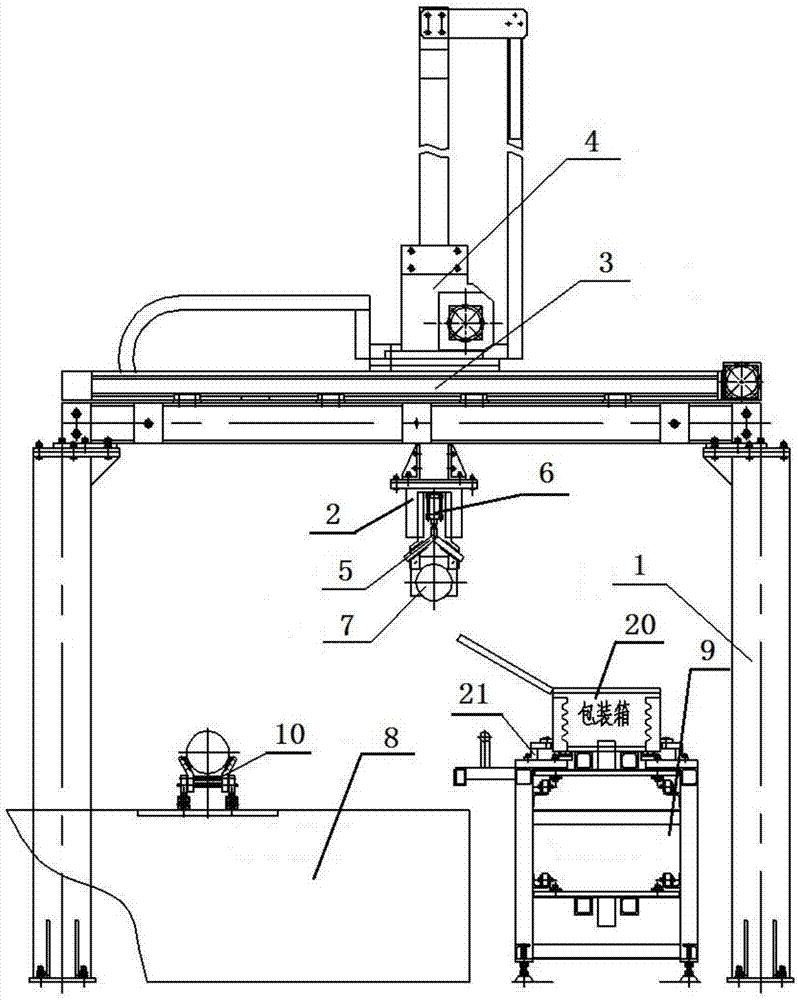

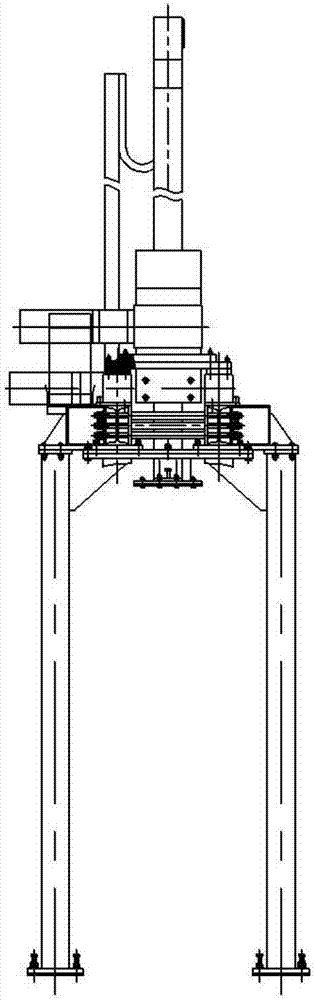

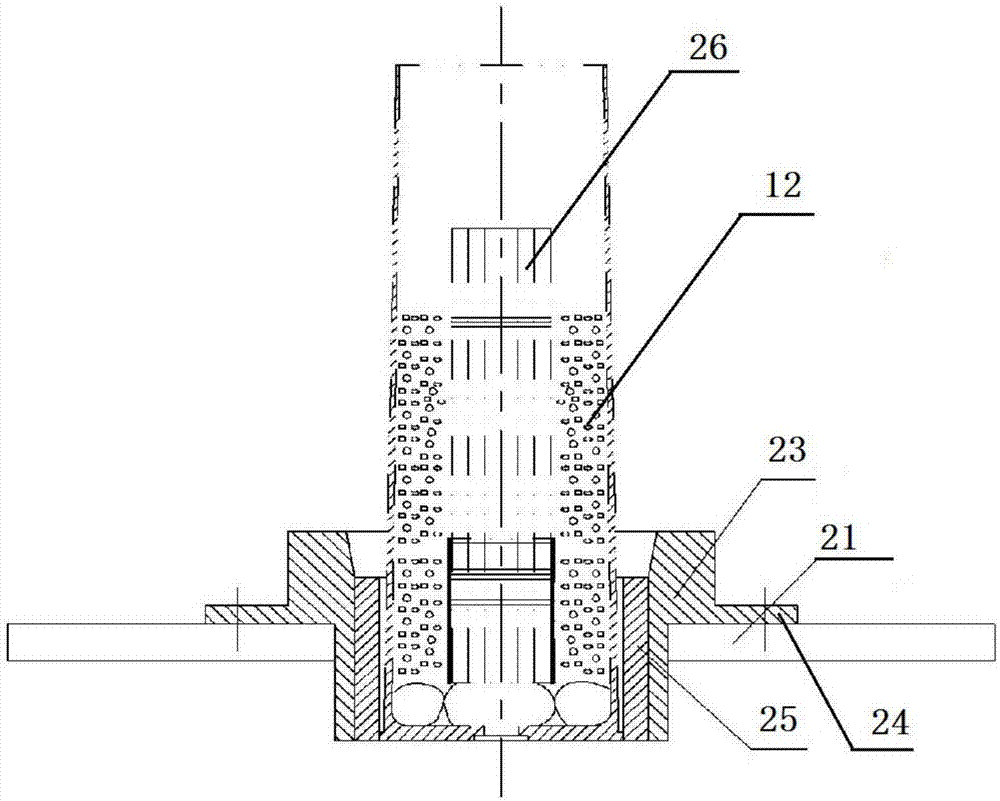

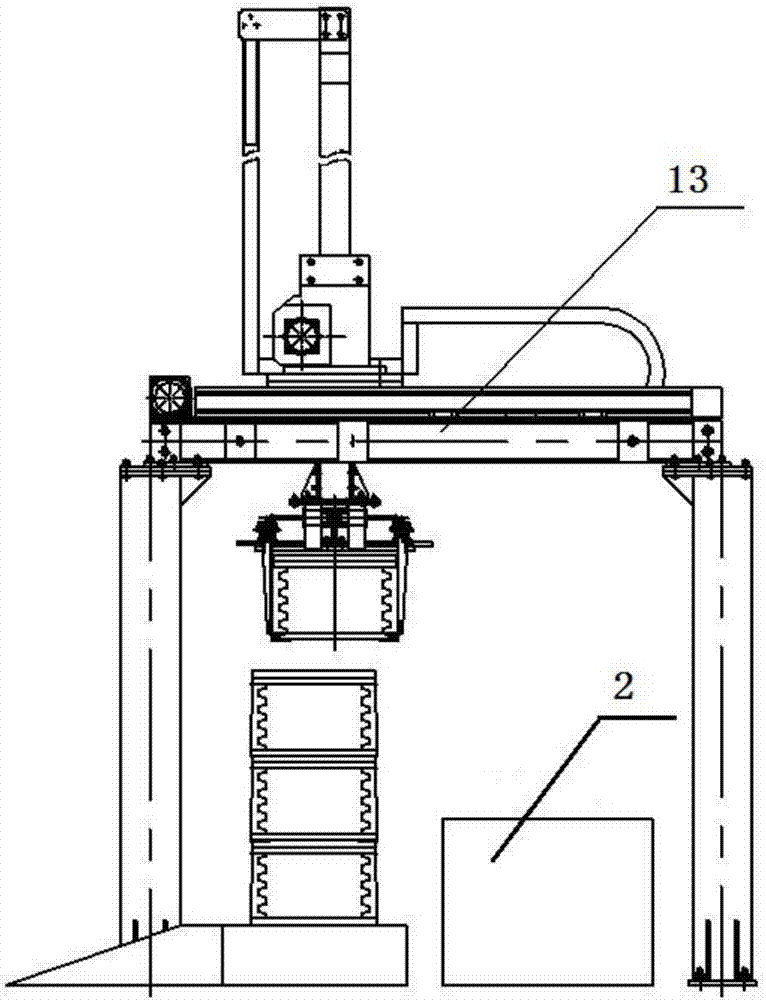

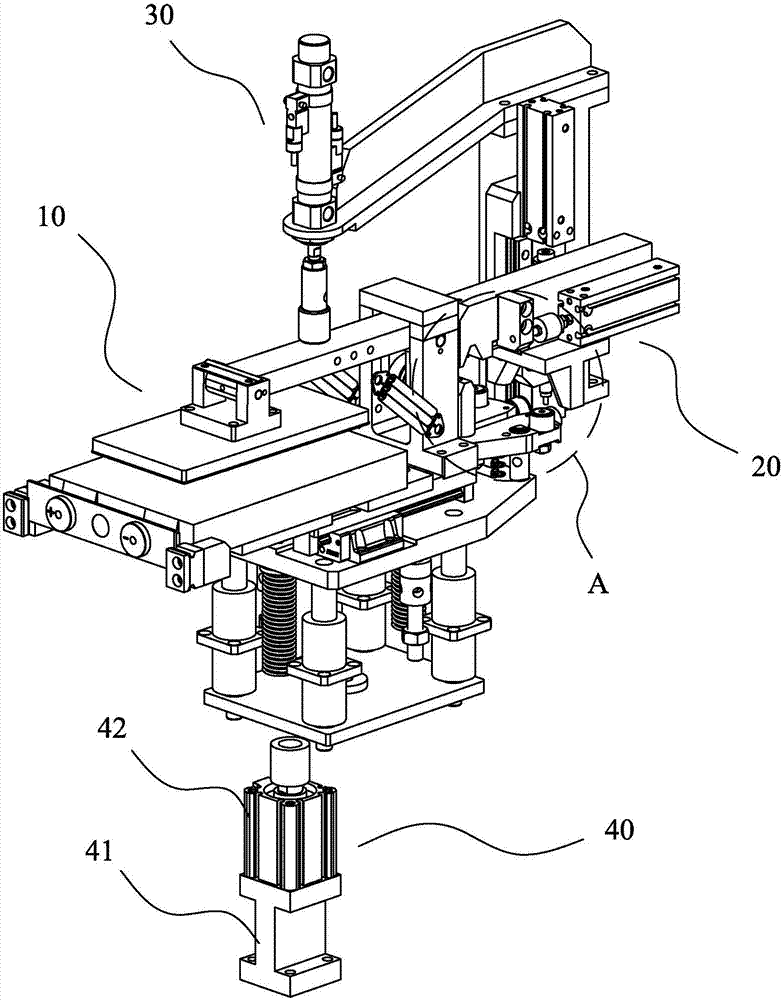

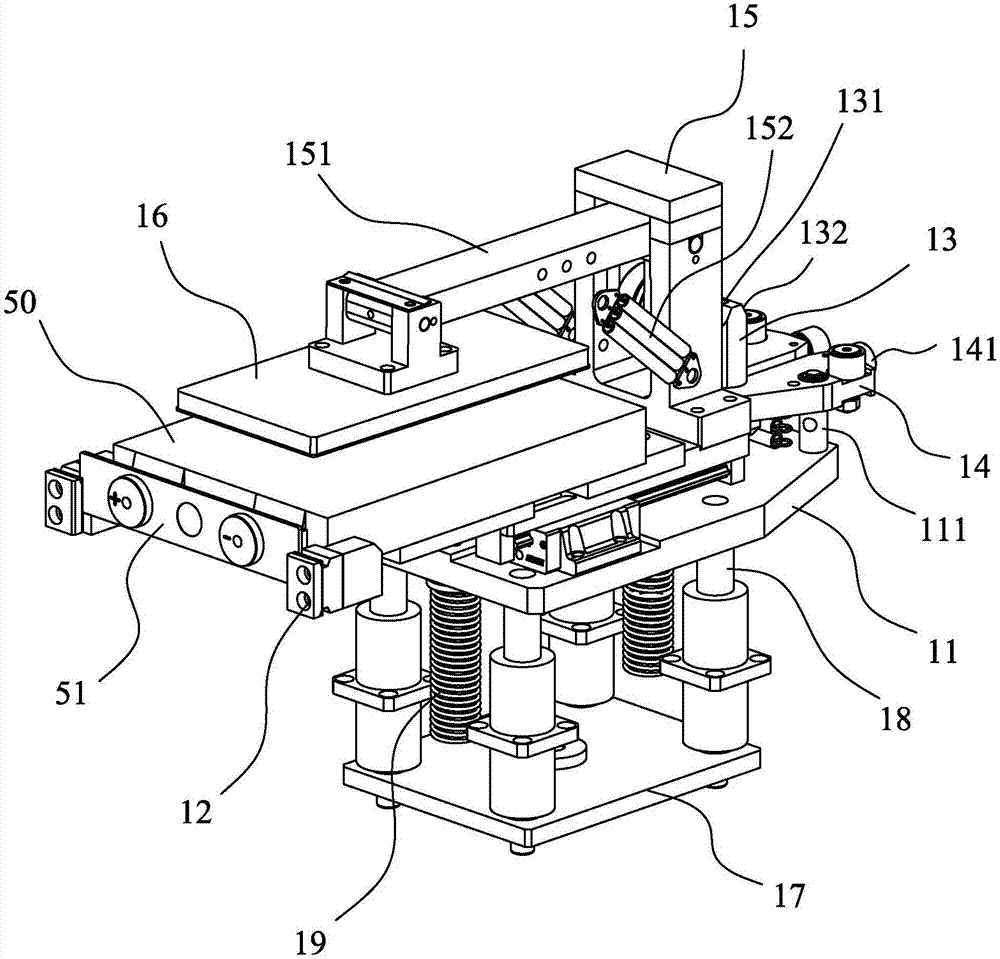

Robot automatic carton loading machine

ActiveCN101704421ARealize fully automated operationCompact structureGripping headsPackaging automatic controlRobot positionCarton

The invention provides a robot automatic carton loading machine which comprises a carton conveyor and a carton packer, and also comprises a carton lifting conveyor positioned between the carton conveyor and the carton packer, and a robot positioned between the carton lifting conveyor and the carton packer. The robot automatic carton loading machine can completely realize automatic carton loading, fundamentally solves the defects of large labor intensity, low work efficiency and the like caused by manpower loading in the prior art, and has compact structure, reasonable arrangement, is capable of loading carton accurately and rapidly, and does not occupy more production space; according to different carton packer arrangement in the prior art, the suitable machine types of the robot automatic carton loading machine can be selected; and the robot automatic carton loading machine has wide application range, convenient installation and saved investment, and is capable of providing guarantee for cigarette packaging to realize full automatic operation.

