Automatic oil removing machine

A degreaser and automatic technology, applied in the direction of centrifuges, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of easy danger caused by operators, low efficiency of manual operation, lack of oil recovery function, etc., to achieve The effect of solving safety problems and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

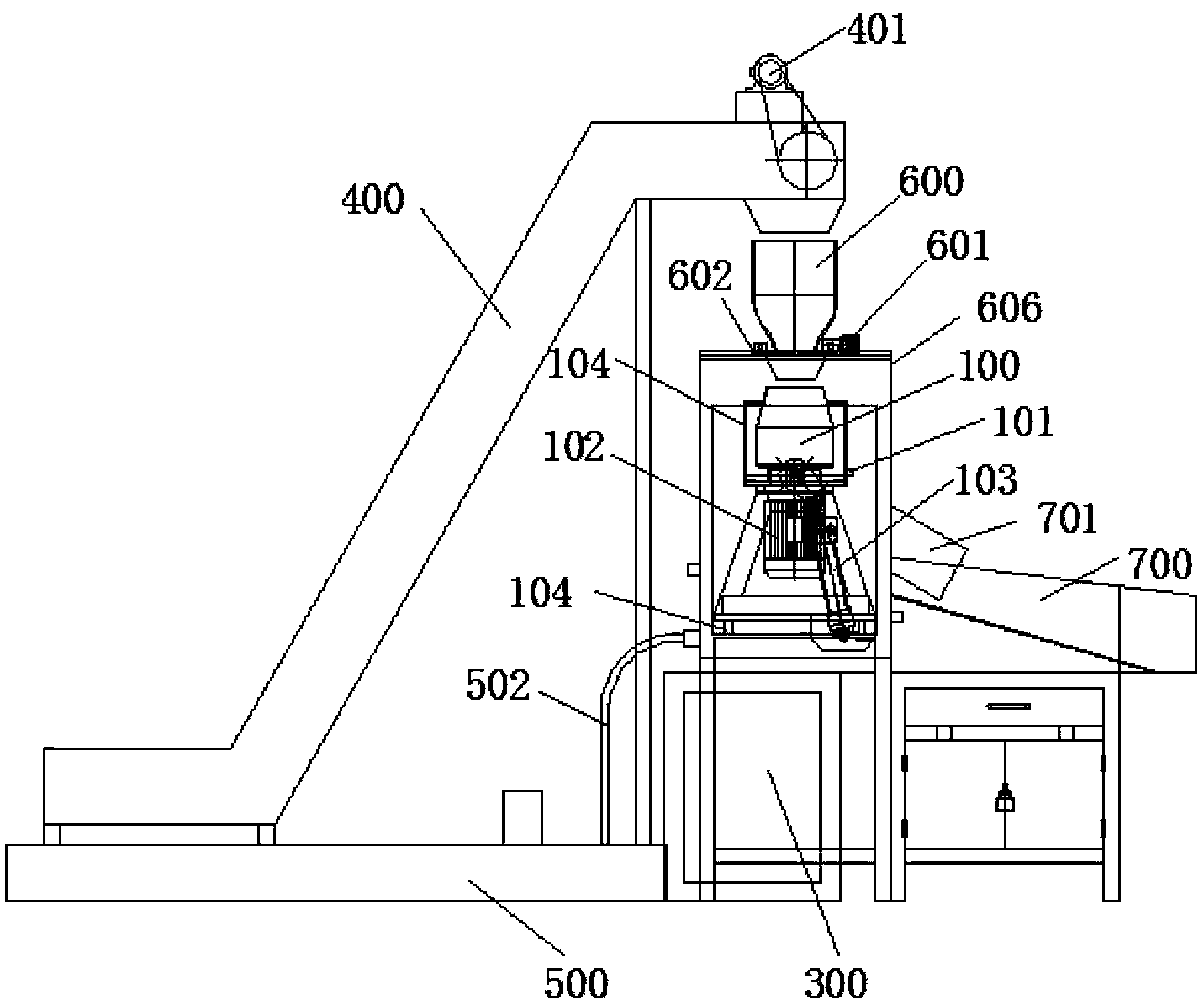

[0020] Such as figure 1 A kind of automatic degreasing machine shown, comprises centrifuge, automatic loading device, control cabinet 300 and unloading device, wherein

[0021] The centrifuge includes a centrifugal basket 100 and a centrifugal motor 102 that drives the centrifugal basket 100 to rotate;

[0022] The automatic feeding device includes a feeding rack 400 with one end carrying the product movement and the other end placed on the upper end of the centrifugal basket 100 and a feeding motor 401 driving the feeding rack 400 to move;

[0023] The unloading device includes a discharge port 103 placed below the centrifugal basket 100, a receiving hopper 700 for accepting products, and a discharge power device 103 for discharging in the centrifugal basket 100;

[0024] And the control cabinet 300 is respectively connected with the discharging power devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com