A high-pressure remote conveying device for magnetic material slurry and its application method

A magnetic material and long-distance transportation technology, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of environmental pollution, non-automation, low production efficiency, etc. The effect of improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

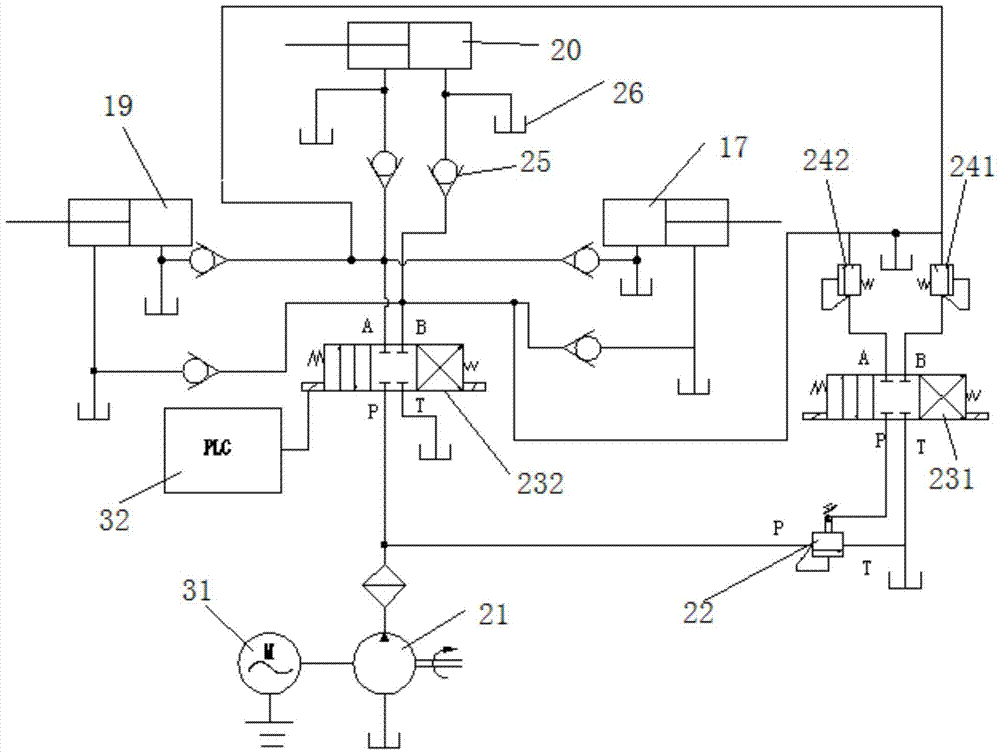

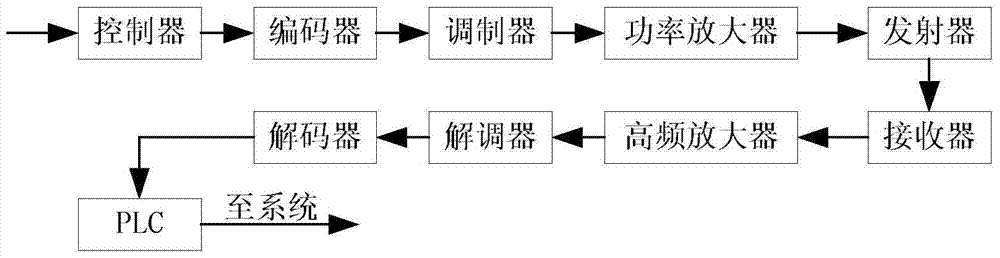

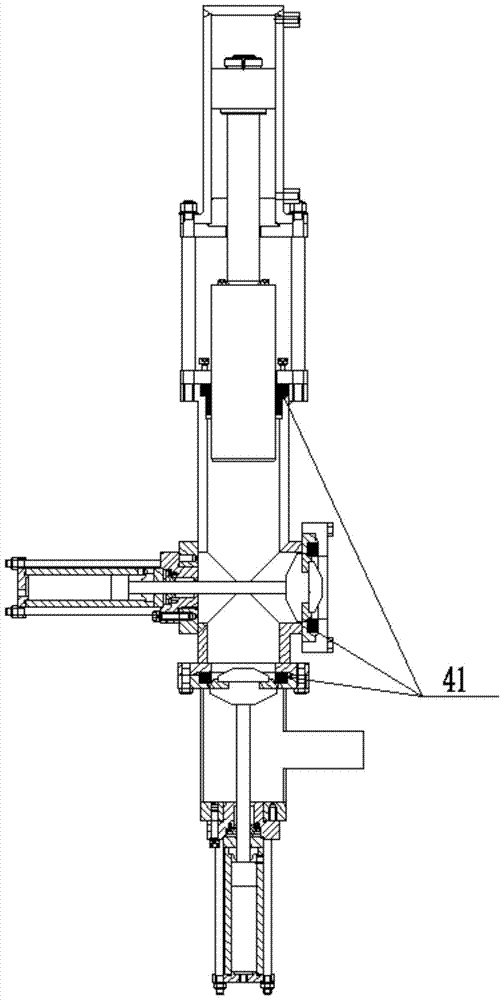

[0056] combine Figure 1-5, a high-pressure remote conveying device for magnetic material slurry, including a stirring part, an electrical system 6, a hydraulic system 5, and a double-screw feeding system 4, an electric remote control system, and a press 11; wherein, the stirring part includes rough stirring Part and fine stirring part, the described coarse stirring part conveys the slurry to the double-screw feeding system 4; the described double-screw feeding system 4 sends the slurry to the fine stirring part, and the described fine stirring part conveys the slurry To the press 11, the press 11 is connected with the touch screen electrical cabinet 13; the touch screen electrical cabinet 13 electrically controls the press 11 to carry out operation and press the slurry into shape.

[0057] The rough mixing part includes a raw material mixing tank 1 , a ball mill 2 and a sedimentation mixing tank 3 , the outlet of the raw material mixing tank 1 is connected to the inlet of the...

Embodiment 2

[0086] In this embodiment, the model of the hydraulic pump 21 is YYB-AA; the electromagnetic reversing valve is three-position four-way; the model of the oil cylinder 26 is: PY497-100 / 70-1801-313*991; the main overflow valve 22 is Pilot type; the remote pressure regulating valve is Y / YF type, and the rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com