Owner:东方机器制造(昆明)有限公司

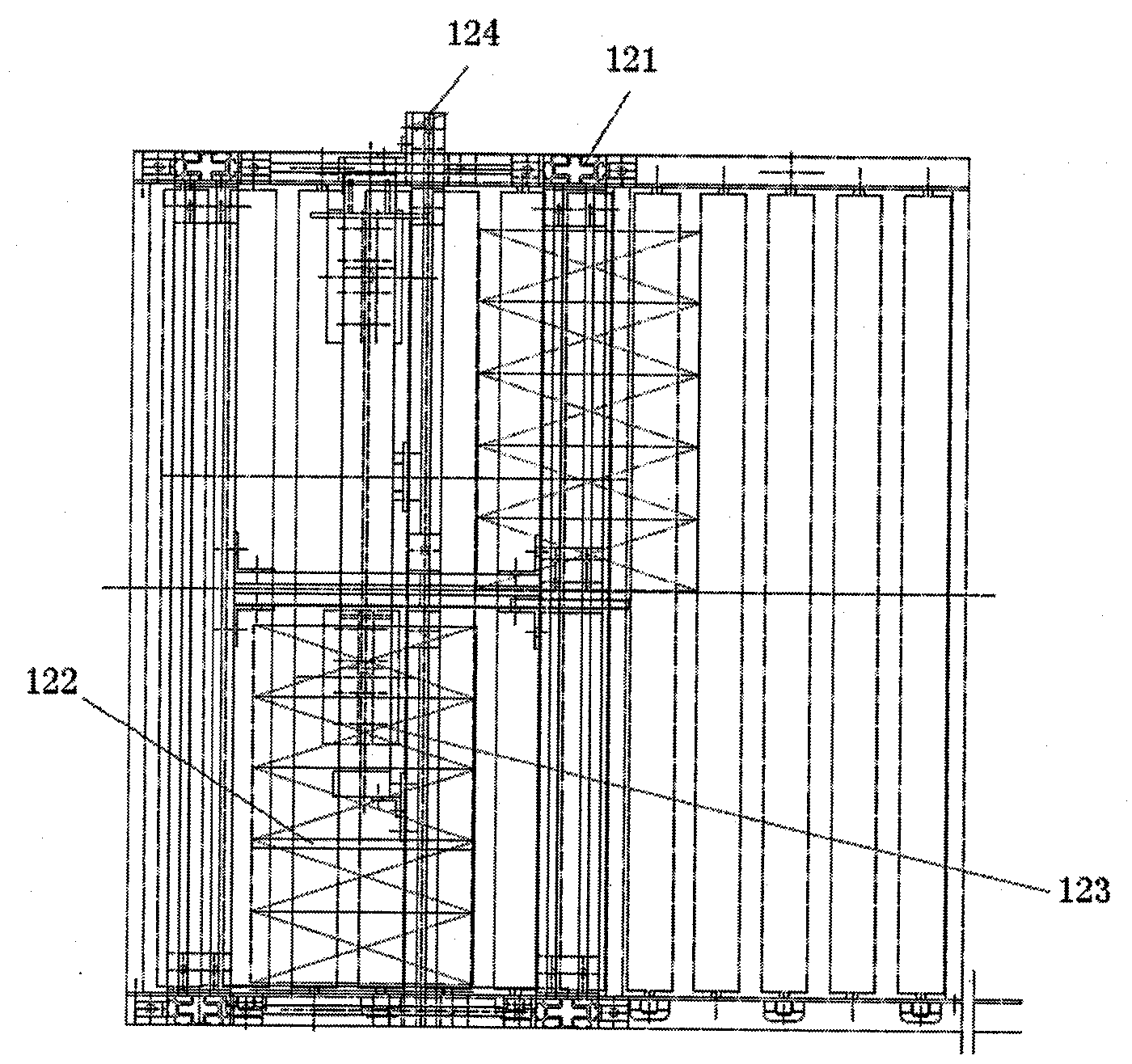

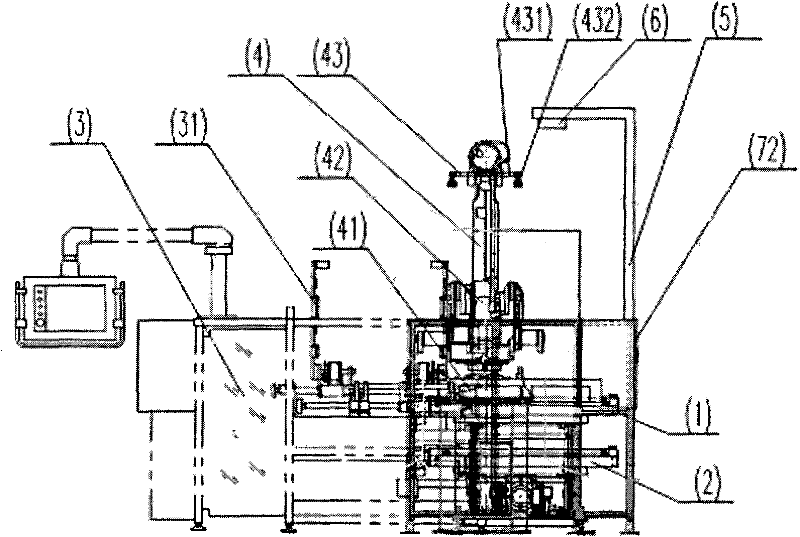

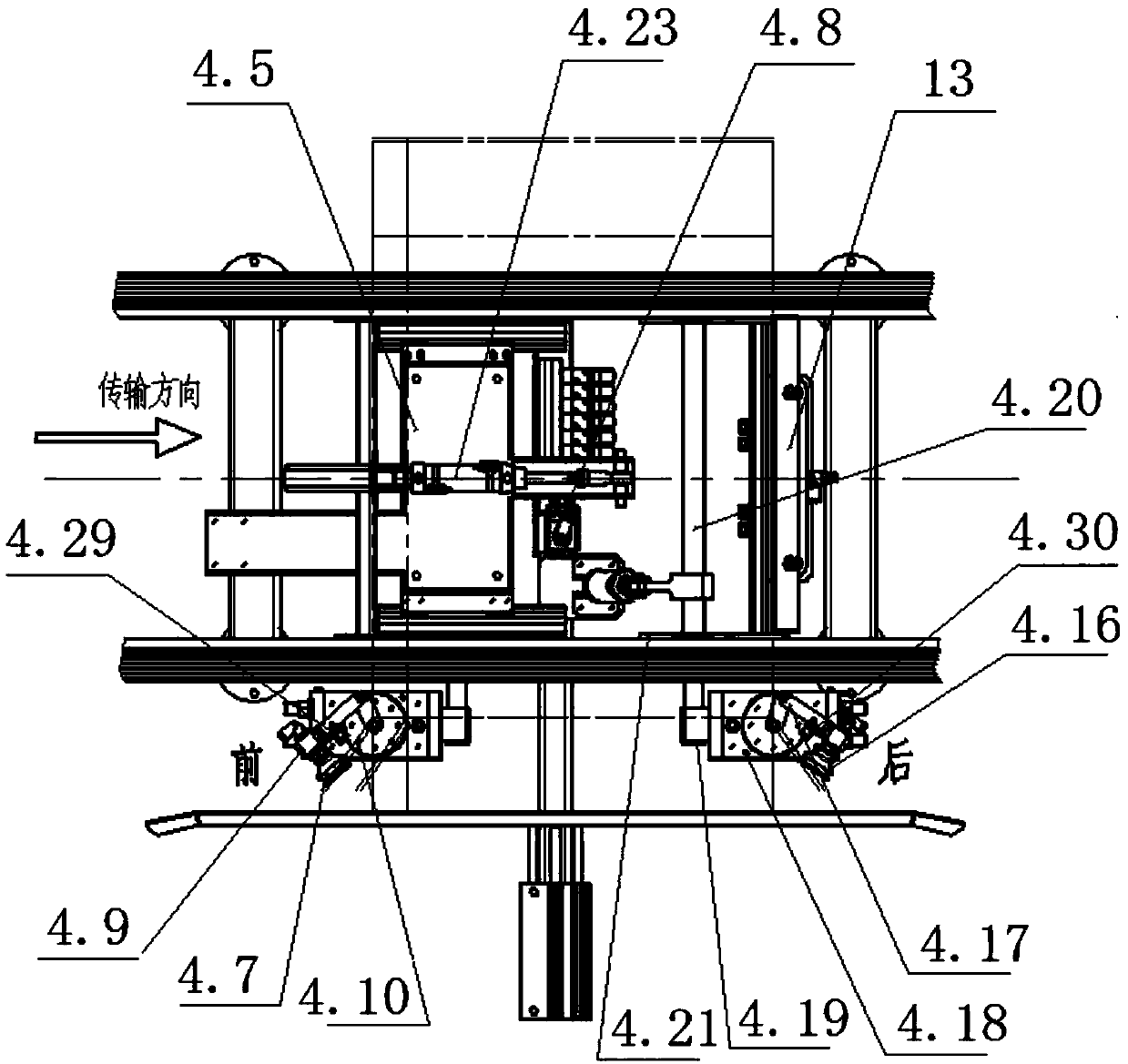

Tobacco shred box sealing machine

ActiveCN102381497ACompact structureReasonable layoutWrapper twisting/gatheringPackaging automatic controlUltimate tensile strengthMechanical engineering

The invention provides a tobacco shred box sealing machine which comprises a rack and is characterized in that the rack is provided with a tobacco shred box, a tobacco shred box opening mechanism, a tobacco shred box folding mechanism, a tobacco shred box conveying mechanism and a tobacco shred box sealing mechanism. The tobacco shred box sealing machine can completely realize the automatic opening, the cover folding, the sealing and the conveying of the tobacco shred box and fundamentally overcome the defects such as high labor intensity, low working efficiency and the like which are caused by the reason that in the prior art, the opening, the cover folding and the sealing of the tobacco shred box are operated by manual work; and the tobacco shred box sealing machine is compact in structure, reasonable in layout, correct and rapid in the operations of the automatic opening, the cover folding and the sealing of the tobacco shred box, wide in application range and convenient to install, does not occupy more production space, saves investment, and can provide technical support for the realization of full-automatic production in a tobacco primary processing logistics system.

