Centered electromagnetic coil and preparation method thereof

An electromagnetic coil, Chinese-style technology, applied in coil manufacturing, inductance/transformer/magnet manufacturing, transformer/inductor coil/winding/connection, etc., can solve the problem of reducing product life, copper wire getting wet, increasing labor and time Cost and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

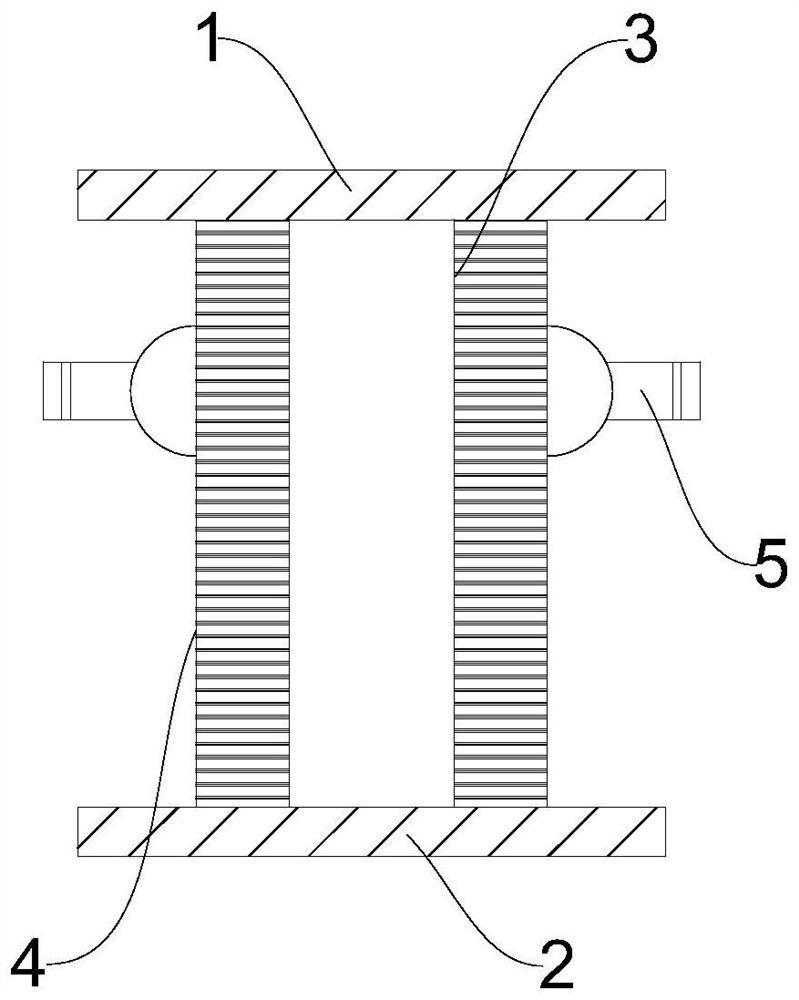

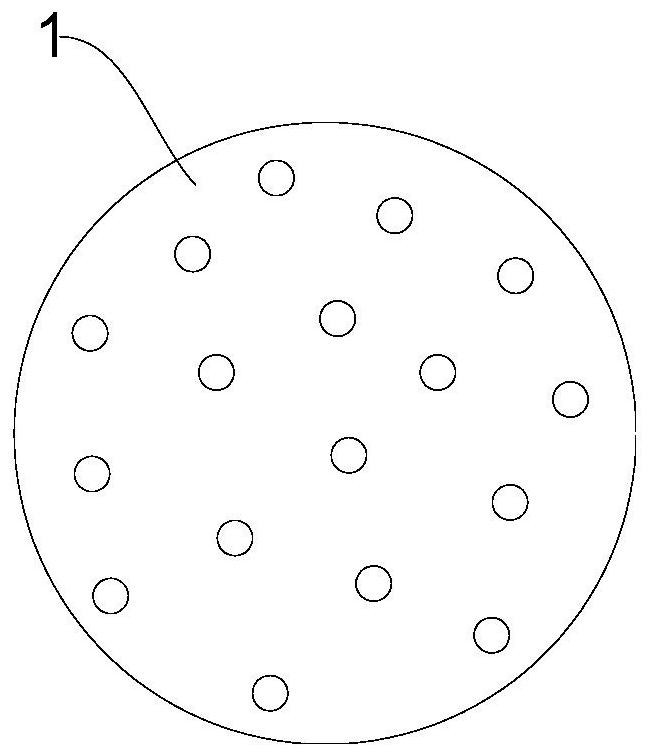

[0037] Please refer to figure 1 , image 3 and Figure 4 Indicated. A homogeneous electromagnetic coil, including a skeleton body, both ends of the skeleton body, respectively, have an upper limit portion 1 and a lower limit bit portion 2, and the skeleton body has a coil winding portion for winding the electromagnetic coil, and the coil winding portion is wrapped around. The electromagnetic coil is connected to the coil winding portion, and the coil winding portion is located between the upper limit portion 1 and the lower limit bit 2.

[0038] In the above embodiment, a centrifugal electromagnetic coil is composed of a skeleton body, a upper limit portion 1, a lower limit bit portion 2, and a coil winding portion, wherein one end of the skeleton body is disposed, and the other end of the skeleton body is set. The middle portion of the portion 2, the middle portion of the skeleton body is the coil winding portion, and the coil winding portion is wound around the electromagnetic coi...

