Disc type permanent magnet motor comprising winding in printed circuit board structure

A technology for printed circuit boards and permanent magnet motors, which is applied to electrical components, electromechanical devices, etc., can solve the problems of complex off-line process of disc permanent magnet motors, serious cross-piling of winding ends, and high production costs, so as to reduce product defects. , the effect of high production efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Through the description of the following examples, it will help to understand the technical essence and technical effects of the present invention, but the present invention cannot be limited by the examples.

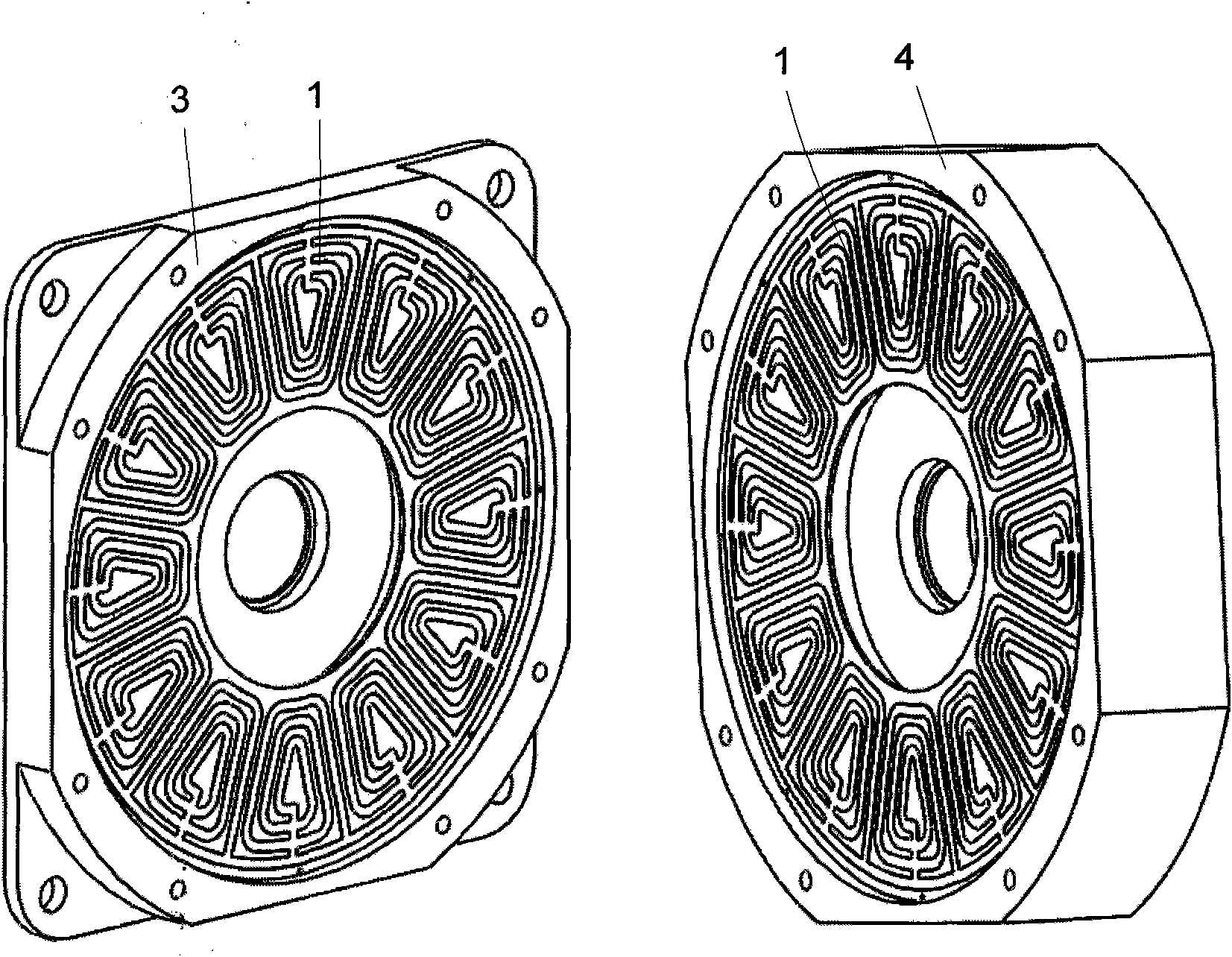

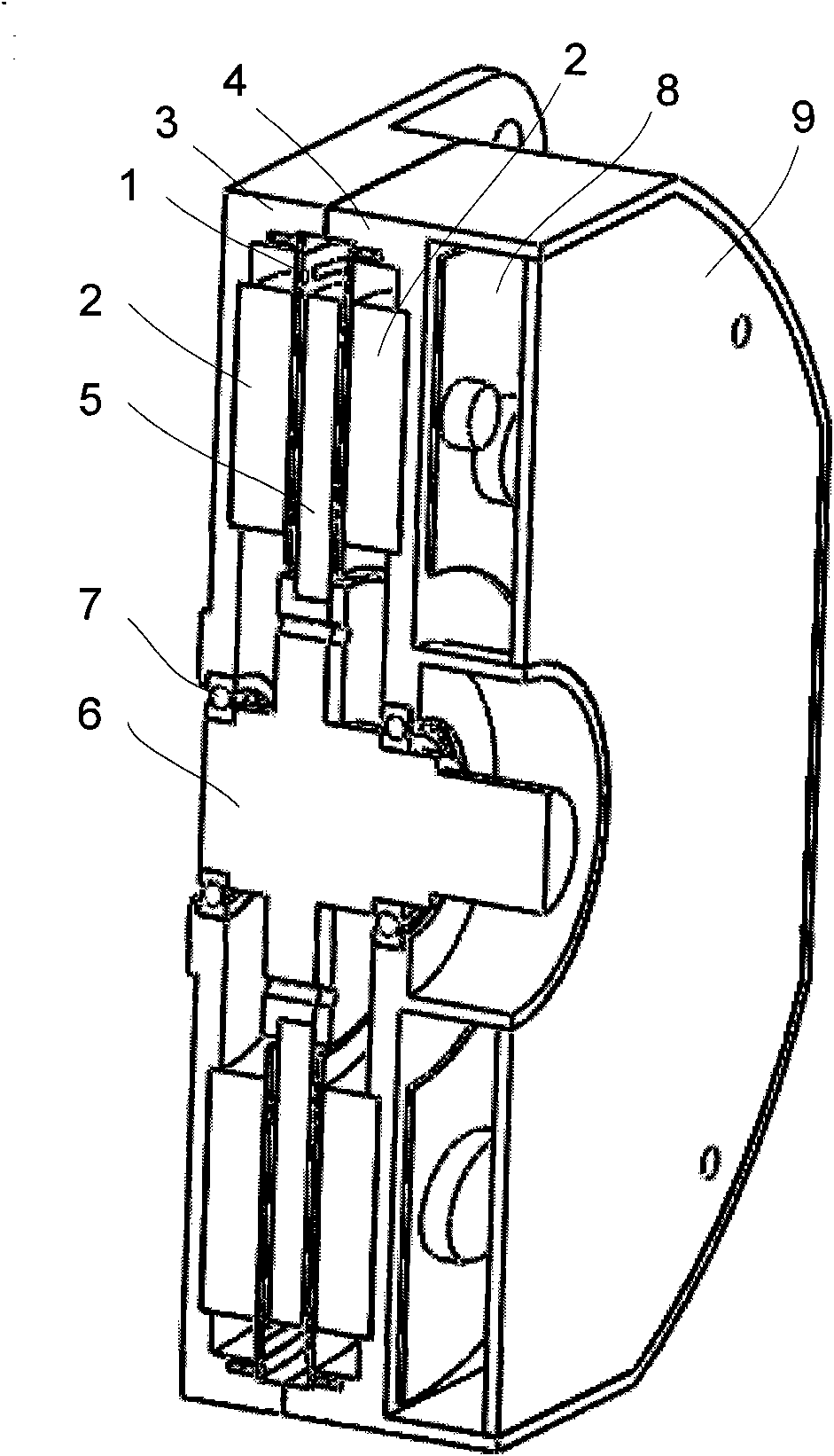

[0017] Figure 1 to Figure 4 It is an embodiment of the disc permanent magnet motor in this technical solution. The structure of the disc permanent magnet motor is the middle rotor of the stator on both sides, and the stator winding is the armature winding. ; In addition, the disk permanent magnet motor and its controller in this embodiment are structurally integrated.