Owner:东方机器制造(昆明)有限公司

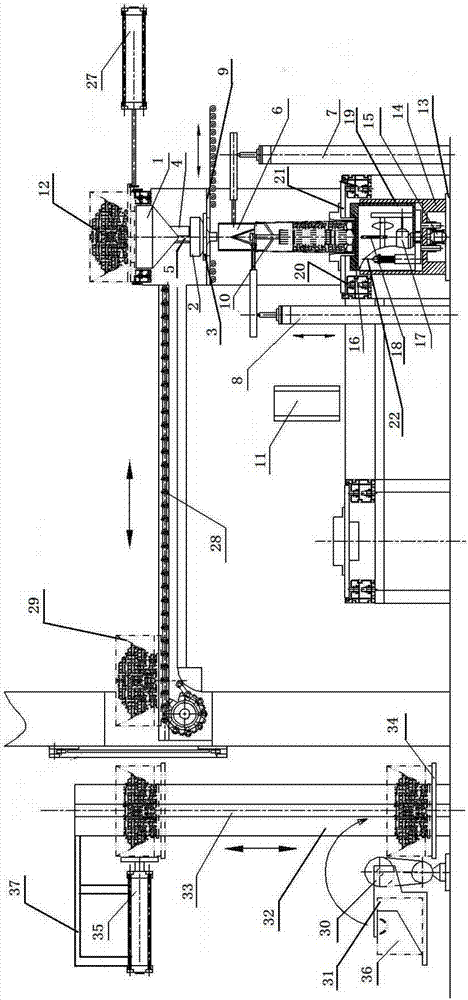

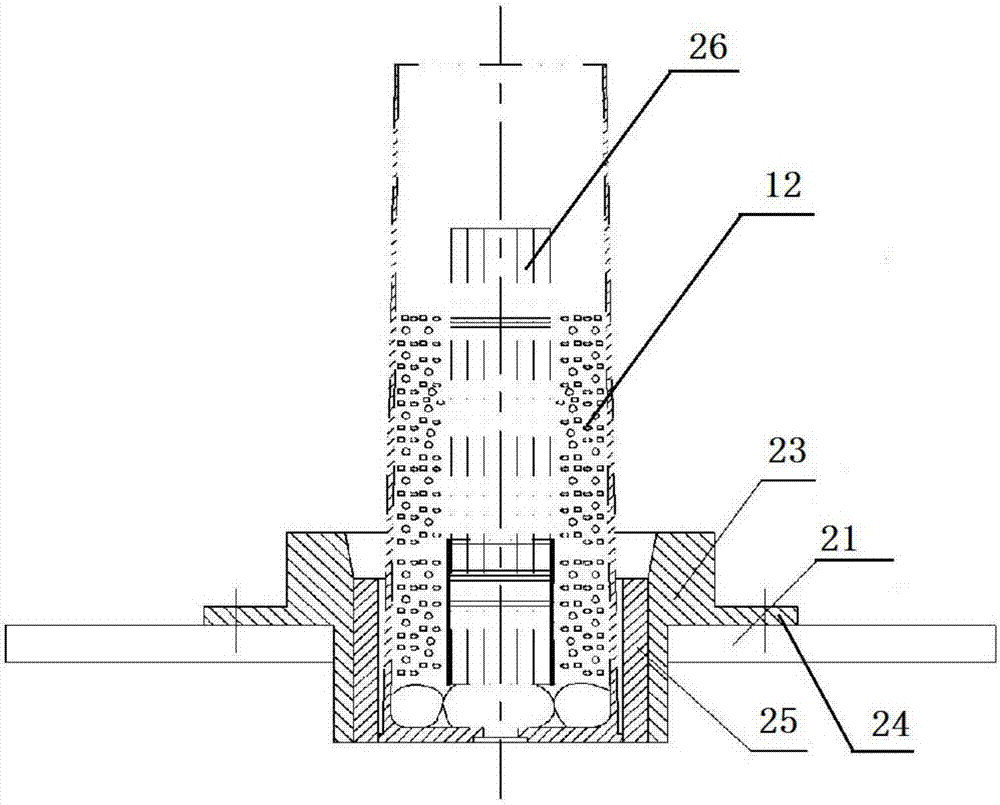

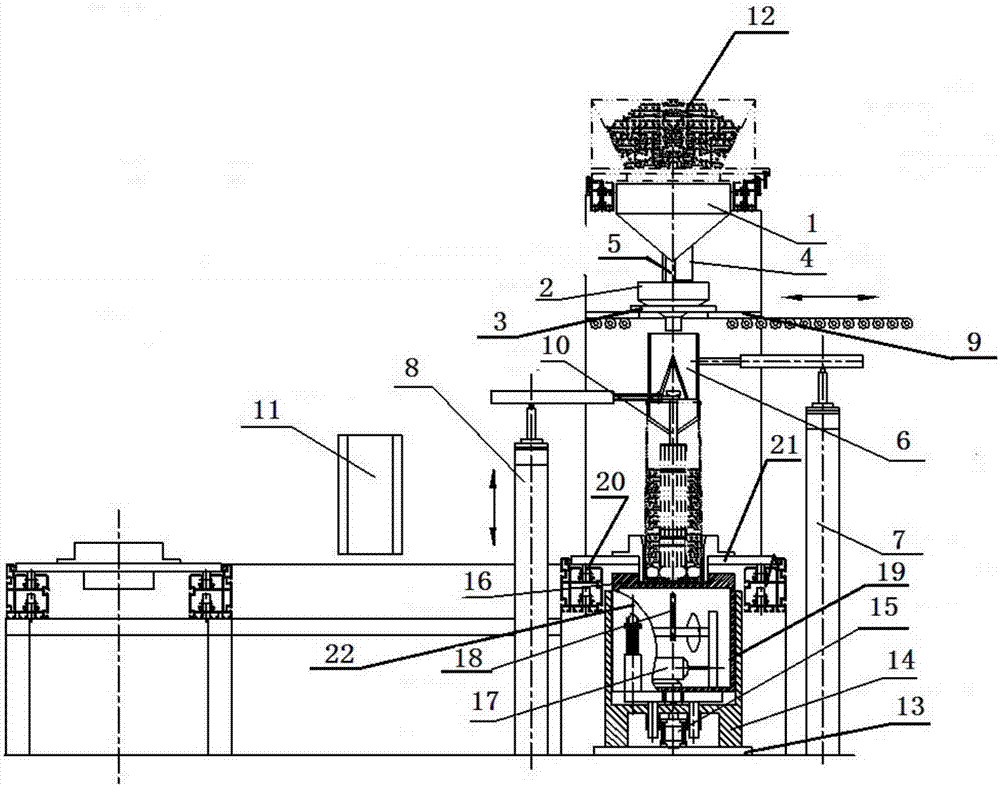

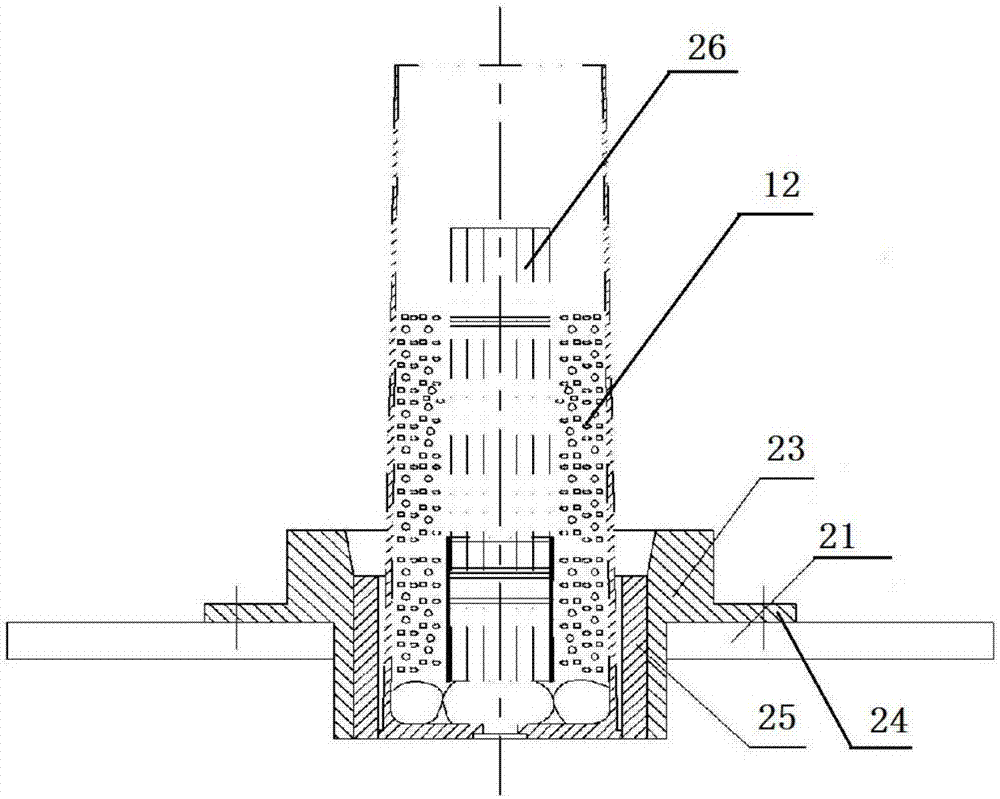

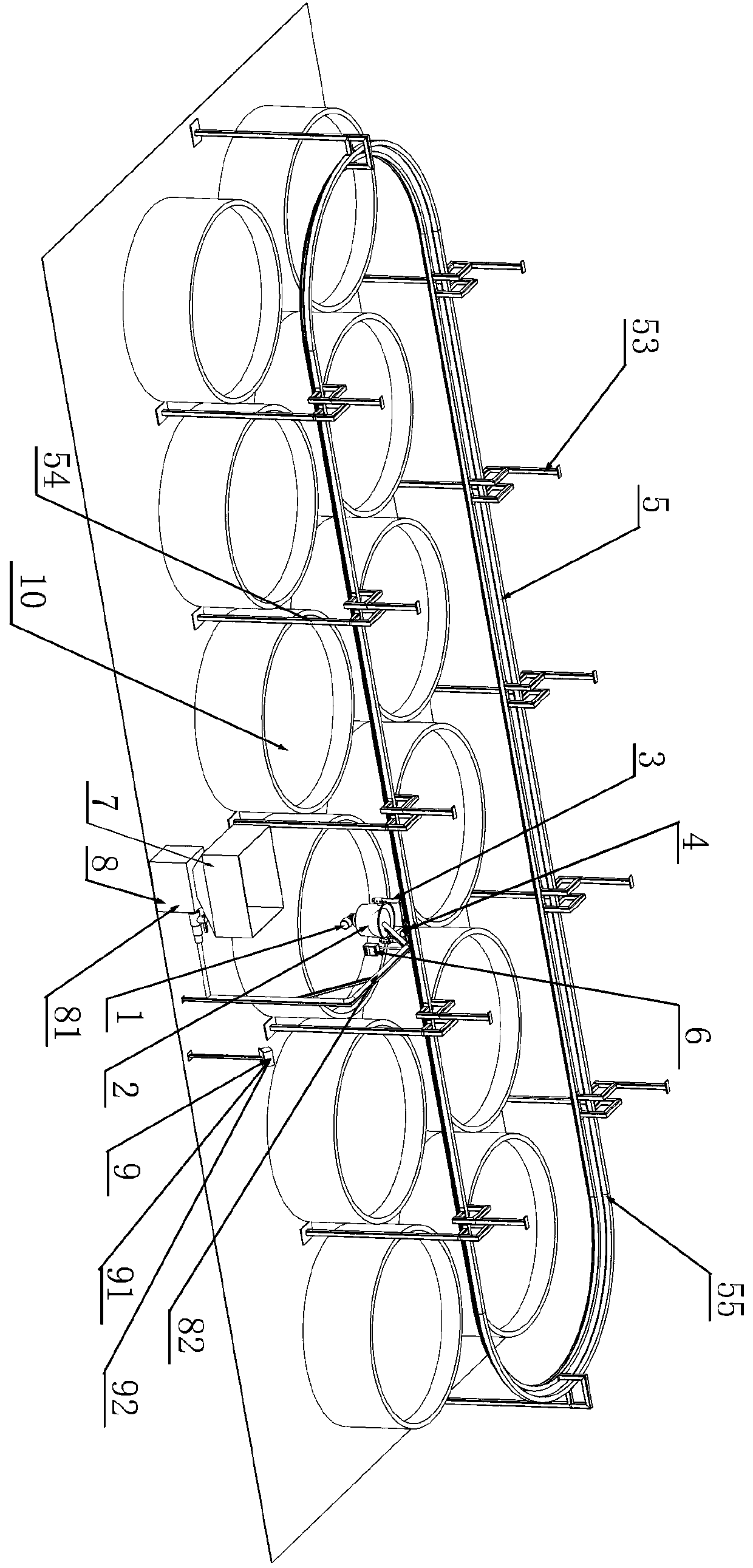

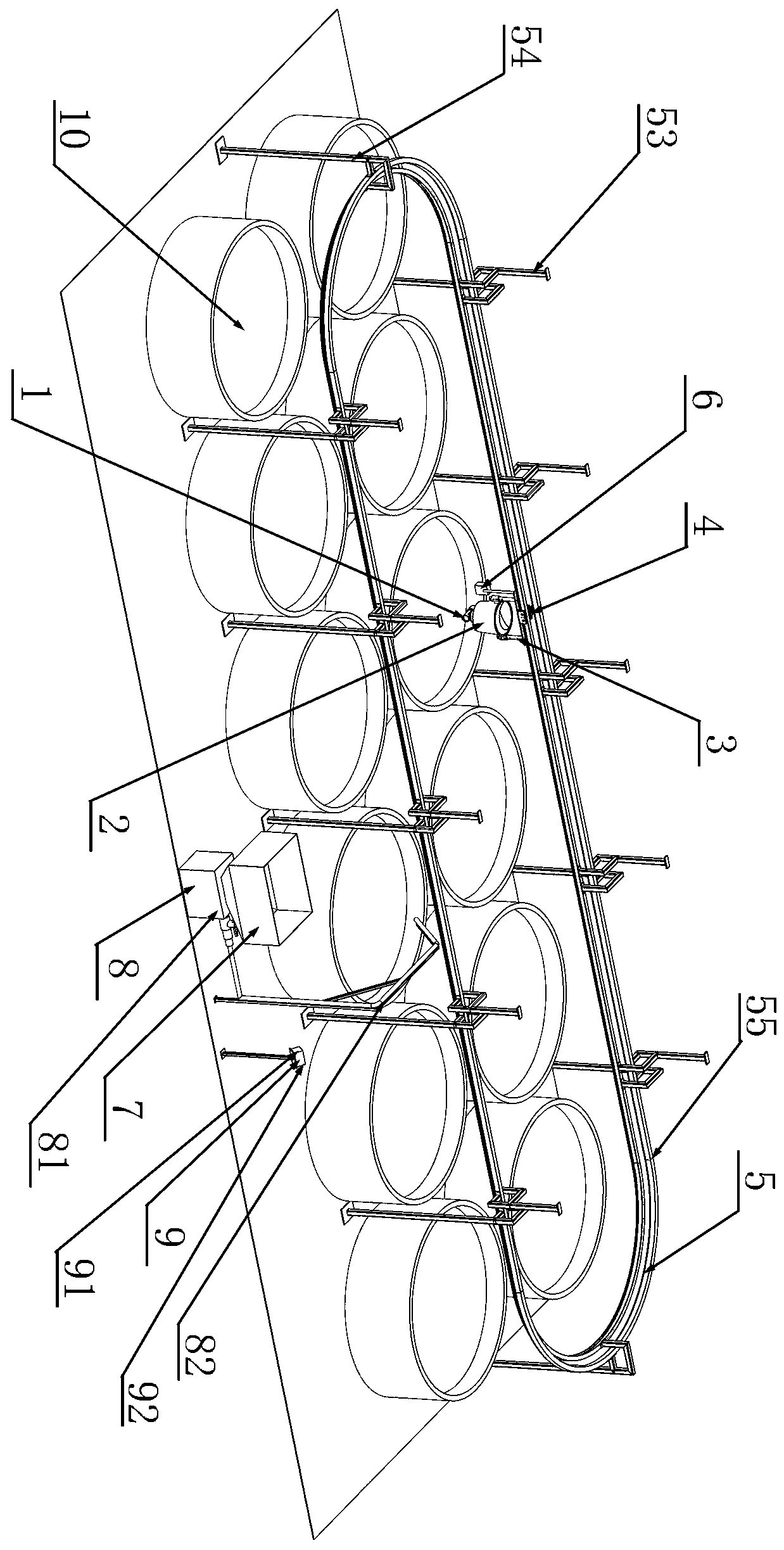

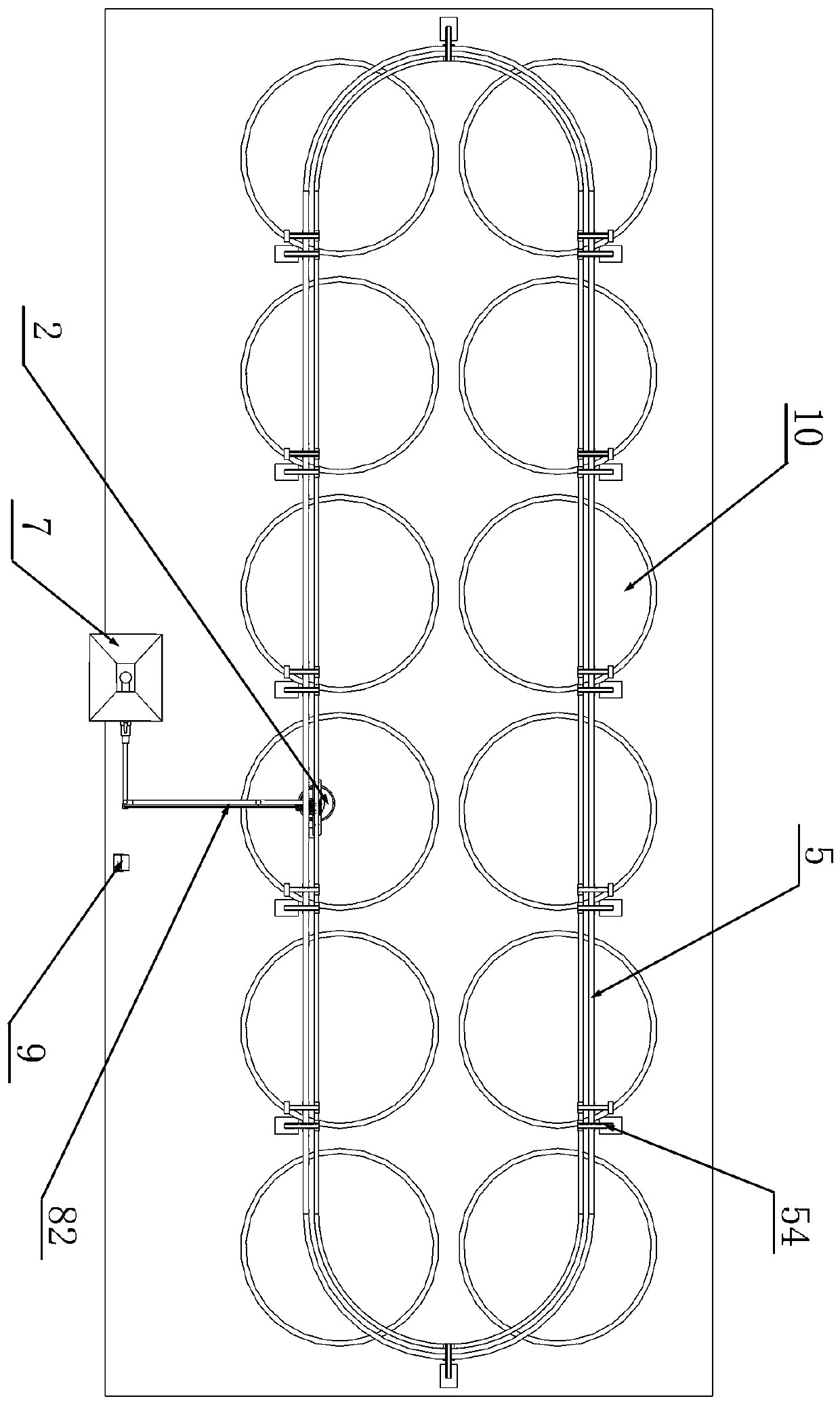

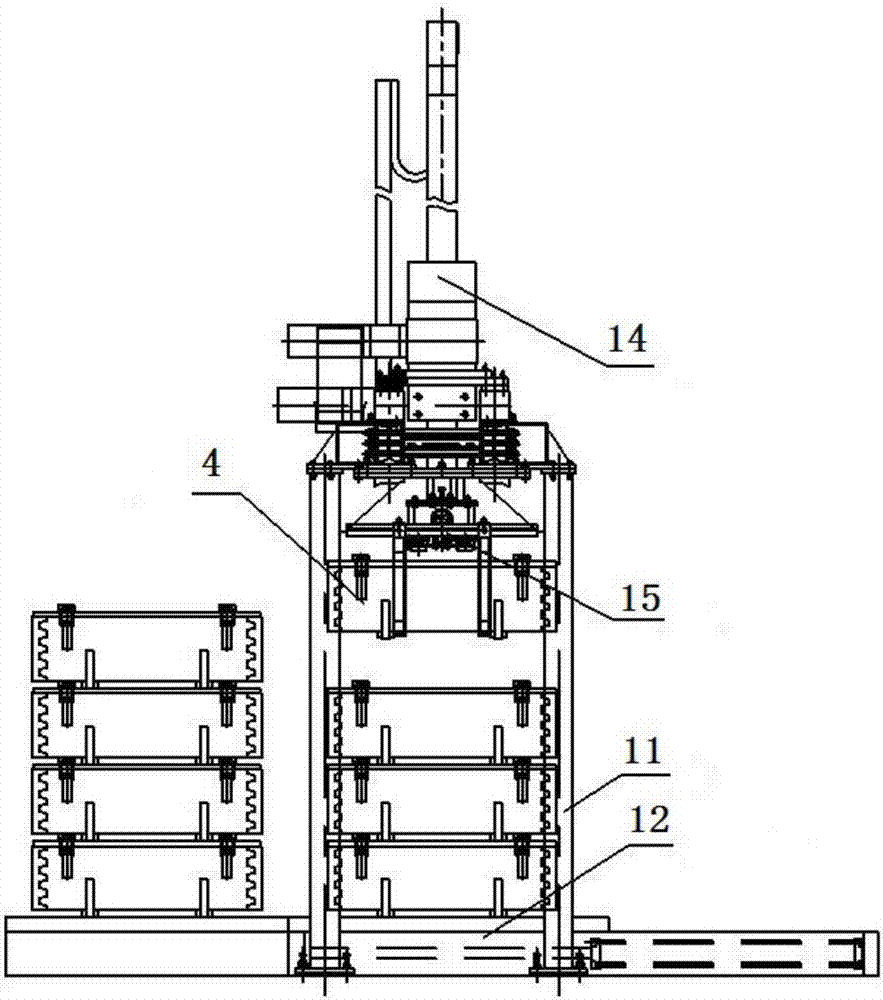

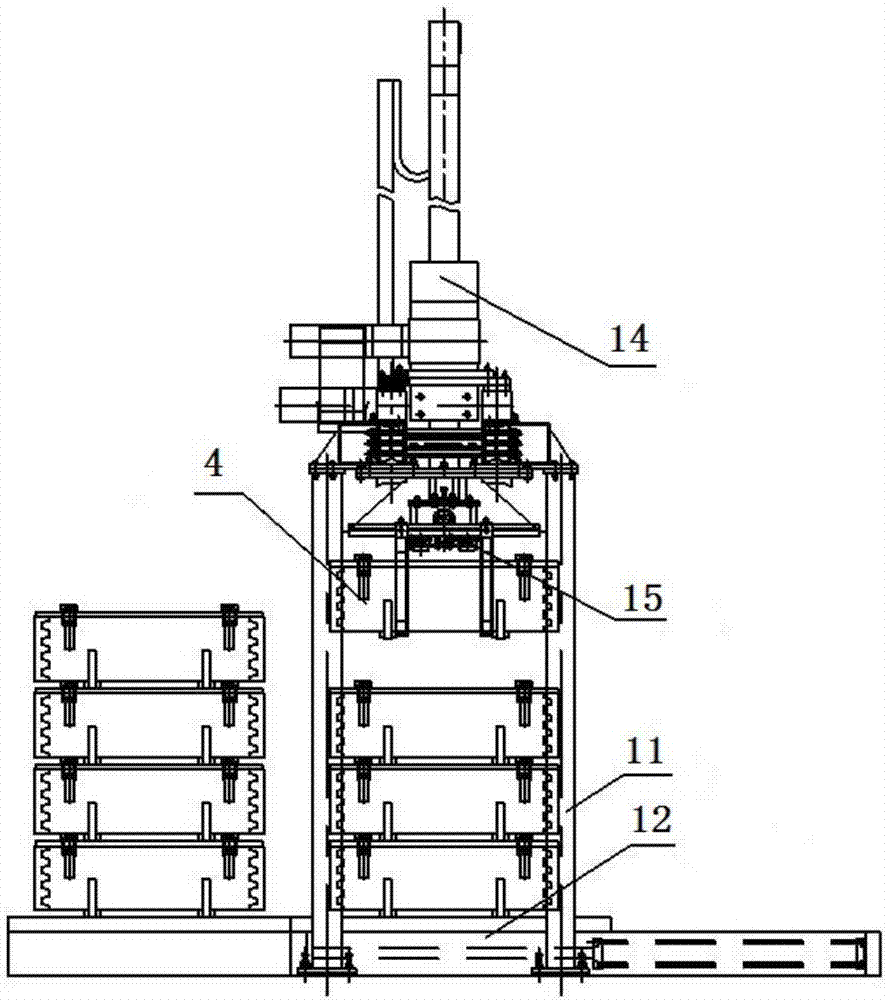

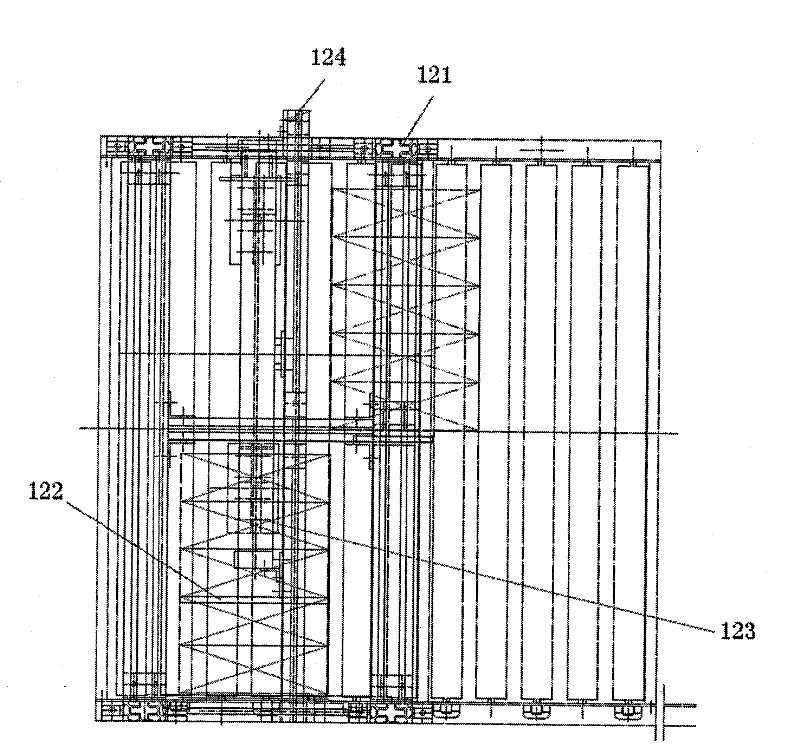

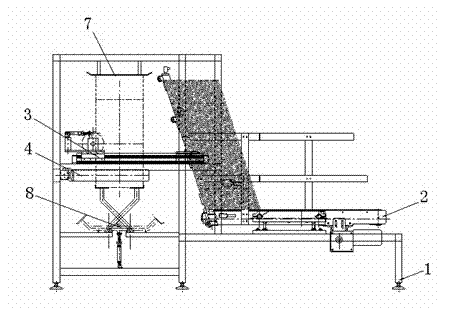

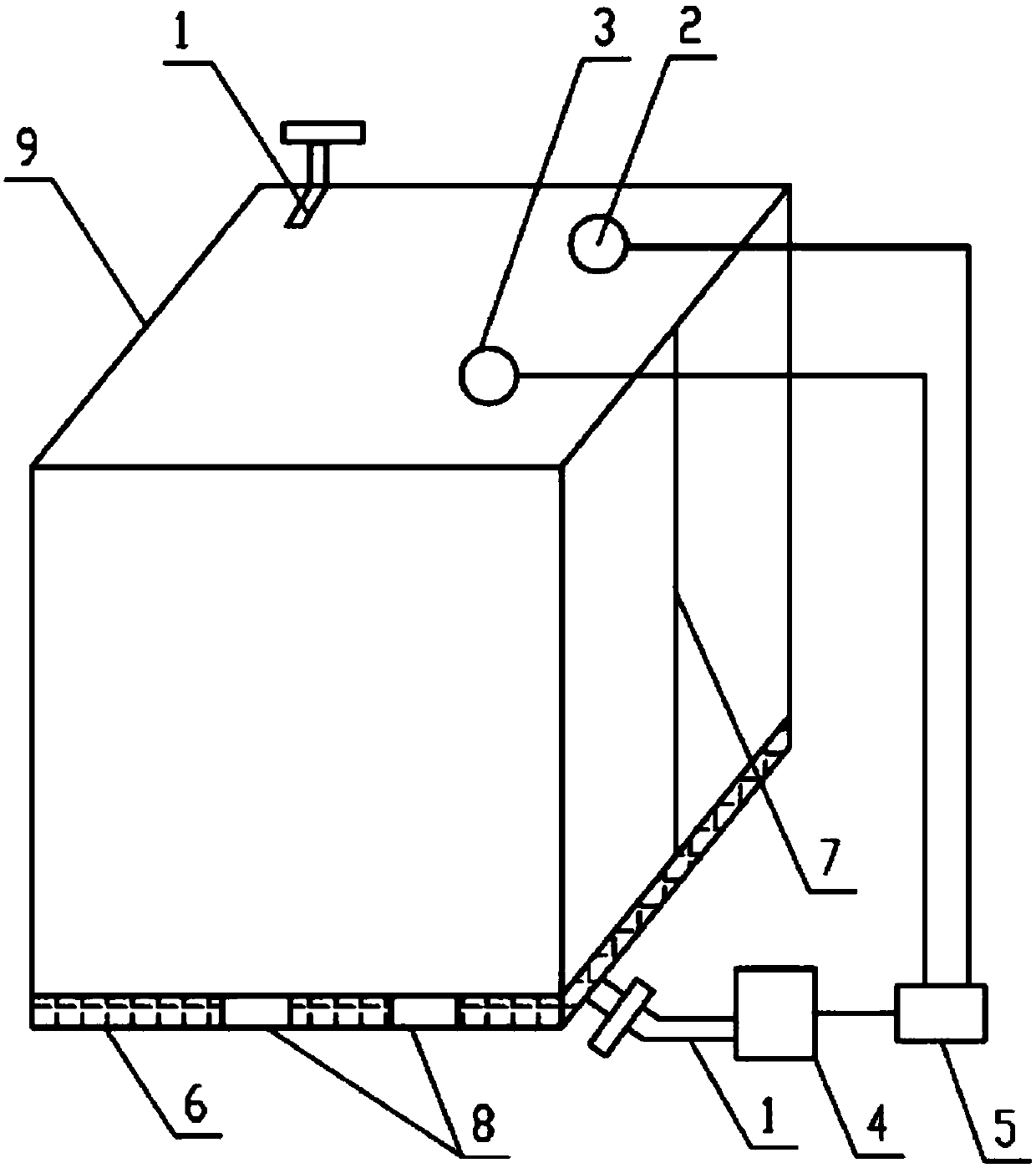

Powder charging production line and use method thereof

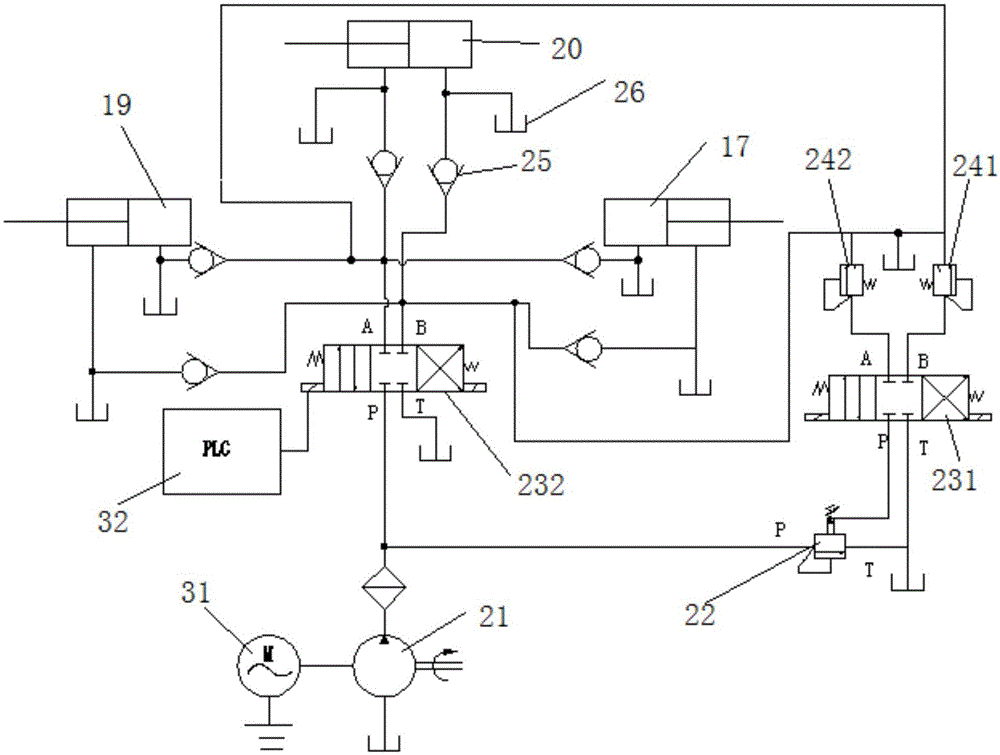

A powder charging production line comprises an automatic weighing and powder charging machine, a vibration machine, an automatic powder charging conveyor line and a powder pouring and lifting device. The automatic weighing and powder charging machine and the powder pouring and lifting device are separately arranged at the two ends of the automatic powder charging conveyor line. The vibration machine and the automatic weighing and powder charging machine are coaxially arranged below the automatic powder charging conveyor line. The powder pouring and lifting device lifts powder in a transferring box and pushes the powder to the automatic powder charging conveyor line; and the automatic weighing and powder charging machine and the vibration machine complete powder charging after the automatic powder charging conveyor line pushes the transferring box to the automatic weighing and powder charging machine. The powder charging production line can completely achieve automatic weighing and powder charging, solves the defects of weighing and powder charging in the prior art, is high in weighing precision and can provide guarantee for achieving full-automatic operation.

Owner:BEIJING AEROSPACE SANFA HIGH TECH

Weighing and charging machine and application method thereof

ActiveCN107152960ACompact structureReasonable layoutAmmunitionWeighing apparatus detailsControl engineeringTransfer line

The invention discloses a weighing and charging machine which comprises an automatic weighing and charging machine, a vibrating machine and an automatic charging conveying line, wherein the automatic weighing and charging machine is arranged at one end of the automatic charging conveying line; the vibrating machine is coaxially arranged with the automatic weighing and charging machine and arranged below the automatic weighing and charging machine; after the automatic charging conveying line pushes a turnover box to the automatic weighing and charging machine, the automatic weighing and charging machine and the vibrating machine finish charging. The weighing and charging machine disclosed by the invention can totally realize automatic weighing and charging; the shortcomings of weighing and charging in the prior art are overcome; the weighing precision is high; full-automatic operation of the charging machine can be ensured.

Owner:BEIJING AEROSPACE SANFA HIGH TECH

Automatic box feeding machine

ActiveCN101492104BRealize fully automated operationCompact structureOverturning articlesPackagingCartonEngineering