Embodiment 2

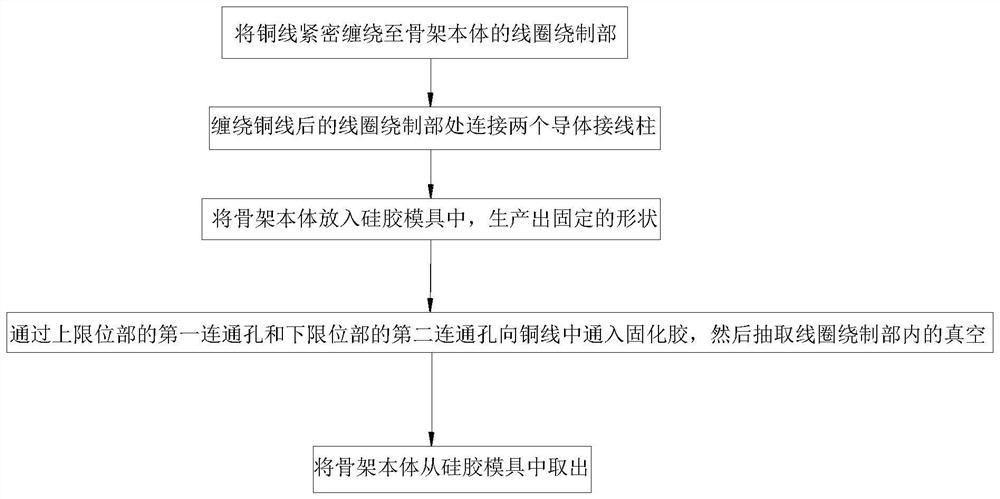

[0051] Please refer to figure 2 Indicated. A hydraulic electromagnetic coil preparation method, including the step of being tightly wound around the coil winding portion of the skeleton body; connecting two conductor terminals at the coil of the copper wire; put the skeleton body into silica gel In the mold, a fixed shape is produced. The cured glue is passed through the second communication hole of the upper limit portion 1, and the second communication hole of the lower limit bit portion 2 is introduced into the copper wire, and then the vacuum in the coil is extracted; the skeleton body Remove from the silicone mold.

[0052] In the above embodiment, the copper wire is first wound around the coil winding portion of the skeleton body, and the coil of the skeleton body is wrapped around the uniform copper wire to connect the two conductor terminals to the above-mentioned copper wire. Used to connect electrical conductive (copper wire wound to the inner layer 3), then place the sk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com