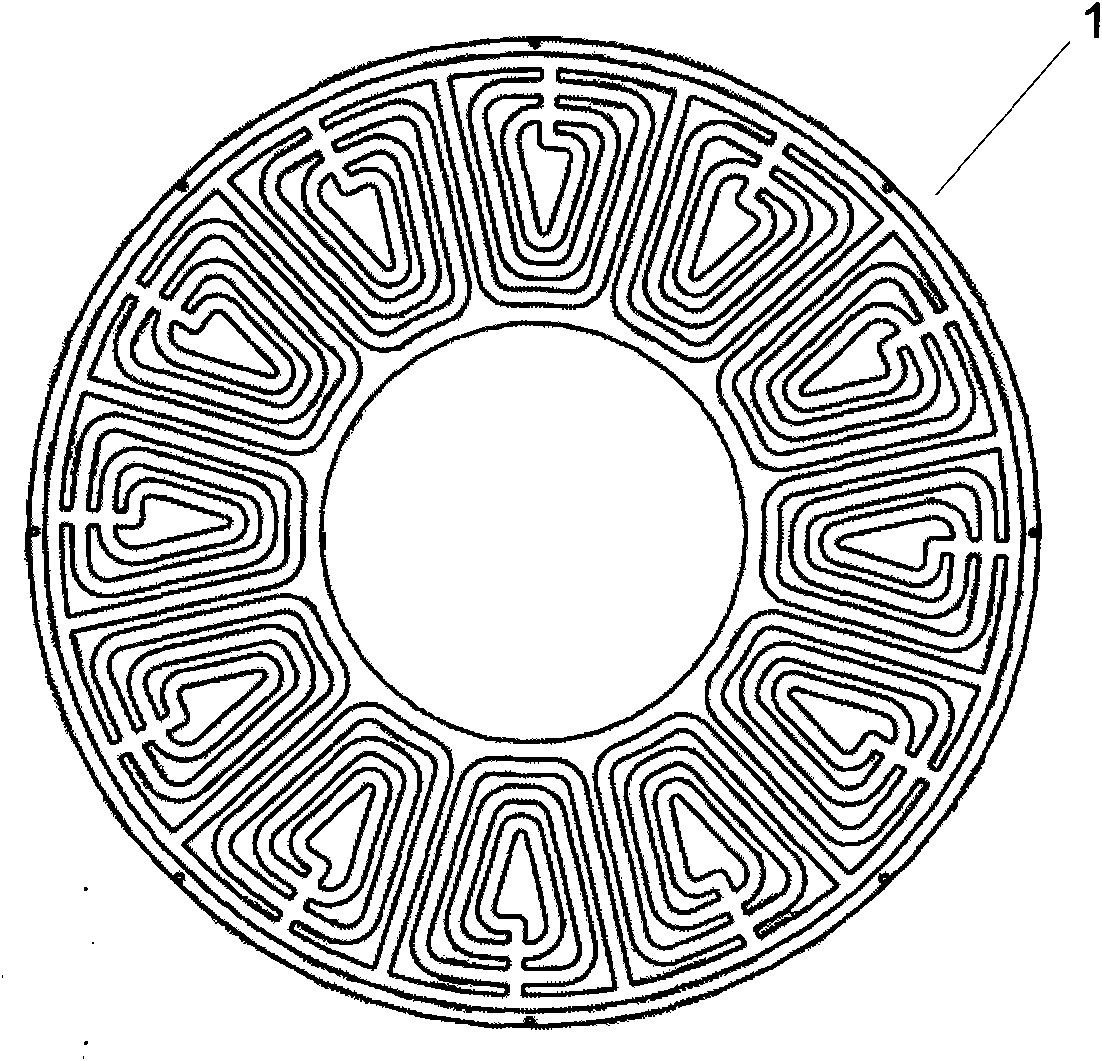

[0018] See figure 1 , the circuit of the printed circuit board PCB is designed and manufactured according to the winding and wiring of the disc permanent magnet motor winding, forming the printed circuit board PCB winding 1 . See figure 2 and image 3 , the printed circuit board PCB winding 1 and the stator core 2 together constitute the motor stator, wherein the stator core 2 is a slotless ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com