The invention provides an automatic box feeding machine, which comprises a machine frame provided with a box inlet and a box outlet. The automatic box feeding machine is characterized in that the machine frame is provided with a lifting device which is connected with the box inlet; and the upper side of the lifting device is provided with a moving and rotating device, and the lower side of the moving and rotating device on one side of the lifting device is provided with a paper box aligning and stacking device which is connected with the box outlet. The automatic box feeding machine can completely achieve automatic box feeding, and overcome the defects of high labor intensity, low work efficiency, and the like, brought by feeding boxes by workers in the prior art. The automatic box feeding machine has the advantages of compact structure, reasonable layout and accurate and quick automatic box feeding, and does not occupy more production spaces. Proper automatic box feeding machine models can be selected according to different box sealing machine layouts of the prior art, so that the automatic box feeding machine also has the advantages of wide application range, convenient installation and investment conversation, and can provide guarantee for cigarette packing to achieve fully-automatic operation.

Owner:东方机器制造(昆明)有限公司

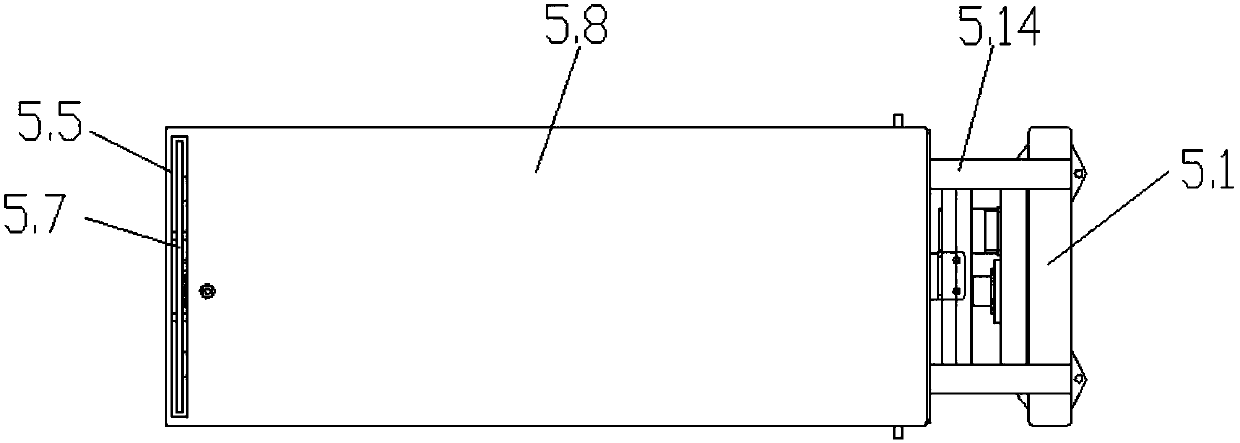

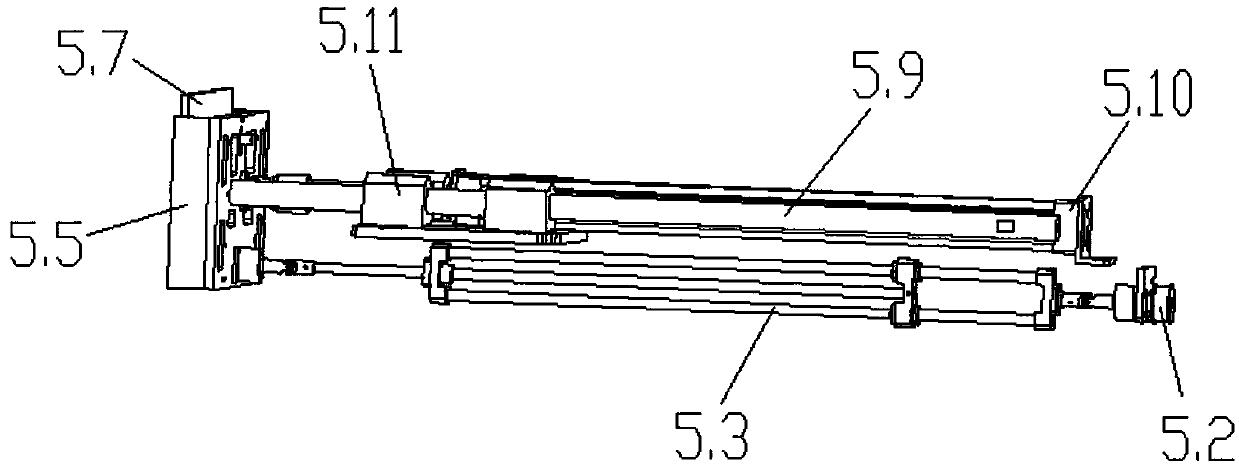

Cigarette pushing mechanism of cigarette box

PendingCN107826717ACompact structureReasonable layoutConveyor partsMechanical engineeringEngineering

Owner:GUIYANG PUTIAN LOGISTICS TECH

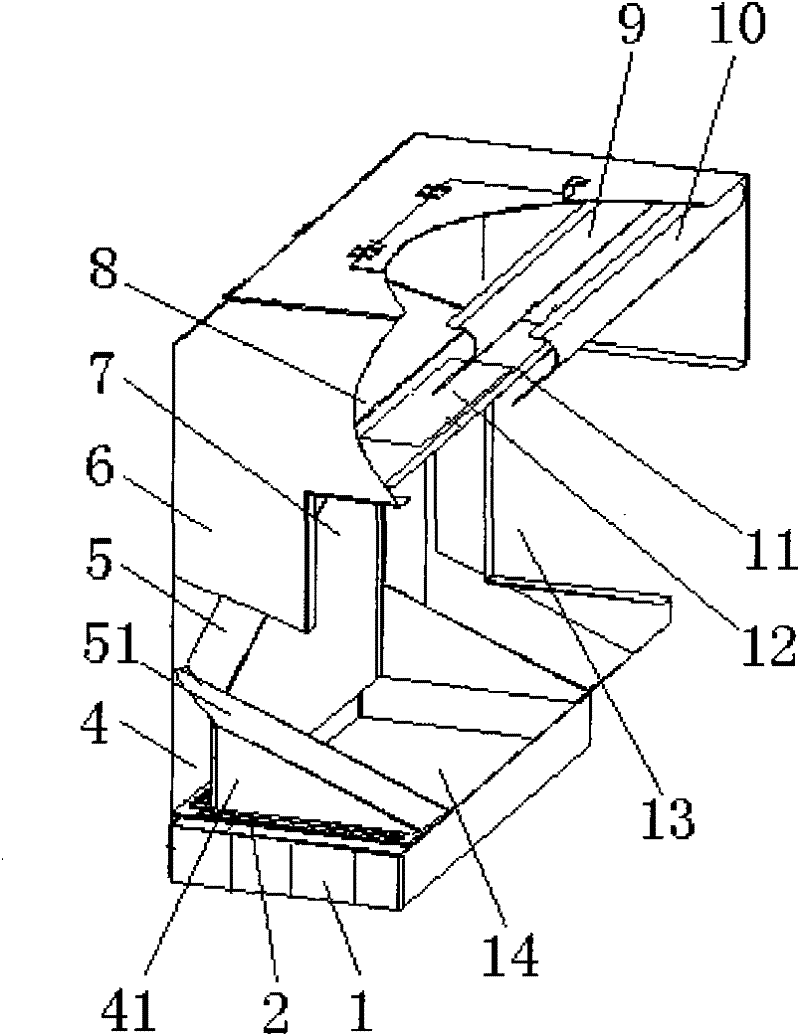

Efficient PC component hot mold platform integrating dry and wet heat curing

The invention discloses an efficient PC component hot mold platform integrating dry and wet heat curing. The hot mold platform comprises a concrete bottom frame, a mold platform for installing and fixing a PC component mold, and a sliding telescopic type steam curing cover; heat preserving plates are attached to the periphery of the inner side of the concrete bottom frame which comprises two sunken holes; positioning FRP ribs are arranged at the bottoms of the sunken holes; colored steel plates are arranged on the tops of the FRP ribs; meshes are laid on the colored steel plates; by means of casting of foam concrete, the colored steel plates, the meshes and the foam concrete are connected into a whole to form a heat insulating concrete layer; the mold platform is installed on the concrete bottom frame through welding between the mold platform and an embedded part; a heat preserving layer with a cavity is formed between a panel and each sunken hole; and the sliding telescopic type steam curing cover comprises a supporting framework and heat preserving tarpaulin. The efficient PC component hot mold platform integrating dry and wet heat curing can perform full-dry heat curing, full-wet heat curing and dry-wet heat curing on PC components and has the beneficial effects of being high in temperature rise speed, good in heat accumulation, small in energy consumption and high in production efficiency and space utilizing rate.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD

