A polyamide processing device

A processing device and polyamide technology, which is applied in the field of polyamide preparation, can solve problems such as poor flexibility, low screening efficiency, troublesome cleaning, etc., and achieve the effects of improving safety, improving flexibility, and preventing loose deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings.

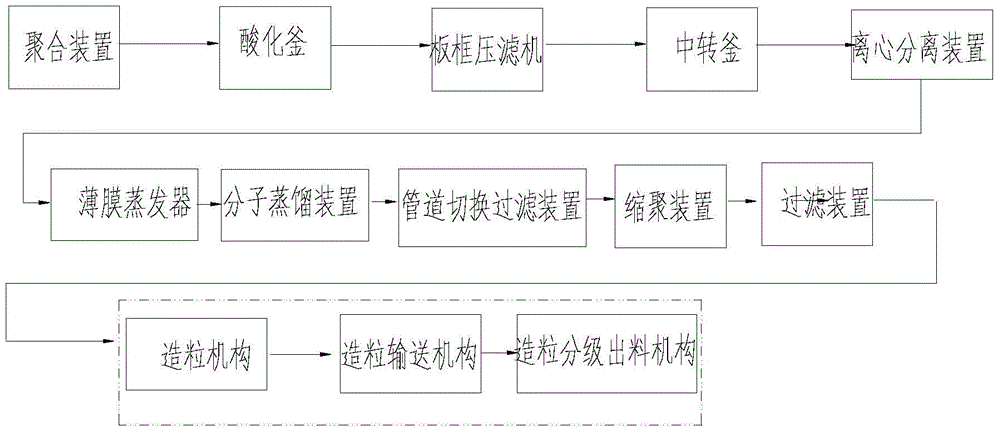

[0041] like figure 1 As shown, this embodiment includes a polymerization device, an acidification tank, a plate and frame filter press, a transfer tank, a centrifugal separation device, a thin film evaporator, a molecular distillation device, a pipeline switching filter device, a polycondensation device, and a filtration device from front to back according to the process flow. device and granulation system.

[0042] The acidification kettle, the plate and frame filter press, the thin film evaporator and the molecular distillation device are all existing equipment.

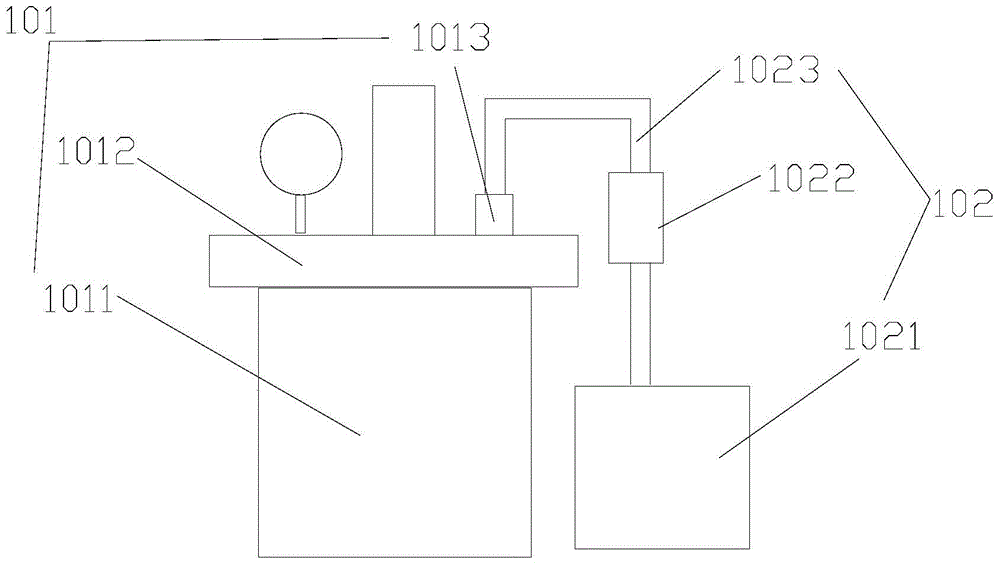

[0043] like figure 2 As shown, the polymerization device includes a polymerization kettle 101 and a material lifting device 102. The polymerization kettle 101 includes a polymerization kettle body 1011 and a polymerization kettle cover 1012, and a first feed inlet 1013 is opened on the polymerization k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com