Device and method for processing large square hay bundle into high-density small square hay bundle

A high-density, generous technology, applied in the direction of cutting equipment, packaging, agricultural machinery and tools, etc., can solve the problems of loose bales, low productivity, high labor intensity, etc., meet the needs of reducing system pressure, prevent loose deformation, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The specific implementation manners of the present invention will be further described below according to the accompanying drawings, but the present invention is not limited to the following examples.

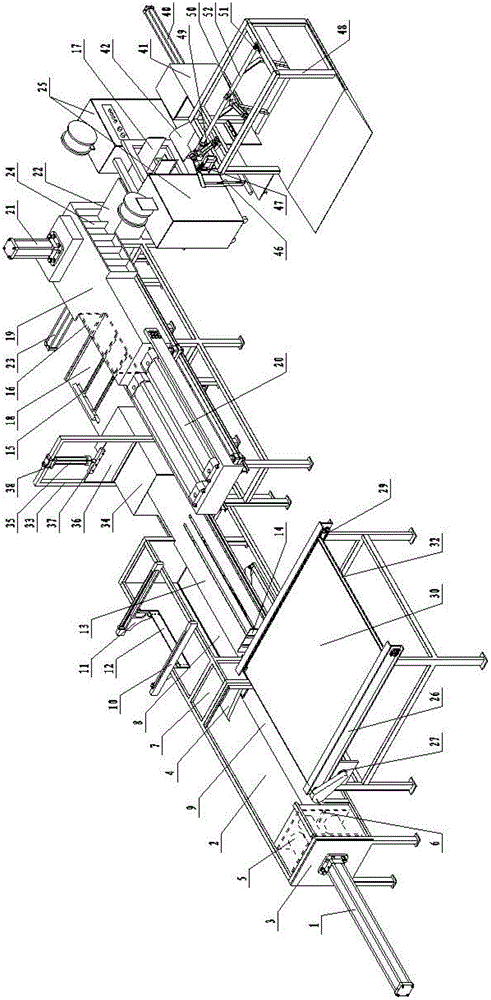

[0087] figure 1 It is a schematic diagram of the overall structure of the device for processing large square bales into high-density small square bales of the present invention. It includes a feeding mechanism, a large square bale slicing mechanism, a grass piece separation and conveying mechanism, a grass piece cutting mechanism, a secondary compression mechanism, a binding mechanism, a formed bale cutting mechanism and a formed bale collecting mechanism.

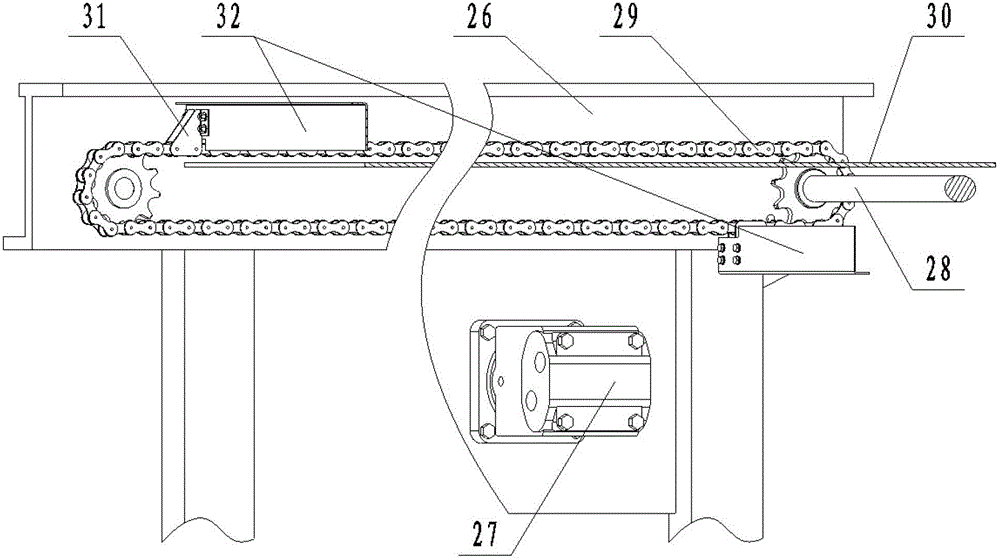

[0088] figure 2 Be the structural representation of feeding mechanism of the present invention, by figure 1 and figure 2 As shown, the feeding mechanism includes: a support 26, a hydraulic motor 27, a transmission shaft 28, a special attachment chain 29, a platform 30 and a scraper 32. The feeding mechanism is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com