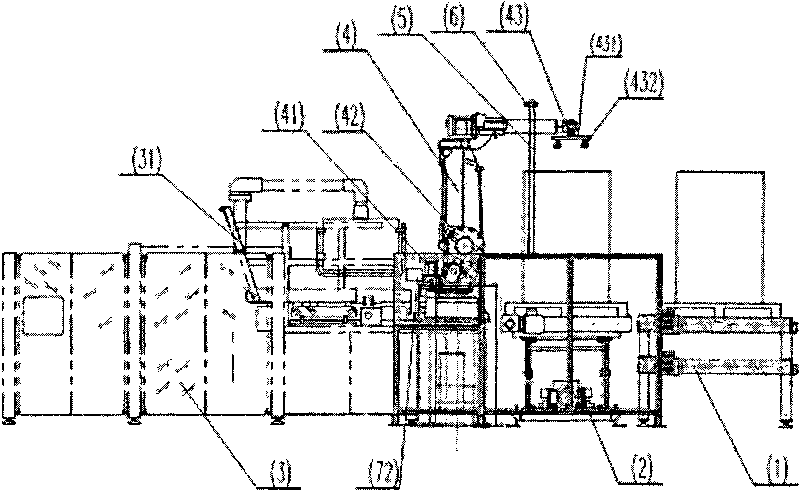

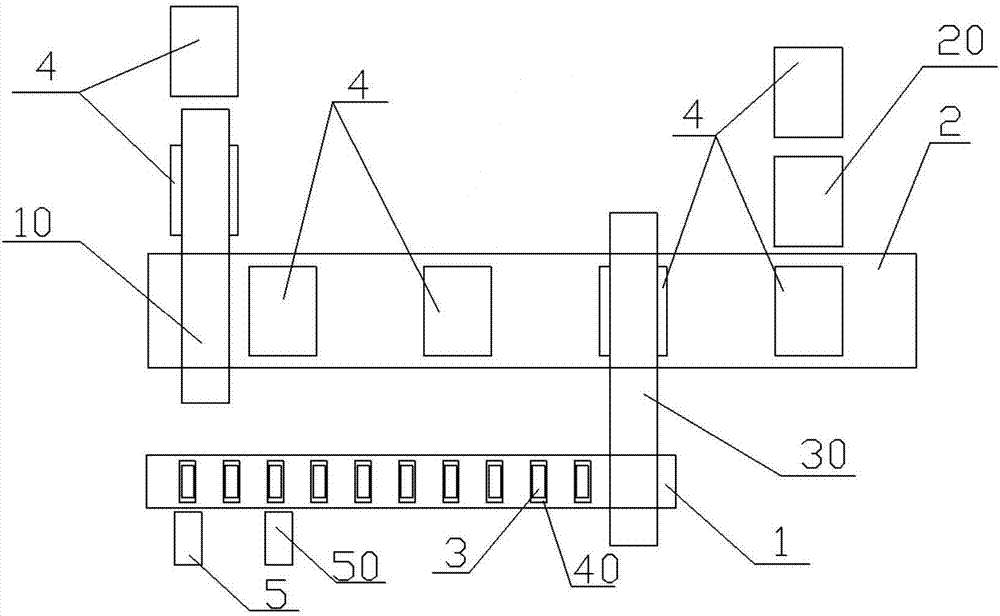

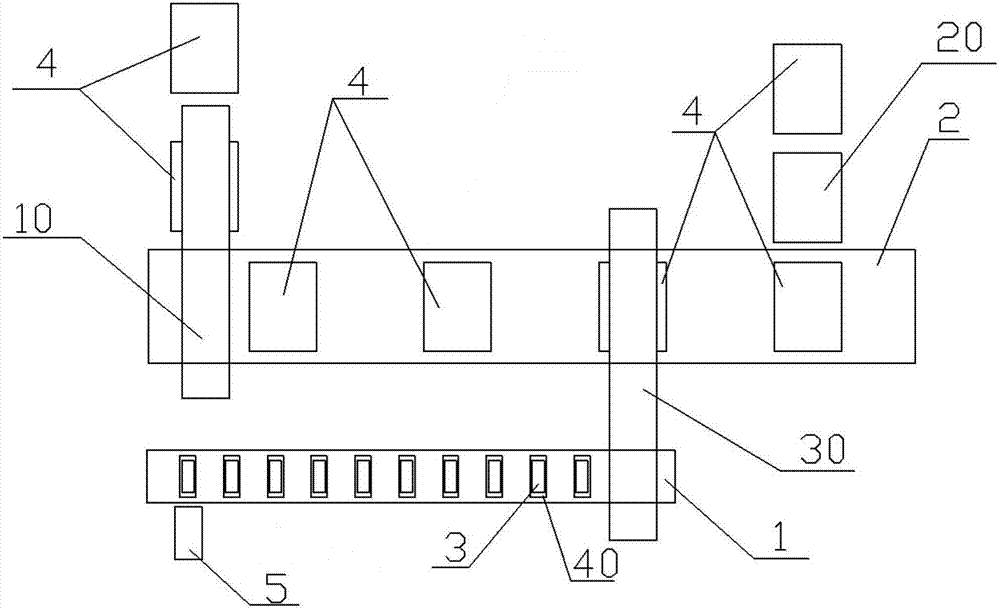

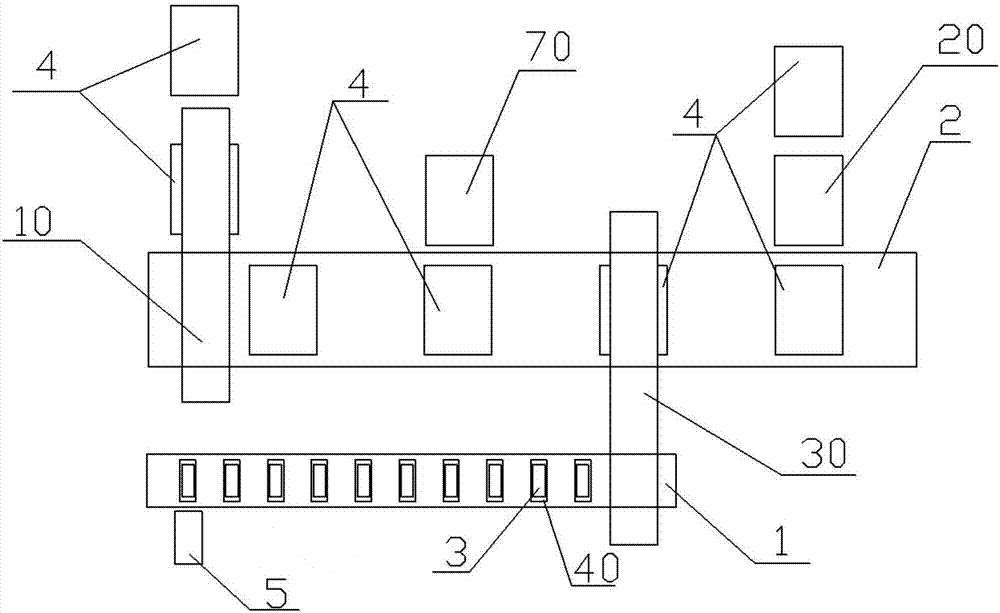

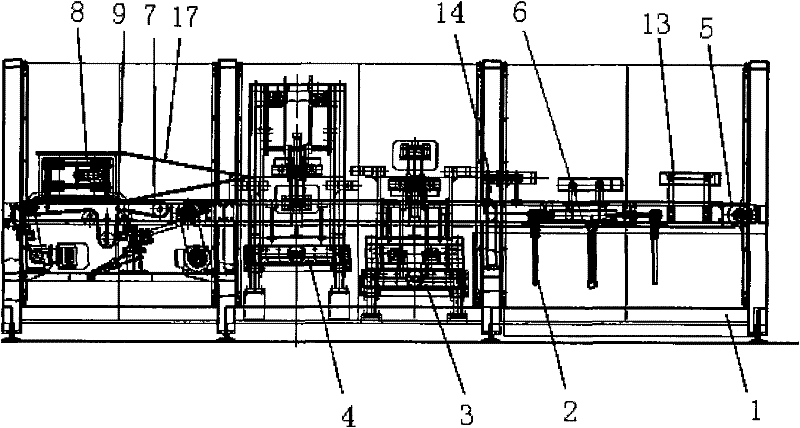

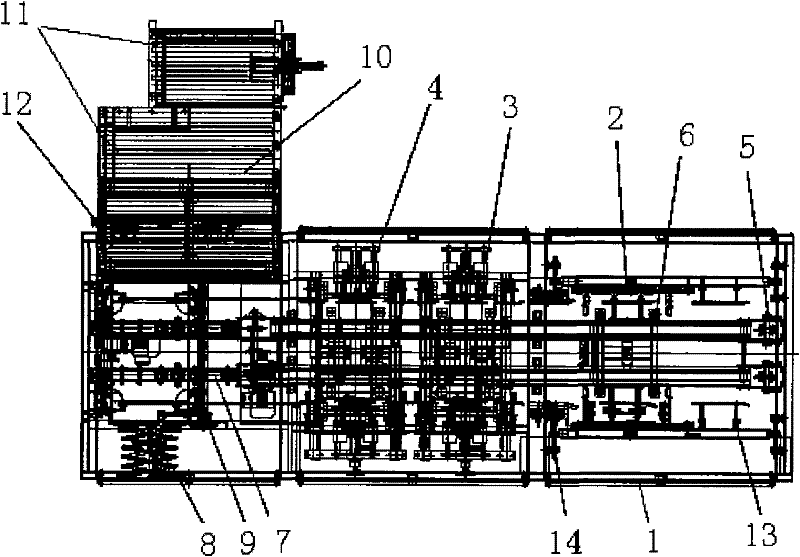

Product marking and packaging machine and application method thereof

PendingCN107187669ACompact structureReasonable layoutPackaging automatic controlEngineeringTransfer line

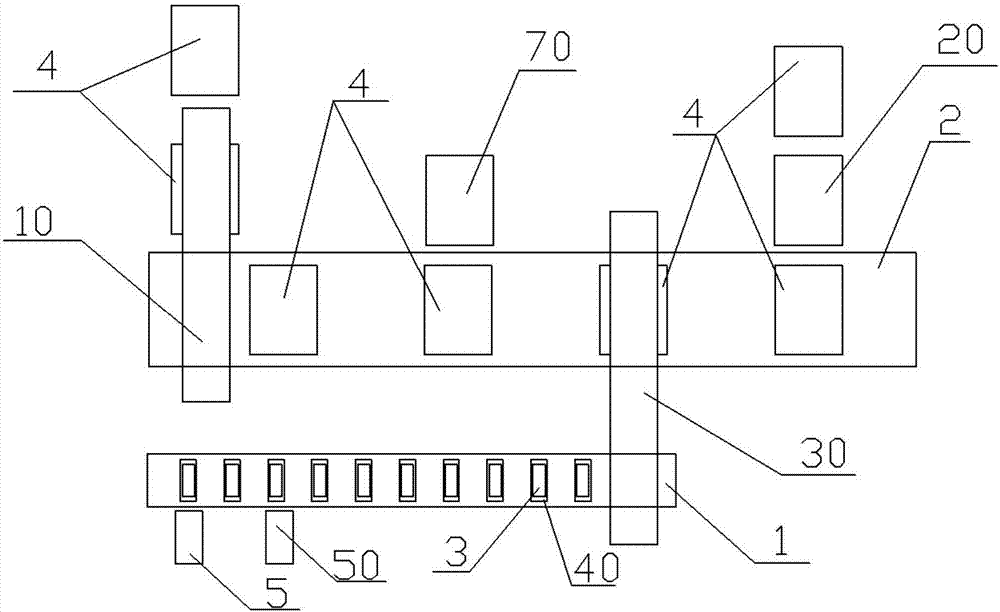

The invention discloses a product marking and packaging machine and an application method thereof. An assembling detection conveying line and a packaging box conveying line are arranged in parallel. A box feeding machine is arranged at the initial end of the packaging box conveying line. Longitudinal beams of a box feeding machine rack are arranged on the two sides of the packaging box conveying line. A box discharging stacking machine is arranged at the tail end of the packaging box conveying line and located at one side of the packaging box conveying line. A box loading machine is arranged between the box feeding machine and the box discharging stacking machine. The assembling detection conveying line and the packaging box conveying line are arranged between two longitudinal beams of a box loading machine rack. A product detecting device is arranged at the initial end of the assembling detection conveying line and located at one side of the assembling detection conveying line. A product mark printing machine is arranged between the product detecting device and the box loading machine and located at one side of the assembling detection conveying line. Packaging boxes are arranged on the packaging box conveying line. Assembling detection conveying line supporting plate toolings are arranged on the assembling detection conveying line. Products are arranged on the assembling detection conveying line supporting plate toolings.

Owner:BEIJING AEROSPACE SANFA HIGH TECH

Product printing mark packaging device and using method thereof

PendingCN107215512ACompact structureReasonable layoutPackaging automatic controlStacking articlesEngineeringStacker

Provided is a product printing mark packaging device. An assembly detecting conveying line and a packaging box conveying line are parallelly arranged. A box feeding machine is arranged at the initial end of the packaging box conveying line. Longitudinal beams of a box feeding machine frame are arranged at the two sides of the packaging box conveying line. A box discharging stacker is arranged at the tail end of the packaging box conveying line and is located at one side of the packaging box conveying line. A box filling machine is arranged between the box feeding machine and the box discharging stacker. The assembly detecting conveying line and the packaging box conveying line are arranged between two longitudinal beams of a box filling machine frame. A product detecting device is arranged at the initial end of the assembly detecting conveying line and is located at one side of the assembly detecting conveying line. A product printing mark machine is arranged between the product detecting device and the box filling machine and is located at one side of the assembly detecting conveying line. A packaging box printing mark machine is arranged between the box feeding machine and the box filling machine and is located at one side of the packaging box conveying line. Packaging boxes are placed on the packaging box conveying line. Assembly detecting conveying line carrying plate tools are placed on the assembly detecting conveying line. Products are placed on the assembly detecting conveying line carrying plate tools.

Owner:BEIJING AEROSPACE SANFA HIGH TECH

Robot automatic carton loading machine

ActiveCN101704421BRealize fully automated operationCompact structureGripping headsPackaging automatic controlCartonRobot position

The invention provides a robot automatic carton loading machine which comprises a carton conveyor and a carton packer, and also comprises a carton lifting conveyor positioned between the carton conveyor and the carton packer, and a robot positioned between the carton lifting conveyor and the carton packer. The robot automatic carton loading machine can completely realize automatic carton loading,fundamentally solves the defects of large labor intensity, low work efficiency and the like caused by manpower loading in the prior art, and has compact structure, reasonable arrangement, is capable of loading carton accurately and rapidly, and does not occupy more production space; according to different carton packer arrangement in the prior art, the suitable machine types of the robot automatic carton loading machine can be selected; and the robot automatic carton loading machine has wide application range, convenient installation and saved investment, and is capable of providing guaranteefor cigarette packaging to realize full automatic operation.

Owner:东方机器制造(昆明)有限公司

Opening mechanism for left side and right side seal covers of cigarette cartons

InactiveCN107813999ASolve labor intensitySolve efficiency problemsPackagingCartonStructural engineering

The invention discloses an opening mechanism for left side and right side seal covers of cigarette cartons. The opening mechanism comprises a first machine frame fixedly installed at the bottom of a conveyor line, and a blocking mechanism arranged on the conveyor line. An upper guide protection rail, a lower guide protection rail and a middle guide protection rail are arranged on the portions, onone side or two sides of the conveyor line, on the first machine frame. Meanwhile, a front suction device, a rear suction device and a side seal cover pressing mechanism are arranged on one side or two sides on the first machine frame. A slippage assembly and a holding and clamping mechanism are arranged under the front end of the first machine frame. By means of the opening mechanism, the work ofautomatically opening the left side and right side seal covers of the cigarette cartons can be completely achieved, and the defects that in the prior art, because of manual box opening and cigarettetaking, the labor intensity is high, the work efficiency is low and manual operation errors are caused are fundamentally overcome. The opening mechanism is compact in structure and reasonable in layout, automatic box opening is accurate and rapid, no other production space is occupied, and the opening mechanism is suitable for the opening work of the left side and right side seal covers of the cigarette cartons of different size specifications within a certain size range.

Owner:GUIYANG PUTIAN LOGISTICS TECH

Mobile full-automatic precise bait casting system

PendingCN110169384AAutomatic feedingRealize one machine multi-point feedingClimate change adaptationPisciculture and aquariaEngineeringAutomation

The invention discloses a mobile full-automatic precise bait casting system, which comprises a bait casting machine, a feed container of the bait casting machine, a suspension arm, a driving device, arail beam, bait casting control units, a feed storage container, a feed conveying device and a feeding control unit, wherein a mobile bait casting component consisting of the bait casting machine, the feed container of the bait casting machine, the suspension arm, the driving device and the bait casting control units moves along the rail beam, and in the moving process, the bait casting control units control the moving speed, the staying position, the bait casting time and the bait casting amount to finish precise feed casting; and when feeds in the feed container of the bait casting machineneeds to be replenished (hereinafter referred to as feeding), the mobile bait casting component consisting of the bait casting machine, the feed container of the bait casting machine, the suspension arm and the driving device stays at the feeding position under the control of the feeding control units, and the feeds in the feed storage container is conveyed to the feed container of the bait casting machine through the feed conveying device and the feeding control units, and thus the automation of multi-point feeding and feed feeding processes of one machine is realized.

Owner:苏州益品德环境科技有限公司

Product packaging machine and using method thereof

PendingCN107215511ASolve the labor-intensiveHigh precisionPackaging automatic controlStacking articlesStackerTransfer line

Provided is a product packaging machine. An assembly detecting conveying line and a packaging box conveying line are parallelly arranged. A box feeding machine is arranged at the initial end of the packaging box conveying line. Longitudinal beams of a box feeding machine frame are arranged at the two sides of the packaging box conveying line. A box discharging stacker is arranged at the tail end of the packaging box conveying line and is located at one side of the packaging box conveying line. A box filling machine is arranged between the box feeding machine and the box discharging stacker. The assembly detecting conveying line and the packaging box conveying line are arranged between two longitudinal beams of a box filling machine frame. A product detecting device is arranged at the initial end of the assembly detecting conveying line and is located at one side of the assembly detecting conveying line. Packaging boxes are placed on the packaging box conveying line. Assembly detecting conveying line carrying plate tools are placed on the assembly detecting conveying line. Products are placed on the assembly detecting conveying line carrying plate tools.

Owner:BEIJING AEROSPACE SANFA HIGH TECH

Primer tightening machine and application method thereof

PendingCN107270786AImprove tightening qualityCompact structureAmmunitionReciprocating motionControl engineering

A primer tightening machine comprises a clamping machine and a tightening machine body. The clamping machine comprises a clamping rack, a lifting mechanism and a clamping device. The clamping rack is located on one side of an assembling detection conveying line. The lifting mechanism is fixedly arranged on the clamping rack and located above the assembling detection conveying line. The clamping device and the lifting mechanism are fixedly connected. The tightening machine body comprises a tightening rack, a frame, a longitudinal horizontal movement drive device, a guide rail, a sliding block, an installing frame, a tightening drive device and a primer fixing device. The bottom of the frame and the tightening rack are fixedly connected, the guide rail is fixedly arranged on the upper surface of the frame, the sliding block is arranged on the guide rail, and the longitudinal horizontal movement drive device is arranged on the frame and drives the sliding block to reciprocate on the guide rail. The lower surface of the installing frame is fixedly connected with the upper surface of the sliding block, the tightening drive device is fixedly arranged on the upper surface of the installing frame, an output shaft of the tightening drive device is connected with the primer fixing device, and the tightening drive device drives the primer fixing device to reciprocate on the upper surface of the installing frame.

Owner:BEIJING AEROSPACE SANFA HIGH TECH

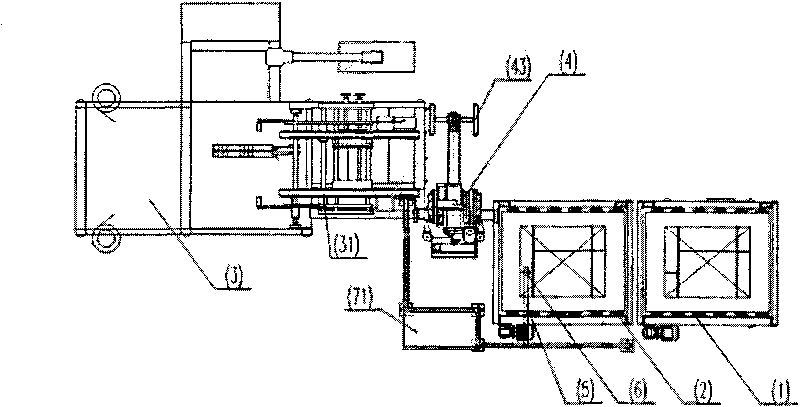

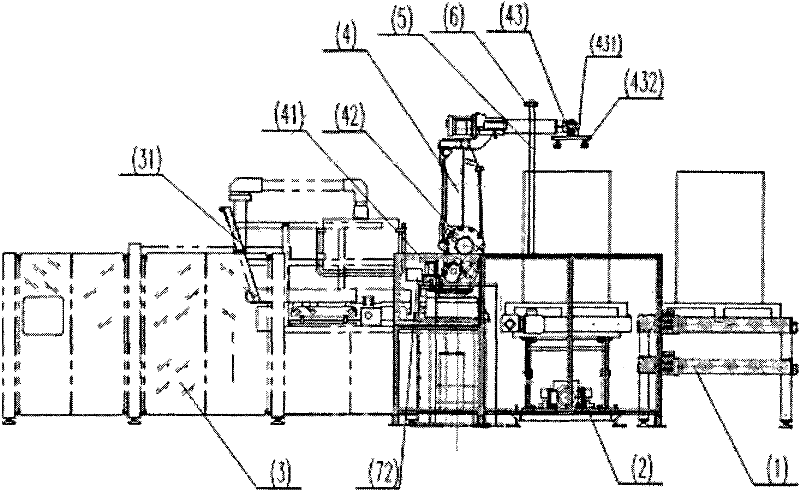

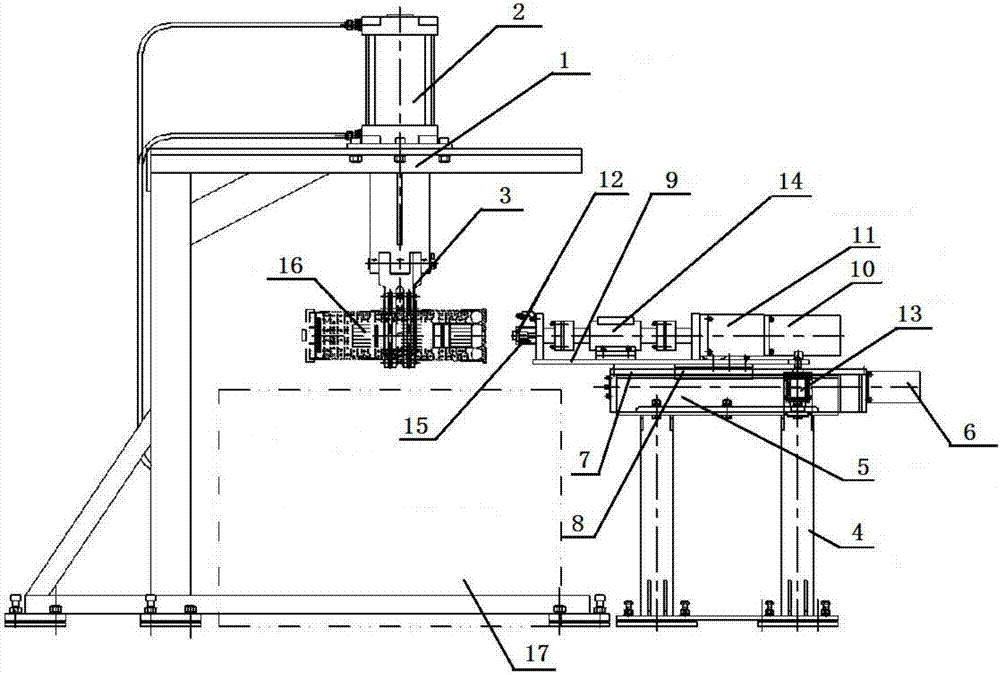

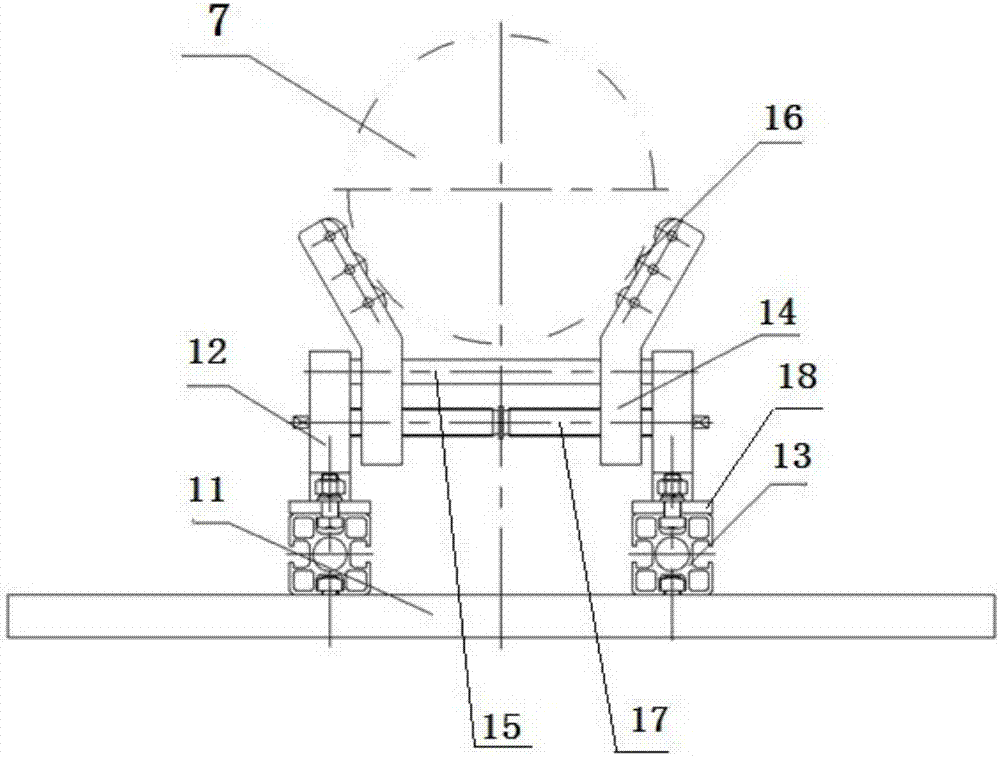

Box filling machine and using method thereof

PendingCN107314719ASolve the labor-intensiveImprove detection accuracyAmmunition testingAmmunition storageGunpowderStructural engineering

The invention provides a box filling machine. The box filling machine comprises a frame, a clamping installing frame, a transversal horizontal moving mechanism, a lifting mechanism, a mechanical claw and a clamping driving device. The frame comprises a transversal beam and two pairs of longitudinal beams arranged vertically, the transversal beam is fixedly connected with the longitudinal beams, a gunpowder loading assembling conveying line and an assembling detecting conveying line are horizontally arranged in the longitudinal direction in parallel and are located between the two pairs of longitudinal beams, and the assembling detecting conveying line supporting plate tool is placed on the assembling detecting conveying line, and packaging boxes are placed on the gunpowder loading assembling conveying line; the transversal horizontal moving mechanism is arranged on the transversal beam and horizontally moves on the transversal beam in the transversal direction; the lifting mechanism is arranged on the transversal horizontal moving mechanism, and the clamping installing frame is connected with the lifting mechanism; and the clamping driving device is fixedly arranged on the clamping installing frame, and the clamping driving device is connected with the mechanical claw. According to the box filling machine, automatic product detecting and box filling are achieved, the problems of high labor intensity and low working efficiency caused by manual operation in the prior art is solved, and guarantee for realizing full-automatic operation of the gunpowder loading machine can be provided.

Owner:BEIJING AEROSPACE SANFA HIGH TECH

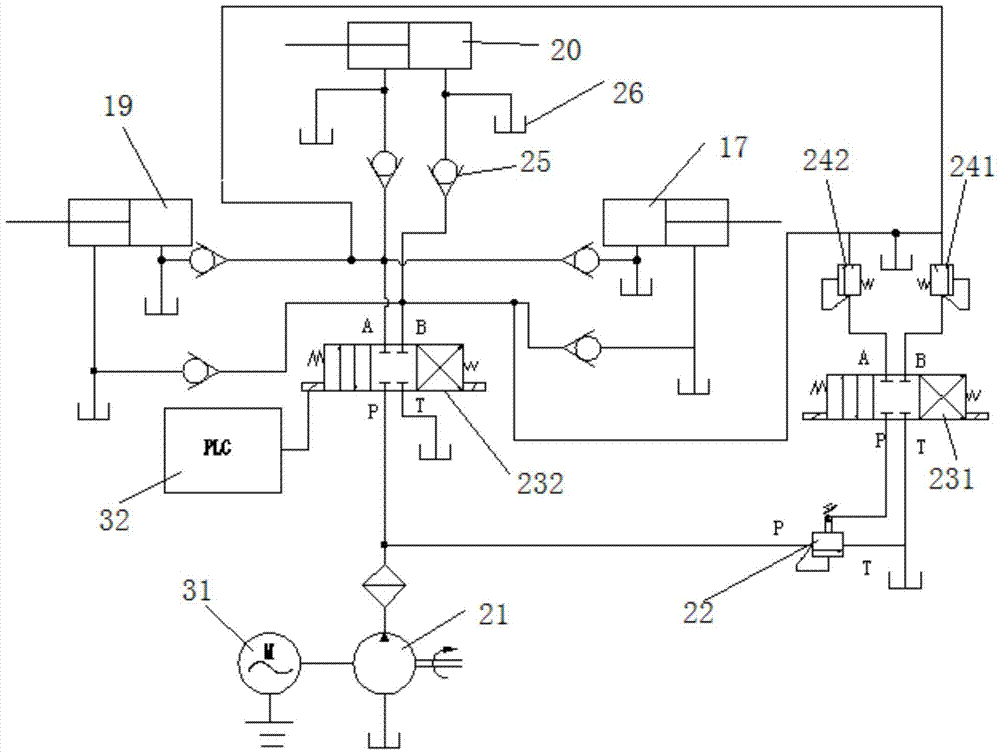

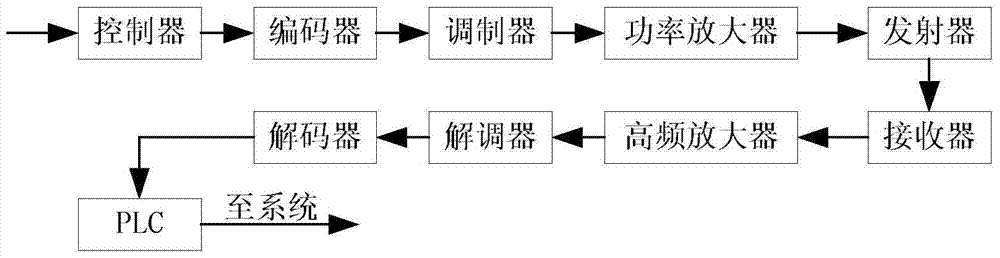

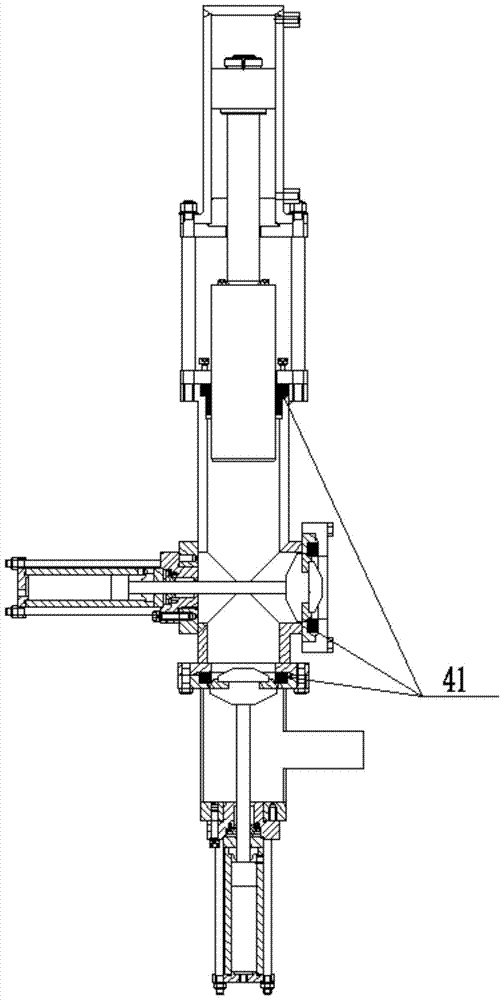

High-pressure long-range conveying device for magnetic material slurry and using method of high-pressure long-range conveying device

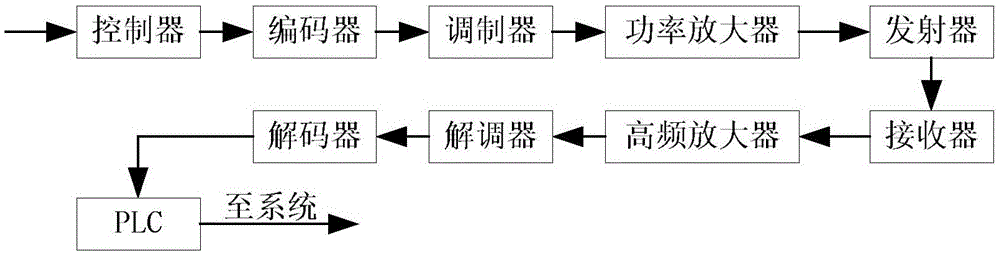

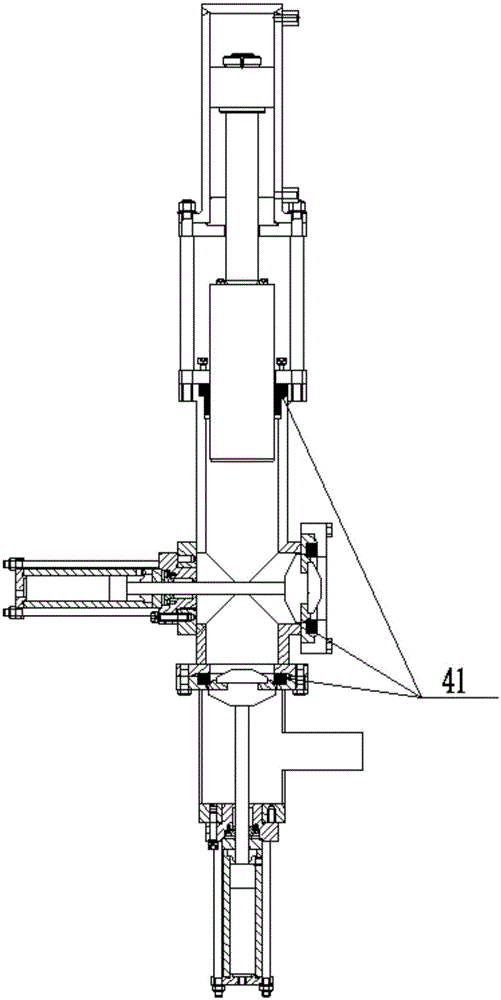

ActiveCN105084003APrevent leakageImprove product qualityMixersBulk conveyorsElectrical controlEngineering

The invention discloses a high-pressure long-range conveying device for magnetic material slurry and a using method of the high-pressure long-range conveying device, and belongs to the field of magnetic material slurry conveying equipment. The high-pressure long-range conveying device comprises a stirring part, an electrical system and a hydraulic system, and further comprises a double helix feeding system, an electrical remote control system and a press; the stirring part comprises a thick stirring part and a thin stirring part, and the slurry is conveyed to the double helix feeding system through the thick stirring part; the slurry is conveyed to the thin stirring part through the double helix feeding system, the thin stirring part conveys the slurry to the press, and the press is connected with an electrical cabinet of a touch screen; and the press is electrically controlled through the electrical cabinet of the touch screen to conduct operation, and therefore the slurry is pressed and molded. The electrical remote control system comprises a remote control transmitting system and a remote control receiving system, the remote control transmitting system transmits signals to the remote control receiving system, the remote control receiving system is connected with the electrical system which is connected with the hydraulic system, and a hydraulic cylinder of the hydraulic system is arranged in the double helix feeding system. By means of the high-pressure long-range conveying device, long-range conveying of the slurry can be achieved, sealing is achieved, and pollution is avoided.

Owner:MAANSHAN QILI ELECTRICAL & MECHANICAL EQUIP CO LTD

Gunpowder charging machine and use method thereof

ActiveCN107388906ACompact structureReasonable layoutAmmunitionProcess engineeringMechanical engineering

A gunpowder charging machine comprises an automatic weighing gunpowder charging machine body, a vibrating machine and an automatic gunpowder charging and conveying line. The automatic weighing gunpowder charging machine is arranged at one end of the automatic gunpowder charging and conveying line; the vibrating machine and the automatic weighing gunpowder charging machine are coaxially arranged below the automatic weighing gunpowder charging machine; and the automatic weighing gunpowder charging machine and the vibrating machine complete gunpowder charging after a turnover box is pushed to the automatic weighing gunpowder charging machine by the automatic gunpowder charging and conveying line. The gunpowder charging machine can fully achieve automatic weighing and gunpowder charging, overcomes the defects of weighing and gunpowder charging in the prior art, and can provide a guarantee for full automatic operation of the gunpowder charging machine.

Owner:BEIJING AEROSPACE SANFA HIGH TECH

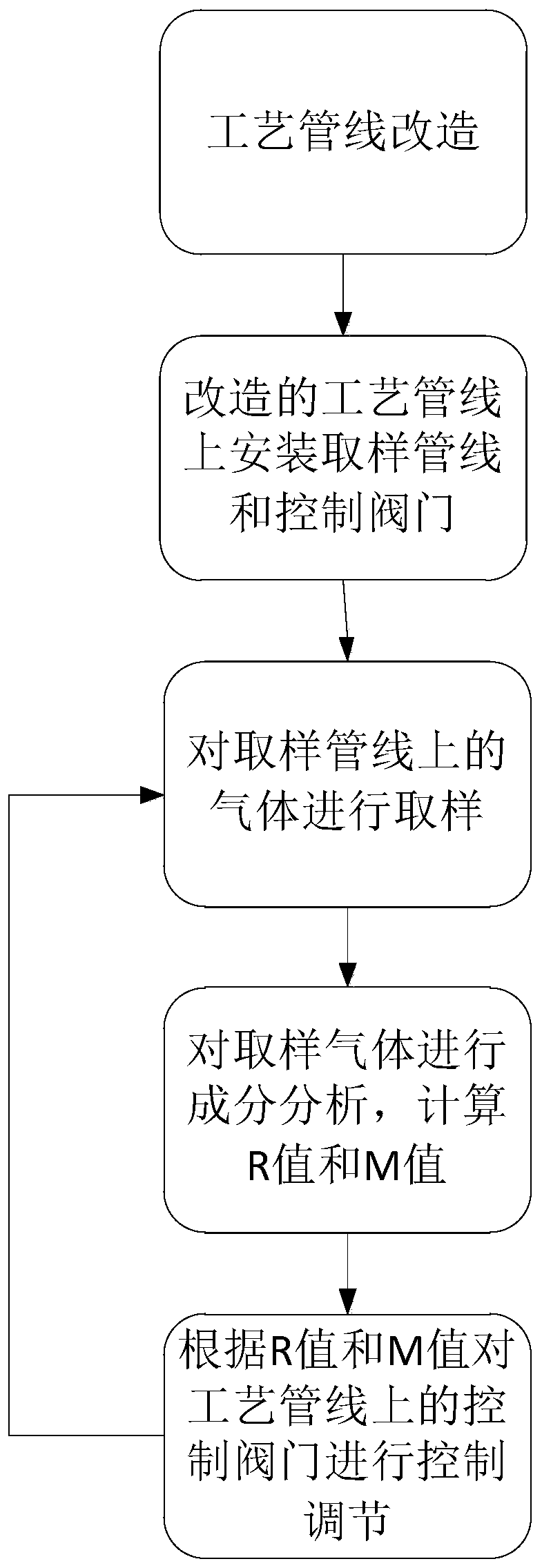

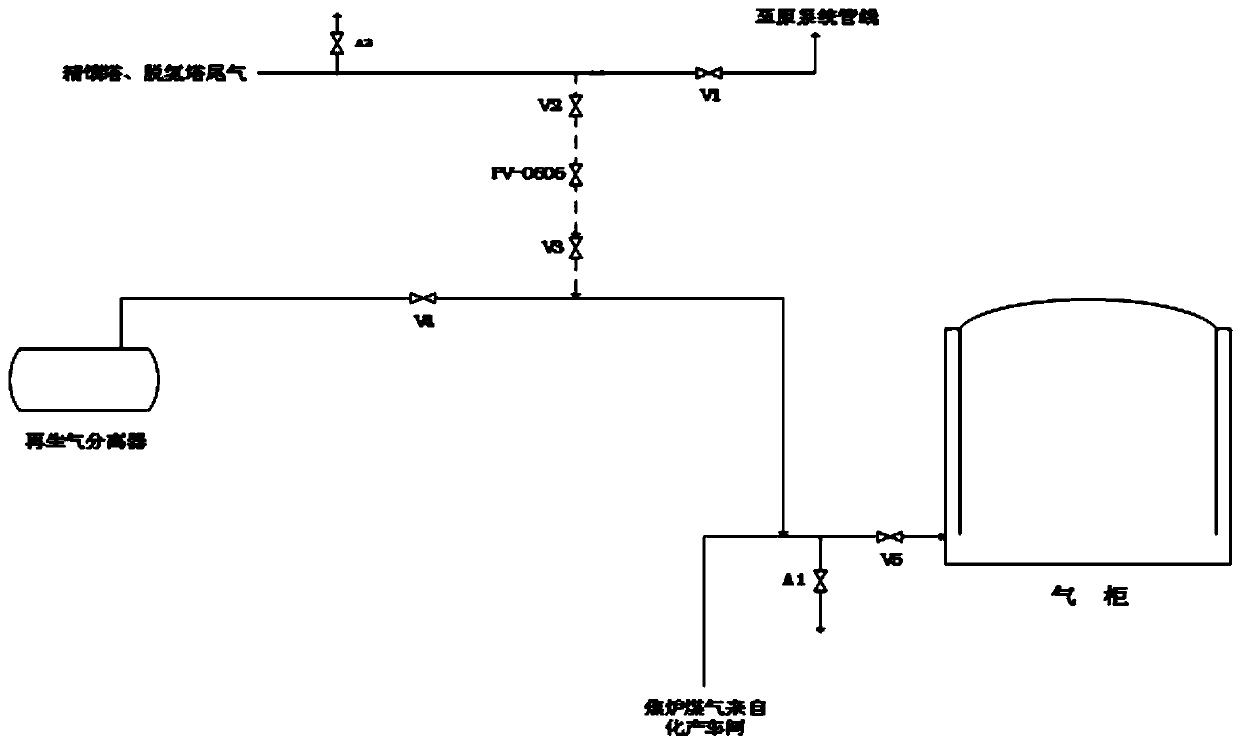

Exhaust gas recovery and utilization method for producing liquefied natural gas from coke oven gas

InactiveCN110684571AImprove stabilityStable gas percentage contentGaseous fuelsPipeline systemsGas analysisGas composition

The invention discloses a tail gas recovery and utilization method for producing liquefied natural gas from coke oven gas, which comprises the following steps of: dividing nitrogen gas and hydrogen tail gas separated and discharged from the top of a dehydrogenation tower and a rectification tower into two paths; one of them is connected with a flare venting pipeline, the other is connected to a gas supply source pipeline of coke oven gas, and installing sampling pipelines on the two pipelines; sampling the gas on the sampling pipeline; performing composition analysis of the sampled gas; according to the gas analysis results on the two pipelines, adjusting the control valves on the process transformation pipelines until the gas composition fluctuation of coke oven gas in the gas supply pipeline remains within a normal and reasonable range. The invention not only realizes the effective adjustment of the gas components in the production system, ensures the stability of the production of the system, but also realizes the reasonable recovery and utilization of the tail gas from the production of liquefied natural gas by the coke oven gas, increases the output and saves the production cost.

Owner:INNER MONGOLIA HENGKUN CHEM CO LTD

Product packaging and marking machine and application method thereof

PendingCN107187670ACompact structureReasonable layoutPackaging automatic controlTransfer lineStacker

The invention discloses a product packaging and marking machine. An assembling detection conveying line and a packaging box conveying line are arranged in parallel. A box feeding machine is arranged at the initial end of the packaging box conveying line. Longitudinal beams of a box feeding machine rack are arranged on the two sides of the packaging box conveying line. A box discharging stacking machine is arranged at the tail end of the packaging box conveying line and located at one side of the packaging box conveying line. A box loading machine is arranged between the box feeding machine and the box discharging stacking machine. The assembling detection conveying line and the packaging box conveying line are arranged between two longitudinal beams of a box loading machine rack. A product detecting device is arranged at the initial end of the assembling detection conveying line and located at one side of the assembling detection conveying line. A packaging box mark printing machine is arranged between the box feeding machine and the box loading machine and located at one side of the packaging box conveying line. Packaging boxes are arranged on the packaging box conveying line. Assembling detection conveying line supporting plate toolings are arranged on the assembling detection conveying line. Products are arranged on the assembling detection conveying line supporting plate toolings.

Owner:BEIJING AEROSPACE SANFA HIGH TECH

Automatic case unpacking machine

ActiveCN101792035BCompact structureReasonable layoutArticle unpackingEngineeringLogistic distribution

The invention provides an automatic case unpacking machine, which comprises a conveyor and a cigarette case pre-locating mechanism, a cigarette case lift mechanism, a cigarette case upright cutting mechanism, a cigarette case cross cutting mechanism, a cigarette case lower cover opening mechanism, a cigarette case upper cover opening mechanism, a cigarette case side cover opening mechanism, a cigarette pushing mechanism, a distributary output mechanism and a transverse output mechanism which are arranged on the conveyor. The invention can realize full-automatic case unpacking, and thereby, the problems of high labour intensity, low work efficiency and the like brought by artificial case unpacking in the prior art are fundamentally solved. Moreover, the automatic case unpacking machine hascompact structure, reasonable layout, accurate and rapid automatic case packing, wide applying range, convenient installation and investment saving, does not occupy more production space and can provide guarantee for the cigarette logistics distribution center to realize full-automatic operation.

Owner:东方机器制造(昆明)有限公司

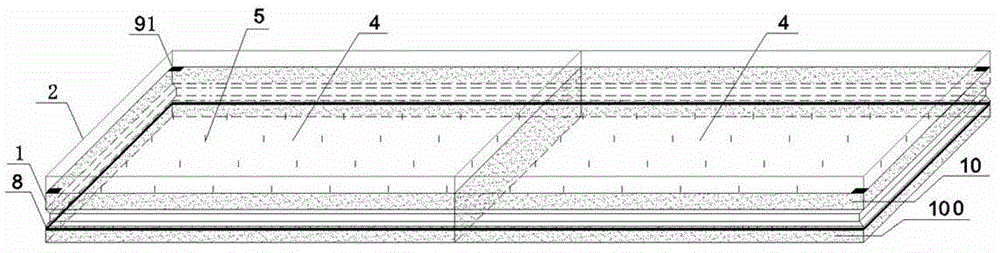

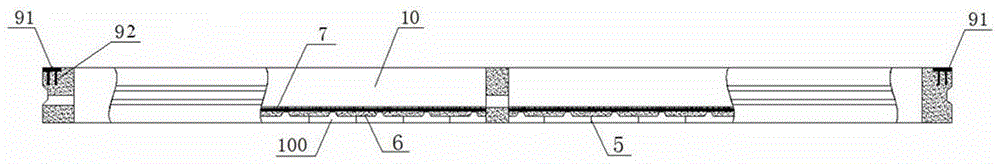

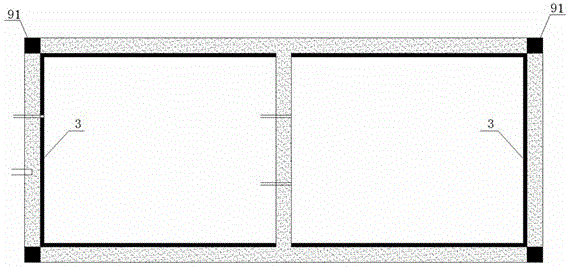

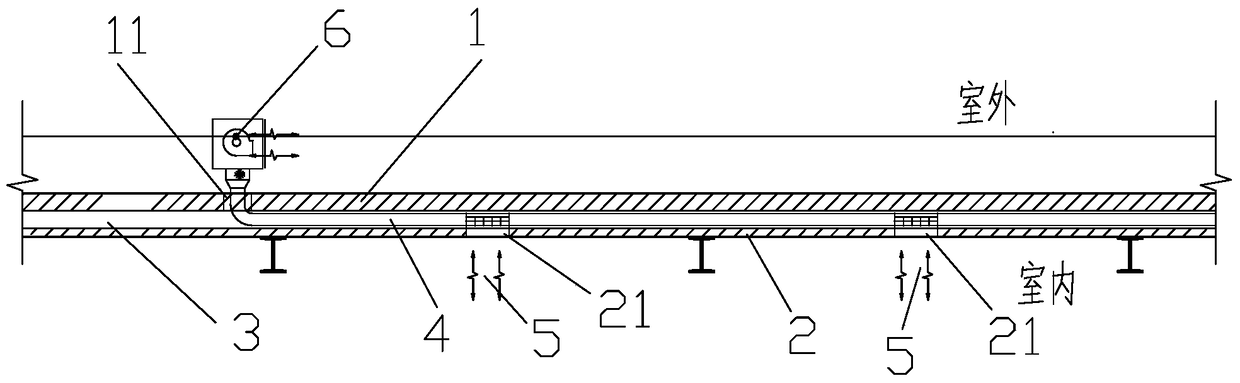

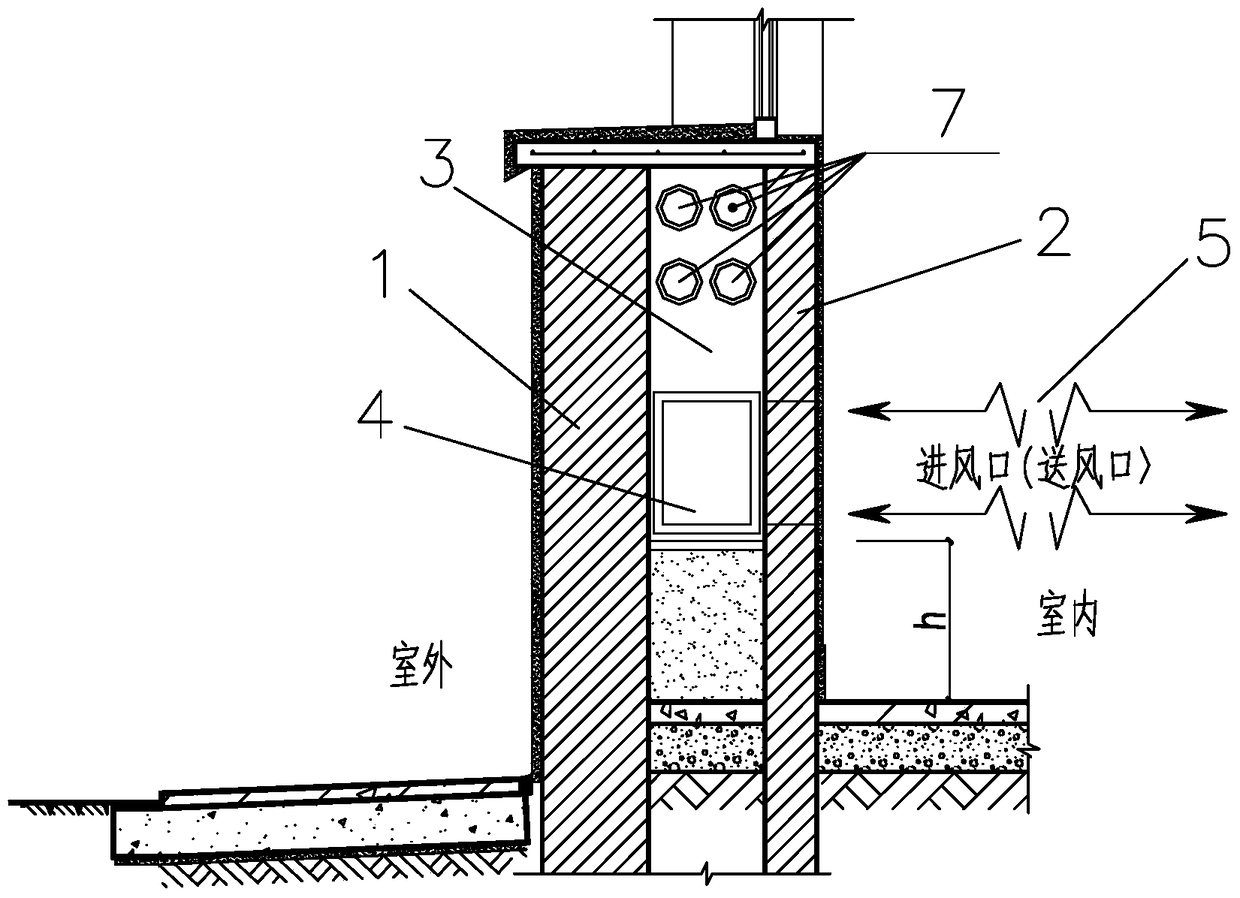

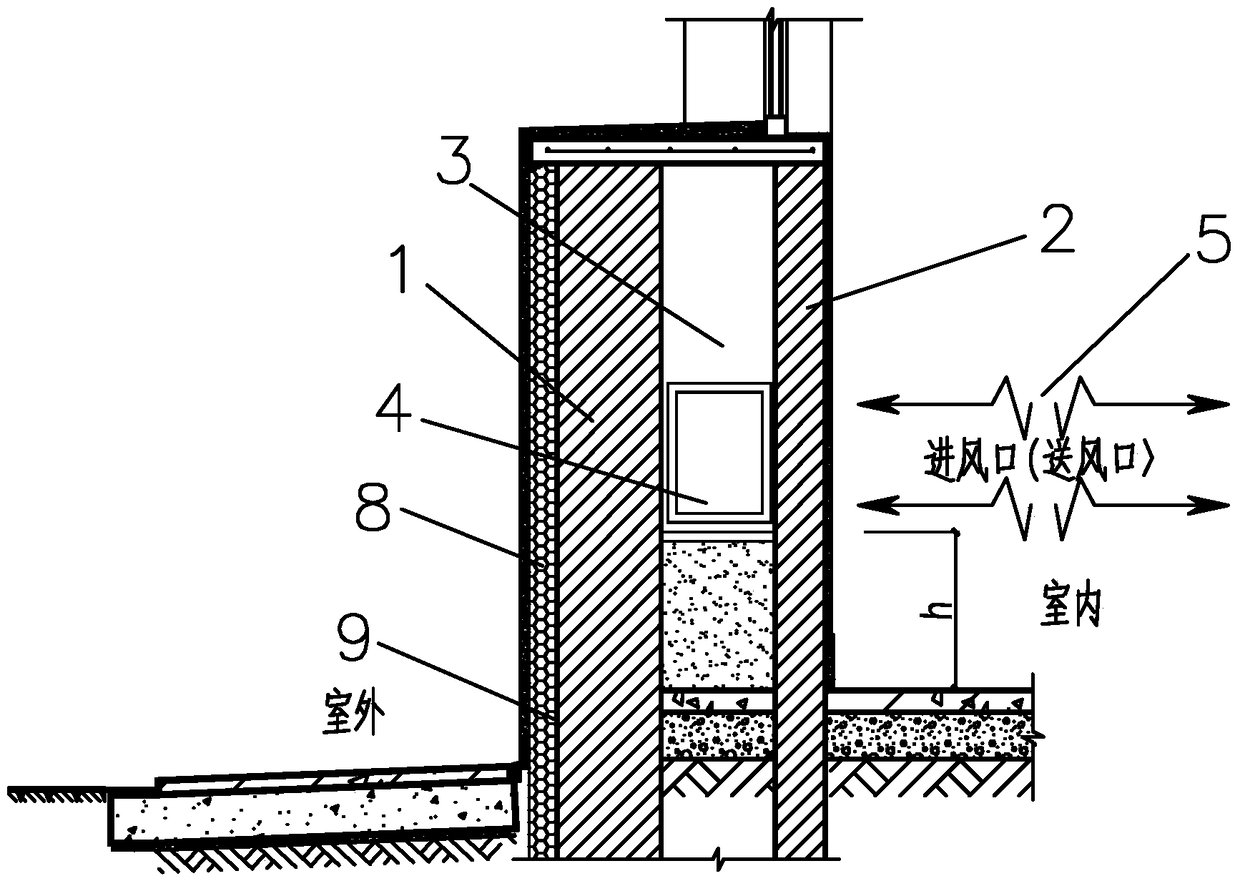

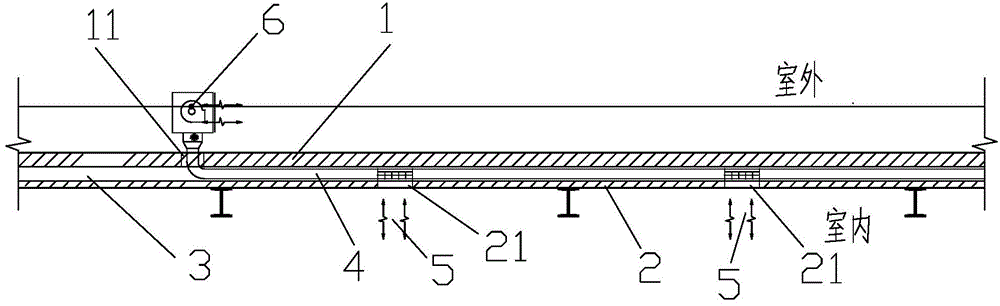

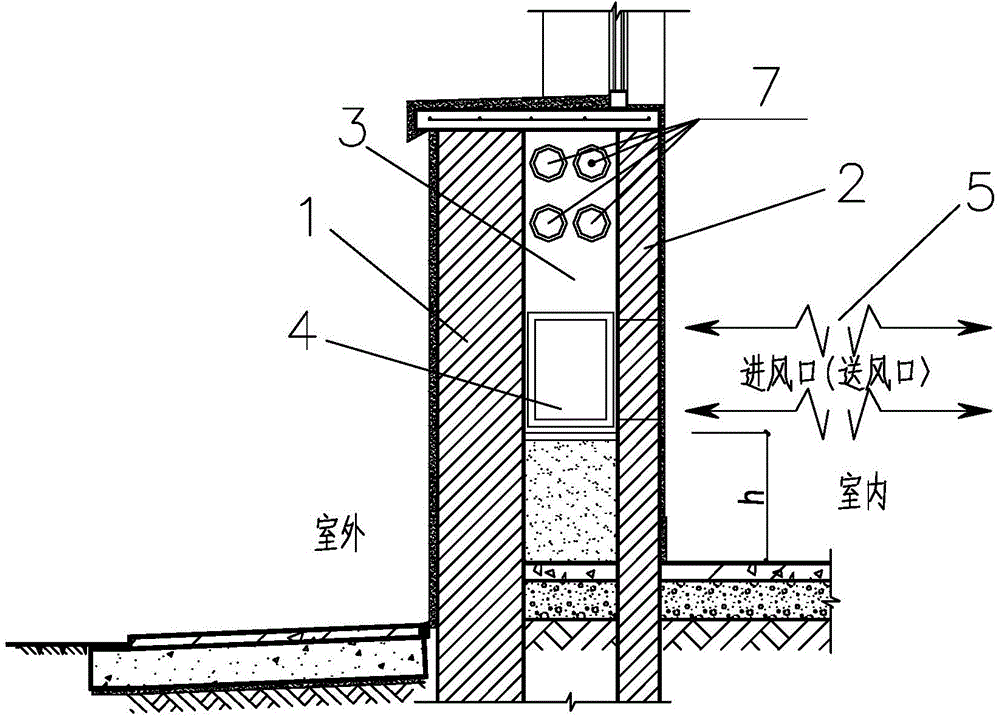

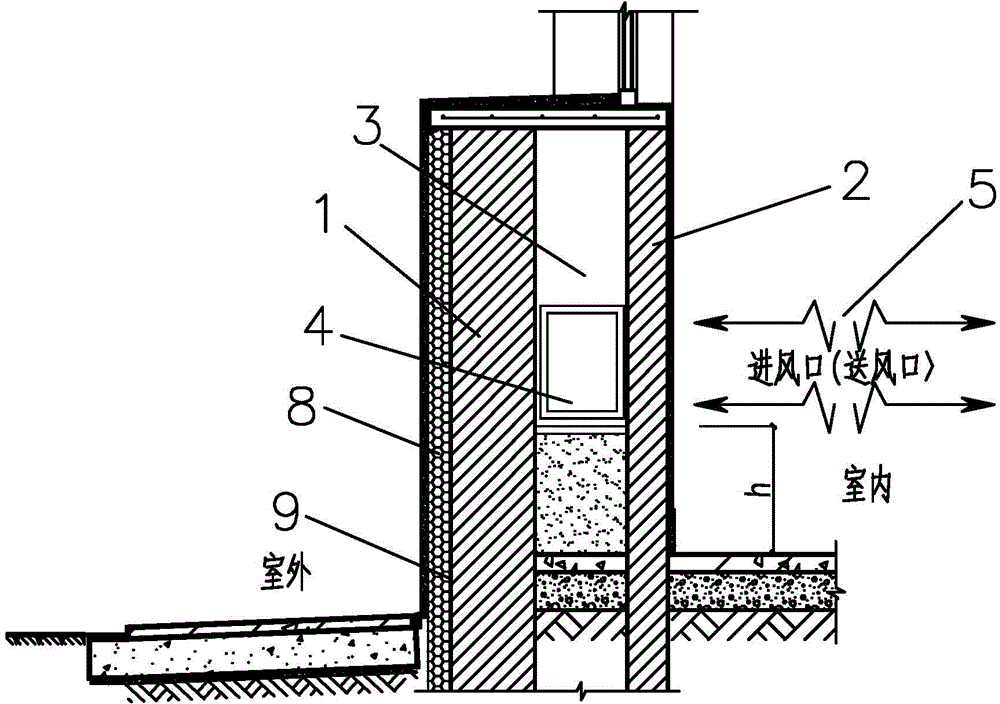

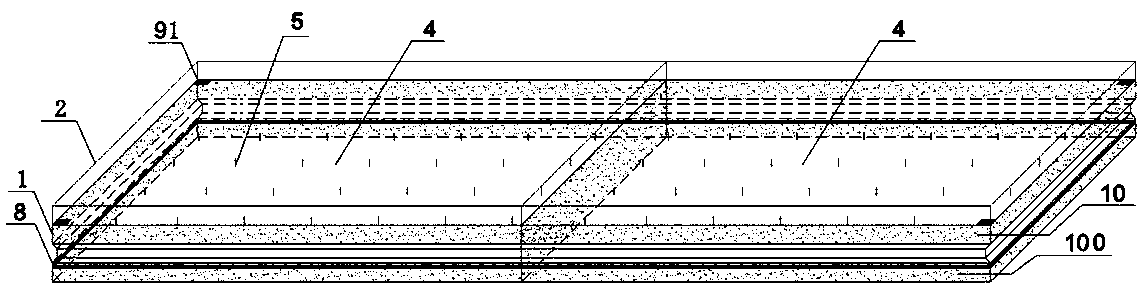

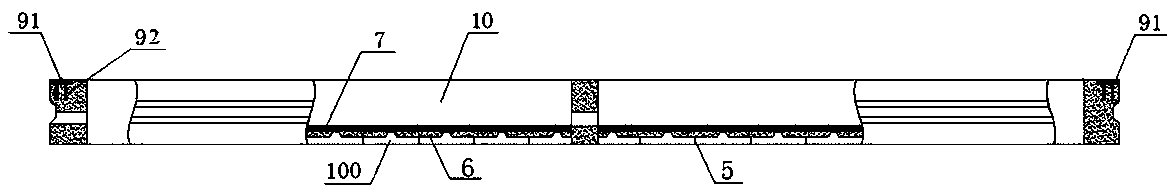

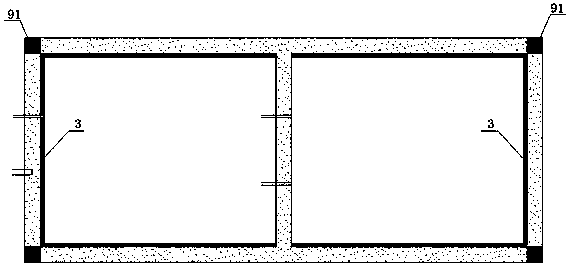

Double Vented Masonry Wall

ActiveCN104420553BMeet the requirements for venting hazardous gasesDoes not take up production spaceLighting and heating apparatusWallsFresh airDouble wall

The invention relates to a double-layer ventilation masonry wall, which is used for the inner wall or outer wall of an industrial building, and comprises a first wall body, a second wall body, a ventilation air layer, a ventilation pipe, a blower fan and an exhaust fan. The ventilation air layer is arranged between the first wall body and the second wall body. The ventilation duct is arranged in the ventilation air layer. The blower is connected to the ventilation duct, and is used for sucking an indoor / outdoor air into the ventilation duct. The exhaust fan is connected to the terminal of the ventilation duct, and is used for exhausting the gas sucked into the ventilation duct to the outdoor / indoor. The invention can not only meet the requirement of discharging dangerous gas, but also can deliver fresh air to rooms that need fresh air, and can also reserve space for the laying of other pipelines, thereby not occupying the production space, and avoiding rainwater pipes, which can provide a complete system for production. , flexible and free space.

Owner:CHINA IPPR INT ENG

Tobacco shred box sealing machine

ActiveCN102381497BCompact structureReasonable layoutWrapper twisting/gatheringPackaging automatic controlEngineeringMechanical engineering

The invention provides a tobacco shred box sealing machine which comprises a rack and is characterized in that the rack is provided with a tobacco shred box, a tobacco shred box opening mechanism, a tobacco shred box folding mechanism, a tobacco shred box conveying mechanism and a tobacco shred box sealing mechanism. The tobacco shred box sealing machine can completely realize the automatic opening, the cover folding, the sealing and the conveying of the tobacco shred box and fundamentally overcome the defects such as high labor intensity, low working efficiency and the like which are caused by the reason that in the prior art, the opening, the cover folding and the sealing of the tobacco shred box are operated by manual work; and the tobacco shred box sealing machine is compact in structure, reasonable in layout, correct and rapid in the operations of the automatic opening, the cover folding and the sealing of the tobacco shred box, wide in application range and convenient to install, does not occupy more production space, saves investment, and can provide technical support for the realization of full-automatic production in a tobacco primary processing logistics system.

Owner:东方机器制造(昆明)有限公司

Double ventilation masonry wall

ActiveCN104420553AMeet the requirements for venting hazardous gasesDoes not take up production spaceWallsLighting and heating apparatusFresh airEngineering

The invention relates to a double ventilation masonry wall applied to interior walls or exterior walls for industrial buildings. The double ventilation masonry wall comprises a first wall, a second wall, a ventilation air layer, a ventilation pipeline, blowers and an exhaust fan. The ventilation layer is disposed between the first wall and the second wall; the ventilation pipeline is disposed in the ventilation air layer. The blowers are connected to the ventilation pipeline and are used for indoor / outdoor air into the ventilation pipeline. The exhaust fan is connected to a terminal of the ventilation pipeline and used for discharging the air sucked into the ventilation pipeline, to the outdoor / indoor. The double ventilation masonry wall has the advantages that the requirement for emission of dangerous gases is met, fresh air can be provided for a room needing the fresh air, space is reserved for laying other pipelines, production space is saved, a rain pipeline is avoided, and complete, flexible and free space is provided for production.

Owner:CHINA IPPR INT ENG

A high-pressure remote conveying device for magnetic material slurry and its application method

ActiveCN105084003BPrevent leakageCreate pollutionMixersBulk conveyorsHydraulic cylinderRemote control

The invention discloses a high-pressure remote conveying device for magnetic material slurry and an application method thereof, belonging to the field of magnetic material slurry conveying equipment. It includes a stirring part, an electrical system, a hydraulic system, and a double-screw feeding system, an electrical remote control system, and a press; the stirring part includes a coarse mixing part and a fine mixing part, and the coarse mixing part transmits the slurry to the double-screw feeding system The double-screw feeding system transmits the slurry to the fine mixing part, and the fine mixing part delivers the slurry to the press, which is connected to the touch-screen electrical cabinet; the touch-screen electrical cabinet controls the electrical control of the press to perform operations and press the slurry forming. The electrical remote control system includes a remote control sending system and a remote receiving system. The remote sending system sends signals to the remote receiving system. The remote receiving system is connected to the electrical system. The electrical system is connected to the hydraulic system. The hydraulic cylinder of the hydraulic system is set in the double-screw feeding system. It can transport slurry remotely, and it is sealed and pollution-free.

Owner:MAANSHAN QILI ELECTRICAL & MECHANICAL EQUIP CO LTD

Cell fixture pushing device and automatic welding machine using the pushing device

ActiveCN105817823BImprove welding qualityIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesUltrasonic weldingEngineering

The invention discloses a battery cell clamp pushing device which comprises a battery cell clamp and a clamp pushing mechanism. The clamp pushing mechanism comprises a pushing base, a pushing air cylinder and a pushing piece, wherein the pushing air cylinder and the pushing piece are arranged on the pushing base; and the pushing piece is movably arranged on the pushing base and can be driven by the pushing air cylinder to move. The battery cell clamp comprises a battery cell tray and a tray base, and the battery cell tray is arranged on the tray base and can be pushed by the pushing piece to move. By arranging the clamp pushing mechanism matched with the battery cell clamp, when ultrasonic welding is carried out on a battery cell, a welding base of an ultrasonic welding machine does not need to be moved any more, only the battery cell clamp needs to be pushed by the clamp pushing mechanism to the welding base, then welding of the battery cell can be achieved, the ultrasonic welding procedure is simplified, and the production efficiency of a battery is improved; and meanwhile, compared with a manner that the ultrasonic welding base is pushed to conduct welding, a manner of pushing the battery cell with small weight is higher in pushing accuracy, and the welding accuracy and the welding quality of the battery cell are improved.

Owner:DONGGUAN HONBRO LI BATTERY EQUIP TECH

A high-efficiency thermal mold table for pc components integrating dry and wet heat maintenance

The invention discloses an efficient PC component hot mold platform integrating dry and wet heat curing. The hot mold platform comprises a concrete bottom frame, a mold platform for installing and fixing a PC component mold, and a sliding telescopic type steam curing cover; heat preserving plates are attached to the periphery of the inner side of the concrete bottom frame which comprises two sunken holes; positioning FRP ribs are arranged at the bottoms of the sunken holes; colored steel plates are arranged on the tops of the FRP ribs; meshes are laid on the colored steel plates; by means of casting of foam concrete, the colored steel plates, the meshes and the foam concrete are connected into a whole to form a heat insulating concrete layer; the mold platform is installed on the concrete bottom frame through welding between the mold platform and an embedded part; a heat preserving layer with a cavity is formed between a panel and each sunken hole; and the sliding telescopic type steam curing cover comprises a supporting framework and heat preserving tarpaulin. The efficient PC component hot mold platform integrating dry and wet heat curing can perform full-dry heat curing, full-wet heat curing and dry-wet heat curing on PC components and has the beneficial effects of being high in temperature rise speed, good in heat accumulation, small in energy consumption and high in production efficiency and space utilizing rate.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD

Movable chemical raw material heating and heat preserving device

InactiveCN109850417AEasy to moveDoes not take up production spaceLarge containersTank wagonsHeat conductingProcess engineering

The invention provides a movable chemical raw material heating and heat preserving device which comprises a movable house body and a heating pipeline located in the movable house body. The heating pipeline is arranged on the top and the side wall of the movable house body in a detouring manner. A heat-conducting medium inlet and a heat-conducting medium outlet of the heating pipeline extend to theexterior of the movable house body and are connected with a heat-conducting medium supply device. The movable chemical raw material heating and heat preserving device has the following beneficial effects that a chemical raw material heat preserving house is arranged to be the movable house body, the heat preserving house can be moved conveniently, when the device does not need to be used in summer, the device can be moved to the proper position conveniently, and the production space is not occupied.

Owner:西安玖诚玖谊实业有限公司

Air-circulation dust remover

ActiveCN101972570BLow powerPrevent proliferationDispersed particle separationDirt cleaningAir volumeEnergy consumption

The invention provides an air-circulation dust remover. The air-circulation dust remover comprises a shade body provided with a feed port and a discharge port, and is characterized in that a pore plate is arranged at the periphery of the discharge port of the shade body, and the outer edge of the pore plate is provided with a downward skirt border and an upward shell; a hollow interlayer is formed between the upward shell and the shade body, and a bevel plate is arranged in the hollow interlayer above the pore plate; a hollow air suction duct is formed in the hollow interlayer through the bevel plate, the inside shade body, the outside shell and the downside pore plate; the hollow air suction duct obliquely extends upwards to be connected with the inlet of a fan; the outlet of the fan is connected with the inlet of a settling chamber positioned above the feed port of the shade body; and the outlet of the settling chamber is provided with a guide plate, thus forming circulating air among the discharge port, the hollow air suction duct, the fan, the settling chamber, an air outlet, the feed port and the discharge port. In the air circulating process, raised dust is sent into the settling chamber with the air so as to finish dust removal; and on the premise of maintaining smaller and balanced air quantity and air pressure, the air-circulation dust remover can improve the dust removal efficiency and reduce the energy consumption to the hilt.

Owner:深圳市格雷柏智能装备股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com